|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

airspeedx3(at)yahoo.com

Guest

|

Posted: Wed Apr 23, 2008 8:35 am Post subject: Wing design and other stuff Posted: Wed Apr 23, 2008 8:35 am Post subject: Wing design and other stuff |

|

|

Kolb guys,

Hey, did I mention I am making MY OWN fiberglass wing tips? I liked the progress report John H had shared with us, on the MkIII Xtra's flight data. It appears that by adding droop tips, the Xtra's stall speed dropped by about 4 mph. To 26 mph!!! Plus, he felt like he had better control authority of the ailerons at slower airspeeds.

First of all, it was NOT my preference to make them. I checked with Donnie at TNK, and he said their's may not be be ready to sell for 6+ weeks (maybe more, who knows?). I can't wait. I need them now. I am ready to begin covering my wings, and prefer not to wait.

Some background and reasons why they are a good idea:

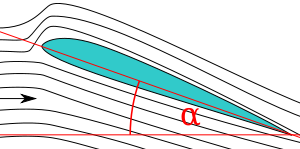

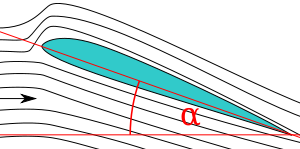

If you take a look at the outer three feet of most MkIII wings (without tips), it seems fairly obvious why this would be an area of concern. Several airflow issues come to mind. I'll explain...

First, and most obvious, air will travel the path of least resistance. Duh. Right? So, as air is traveling rearward during flight under the wing, rather than continue inline with all the other compressed air, the air near the tip will prefer to "spill" off. The idea seems kind of intuitive, IMO.

If you think about it, as you force a canted airfoil into the wind, air is being compressed as it piles up against the lower surface. Plus, the further rearward you go, the more the compression, due to a combination of accumulated air, from the front....increasing all the way to the back (see lower drawing). In other words, in the front, you have "front" air. In the middle, you have "front and middle" air. At the rear, you have "front, middle, and rear air"....all trying to get past the airfoil (see drawing below to see what I'm getting at). Clearly, some of the air near the outer edge will prefer to "jump ship", and divert out to the undisturbed air beyond the wing.

Secondly, the top of the wing has that "rounded off" shape. It, too, appears that as air is trying to go over the top of the wing's outer two feet, there is some preference for the air to "fall" off the bump, away from the wing. By it's design, there is a perpendicular (a sideways) vector component to passing air. It also seems intuitive that if you watched the air (smoke) pass over the outer portion of the wing, some will spill off the top toward the direction away from the wing.

And then there's the 1" leading edge tube. This is a fairly large tube to be ramming through the air. It has a large curve that connects the leading edge to the wing's outer side edge. By it's shape, this leading edge "curve" is pushing air away from the wing. How much? Don't know. But, it darn sure is "some".

Keep in mind all this diminished airflow is going on near the outer tip. This the place where you DON'T want it to happen!!! You would prefer to keep ALL the air that goes under the wing to remain under the wing, until it passes beyond the aileron.

My ailerons are just under 6 feet long. My outer wing panel is just OVER 3 feet wide!! This tells me that over half of my aileron is less efficient than it could be. At the place you want the most air, for aileron control, you are losing some. Undoubedly, this is why some fliers claim their ailerons are "sloppy" at slower airspeeds. Of course, slower air will give less control, but it doesn't help to be giving up some control authority to "losing air".

For those of you high on your math skills, you do recall that air's effect (and drag) is determined by it's airspeed. Specifically, by it's square of the velocity. In other words, a wing travelling at 40 mph will have a certain performance level (and, or drag). That same wing will have 1/4th of it's performance at 20!! Or, said another way, as you double the airspeed, you quadruple it's effect, or...as you cut in half your airspeed, you reduce your control to only 25%.

This is huge!!! When you couple this concept with the fact you are "giving up" some of your air, due to the wing's design, well, that is not good!!

By the way, this math formula applies to MANY MANY other aspect of life, including impacts. An airplane that crashes at 50 mph will have 4 times that impact an airplane at 25 mph has!! If you don't think that is a big deal, try crashing at 25 mph in a plane. I did. As bad as I hurt, there is NO way I would have lived if the impact was 4 times as great.

Back to the droop wing tips. By designing a wing tip that is able to keep all this air under the wing, and not produce any negative drag concerns, you can improve the aileron's slow airspeed performance. In essence, all you are doing is placing an aerodynamic "dam" at the wing tip's outer edge. Of course, only a wind-tunnel will show you how effective your particular design is, but for the most part, a basic droop tip should be a huge improvement.

Considering the results posted by John H. regarding the new Kolb company's Xtra, I would say that was "huge". Stall speed reduced from 30 mph to 26 mph. That's well over 10% slower stall speed, and that means safety.

For any questions, pictures, etc, contact me directly. I am almost finished making the "plugs". (These are my sculpted shapes, once they are finished I will make molds from them). I ordered all the fiberglassing products that I don't have on hand yesterday. Things like wax, gel coat, etc.)

BTW, all this wing tip modification required taking off the existing "stock" shape wing tip, and building a special end rib. I now have 13' 7" of straight airfoil, per side, and then the droop tips begin. How did I handle the fact that the 6" tube spar ended at out 30" short?? I built a chromoly truss. Not very heavy and gawd-aweful strong!!! It looks a lot like the tube reinforcements we slid into the spars and boom tubes. Phenominally strong!!! (Plus, of course, all the usual aluminum tubes for triangulation.......)

I know this modification isn't for everyone, but I, for one, like the performance, the looks, and the added styling droop tips add. Besides, they purdy!

I have kept a fairly detailed photo log of the process. I'm not finished, yet, so if anyone wants any additional information, I will wait until I'm finished before send out stuff, drawings, photos, etc.

BTW, I talked to a guy yesterday that makes all the products you'd ever need for fiberglassing work. He has a auction site site on eBay ,just for showing his countless

"how to" videos. You want to see tons and tons of demonstration videos on fiberglassing products, check out eBay item #280178620496. Awesome site!!!! Plus, there is a link to photobucket you should look for. This is another place where he has over a hundred displays of his products in action. Worth checking out, if you're interested in your own fiberglassing projects.

Next......my custom dash panel that mounts at the lower line along the windscreen, then my overhead panel like Scott built. I already had one of these in aluminum for the Classic, but it doesn't fit, anymore. Next one will be fiberglass like Scotts.

Gotta get to work on those droop tips. They ainta gettin' done without me.

Mike Welch

MkIII CX

PS. My droop tip molds are SUPPOSED to be reuseable. We'll see.

Be a better friend, newshound, and Be a better friend, newshound, and [quote][b]

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

JetPilot

Joined: 10 Jan 2006

Posts: 1246

|

Posted: Wed Apr 23, 2008 8:09 pm Post subject: Re: Wing design and other stuff Posted: Wed Apr 23, 2008 8:09 pm Post subject: Re: Wing design and other stuff |

|

|

Mike,

I think you are right on about the Wingtips, and you are definitely right on about increasing safety any time you can lower the approach and stall speeds in your Kolb. Are you adding any length to your wings ? What will your total wingspan be ?

I am also going to add the wingtips to my Kolb, but I don't have the time or the skill to make fiberglass ones, so I will have to wait for Kolb to start selling them. At the same time I am putting on the new wingtips, I will also add 2 feet of spar to each wingtip to make the wings as long as the new Kolb MK III, that also seems to have helped a good bit.

What happened in your accident at 25 mph ? Did you live  If you could post the details it might help someone avoid the same thing one day. I look forward to seeing the pictures of what you are doing, and especially the truss structure you were talking about for the tips. If you could post the details it might help someone avoid the same thing one day. I look forward to seeing the pictures of what you are doing, and especially the truss structure you were talking about for the tips.

Mike

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

"NO FEAR" - If you have no fear you did not go as fast as you could have !!!

Kolb MK-III Xtra, 912-S |

|

| Back to top |

|

|

airspeedx3(at)yahoo.com

Guest

|

Posted: Thu Apr 24, 2008 7:26 am Post subject: Wing design and other stuff Posted: Thu Apr 24, 2008 7:26 am Post subject: Wing design and other stuff |

|

|

Mike,

I don't know how long you're wings are, but mine were built to standard MkIII Classic (there wasn't an Xtra when I built my wings). As you are aware, the trailing edge tube is full length. The leading edge stops about 2 feet short and then begins the "bow" tip. Prior to any wing tip mods, my wings were 13' 7" at the trailing edge (after mods, they still are.) Of course, you don't get the full length of true airfoil on a standard wing, because once you begin the bow tip, you encounter all that loss of "air" I was talking about.

My 6" tubular wing spar ended at about 11 feet 8 inches (and then at the front, the bow tip curve began). The trailing edge tube continues for another 23". To make the modification, this entire length is what I kept. First, I removed the bow tip, and all the skinny diagonal reinforcement tubes. (Remember, I don't have fabric, yet. More on this later.)

Next, I made an extension to the leading edge tube, to match the length of the trailing edge. I will now have the entire 13' 7" of full shaped airfoil.

While I was waiting on the epoxy resin to harden on the droop tip plugs, I began building the truss extension. At first, I began using aluminum. But within minutes I could see it would take me days to go that route. Cutting the shaped tubes, making plates to mount them, etc., etc. No can do!! Then I thought "hey, why not chromoly" Not too heavy. Easy as hell to simply cut web tubes and weld in place. Try it.

So I cut the lengths (32 inches each, top and bottom), and cut some web diagonals, and tacked them in place. Fast, fast fast. Welded all the locations, ground them smooth. Best idea, yet. In the "up and down" direction, this SOB is SOLID!!!

Slide it in the 6" spar eleven inches, bolt it in place, and it will easily carry just the last two feet of wing. BTW, although I haven't done it yet, I will weld several tabs to this truss, for the diagonal braces. I am very comfortable with the internal structure of the wing extension. It damn sure will get the job done!!

Regarding the "last rib". I built it with aluminum stock that I had on hand. I used some angle aluminum. If I were to do it again, I would buy some 1" wide FLAT alum. strap X 1/8" thick. Your end rib can NOT be made of tubes, like all the other ribs.

My wingspan was originally close to 30' 2". The only addition is just the tips, about 6" each.

With regard to my crash, I restored an older Wizard ultralight. It looks like a Quicksilver.

I had "some" pilot training years earlier, and thought that would be enough to allow me to do some crow hops. I was doing fine all day, but not really ever in complete control. As I added power, it climbed. But this scared me, so I held just enough airspeed to stay aloft (riding on the edge of stall all day). Eventually, fate will catch up with that plan! I started drifting away from the runway, and toward some trees. As I tried to turn back to the runway, I just nosed in, into the dirt. Crumpled the nosegear, etc. Hurt so goddamn much I thought I WAS dying!! I wiped out one of the reinforced downtubes with my neck. This twisted my back beyond anything I have ever done before. My pain was in the red, on the "shit-o-meter"!!

Analysis. All this was MY fault. The ultralight flew just fine. Good friend and pilot, Lou Wetzel flew it earlier, prior to me. The fault lies with the idiot in the pilot seat not flying the damn plane!!! I don't want to EVER want to hurt that bad again! I have since then gotten my pilot's license. However, I also don't want to ASSUME anything anymore. Even prior to flying my MkIII I will try and find someone who will share some MkIII flying time with me.

BTW, how did YOU manage to solo your Xtra? I'll be honest with you, it scares the livin' bu'jesus out of me to think about soloing my plane. I think I'm a pretty good pilot in my Cessna, but I found out what can happen if you aren't correct.

Yes, I think you can add droop tips. BUT!!!!

With regard to you making the droop tip conversion to YOUR plane. I would NOT alter anything on your present wing. DO NOT CUT ANYTHING. If you do, you'll open up such a shitstorm of grief you won't believe it! It would be easier to build brand new wings, at that point! Once you cut the fabric along the outer edge, the entire wing loses it's tension.

That would be so much work I wouldn't even want to think about it!

What you CAN do is like I suggested a while back. Build the droop tip design completely around your finished wing. This would be absolutely EASY. But Kolbs droop tips, get some of that aluminum flat strap, etc....build a solid substructure, making it look like you have full airfoil all the way to the end, fabric, paint, slide on tips...you're done. You don't need to add any 6" spar, because your wing isn't carrying any more lift requirement than it did prior to addition of droop tips, except you will no longer have "spilled" air.

Put simplistically, you'd build your droop tip addition AROUND your present wing. Cheap, easy and just as effective as if you built them that way in the first place. Plus, NO ONE would ever know you had stock wings inside your droop tip wings. That penalty would be several ounces of aluminum and fabric that were left inside your new shape. Big deal!!!!

After working with Poly Fiber recently, I am even more convinced this is the best way. Like I said, if you cut that outer edge fabric, you're in for a total wing rebuild. $$$$$$$$

An expression like "you're screwed!!" comes to mind!!

More later, when I can post some pictures....

Mike Welch

BTW, With VGs, which are a hellava good idea, I would think your stall could be down to about 22-23 mph, with MORE aileron control (due to the droop tips). You are already getting better aileron control from the VGs.

JetPilot <orcabonita(at)hotmail.com> wrote:

[quote]--> Kolb-List message posted by: "JetPilot"

Mike,

I think you are right on about the Wingtips, and you are definitely right on about increasing safety any time you can lower the approach and stall speeds in your Kolb. Are you adding any length to your wings ? What will your total wingspan be ?

I am also going to add the wingtips to my Kolb, but I don't have the time or the skill to make fiberglass ones, so I will have to wait for Kolb to start selling them. At the same time I am putting on the new wingtips, I will also add 2 feet of spar to each wingtip to make the wings as long as the new Kolb MK Be a better friend, newshound, and [quote][b]

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

rrhoyt_list(at)msn.com

Guest

|

Posted: Fri Apr 25, 2008 10:48 am Post subject: Wing design and other stuff Posted: Fri Apr 25, 2008 10:48 am Post subject: Wing design and other stuff |

|

|

Mike

I just read your e-mail on the droop wing tips. Thought you might like

seeing my wing development and tip fabrication activity. (The photos are

compressed because the list rejected the originals)

Ron

Mike Welch wrote:

[quote] Mike,

I don't know how long you're wings are, but mine were built to

standard MkIII Classic (there wasn't an Xtra when I built my wings).

As you are aware, the trailing edge tube is full length. The leading

edge stops about 2 feet short and then begins the "bow" tip. Prior to

any wing tip mods, my wings were 13' 7" at the trailing edge (after

mods, they still are.) Of course, you don't get the full length of

true airfoil on a standard wing, because once you begin the bow tip,

you encounter all that loss of "air" I was talking about.

My 6" tubular wing spar ended at about 11 feet 8 inches (and then at

the front, the bow tip curve began). The trailing edge tube continues

for another 23". To make the modification, this entire length is what

I kept. First, I removed the bow tip, and all the skinny diagonal

reinforcement tubes. (Remember, I don't have fabric, yet. More on this

later.)

Next, I made an extension to the leading edge tube, to match the

length of the trailing edge. I will now have the entire 13' 7" of full

shaped airfoil.

While I was waiting on the epoxy resin to harden on the droop tip

plugs, I began building the truss extension. At first, I began using

aluminum. But within minutes I could see it would take me days to go

that route. Cutting the shaped tubes, making plates to mount them,

etc., etc. No can do!! Then I thought "hey, why not chromoly" Not too

heavy. Easy as hell to simply cut web tubes and weld in place. Try it.

So I cut the lengths (32 inches each, top and bottom), and cut some

web diagonals, and tacked them in place. Fast, fast fast. Welded all

the locations, ground them smooth. Best idea, yet. In the "up and

down" direction, this SOB is SOLID!!!

Slide it in the 6" spar eleven inches, bolt it in place, and it will

easily carry just the last two feet of wing. BTW, although I haven't

done it yet, I will weld several tabs to this truss, for the diagonal

braces. I am very comfortable with the internal structure of the wing

extension. It damn sure will get the job done!!

Regarding the "last rib". I built it with aluminum stock that I had on

hand. I used some angle aluminum. If I were to do it again, I would

buy some 1" wide FLAT alum. strap X 1/8" thick. Your end rib can NOT

be made of tubes, like all the other ribs.

My wingspan was originally close to 30' 2". The only addition is just

the tips, about 6" each.

With regard to my crash, I restored an older Wizard ultralight. It

looks like a Quicksilver.

I had "some" pilot training years earlier, and thought that would be

enough to allow me to do some crow hops. I was doing fine all day, but

not really ever in complete control. As I added power, it climbed. But

this scared me, so I held just enough airspeed to stay aloft (riding

on the edge of stall all day). Eventually, fate will catch up with

that plan! I started drifting away from the runway, and toward some

trees. As I tried to turn back to the runway, I just nosed in, into

the dirt. Crumpled the nosegear, etc. Hurt so goddamn much I thought I

WAS dying!! I wiped out one of the reinforced downtubes with my neck.

This twisted my back beyond anything I have ever done before. My pain

was in the red, on the "shit-o-meter"!!

Analysis. All this was MY fault. The ultralight flew just fine. Good

friend and pilot, Lou Wetzel flew it earlier, prior to me. _The fault

lies with the idiot in the pilot seat not flying the damn plane!!! _ I

don't want to EVER want to hurt that bad again! I have since then

gotten my pilot's license. However, I also don't want to ASSUME

anything anymore. Even prior to flying my MkIII I will try and find

someone who will share some MkIII flying time with me.

BTW, how did YOU manage to solo your Xtra? I'll be honest with you, it

scares the livin' bu'jesus out of me to think about soloing my plane.

I think I'm a pretty good pilot in my Cessna, but I found out what can

happen if you aren't correct.

Yes, I think you can add droop tips. BUT!!!!

With regard to you making the droop tip conversion to YOUR plane. I

would NOT alter anything on your present wing. DO NOT CUT ANYTHING. If

you do, you'll open up such a shitstorm of grief you won't believe it!

It would be easier to build brand new wings, at that point! Once you

cut the fabric along the outer edge, the entire wing loses it's tension.

That would be so much work I wouldn't even want to think about it!

What you CAN do is like I suggested a while back. Build the droop tip

design completely around your finished wing. This would be absolutely

EASY. But Kolbs droop tips, get some of that aluminum flat strap,

etc...build a solid substructure, making it look like you have full

airfoil all the way to the end, fabric, paint, slide on tips...you're

done. You don't need to add any 6" spar, because your wing isn't

carrying any more lift requirement than it did prior to addition of

droop tips, except you will no longer have "spilled" air.

Put simplistically, you'd build your droop tip addition AROUND your

present wing. Cheap, easy and just as effective as if you built them

that way in the first place. Plus, NO ONE would ever know you had

stock wings inside your droop tip wings. *_That penalty would be

several ounces of aluminum and fabric that were left inside your new

shape. Big deal!!!!_*

After working with Poly Fiber recently, I am even more convinced this

is the best way. Like I said, if you cut that outer edge fabric,

you're in for a total wing rebuild. $$$$$$$$

An expression like "you're screwed!!" comes to mind!!

More later, when I can post some pictures....

Mike Welch

BTW, With VGs, which are a hellava good idea, I would think your stall

could be down to about 22-23 mph, with MORE aileron control (due to

the droop tips). You are already getting better aileron control from

the VGs.

*/JetPilot /* wrote:

[quote][b]

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

rrhoyt_list(at)msn.com

Guest

|

Posted: Sat Apr 26, 2008 5:50 am Post subject: Wing design and other stuff Posted: Sat Apr 26, 2008 5:50 am Post subject: Wing design and other stuff |

|

|

OOps! It looks like the images didn't stay attached. See if this works.

This is the extension of the spar and the full fibs to the wing tip. If

this works I will show the plug mold for the wing tips.

Ron Hoyt wrote:

[quote] Mike

I just read your e-mail on the droop wing tips. Thought you might like

seeing my wing development and tip fabrication activity. (The photos are

compressed because the list rejected the originals)

Ron

Mike Welch wrote:

> Mike,

> I don't know how long you're wings are, but mine were built to

> standard MkIII Classic (there wasn't an Xtra when I built my wings).

> As you are aware, the trailing edge tube is full length. The leading

> edge stops about 2 feet short and then begins the "bow" tip. Prior to

> any wing tip mods, my wings were 13' 7" at the trailing edge (after

> mods, they still are.) Of course, you don't get the full length of

> true airfoil on a standard wing, because once you begin the bow tip,

> you encounter all that loss of "air" I was talking about.

> My 6" tubular wing spar ended at about 11 feet 8 inches (and then at

> the front, the bow tip curve began). The trailing edge tube continues

> for another 23". To make the modification, this entire length is what

> I kept. First, I removed the bow tip, and all the skinny diagonal

> reinforcement tubes. (Remember, I don't have fabric, yet. More on this

> later.)

> Next, I made an extension to the leading edge tube, to match the

> length of the trailing edge. I will now have the entire 13' 7" of full

> shaped airfoil.

> While I was waiting on the epoxy resin to harden on the droop tip

> plugs, I began building the truss extension. At first, I began using

> aluminum. But within minutes I could see it would take me days to go

> that route. Cutting the shaped tubes, making plates to mount them,

> etc., etc. No can do!! Then I thought "hey, why not chromoly" Not too

> heavy. Easy as hell to simply cut web tubes and weld in place. Try it.

> So I cut the lengths (32 inches each, top and bottom), and cut some

> web diagonals, and tacked them in place. Fast, fast fast. Welded all

> the locations, ground them smooth. Best idea, yet. In the "up and

> down" direction, this SOB is SOLID!!!

> Slide it in the 6" spar eleven inches, bolt it in place, and it will

> easily carry just the last two feet of wing. BTW, although I haven't

> done it yet, I will weld several tabs to this truss, for the diagonal

> braces. I am very comfortable with the internal structure of the wing

> extension. It damn sure will get the job done!!

> Regarding the "last rib". I built it with aluminum stock that I had on

> hand. I used some angle aluminum. If I were to do it again, I would

> buy some 1" wide FLAT alum. strap X 1/8" thick. Your end rib can NOT

> be made of tubes, like all the other ribs.

> My wingspan was originally close to 30' 2". The only addition is just

> the tips, about 6" each.

> With regard to my crash, I restored an older Wizard ultralight. It

> looks like a Quicksilver.

> I had "some" pilot training years earlier, and thought that would be

> enough to allow me to do some crow hops. I was doing fine all day, but

> not really ever in complete control. As I added power, it climbed. But

> this scared me, so I held just enough airspeed to stay aloft (riding

> on the edge of stall all day). Eventually, fate will catch up with

> that plan! I started drifting away from the runway, and toward some

> trees. As I tried to turn back to the runway, I just nosed in, into

> the dirt. Crumpled the nosegear, etc. Hurt so goddamn much I thought I

> WAS dying!! I wiped out one of the reinforced downtubes with my neck.

> This twisted my back beyond anything I have ever done before. My pain

> was in the red, on the "shit-o-meter"!!

> Analysis. All this was MY fault. The ultralight flew just fine. Good

> friend and pilot, Lou Wetzel flew it earlier, prior to me. _The fault

> lies with the idiot in the pilot seat not flying the damn plane!!! _ I

> don't want to EVER want to hurt that bad again! I have since then

> gotten my pilot's license. However, I also don't want to ASSUME

> anything anymore. Even prior to flying my MkIII I will try and find

> someone who will share some MkIII flying time with me.

> BTW, how did YOU manage to solo your Xtra? I'll be honest with you, it

> scares the livin' bu'jesus out of me to think about soloing my plane.

> I think I'm a pretty good pilot in my Cessna, but I found out what can

> happen if you aren't correct.

> Yes, I think you can add droop tips. BUT!!!!

> With regard to you making the droop tip conversion to YOUR plane. I

> would NOT alter anything on your present wing. DO NOT CUT ANYTHING. If

> you do, you'll open up such a shitstorm of grief you won't believe it!

> It would be easier to build brand new wings, at that point! Once you

> cut the fabric along the outer edge, the entire wing loses it's tension.

> That would be so much work I wouldn't even want to think about it!

> What you CAN do is like I suggested a while back. Build the droop tip

> design completely around your finished wing. This would be absolutely

> EASY. But Kolbs droop tips, get some of that aluminum flat strap,

> etc....build a solid substructure, making it look like you have full

> airfoil all the way to the end, fabric, paint, slide on tips...you're

> done. You don't need to add any 6" spar, because your wing isn't

> carrying any more lift requirement than it did prior to addition of

> droop tips, except you will no longer have "spilled" air.

> Put simplistically, you'd build your droop tip addition AROUND your

> present wing. Cheap, easy and just as effective as if you built them

> that way in the first place. Plus, NO ONE would ever know you had

> stock wings inside your droop tip wings. *_That penalty would be

> several ounces of aluminum and fabric that were left inside your new

> shape. Big deal!!!!_*

> After working with Poly Fiber recently, I am even more convinced this

> is the best way. Like I said, if you cut that outer edge fabric,

> you're in for a total wing rebuild. $$$$$$$$

> An expression like "you're screwed!!" comes to mind!!

> More later, when I can post some pictures....

> Mike Welch

> BTW, With VGs, which are a hellava good idea, I would think your stall

> could be down to about 22-23 mph, with MORE aileron control (due to

> the droop tips). You are already getting better aileron control from

> the VGs.

> */JetPilot /* wrote:

>

>

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

| Description: |

|

| Filesize: |

72.17 KB |

| Viewed: |

273 Time(s) |

|

|

|

| Back to top |

|

|

mdnanwelch7(at)hotmail.co

Guest

|

Posted: Sat Apr 26, 2008 6:05 am Post subject: Wing design and other stuff Posted: Sat Apr 26, 2008 6:05 am Post subject: Wing design and other stuff |

|

|

Yep, Ron,

The photo came through. I'm interested in seeing youu plug molds.

Mike Welch

_________________________________________________________________

Make i'm yours. Create a custom banner to support your cause.

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

rrhoyt_list(at)msn.com

Guest

|

Posted: Sat Apr 26, 2008 7:45 am Post subject: Wing design and other stuff Posted: Sat Apr 26, 2008 7:45 am Post subject: Wing design and other stuff |

|

|

This photo is the plug mold in development for both wingtips. The plan

is to split the wing tips apart after casting. I plan on using a vacuum

mold process.

| Quote: | Yep, Ron,

The photo came through. I'm interested in seeing youu plug molds.

Mike Welch

|

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

| Description: |

|

| Filesize: |

57.56 KB |

| Viewed: |

275 Time(s) |

|

|

|

| Back to top |

|

|

JetPilot

Joined: 10 Jan 2006

Posts: 1246

|

Posted: Sat Apr 26, 2008 6:28 pm Post subject: Re: Wing design and other stuff Posted: Sat Apr 26, 2008 6:28 pm Post subject: Re: Wing design and other stuff |

|

|

Nice looking wingtip Mike, looks like a great solution to modify a standard wing to accept the tips. Your idea about just building over the original wingtips on my Kolb makes a lot of sense, easier is always better

Keep the pictures coming, I look forward to seeing your progress. Did you see how forward did the counterweights for the ailerons with the droop tips ? I have detailed pictures of that if you need them.

Mike

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

"NO FEAR" - If you have no fear you did not go as fast as you could have !!!

Kolb MK-III Xtra, 912-S |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|