|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

crazyivan

Joined: 25 Aug 2006

Posts: 62

Location: Pensacola

|

Posted: Sat Mar 14, 2009 4:11 am Post subject: Engine Mount Crack Posted: Sat Mar 14, 2009 4:11 am Post subject: Engine Mount Crack |

|

|

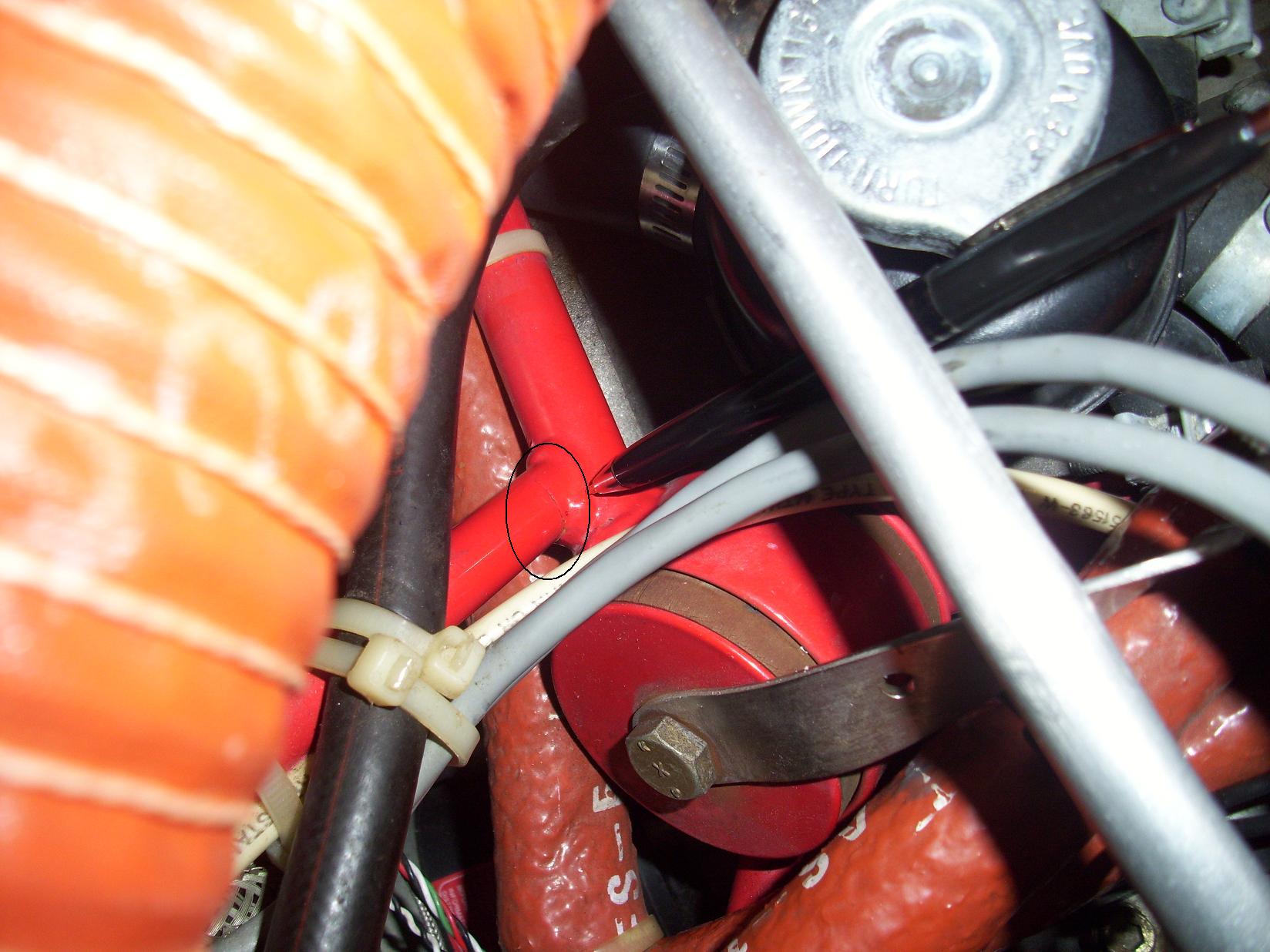

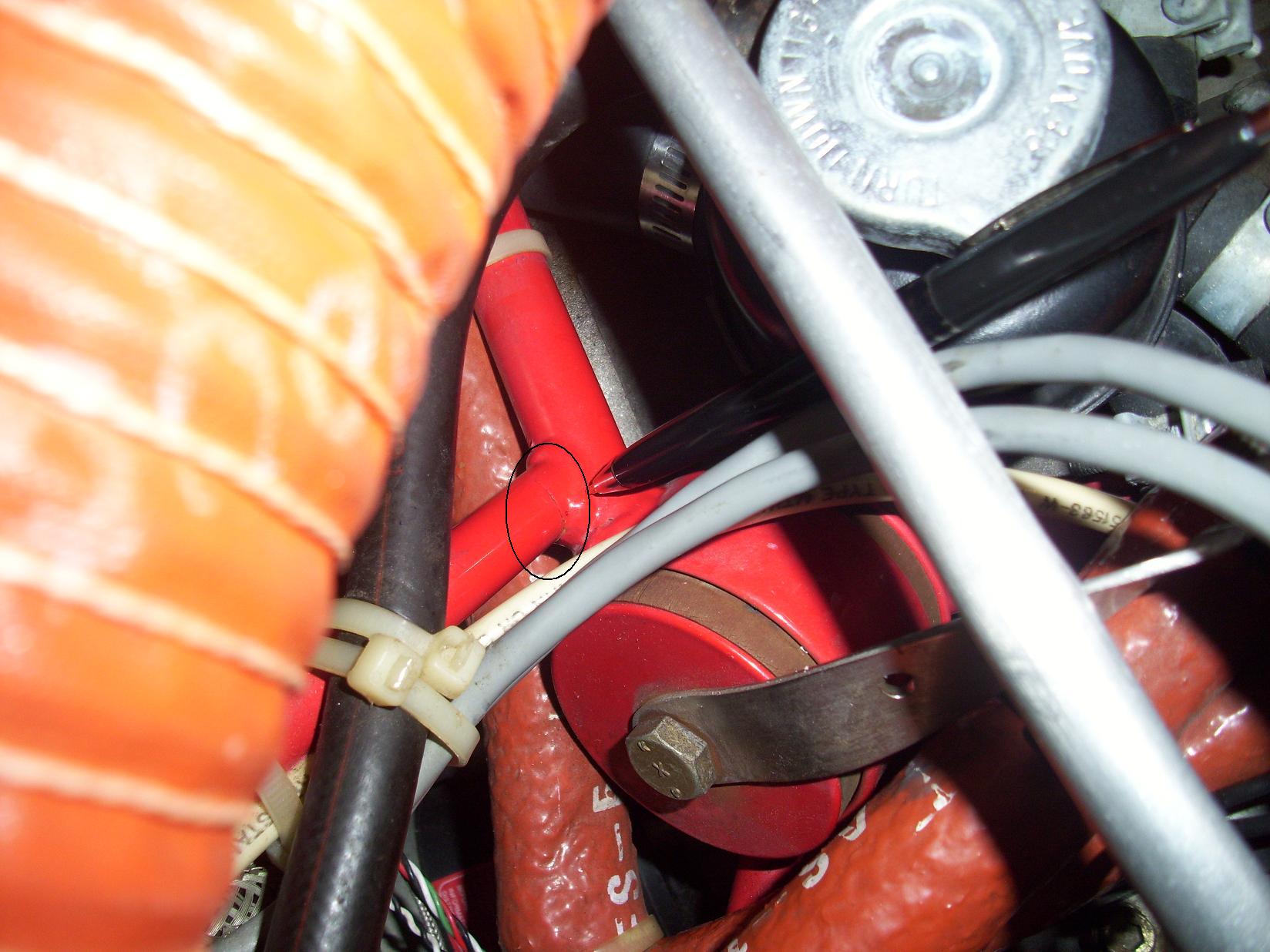

I wanted to pass along some critical information to the group. I have a Kitfox Speedster with a 1995 standard firewall forward Rotax 912UL (80hp). I found a crack 3/4 of the way around one of the engine mount tubes that go from the firewall to the "ring." Kitfox has an SB regarding cracks in this tube and require a gusset to be welded in to reinforce. Thing is, the SB targets the 912ULS (100hp) installation because of the kickback the engine gives during start-up and shut-down. I'm here to tell ya, the 80hp will crack it as well.

It's the tube that comes from the upper right (pilot's view) firewall attach point to the "ring." It has the right oil tank support bracket attached. It looks like the crack started in the lower, outboard quadrant of the weld seam by the "ring."

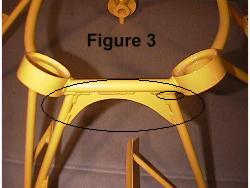

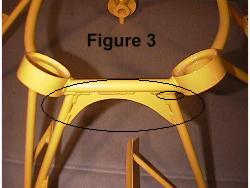

The red mount in the pictures are my mount. The yellow mount is the replacement Kitfox sells with a circle around the gusset and the area where my mount cracked.

If you have a 912 and the engine mount without the gusset, then inspect these areas carefully.

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

| Description: |

|

| Filesize: |

9.31 KB |

| Viewed: |

6864 Time(s) |

|

| Description: |

|

| Filesize: |

450.46 KB |

| Viewed: |

6864 Time(s) |

|

| Description: |

|

| Filesize: |

269.4 KB |

| Viewed: |

6864 Time(s) |

|

_________________

Dave

Piper PA-22/20 |

|

| Back to top |

|

|

Paul A. Franz, P.E.

Joined: 02 Dec 2008

Posts: 280

Location: Bellevue WA

|

Posted: Sat Mar 14, 2009 7:07 am Post subject: Engine Mount Crack Posted: Sat Mar 14, 2009 7:07 am Post subject: Engine Mount Crack |

|

|

On Sat, March 14, 2009 4:12 am, crazyivan wrote:

| Quote: |

Thing is, the SB targets the 912ULS (100hp) installation

because of the kickback the engine gives during start-up and shut-down. I'm here to

tell ya, the 80hp will crack it as well.

|

Which propeller are you using?

--

Paul A. Franz

Registration/Aircraft - N14UW/Merlin GT

Engine/Prop - Rotax 914/NSI CAP

Bellevue WA

425.241.1618 Cell

"We have rights, as individuals, to give as much of our own money as

we please to charity; but as members of Congress we have no right so

to appropriate a dollar of public money."

-- American hunter, frontiersman, soldier and politician Davy Crockett (1786-1836)

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Paul A. Franz, P.E.

Registration/Aircraft - N14UW/Merlin GT

Engine/Prop - Rotax 914/NSI CAP

Bellevue WA

425.241.1618 Cell

425.440.9505 Office |

|

| Back to top |

|

|

crazyivan

Joined: 25 Aug 2006

Posts: 62

Location: Pensacola

|

Posted: Sat Mar 14, 2009 7:49 am Post subject: Re: Engine Mount Crack Posted: Sat Mar 14, 2009 7:49 am Post subject: Re: Engine Mount Crack |

|

|

I'm using an IVO ultralight 70". It's a few lbs lighter than the GSC I removed 2.5 years ago.

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Dave

Piper PA-22/20 |

|

| Back to top |

|

|

Paul A. Franz, P.E.

Joined: 02 Dec 2008

Posts: 280

Location: Bellevue WA

|

Posted: Sat Mar 14, 2009 12:01 pm Post subject: Engine Mount Crack Posted: Sat Mar 14, 2009 12:01 pm Post subject: Engine Mount Crack |

|

|

On Sat, March 14, 2009 7:49 am, crazyivan wrote:

| Quote: |

I'm using an IVO ultralight 70". It's a few lbs lighter than the GSC I removed 2.5

years ago.

|

This reason I asked is a lighter prop would make the torsional vibration in shutdown a

little higher frequency. That might be contribute to this failure mode which is a

fatigue type failure. Fatigue in an Engineering sense is a failure mode that occurs

within the linearly elastic range of the material's stress-strain curve. The slope of

that curve is E, the modulus of Elasticity and where that line is linear, that is the

material's elastic range.

The lighter weight prop might produce either higher or lower torsional loads in

shutdown but they will occur in more cycles over a long period of time. Can you recall

any differences when you went to the lighter prop during shutdown?

--

Paul A. Franz

Registration/Aircraft - N14UW/Merlin GT

Engine/Prop - Rotax 914/NSI CAP

Bellevue WA

425.241.1618 Cell

"The great advances of civilization, whether in architecture or

painting, in science or in literature, in industry or agriculture,

have never come from centralized government."

--economist Milton Friedman (1912-2006)

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Paul A. Franz, P.E.

Registration/Aircraft - N14UW/Merlin GT

Engine/Prop - Rotax 914/NSI CAP

Bellevue WA

425.241.1618 Cell

425.440.9505 Office |

|

| Back to top |

|

|

crazyivan

Joined: 25 Aug 2006

Posts: 62

Location: Pensacola

|

Posted: Sat Mar 14, 2009 12:28 pm Post subject: Re: Engine Mount Crack Posted: Sat Mar 14, 2009 12:28 pm Post subject: Re: Engine Mount Crack |

|

|

I was thinking about the resonance thing as well. Problem is that there was not a substantial difference between the GSC kick and the Ivo kick. Then again, higher frequency resonance won't have the higher amplitude that lower f resonance will have, generally speaking, so I probably would not feel a big increase of high f resonance for such a short period of time.

Theory aside, a 1 to 2 pound difference in props should not make a difference regarding a crack in a chromoly tube. Ultimately, I think it was a fatigue issue caused by a stress riser in the weld seam. It would have cracked eventually regardless of the prop.

As usual, my 2 cents.

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Dave

Piper PA-22/20 |

|

| Back to top |

|

|

akflyer

Joined: 07 May 2007

Posts: 574

Location: Soldotna AK

|

Posted: Sat Mar 14, 2009 2:45 pm Post subject: Re: Engine Mount Crack Posted: Sat Mar 14, 2009 2:45 pm Post subject: Re: Engine Mount Crack |

|

|

The weld does come in pretty sharply at the toe on the bottom. The stress riser theory has alot going for it, and once the crack started it just propagated around the heat affected zone. One reason I make sure all the welds I visual and accept transition smoothly to the base metal.

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

DO NOT ARCHIVE

Leonard Perry aka SNAKE

Soldotna AK

Avid "C" / Mk IV

582 (147 hrs and counting on the rebuild)

IVO IFA

Full Lotus 1450

#1 snake oil salesman since 1-22-2009

I would rather die trying to live, than to live trying not to die.... |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|