|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

cristalclear13

Joined: 19 Sep 2007

Posts: 363

Location: Southeast Georgia

|

Posted: Sat Mar 21, 2009 7:22 pm Post subject: Broken exhaust bracket Posted: Sat Mar 21, 2009 7:22 pm Post subject: Broken exhaust bracket |

|

|

I don't know how many of you read the Rotax forum also, but if you do you'll remember that I have an exhaust leak. Here's the thread:

http://forums.matronics.com/viewtopic.php?t=55938

I first tried to simply replace the outside exhaust gaskets. That didn't stop the leak. So today I replaced the inside exhaust gaskets.

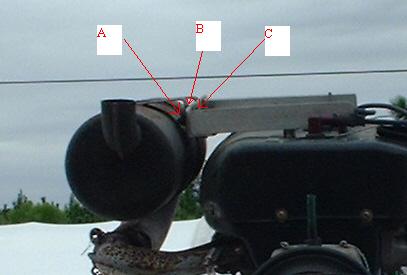

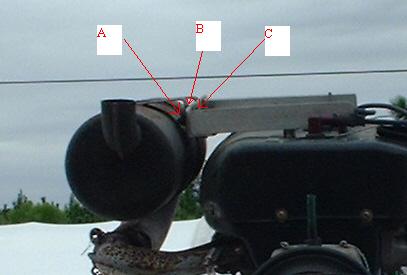

Since Lucien also mentioned checking the support and since I had been noticing lately that the rubber bushings on my exhaust mount were looking pretty worn AND since I had it all apart anyways to replace the inner exhaust gaskets (those were a challenge to scrape off the cowl), I decided to go ahead and take the mount apart and inspect it. Should have done that sooner! I attached a picture of what I found. The rubber bushings were useless and the bracket (or plate? whatever it's called) on the exhaust has cracked all the way through.

I've also attached a picture of my exhaust with the mount with some letters pointing to various places.

The male rubber bushing was currently where letter A is pointing (actually inside the exhaust bracket or plate).

The female rubber bushing was currently where letter C is pointing.

The people helping me say that the male bushing should be where letter B is pointing (between the exhaust bracket and the exhaust mount).

If it is currently set up wrong that might have further aggravated and caused the crack (besides the bushings being rotten).

I know there aren't many of you out there that have a 503 anymore and probably don't even have the same set up for the exhaust if you do have a 503, but if you have something similar could you please post a picture and/or diagram?

The CPS catalogue shows a mounting kit that uses a bolt-driven mounting clamp...does anyone use that?

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

| Description: |

|

| Filesize: |

15.26 KB |

| Viewed: |

14071 Time(s) |

|

| Description: |

|

| Filesize: |

17.45 KB |

| Viewed: |

14071 Time(s) |

|

_________________

Cristal Waters

Kolb Mark II Twinstar Rotax 503 DCSI Sept 2007 - sold Sept 2012

Private Pilot Aug 2008

ELSA Repairman for N193Y April 2008

Rotax 2 stroke maintenance April 2009 |

|

| Back to top |

|

|

Ralph B

Joined: 14 Apr 2007

Posts: 367

Location: Mound Minnesota

|

Posted: Sat Mar 21, 2009 7:59 pm Post subject: Re: Broken exhaust bracket Posted: Sat Mar 21, 2009 7:59 pm Post subject: Re: Broken exhaust bracket |

|

|

Cristal, a couple of things I see in the pictures:

1) the reason it cracked is that you have the old style single-jointed muffler with one set of 3 springs. These older mufflers are prone to cracking.

2) it looks like the previous owner may have welded a washer to the muffler where it cracked. Maybe the weld job had the opposite effect and weakening it instead of making it stronger.

Ralph B

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

Ralph B

Kolb Kolbra 912uls

N20386

550 hours |

|

| Back to top |

|

|

jimh474(at)embarqmail.com

Guest

|

Posted: Sun Mar 22, 2009 3:54 am Post subject: Broken exhaust bracket Posted: Sun Mar 22, 2009 3:54 am Post subject: Broken exhaust bracket |

|

|

Good morning Cristal;

Yes, the rubber bushings should be on the muffler bracket and not on one

side of the muffler bracket and on half on the back side of the support

angle.

The cracked bracket could be contributed to the set up and also could just

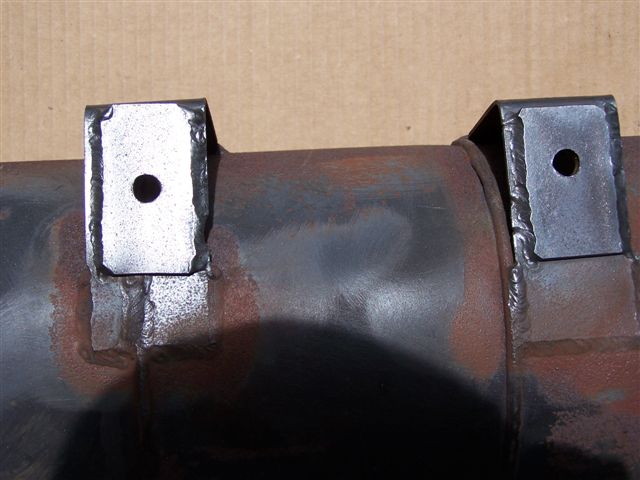

be fair wear and tear from vibration.

I would suggest grinding the washer off the muffler bracket and welding an

1/8" thick plate the full length of the bracket where the washer is located

now. Just weld the sides of the muffler bracket, not across the top or

bottom as that will cause a stress point where the bracket bends.

Ha, you live to far away or I would weld it up for you.

Jim

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

lucien

Joined: 03 Jun 2007

Posts: 721

Location: santa fe, NM

|

Posted: Sun Mar 22, 2009 5:04 am Post subject: Re: Broken exhaust bracket Posted: Sun Mar 22, 2009 5:04 am Post subject: Re: Broken exhaust bracket |

|

|

| Ralph B wrote: |

1) the reason it cracked is that you have the old style single-jointed muffler with one set of 3 springs. These older mufflers are prone to cracking.

Ralph B |

This is a good point. These older style mufflers had only one point in the tubing where they could flex. A common area of cracking on these is in an almost perfect circle right at the seam where the main expansion tube goes into the can.

I had an eipper style one of these older mufflers on my quicksilver that gave this exact circle-wise cracking in that area. Got a friend to TIG weld a new bead around there which fixed it.

But you have to pay very close attention to the tension of the springs and the muffler mounting with the old style. They can't be too tight to where they prevent movement of the joint, a common installation problem. Anti-sieze on the parts during assembly helps a bit as well.

But the new style with the seperate elbow is a lot better as it has 2 joints where the whole works can move and better isolates the vibration of the motor from the muffler.

The Kolb mounting design with the bracket bolted to the heads is actually very secure and gives good support for the can (mine would hold the muffler can perfectly in place even with no elbow installed yet) so repairing the bracket may be all you need to do.

But if it keeps cracking, you might want to replace the muffler with the new style......

LS

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

LS

Titan II SS |

|

| Back to top |

|

|

cristalclear13

Joined: 19 Sep 2007

Posts: 363

Location: Southeast Georgia

|

Posted: Sun Mar 22, 2009 10:52 am Post subject: Re: Broken exhaust bracket Posted: Sun Mar 22, 2009 10:52 am Post subject: Re: Broken exhaust bracket |

|

|

| jimh474(at)embarqmail.com wrote: | Yes, the rubber bushings should be on the muffler bracket and not on one

side of the muffler bracket and on half on the back side of the support

angle.

Jim |

I found what I think is the rubber bushings that was used originally. In the CPS catalogue I found part numbers 9406 (male bushing) and 9408 (female bushing):

http://www.rotaxparts.net/scripts/prodView.asp?idproduct=838

However a friend mentioned that I should probably use barry mount isolators:

http://www.greenskyadventures.com/Installation_items/vibmntimages.htm

However it looks like there are various ones to choose from (according to the chart at the bottom of that webpage). Has anyone used these and if so, which ones (what series and color)?

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

Cristal Waters

Kolb Mark II Twinstar Rotax 503 DCSI Sept 2007 - sold Sept 2012

Private Pilot Aug 2008

ELSA Repairman for N193Y April 2008

Rotax 2 stroke maintenance April 2009 |

|

| Back to top |

|

|

George Alexander

Joined: 10 Jan 2006

Posts: 245

Location: SW Florida

|

Posted: Sun Mar 22, 2009 12:01 pm Post subject: Re: Broken exhaust bracket Posted: Sun Mar 22, 2009 12:01 pm Post subject: Re: Broken exhaust bracket |

|

|

| cristalclear13 wrote: |

- - - snip- - -

I know there aren't many of you out there that have a 503 anymore and probably don't even have the same set up for the exhaust if you do have a 503, but if you have something similar could you please post a picture and/or diagram?

- - - snip- - -

|

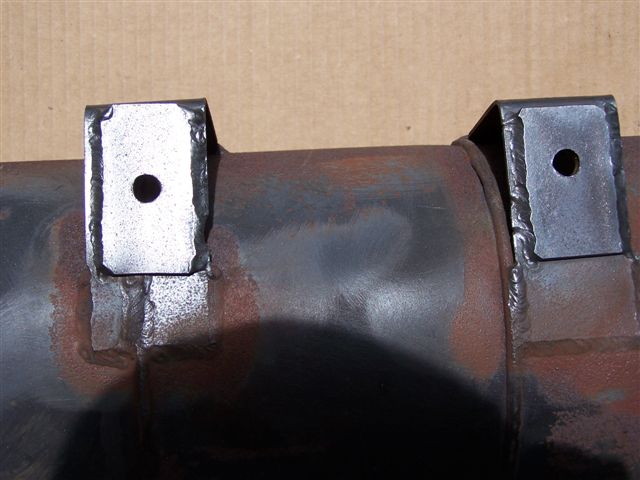

Cristal:

Know you've gotten lots of input since the posting..... but here's a picture of my set up on my FSII. (R503).

If you go with the recommended bushings from CPS, don't forget the backing washers.

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

| Description: |

|

| Filesize: |

46.18 KB |

| Viewed: |

14043 Time(s) |

|

_________________

George Alexander

FS II R503

E-LSA N709FS

http://www.oh2fly.net |

|

| Back to top |

|

|

mdnanwelch7(at)hotmail.co

Guest

|

Posted: Sun Mar 22, 2009 2:08 pm Post subject: Broken exhaust bracket Posted: Sun Mar 22, 2009 2:08 pm Post subject: Broken exhaust bracket |

|

|

> I've also attached a picture of my exhaust with the mount with some letters pointing to various places.

| Quote: | Cristal Waters

Kolb Mark II Twinstar

Rotax 503 DCSI

|

Cristal C

It seems to me Jim H. has suggested the best way to repair the bracket. A TIG weld as he described should last a long time.

If you have the room on your support bracket C you might consider adding a duplicate bracket C while the muffler is being welded C anyway.

By distributing the vibration load between 2 mounting locations C you may not have a problem for a very long time.

Just an idea....

Mike Welch

MkIII

Get quick access to your favorite MSN content with Internet Explorer 8. Download FREE now! [quote][b]

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

cristalclear13

Joined: 19 Sep 2007

Posts: 363

Location: Southeast Georgia

|

|

| Back to top |

|

|

Ralph B

Joined: 14 Apr 2007

Posts: 367

Location: Mound Minnesota

|

Posted: Mon Mar 23, 2009 6:03 am Post subject: Re: Broken exhaust bracket Posted: Mon Mar 23, 2009 6:03 am Post subject: Re: Broken exhaust bracket |

|

|

cristalclear13

| Quote: |

It may be time to replace my muffler springs as well. They are looking pretty rusty and I saw in the CPS catalogue where it says to replace them every 75 hours (Mark II manual says 100 hrs). My engine has almost 70 hours on it (don't know how old the muffler or springs are however). That doesn't look like an easy job. Maybe I should wait until after my Rotax class in a couple weeks to tackle that. I don't know how much anti-seize to put on the joint or where exactly.

|

Cristal, On the muffler joint, clean it with lacquer thinner and apply a thin coating of anti-seize compound, on each side of the joint. It's easy to install the springs. Just don't use any pliers when putting them in. Hook one end of the spring to the muffler and hook the other end with a small screwdriver and pull it over the other muffler hook. Using pliers can create stress points on the brittle spring steel and it can cause it to break. After the springs are installed, be sure and use safety wire between the muffler hooks. After that, clean the springs with lacquer thinner (to get rid of the oil on the outside) and apply two beads of the red high temp gasket sealer along the side of each spring.

Ralph

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

Ralph B

Kolb Kolbra 912uls

N20386

550 hours |

|

| Back to top |

|

|

lucien

Joined: 03 Jun 2007

Posts: 721

Location: santa fe, NM

|

Posted: Mon Mar 23, 2009 6:09 am Post subject: Re: Broken exhaust bracket Posted: Mon Mar 23, 2009 6:09 am Post subject: Re: Broken exhaust bracket |

|

|

| cristalclear13 wrote: |

It may be time to replace my muffler springs as well. They are looking pretty rusty and I saw in the CPS catalogue where it says to replace them every 75 hours (Mark II manual says 100 hrs). My engine has almost 70 hours on it (don't know how old the muffler or springs are however). That doesn't look like an easy job. Maybe I should wait until after my Rotax class in a couple weeks to tackle that. I don't know how much anti-seize to put on the joint or where exactly.

I don't suppose I'll be making it to that Ashburn fly-in this weekend.  |

The muffler springs can be easily replaced but it's crucial that you use the right tool. Never use pliers - they gouge the spring, increasing the likelihood of future breakage.

A tool is easy to make, tho. A piece of safety wire in a loop with the ends attached to a screwdriver or other metal rod (something strong that's easy to grip) works fine (I got em kind of all over the place in the hangar still).

You can then thread the loop into the hook of the spring and pull, easily popping the spring off. Same with installation - put the loop in the hook and pull the sucker over the fitting on the muffler.

As for anti-sieze, put a thin film around the area on the elbows where they make contact. You don't need much, a very thin film on both surfaces is all you need. Once heated, the stuff will boil off but a kind of dust will remain and act like a lubricant. Stays there quite a while, I've seen the lubricant dust still there after 100 hours in some cases. So a good interval is every 50 to 75 hours I'd say.

LS

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

LS

Titan II SS |

|

| Back to top |

|

|

HShack(at)aol.com

Guest

|

Posted: Mon Mar 23, 2009 6:45 am Post subject: Broken exhaust bracket Posted: Mon Mar 23, 2009 6:45 am Post subject: Broken exhaust bracket |

|

|

It is well worth it to buy a "spring hook" or to make one out of a piece of coat hanger & a short piece of broom handle; makes the job a lot easier.

Howard Shackleford

FS II

SC

In a message dated 3/23/2009 10:04:00 A.M. Eastern Daylight Time, ul15rhb(at)juno.com writes:

| Quote: | | Hook one end of the spring to the muffler and hook the other end with a small screwdriver and pull it over the other muffler hook. |

A Go0126575x1219858252x1201366219/aol?redir=http:%2F%2Fwww.freecreditreport.com%2Fpm%2Fdefault.aspx%3Fsc%3D668072%26hmpgID%3D62%26bcd%3DMarchfooterNO62"> See yours in just 2 easy steps!

[quote][b]

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

zeprep251(at)aol.com

Guest

|

Posted: Mon Mar 23, 2009 9:09 am Post subject: Broken exhaust bracket Posted: Mon Mar 23, 2009 9:09 am Post subject: Broken exhaust bracket |

|

|

The stainless springs from JBM last forever.

G Aman

--

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

russ(at)rkiphoto.com

Guest

|

Posted: Mon Mar 23, 2009 9:25 am Post subject: Broken exhaust bracket Posted: Mon Mar 23, 2009 9:25 am Post subject: Broken exhaust bracket |

|

|

Cristal

It seems obvious, but many people seem to forget that with a pusher

aircraft, ANYTHING that gets loose will go thru the prop. And usually

cause some damage. Replace anything that looks iffy, no matter how

many hours it has.

You can hardly go wrong with anti-seize; simply put it on threads

or mating surfaces, just enough to coat the surfaces. Any excess will

just paint a stripe on your prop, if you don't wipe it off.

Russ

On Mar 23, 2009, at 8:53 AM, cristalclear13 wrote:

| Quote: |

<cristalclearwaters(at)gmail.com>

George Alexander wrote:

> Cristal:

> Know you've gotten lots of input since the posting..... but here's

> a picture of my set up on my FSII. (R503).

> If you go with the recommended bushings from CPS, don't forget the

> backing washers.

Thank you for the picture George. The more I think about it the

more I think perhaps me and my friends remembered incorrectly. I

wrote down everything I did as I took everything apart and laid

things out in order as I took them apart, but when I took this

piece apart it drew a lot of attention and I believe things may

have gotten out of order (physically and in our minds). From now

on I'll be taking pictures before I take things apart.

I have a friend of a friend welding it for me since I don't weld.

I'm sure he'll do a good job.

Thanks for everyone's input and help. Again if anyone has used

those barry mounts please let me know how it goes and what type/

size should be used. Otherwise I suppose I'll go with the male/

female rubber bushings I found in the CPS catalogue (with the

backing washers).

It may be time to replace my muffler springs as well. They are

looking pretty rusty and I saw in the CPS catalogue where it says

to replace them every 75 hours (Mark II manual says 100 hrs). My

engine has almost 70 hours on it (don't know how old the muffler or

springs are however). That doesn't look like an easy job. Maybe I

should wait until after my Rotax class in a couple weeks to tackle

that. I don't know how much anti-seize to put on the joint or

where exactly.

I don't suppose I'll be making it to that Ashburn fly-in this

weekend.

--------

Cristal Waters

Kolb Mark II Twinstar

Rotax 503 DCSI

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p 35789#235789

|

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

cristalclear13

Joined: 19 Sep 2007

Posts: 363

Location: Southeast Georgia

|

Posted: Mon Mar 23, 2009 9:58 am Post subject: Re: Broken exhaust bracket Posted: Mon Mar 23, 2009 9:58 am Post subject: Re: Broken exhaust bracket |

|

|

Just ordered the rubber bushings from Travis at Kolb (he's so nice). Gonna pick up my muffler from the friend who welded it for me tonight.

Talked to Ronnie Smith at South MS Light Aircraft and he said it would be ok to bring my muffler along to the Rotax class I'm taking the weekend after next and we'll change out the springs right there in his shop.

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

Cristal Waters

Kolb Mark II Twinstar Rotax 503 DCSI Sept 2007 - sold Sept 2012

Private Pilot Aug 2008

ELSA Repairman for N193Y April 2008

Rotax 2 stroke maintenance April 2009 |

|

| Back to top |

|

|

Jim Baker

Joined: 30 Mar 2006

Posts: 181

Location: Sayre, PA

|

Posted: Mon Mar 23, 2009 5:56 pm Post subject: Broken exhaust bracket Posted: Mon Mar 23, 2009 5:56 pm Post subject: Broken exhaust bracket |

|

|

X-SpamReason %%SpamReason%%:

| Quote: | > It may be time to replace my muffler springs as well.

|

snip.....

| Quote: | The muffler springs can be easily replaced but it's crucial that you use the right tool.

|

Rid yourself of the springs.

http://www.rotaxparts.net/scripts/prodView.asp?idproduct=324

You'll never look back and wonder if a spring is going to go thru the

prop (well, at least for pushers). A bit pricy but well worth the

expense. I've had two for several years.

Jim Baker

580.788.2779

405. 426.5377 cell

Elmore City, OK

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

rowedenny

Joined: 09 Mar 2008

Posts: 338

Location: Western PA

|

Posted: Tue Mar 24, 2009 2:37 am Post subject: Broken exhaust bracket Posted: Tue Mar 24, 2009 2:37 am Post subject: Broken exhaust bracket |

|

|

[quote]

The stainless springs from JBM last forever.

G Aman

Gary,

What and where is JBM?

Denny Rowe

[b]

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

zeprep251(at)aol.com

Guest

|

Posted: Tue Mar 24, 2009 4:08 am Post subject: Broken exhaust bracket Posted: Tue Mar 24, 2009 4:08 am Post subject: Broken exhaust bracket |

|

|

Find JBM on e-bay .He is a custom rubber molder,makes carb mounting boots for all rotax applications including HKS, 912 and some special stuff like a rotax to mikuni socket.He is one of the founders of our club, North Coast Lite Flyers.He flies a Chinook 2 with 582.He ships next day.330-678-9537,is his phone.

G Aman MK-3C Jabiru 2200A- 430 hrs

--

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

cristalclear13

Joined: 19 Sep 2007

Posts: 363

Location: Southeast Georgia

|

Posted: Sat Apr 18, 2009 8:07 pm Post subject: Re: Broken exhaust bracket Posted: Sat Apr 18, 2009 8:07 pm Post subject: Re: Broken exhaust bracket |

|

|

I got my muffler back from Jim Hauck this week. He reinforced the welding my friend did by adding an extra piece and welding the sides (you can see in the picture). Thanks again Jim!

I went to put everything back together today and discovered the bolts on the new rubber bushings I got from Travis were larger than the old ones. Luckily I had a friend around who had his drill handy and drilled the holes bigger. Then the nut was also bigger and wouldn't fit behind the bracket on one side where the muffler has that bump that sticks out all the way around it. So he banged that a little with a tool to bend that extra bend down so it wouldn't be in the way of the nut.

Then I went to put everything back together (this time by myself). It is difficult to hold the muffler up and put the bolts through the top of the engine/muffler mount by yourself. Then when I tried to line up the exhaust manifold allen bolts my INSIDE exhaust gaskets kept falling out of place. I tried three times (each time having to take everything apart again). The little tabs on the case that are supposed to hold the inside gaskets in place hold them fine when I have the case off (even shook it a little) but once I'm trying to line up the exhaust manifold to bolt it in those little boogers fall down. I suppose my tabs have worn down too much to hold them good. I want to put something on them to keep them in place but I don't want to use something that is going to be difficult or impossible to get off next time I have to change them out.

Dying to fly...it feels like it has been forever. Lots of people are stopping by our airport for free BBQ and a fillup on their way to Sun N Fun. It's great to see all the various planes but sure wish I was in the air with them! If I can get things running well I will fly to the Vidalia Air Show next weekend and line my Kolb up on the static display. That should be fun.

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

| Description: |

|

| Filesize: |

47.13 KB |

| Viewed: |

13912 Time(s) |

|

_________________

Cristal Waters

Kolb Mark II Twinstar Rotax 503 DCSI Sept 2007 - sold Sept 2012

Private Pilot Aug 2008

ELSA Repairman for N193Y April 2008

Rotax 2 stroke maintenance April 2009 |

|

| Back to top |

|

|

Ralph B

Joined: 14 Apr 2007

Posts: 367

Location: Mound Minnesota

|

Posted: Sun Apr 19, 2009 8:24 am Post subject: Re: Broken exhaust bracket Posted: Sun Apr 19, 2009 8:24 am Post subject: Re: Broken exhaust bracket |

|

|

Cristal, use a little grease to hold nuts and bushings in place while you are readying to tighten them down. This job of putting on the muffler is tedious and frustrating as I have done this a few times myself. The muffler is heavy trying to hold it in place while the bushings stay in place. It sounds like you are just a few steps away before taking to the skies again.

You may want to tie the tail down with a nylon auto tow rope and wrap the other end around the front wheel of your car. Start the engine and run it up to full RPM for a minute to test things out before flying. It's much safer this way in case you missed something.

Ralph

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

Ralph B

Kolb Kolbra 912uls

N20386

550 hours |

|

| Back to top |

|

|

JetPilot

Joined: 10 Jan 2006

Posts: 1246

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|