|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

SteveR

Joined: 10 Jan 2006

Posts: 226

Location: Aledo, TX

|

Posted: Thu Apr 16, 2009 8:34 pm Post subject: Squeaking nose gear Posted: Thu Apr 16, 2009 8:34 pm Post subject: Squeaking nose gear |

|

|

The nose gear in an AA5 Traveler I've been flying lately started squeaking after a rain shower (the plane is kept outside currently). The squeak is coming from the nose gear torque tube area (very near the firewall). I think maybe it just needs to be lubricated as I read about this elsewhere. Would anyone agree with that? I'm new to Grummans so I'm not sure if the squeaky nose gear is common or not. Bouncing the nose up and down slightly makes it squeak fairly loud.

What is the proper procedure and lubricant to use on the torque tube/nose gear strut junction, assuming that is where the squeak is coming from? Does the nose gear strut have to be removed from the torque tube in order to lubricate it?

Or if I'm going in completely the wrong direction, I'd be glad to hear about that too. Thanks for any help.

Steve

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

GrummanDude

Joined: 15 Jan 2006

Posts: 926

Location: Auburn, CA

|

Posted: Thu Apr 16, 2009 9:04 pm Post subject: Squeaking nose gear Posted: Thu Apr 16, 2009 9:04 pm Post subject: Squeaking nose gear |

|

|

Hi Steve,

If you had the shocks on the nose gear, I'd say look there first.

You'll need to remove the cowling and locate where the squeak is coming

from. If it's in the nose gear torque tube attach, remove the boot

around the strut and check the attachment bolts. I've seen a number of

planes with AN bolts installed when they should be NAS. Also, if the

bolts have been crowded out, they'll need to be reamed a half size over

and special bolts installed.

Also, I'd suggest you remove the seats and crawl in under the panel and

have someone move the nose up and down and check for squeaking in the

torque tube itself.

--

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

_________________

Gary

AuCountry Aviation

Home of Team Grumman |

|

| Back to top |

|

|

flyv35b(at)minetfiber.com

Guest

|

Posted: Fri Apr 17, 2009 4:59 am Post subject: Squeaking nose gear Posted: Fri Apr 17, 2009 4:59 am Post subject: Squeaking nose gear |

|

|

I'd say there is a very high probability that the squeaking noise you are

hearing is due to a delaminated torque tube. No lubrication was required

anywhere on the strut/torque tube installation. You will need to have

someone help you bounce the plane up and down while you get under the panel

and put your fingers across both sides of the torque tube joint on the

socket and also at the outboard ends near the fuselage sidewall. Do this on

both sides. Delaminated torque tubes can be rebuilt. A failed joint will

put additional load on the opposite site and if that side fails you will end

up with the prop in the ground!

Cliff A&P/IA

---

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

SteveR

Joined: 10 Jan 2006

Posts: 226

Location: Aledo, TX

|

Posted: Fri Apr 17, 2009 5:37 am Post subject: Re: Squeaking nose gear Posted: Fri Apr 17, 2009 5:37 am Post subject: Re: Squeaking nose gear |

|

|

Cliff, thanks for your help, I really appreciate it. I think we'll ground the plane until we know for sure what the problem is. If anyone has any diagrams of the torque tube assembly that would help us know what to look for, they would be greatly appreciated.

This is where I got the information on lubricating the strut and torque tube:

http://www.grumman.net/cgrcc/aa5.html

| Quote: | | The nosegear demands maintenance and must be lubricated and adjusted strictly by the book. (Not many shops even have the book.) In particular, the strut inside the torque tube should be free of corrosion and well lubricated. |

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

flyv35b(at)minetfiber.com

Guest

|

Posted: Fri Apr 17, 2009 6:08 am Post subject: Squeaking nose gear Posted: Fri Apr 17, 2009 6:08 am Post subject: Squeaking nose gear |

|

|

Good information but not intended to replace the maintenance manual info.

The lubrication Aviation Consumer is referring to is where the nose fork is

mated to the nose strut. This area is where lots of non Grumman shops and

mechanics know very little about and they ignore the maintenance here and

get the fork tension washer installation and adjustment screwed up and the

nose wheel shimmys.

I wouldn't fly the plane until you find out if the torque tube is OK. I'd

also buy a maintenance and parts manual from Fletchair, especially if you

mechanic doesn't have a set.

Cliff

---

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

SteveR

Joined: 10 Jan 2006

Posts: 226

Location: Aledo, TX

|

Posted: Fri Apr 17, 2009 6:43 am Post subject: Re: Squeaking nose gear Posted: Fri Apr 17, 2009 6:43 am Post subject: Re: Squeaking nose gear |

|

|

Thanks again Cliff. The owner might have the manual, I'll check with him.

I found the information below (last paragraph) which describes the torque tube assembly. I'm having trouble understanding which part(s) might be delaminated. It sounds to me like everything is bolted or welded, which I know isn't right. Once I'm under there with a light, and a helper is bouncing the nose, will it be pretty obvious?

And finally, if it is a delaminted torque tube, can you recommend any good shops for rebuilds? I am in the Oklahoma City area, any local experts that anyone could recommend would be greatly appreciated.

Here is the paragraph I found somewhere else...I'm having trouble understanding where to look for delaminations here:

The torque tube assembly is made up of three parts: the T connector, the horizontal tube(s), and the sidewall mounting bracket(s). The T connector has a tube in it which connects to the nose gear strut and is bolted to the floor and firewall. It is welded to the horizontal tubes which on the other ends are welded to the sidewall mounting brackets. The mounting brackets are bolted to the sidewalls.

Thanks again for the help,

Steve Ruse

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

cloudvalley(at)comcast.ne

Guest

|

Posted: Fri Apr 17, 2009 6:50 am Post subject: Squeaking nose gear Posted: Fri Apr 17, 2009 6:50 am Post subject: Squeaking nose gear |

|

|

Hi Cliff!

Ah yes the torque tube. We had a problem with that also.smile

Brian Preston

---

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

grumpyparts

Joined: 28 Jan 2009

Posts: 65

Location: EGHH

|

Posted: Fri Apr 17, 2009 11:45 am Post subject: Re: Squeaking nose gear Posted: Fri Apr 17, 2009 11:45 am Post subject: Re: Squeaking nose gear |

|

|

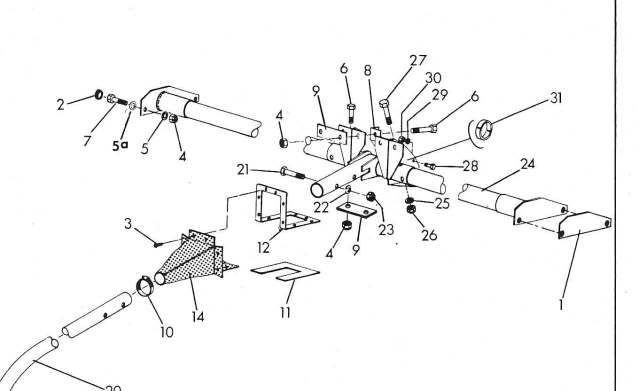

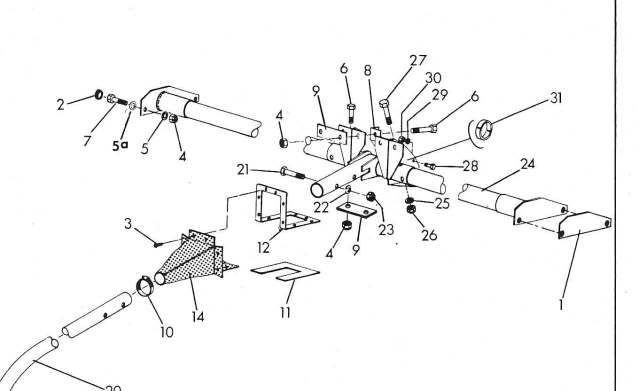

The torque tube can be of three different make-ups, as far as I know. They are primarily made up of five parts. Two end plates, two torque tubes and a centre yoke, which the nose leg attaches to. If you follow the link below to the forum site you will see a picture of the assembly. In the original Grumman/Gulfstream tubes the two torque tubes were solely bonded into the two end plates. If both failed nothing stopped the nose leg rotating up into the bottom of the engine cowl. Frank Johnson then came out with a STC’ed repaired option where the tubes were bonded and tapered pinned to the end plates. Fletchair’s and AGAC’s torque tubes were similar but instead of the one pin in each end plate and yoke they used two bolts at 90 degrees to each other. Pictures of these three different types are shown in the link below also as well as a failed joint

Diagram taken from parts book

Original bonded end plate

Frank Johnson end plate

Fletchair/AGAC/Tiger end plate

Failure mode of bonded joint on end plate

Comparision between Johnson and Fletchair tubes. One on the right is a failed Johnson tube, notice angle difference of nose leg yoke exit. Sorry about the kitchen background.

Regards

Ian

MatAir

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

SteveR

Joined: 10 Jan 2006

Posts: 226

Location: Aledo, TX

|

Posted: Fri Apr 17, 2009 11:50 am Post subject: Re: Squeaking nose gear Posted: Fri Apr 17, 2009 11:50 am Post subject: Re: Squeaking nose gear |

|

|

Wow. Absolutely great information Ian. It'll be fairly easy to diagnose now, the hard part is just crawling under the panel. Thanks for the great information and pictures everyone.

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

grumpyparts

Joined: 28 Jan 2009

Posts: 65

Location: EGHH

|

Posted: Fri Apr 17, 2009 12:44 pm Post subject: Re: Squeaking nose gear Posted: Fri Apr 17, 2009 12:44 pm Post subject: Re: Squeaking nose gear |

|

|

Pictures tell a thousands words. I only wish more would use the forum instead of the email listings. All those formatting emails finally made me give up on the email option. Use the forum and formatting is not an issue.

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

SteveR

Joined: 10 Jan 2006

Posts: 226

Location: Aledo, TX

|

Posted: Sat Apr 18, 2009 6:19 pm Post subject: Re: Squeaking nose gear Posted: Sat Apr 18, 2009 6:19 pm Post subject: Re: Squeaking nose gear |

|

|

I crawled under the panel today to have a look at the torque tubes. The bonded joints definitely do not appear to be broken, and each side of the tube moves together. The squeaking appeared to be coming from the yoke area, between the rotating center of the torque tube and the bracket that holds it to the floor and firewall. After lubricating this joint, the squeaking went away. I think it is safe to say that the torque tube is fine.

I'm attaching a picture of each of the torque tube bonded junctions. Any comments would be appreciated. Thanks again for everyone's input on this.

I couldn't tell how the torque tube rotates in the firewall/floor bracket. The plane's annual is coming up next month, and we do have the service manual for the plane. Is there anything on that bracket that we should tell the shop to look at or lubricate?

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

| Description: |

| Left Outboard Bonded Junction |

|

| Filesize: |

14.22 KB |

| Viewed: |

12942 Time(s) |

|

| Description: |

| Left Inboard Bonded Junction |

|

| Filesize: |

11.69 KB |

| Viewed: |

12942 Time(s) |

|

| Description: |

| Right Inboard Bonded Junction |

|

| Filesize: |

6.91 KB |

| Viewed: |

12942 Time(s) |

|

| Description: |

| Right Outboard Bonded Junction |

|

| Filesize: |

12.47 KB |

| Viewed: |

12942 Time(s) |

|

Last edited by SteveR on Sun Apr 19, 2009 7:05 am; edited 2 times in total |

|

| Back to top |

|

|

SteveR

Joined: 10 Jan 2006

Posts: 226

Location: Aledo, TX

|

Posted: Sat Apr 18, 2009 7:23 pm Post subject: Re: Squeaking nose gear Posted: Sat Apr 18, 2009 7:23 pm Post subject: Re: Squeaking nose gear |

|

|

I should probably add that the nose gear boot was torn, which could've let some moisture in right on the bracket/torque tube in question. A new boot is on the way.

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

GrummanDude

Joined: 15 Jan 2006

Posts: 926

Location: Auburn, CA

|

Posted: Sat Apr 18, 2009 9:51 pm Post subject: Squeaking nose gear Posted: Sat Apr 18, 2009 9:51 pm Post subject: Squeaking nose gear |

|

|

pics didn't come through

--

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

_________________

Gary

AuCountry Aviation

Home of Team Grumman |

|

| Back to top |

|

|

grumpyparts

Joined: 28 Jan 2009

Posts: 65

Location: EGHH

|

Posted: Sun Apr 19, 2009 12:16 am Post subject: Re: Squeaking nose gear Posted: Sun Apr 19, 2009 12:16 am Post subject: Re: Squeaking nose gear |

|

|

Gary

If you go to the bottom of Steve's message you should see a link to the teamgrumman forum, think it reads something like.

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=240007#240007

The pictures are there.

You will also see a similar message at the bottom of this message as I use the forum for all messages now.

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

grumpyparts

Joined: 28 Jan 2009

Posts: 65

Location: EGHH

|

Posted: Sun Apr 19, 2009 2:57 am Post subject: Re: Squeaking nose gear Posted: Sun Apr 19, 2009 2:57 am Post subject: Re: Squeaking nose gear |

|

|

The only free moving parts in the torque tube is within the firewall/floor bracket. Held between the two halves of that bracket is a steel collar which holds a bronze split bearing p/n 702058-6. (part 31 in the picture shown on the forum site) When the torque tube twists under loads exerted to the nose leg attached to the torque tube yoke, the tube yoke section rotates within that bronze bearing. Although the steel collar is held tight within the two halves of the centre brackets, if the friction between the bearing and yoke become too tight, there is nothing to stop that collar trying to rotate within the bracket which may also cause squeaking. Why the parts book call out that p/n for the bearing I don’t know because it is not a replaceable/servicebale item. The only way to replace it is to remove the torque tube from the plane and debond/unbolt the end caps of the tube.

I assume by lubricating you may mean spraying so may be that has penetrated within and between the bearing and tube and helped some what.

For pictures of a broken down split bearing follow the “Read this topic online here” link below.

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

| Description: |

| Comlplete split bearing breakdown |

|

| Filesize: |

47.36 KB |

| Viewed: |

12908 Time(s) |

|

| Description: |

| Bracket disassembled and steel collar removed with split bearing witin |

|

| Filesize: |

47.22 KB |

| Viewed: |

12908 Time(s) |

|

| Description: |

|

| Filesize: |

48.49 KB |

| Viewed: |

12908 Time(s) |

|

|

|

| Back to top |

|

|

SteveR

Joined: 10 Jan 2006

Posts: 226

Location: Aledo, TX

|

Posted: Sun Apr 19, 2009 7:16 am Post subject: Re: Squeaking nose gear Posted: Sun Apr 19, 2009 7:16 am Post subject: Re: Squeaking nose gear |

|

|

Here are some direct links to the bonded tubes if anyone still wants to look at them (see the end of my message). I don't think broken bonds are the problem though. I think it was just the bronze split bearing referenced by Ian. When I lubricated that area with some light silicone lubricant, the squeaking went away. I think some moisture had entered the area through a torn nose gear boot...I flew the plane about six hours then it sat outside overnight in a rain shower immediately before the squeaking started. The annual is about a month away, so we'll be replacing the boot, and maybe adding some lubricant to that bearing, although I'm not sure what the proper lubricant would be. I'd say we're really just trying to prevent corrosion there more than lubricating. Would something like LPS-3 be good for this?

Thanks again for the help everyone...this is a great list!

http://www.wotelectronics.com/flying/DSC04958%20-%20right%20outboard.JPG

http://www.wotelectronics.com/flying/DSC04961%20-%20right%20inboard.JPG

http://www.wotelectronics.com/flying/DSC04965%20-%20left%20outboard.JPG

http://www.wotelectronics.com/flying/DSC04972%20-%20left%20inboard.JPG

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|