|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

Lynn Matteson

Joined: 10 Jan 2006

Posts: 2778

Location: Grass Lake, Michigan

|

Posted: Sun Sep 06, 2009 7:24 pm Post subject: Here's an idea that DIDN'T work Posted: Sun Sep 06, 2009 7:24 pm Post subject: Here's an idea that DIDN'T work |

|

|

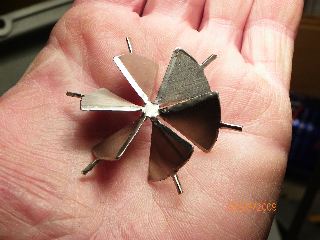

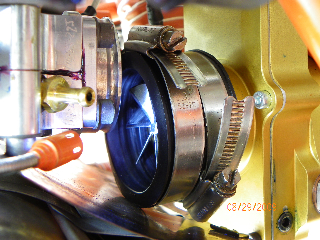

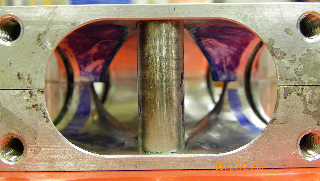

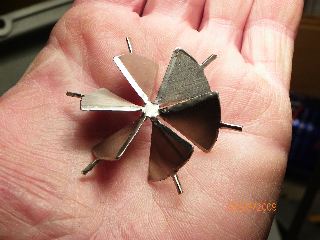

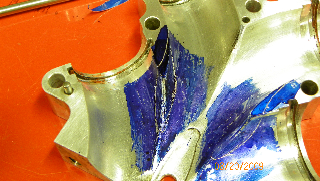

Last week or so, I mentioned I was going to build a "turbulator" for

my induction system. Here are pictures of what I built and what it

looks (looked) like installed.

I cut and bent it out of stainless steel. The little "stems" sticking

out of the tops of the vanes are what is used to hold it in place. I

bent the vanes to about a 45 degree angle. After installation, I ran

the engine up, and it seemed like the rpm's were fine, but on

climbout it was about 200 rpm down, and pretty weak in climb. I

thought it might have been the quite strong wind I was fighting, but

the next day wasn't any better so I removed the device and power was

restored. In retrospect, I think if I had made the outside a complete

circle, and let the center of the vanes be more open...in other

words, just have the vanes at the periphery, I think it might have

worked. But I do not have the means to saw to the inside of a circle

on my bandsaw...no blade welding attachment. I may try this

experiment again if I can find a way to make it here at home.

By the way, this device is not intended to rotate. It is just

supposed to make the air rotate, or become turbulent.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 760.3 hrs

Sensenich 62"x46" Wood prop

Electroair direct-fire ignition system

Rotec TBI-40 injection

Status: flying

do not archive

On Sep 6, 2009, at 9:30 PM, mhubel wrote:

| Quote: |

I am considering using the Rotac TBI 40 for a Jabiru 3300 in a

Zenith CH601XL.

I wonder what your experience was with the primer button on the

regulator, did you connect it to a cable in the cabin? If so just

what sort of assembly was used?

I was also wondering how the mixture cable was supported, I don't

see any method of supporting the mixture cable in the pictures on

the ROTAC web site.

--------

Mark Hubelbank

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p 61793#261793

|

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

| Description: |

|

| Filesize: |

135.05 KB |

| Viewed: |

16440 Time(s) |

|

| Description: |

|

| Filesize: |

145.67 KB |

| Viewed: |

16440 Time(s) |

|

_________________

Lynn

Kitfox IV-Jabiru 2200

N369LM |

|

| Back to top |

|

|

pjdisher(at)bigpond.com

Guest

|

Posted: Sun Sep 06, 2009 8:15 pm Post subject: Here's an idea that DIDN'T work Posted: Sun Sep 06, 2009 8:15 pm Post subject: Here's an idea that DIDN'T work |

|

|

Hi Lynn,

Late last year I tried the very same thing, a product made here, all ready

aviable in Australia and distrubted to the car (auto) industry. Made of SS,

6 vains and enclosed in a tube the diameter of the vains and a 1/2 long.

cost me $165.00.

It did NOT work, just like your results NBG. I did get my money back.

Pete D

VH-PDI

---

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

Peter H

Joined: 20 Mar 2007

Posts: 197

|

Posted: Sun Sep 06, 2009 8:59 pm Post subject: Here's an idea that DIDN'T work Posted: Sun Sep 06, 2009 8:59 pm Post subject: Here's an idea that DIDN'T work |

|

|

Lynn

I tried a device like that and fitted about 6" upstream from the carb. but

did not see measurable improvement and it limited power so that the last

11/2" of throttle made no effect.

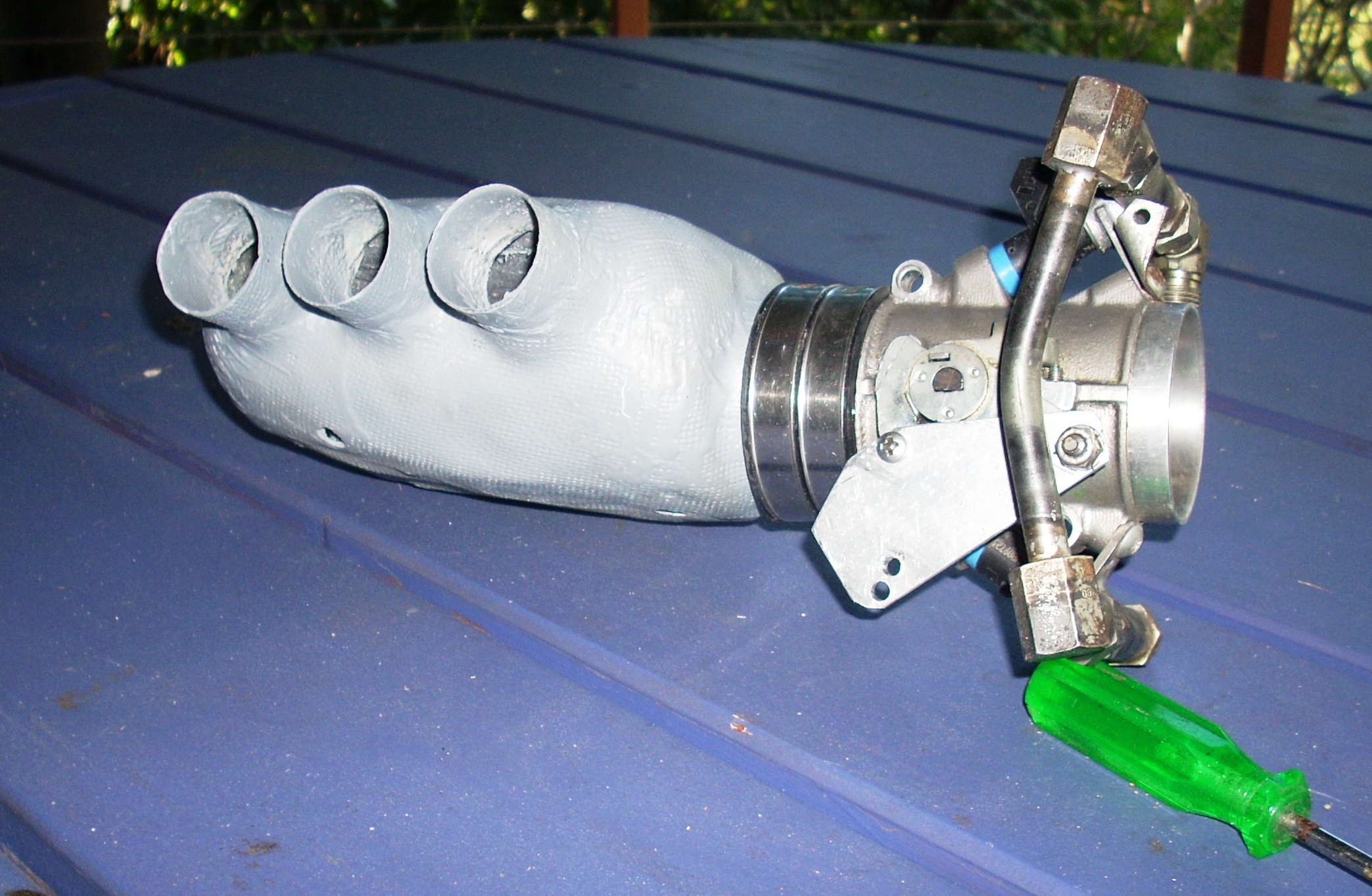

After 12 months of trials using a Jenvey throttle body and two injectors I

made a number of different plenums to replace the induction collector

supplied.

Because the Jab collector is fed from the end I found that fuel mix

distribution was not uniform throughout the power range and at times uneven

distribution R to L was causing the engine to vibrate. Also at WOT when the

butterfly is horizontal there is a significant reduction in turbulence and a

tendency for the heavier fuel droplets to accumulate at the far end,

enriching #1 and #2.

Using a bowl shaped plenum (as attached here) the effect was so bad that the

engine would shut down over the last inch of throttle with #1 and#2 miss

firing rich.

Based on static RPM I got no extra power from the plenum because the engine

failed rich every time.I spent hours trying to figure out why the breakdown.

I was able to correct this problem by fitting a 11/2" wide plate inside my

plenum placed about 1/2" directly in front of the inlet, like a big baffle.

Then the setup behaved exactly like the Jab collector. #1 and2 were rich at

WOT but the engine did not break down. I got the same max RPM, but noticed

that there was no increase in RPM for the last inch of throttle opening.

I have the same effect with my jab collector.

| Quote: | From all of this I deduce that

1. The collector as supplied suffers from internal losses which limit

|

max power at WOT. and prevent rich failure of #1 and#2

2. There is the potential to make a plenum that would solve the problem

provided it has symmetrical outlets and is fed from the centre at the

bottom.

3. There is the potential to get more uniform distribution of the

charge and with less induction losses there is the potential to get more

power.

That will be my next project but at present I have a lot of other

commitments.

Cheers

Peter

--

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

| Description: |

|

| Filesize: |

682.12 KB |

| Viewed: |

16442 Time(s) |

|

|

|

| Back to top |

|

|

aslsa.rng(at)gmail.com

Guest

|

Posted: Sun Sep 06, 2009 9:10 pm Post subject: Here's an idea that DIDN'T work Posted: Sun Sep 06, 2009 9:10 pm Post subject: Here's an idea that DIDN'T work |

|

|

Lynn, Just a thought, but any airfoil surface, even a flat plate will stall at about a 12 to 16 degrees angle of attack. Before you give up, try bending the vanes to something well below this, say 8 to 10 degrees.

Rick Girard

On Sun, Sep 6, 2009 at 10:21 PM, Lynn Matteson <lynnmatt(at)jps.net (lynnmatt(at)jps.net)> wrote:

[quote] Last week or so, I mentioned I was going to build a "turbulator" for my induction system. Here are pictures of what I built and what it looks (looked) like installed.

I cut and bent it out of stainless steel. The little "stems" sticking out of the tops of the vanes are what is used to hold it in place. I bent the vanes to about a 45 degree angle. After installation, I ran the engine up, and it seemed like the rpm's were fine, but on climbout it was about 200 rpm down, and pretty weak in climb. I thought it might have been the quite strong wind I was fighting, but the next day wasn't any better so I removed the device and power was restored. In retrospect, I think if I had made the outside a complete circle, and let the center of the vanes be more open...in other words, just have the vanes at the periphery, I think it might have worked. But I do not have the means to saw to the inside of a circle on my bandsaw...no blade welding attachment. I may try this experiment again if I can find a way to make it here at home.

By the way, this device is not intended to rotate. It is just supposed to make the air rotate, or become turbulent.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 760.3 hrs

Sensenich 62"x46" Wood prop

Electroair direct-fire ignition system

Rotec TBI-40 injection

Status: flying

do not archive

On Sep 6, 2009, at 9:30 PM, mhubel wrote:

| Quote: | --> Kitfox-List message posted by: "mhubel" <mhubel(at)nemon.com (mhubel(at)nemon.com)>

I am considering using the Rotac TBI 40 for a Jabiru 3300 in a Zenith CH601XL.

I wonder what your experience was with the primer button on the regulator, did you connect it to a cable in the cabin? If so just what sort of assembly was used?

I was also wondering how the mixture cable was supported, I don't see any method of supporting the mixture cable in the pictures on the ROTAC web site.

--------

Mark Hubelbank

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=261793#261793

|

[b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

wb2ssj(at)frontiernet.net

Guest

|

Posted: Mon Sep 07, 2009 2:23 am Post subject: Here's an idea that DIDN'T work Posted: Mon Sep 07, 2009 2:23 am Post subject: Here's an idea that DIDN'T work |

|

|

Lyn, your idea is like what was tried many years ago. JC Whitney used to

sell them for cars and motor cycles. They had them installed at the air

cleaner and spun the air prior to the carb. Also you have them too large a

surface area. Cut them down a little and I think you will get better result.

Tex

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

Lynn Matteson

Joined: 10 Jan 2006

Posts: 2778

Location: Grass Lake, Michigan

|

Posted: Mon Sep 07, 2009 2:56 am Post subject: Here's an idea that DIDN'T work Posted: Mon Sep 07, 2009 2:56 am Post subject: Here's an idea that DIDN'T work |

|

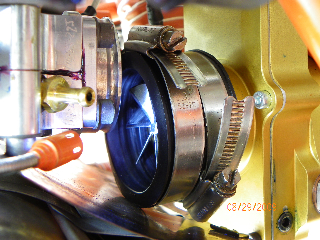

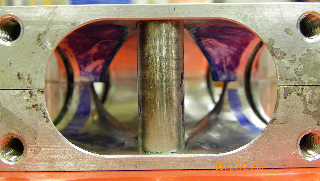

|

Hi Peter-

I've been wondering how you've been making out with your injection

experiments. I too have been thinking about making the fuel

distribution unit more centrally located, and came up with the

thought of mounting my TBI below the engine, so that the intake tubes

would all be equal in length ( your potential item #2) and not have

to compete with each other for the incoming charge. Based on what

I've learned while using this TBI and running "lean of peak EGT"

tests, I made the pictured modifications to the intake manifold/

splitter, and it seems to have brought the front cylinders a bit

closer to the rears in terms of EGT and CHT numbers.

Now when operating the engine lean of peak, the EGT's are within

about 60 degrees F, and the CHT's are within a maximum of 20 degrees

F., and as close as 1 degree of each other. I haven't tried to see

how close the EGT's and CHT's would be at higher throttle openings,

but I will.

Because of the title of this thread, I should state that these

pictures are of an idea that DID work.

The first picture shows the area that I would remove from both

halves, and the second picture shows that removal with just the lower

half of the manifold/plenum done. After doing both halves, and test

flying it, it seems to have helped the distribution of air to the

front cylinders. At least it didn't hurt, and that's always nice when

you're potentially ruining an expensive part. : )

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 760.3 hrs

Sensenich 62"x46" Wood prop

Electroair direct-fire ignition system

Rotec TBI-40 injection

Status: flying

do not archive

On Sep 7, 2009, at 12:55 AM, Peter Harris wrote:

| Quote: | Lynn

I tried a device like that and fitted about 6" upstream from the

carb. but

did not see measurable improvement and it limited power so that the

last

11/2" of throttle made no effect.

After 12 months of trials using a Jenvey throttle body and two

injectors I

made a number of different plenums to replace the induction collector

supplied.

Because the Jab collector is fed from the end I found that fuel mix

distribution was not uniform throughout the power range and at

times uneven

distribution R to L was causing the engine to vibrate. Also at WOT

when the

butterfly is horizontal there is a significant reduction in

turbulence and a

tendency for the heavier fuel droplets to accumulate at the far end,

enriching #1 and #2.

Using a bowl shaped plenum (as attached here) the effect was so bad

that the

engine would shut down over the last inch of throttle with #1 and#2

miss

firing rich.

Based on static RPM I got no extra power from the plenum because

the engine

failed rich every time.I spent hours trying to figure out why the

breakdown.

I was able to correct this problem by fitting a 11/2" wide plate

inside my

plenum placed about 1/2" directly in front of the inlet, like a big

baffle.

Then the setup behaved exactly like the Jab collector. #1 and2 were

rich at

WOT but the engine did not break down. I got the same max RPM, but

noticed

that there was no increase in RPM for the last inch of throttle

opening.

I have the same effect with my jab collector.

> From all of this I deduce that

1. The collector as supplied suffers from internal losses which limit

max power at WOT. and prevent rich failure of #1 and#2

2. There is the potential to make a plenum that would solve the

problem

provided it has symmetrical outlets and is fed from the centre at the

bottom.

3. There is the potential to get more uniform distribution of the

charge and with less induction losses there is the potential to get

more

power.

That will be my next project but at present I have a lot of other

commitments.

Cheers

Peter

|

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

| Description: |

|

| Filesize: |

120.98 KB |

| Viewed: |

16441 Time(s) |

|

| Description: |

|

| Filesize: |

115.77 KB |

| Viewed: |

16441 Time(s) |

|

_________________

Lynn

Kitfox IV-Jabiru 2200

N369LM |

|

| Back to top |

|

|

Lynn Matteson

Joined: 10 Jan 2006

Posts: 2778

Location: Grass Lake, Michigan

|

Posted: Mon Sep 07, 2009 2:56 am Post subject: Here's an idea that DIDN'T work Posted: Mon Sep 07, 2009 2:56 am Post subject: Here's an idea that DIDN'T work |

|

|

Thanks for the tip, Rick. I'll keep that in mind if I decide to

continue with this idea. I think if I tried to use the present piece

and bent it more, the vanes would break off, but making a new one

would let me try that idea. I try to use only the tools I have at

home here, but it may be time to go to a local machine shop for help

on this one. I originally was going to make it out of aluminum, but

it was going to be a major amount of milling, so I tried the

stainless steel and the band saw.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 760.3 hrs

Sensenich 62"x46" Wood prop

Electroair direct-fire ignition system

Rotec TBI-40 injection

Status: flying

On Sep 7, 2009, at 1:02 AM, Richard Girard wrote:

| Quote: | Lynn, Just a thought, but any airfoil surface, even a flat plate

will stall at about a 12 to 16 degrees angle of attack. Before you

give up, try bending the vanes to something well below this, say 8

to 10 degrees.

Rick Girard

|

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

_________________

Lynn

Kitfox IV-Jabiru 2200

N369LM |

|

| Back to top |

|

|

aslsa.rng(at)gmail.com

Guest

|

Posted: Mon Sep 07, 2009 3:06 am Post subject: Here's an idea that DIDN'T work Posted: Mon Sep 07, 2009 3:06 am Post subject: Here's an idea that DIDN'T work |

|

|

Lynn, As it happens I have a small machine shop. If I can help out let me know. Rather than using stainless, you might consider using brass sheet and silver soldering the vanes on a hub.

Rick

On Mon, Sep 7, 2009 at 5:55 AM, Lynn Matteson <lynnmatt(at)jps.net (lynnmatt(at)jps.net)> wrote:

[quote] --> JabiruEngine-List message posted by: Lynn Matteson <lynnmatt(at)jps.net (lynnmatt(at)jps.net)>

Thanks for the tip, Rick. I'll keep that in mind if I decide to continue with this idea. I think if I tried to use the present piece and bent it more, the vanes would break off, but making a new one would let me try that idea. I try to use only the tools I have at home here, but it may be time to go to a local machine shop for help on this one. I originally was going to make it out of aluminum, but it was going to be a major amount of milling, so I tried the stainless steel and the band saw.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 760.3 hrs

Sensenich 62"x46" Wood prop

Electroair direct-fire ignition system

Rotec TBI-40 injection

Status: flying

On Sep 7, 2009, at 1:02 AM, Richard Girard wrote:

| Quote: | Lynn, Just a thought, but any airfoil surface, even a flat plate will stall at about a 12 to 16 degrees angle of attack. Before you give up, try bending the vanes to something well below this, say 8 to 10 degrees.

Rick Girard

|

===========

-List" target="_blank">http://www.matronics.com/Navigator?JabiruEngine-List

===========

http://forums.matronics.com

===========

le, List Admin.

="_blank">http://www.matronics.com/contribution

===========

[b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

Lynn Matteson

Joined: 10 Jan 2006

Posts: 2778

Location: Grass Lake, Michigan

|

Posted: Mon Sep 07, 2009 3:08 am Post subject: Here's an idea that DIDN'T work Posted: Mon Sep 07, 2009 3:08 am Post subject: Here's an idea that DIDN'T work |

|

|

Hi Peter-

What I was trying to copy WAS a product made for the car industry...a

"cyclone-something". Did you try this in your Jabiru engine? When I

searched the websites, I couldn't find one small enough to fit behind

the injector body.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 760.3 hrs

Sensenich 62"x46" Wood prop

Electroair direct-fire ignition system

Rotec TBI-40 injection

Status: flying

On Sep 7, 2009, at 12:07 AM, peter disher wrote:

[quote]

<pjdisher(at)bigpond.com>

Hi Lynn,

Late last year I tried the very same thing, a product made here,

all ready aviable in Australia and distrubted to the car (auto)

industry. Made of SS, 6 vains and enclosed in a tube the diameter

of the vains and a 1/2 long. cost me $165.00.

It did NOT work, just like your results NBG. I did get my money back.

Pete D

VH-PDI

---

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

_________________

Lynn

Kitfox IV-Jabiru 2200

N369LM |

|

| Back to top |

|

|

Lynn Matteson

Joined: 10 Jan 2006

Posts: 2778

Location: Grass Lake, Michigan

|

Posted: Mon Sep 07, 2009 4:40 am Post subject: Here's an idea that DIDN'T work Posted: Mon Sep 07, 2009 4:40 am Post subject: Here's an idea that DIDN'T work |

|

|

Thanks for the input. Tex....after I got to looking at it, I realized

that the vanes were too large, but thought that the edge thickness

was not too much of a restriction, but the air moving through it had

different ideas. : ) And yes, this was just a regurgitation of an

old idea.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 760.3 hrs

Sensenich 62"x46" Wood prop

Electroair direct-fire ignition system

Rotec TBI-40 injection

Status: flying

On Sep 7, 2009, at 6:22 AM, Tex Mantell wrote:

| Quote: |

<wb2ssj(at)frontiernet.net>

Lyn, your idea is like what was tried many years ago. JC Whitney

used to sell them for cars and motor cycles. They had them

installed at the air cleaner and spun the air prior to the carb.

Also you have them too large a surface area. Cut them down a little

and I think you will get better result. Tex

|

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

_________________

Lynn

Kitfox IV-Jabiru 2200

N369LM |

|

| Back to top |

|

|

Lynn Matteson

Joined: 10 Jan 2006

Posts: 2778

Location: Grass Lake, Michigan

|

Posted: Mon Sep 07, 2009 4:50 am Post subject: Here's an idea that DIDN'T work Posted: Mon Sep 07, 2009 4:50 am Post subject: Here's an idea that DIDN'T work |

|

|

Now THERE'S a good idea! Sometimes I really overlook the obvious in

my old age. You're absolutely right, a silver soldered assembly would

be the way to go, and I can do this at home. I have a lathe, milling

attachment, band saw, and all the assorted hand tools in my small

shop, and sometimes I try to make a machined job, when all that is

called for is the hand tools and the silver solder. Thanks for the

suggestion and the offer to help, Rick.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 760.3 hrs

Sensenich 62"x46" Wood prop

Electroair direct-fire ignition system

Rotec TBI-40 injection

Status: flying

On Sep 7, 2009, at 7:02 AM, Richard Girard wrote:

| Quote: | Lynn, As it happens I have a small machine shop. If I can help out

let me know. Rather than using stainless, you might consider using

brass sheet and silver soldering the vanes on a hub.

Rick

On Mon, Sep 7, 2009 at 5:55 AM, Lynn Matteson <lynnmatt(at)jps.net>

wrote:

<lynnmatt(at)jps.net>

Thanks for the tip, Rick. I'll keep that in mind if I decide to

continue with this idea. I think if I tried to use the present

piece and bent it more, the vanes would break off, but making a new

one would let me try that idea. I try to use only the tools I

have at home here, but it may be time to go to a local machine shop

for help on this one. I originally was going to make it out of

aluminum, but it was going to be a major amount of milling, so I

tried the stainless steel and the band saw.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 760.3 hrs

Sensenich 62"x46" Wood prop

Electroair direct-fire ignition system

Rotec TBI-40 injection

Status: flying

On Sep 7, 2009, at 1:02 AM, Richard Girard wrote:

Lynn, Just a thought, but any airfoil surface, even a flat plate

will stall at about a 12 to 16 degrees angle of attack. Before you

give up, try bending the vanes to something well below this, say 8

to 10 degrees.

Rick Girard

===========

-List" target="_blank">http://www.matronics.com/Navigator?

JabiruEngine-List

===========

http://forums.matronics.com

===========

le, List Admin.

="_blank">http://www.matronics.com/contribution

===========

www.matronics.com/contribution _-

============================================================

|

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

_________________

Lynn

Kitfox IV-Jabiru 2200

N369LM |

|

| Back to top |

|

|

zeprep251(at)aol.com

Guest

|

Posted: Mon Sep 07, 2009 6:09 am Post subject: Here's an idea that DIDN'T work Posted: Mon Sep 07, 2009 6:09 am Post subject: Here's an idea that DIDN'T work |

|

|

Lynn,

Is there any way to change the shape of the support bolt housing to tear drop?The round tube has to create a lot of turbulence down stream.

Gary Aman Jabiru 2200A 475 hrs

--

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

dons701

Joined: 22 May 2009

Posts: 80

Location: Hershey, PA

|

Posted: Mon Sep 07, 2009 7:48 am Post subject: Re: Here's an idea that DIDN'T work Posted: Mon Sep 07, 2009 7:48 am Post subject: Re: Here's an idea that DIDN'T work |

|

|

Hi Lynn and All

Just a few thoughts, a device that takes the "wet" flow of air and fuel and imparts a centrifuge effect will tend to throw the heavier droplets to the outside. I also remember a device that used four counter rotating vortices, created by bending metal tabs protruding inward from the inside of a large hole in sheet metal and claimed to solve the separation problem. I thought it was called Swarrup, or something like that, but when I tried to search the net I found nothing.

Thank you for the pictures of your manifold. Heavier droplets of fuel retain their kinetic energy and do not want to turn with the air only to slam to the front for 1&2. One could wonder what would happen if the center divider was completely removed, what encouragement would the high velocity fuel and air have to alternately flow to the rear cylinders (3&4).

If the fuel and air were heated to the point of vaporization before entering the manifold you could have the even distribution needed to run leaner because the current system is rich to compromise the factory design. Don

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

_________________

Zenith 701 #76120

Jabiru 2200A #2456 95 hours

Sensenich Wood 64-PJ-36 Prop |

|

| Back to top |

|

|

Lynn Matteson

Joined: 10 Jan 2006

Posts: 2778

Location: Grass Lake, Michigan

|

Posted: Mon Sep 07, 2009 8:10 am Post subject: Here's an idea that DIDN'T work Posted: Mon Sep 07, 2009 8:10 am Post subject: Here's an idea that DIDN'T work |

|

|

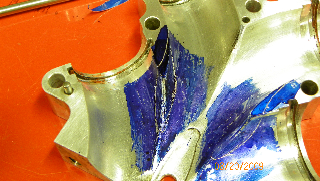

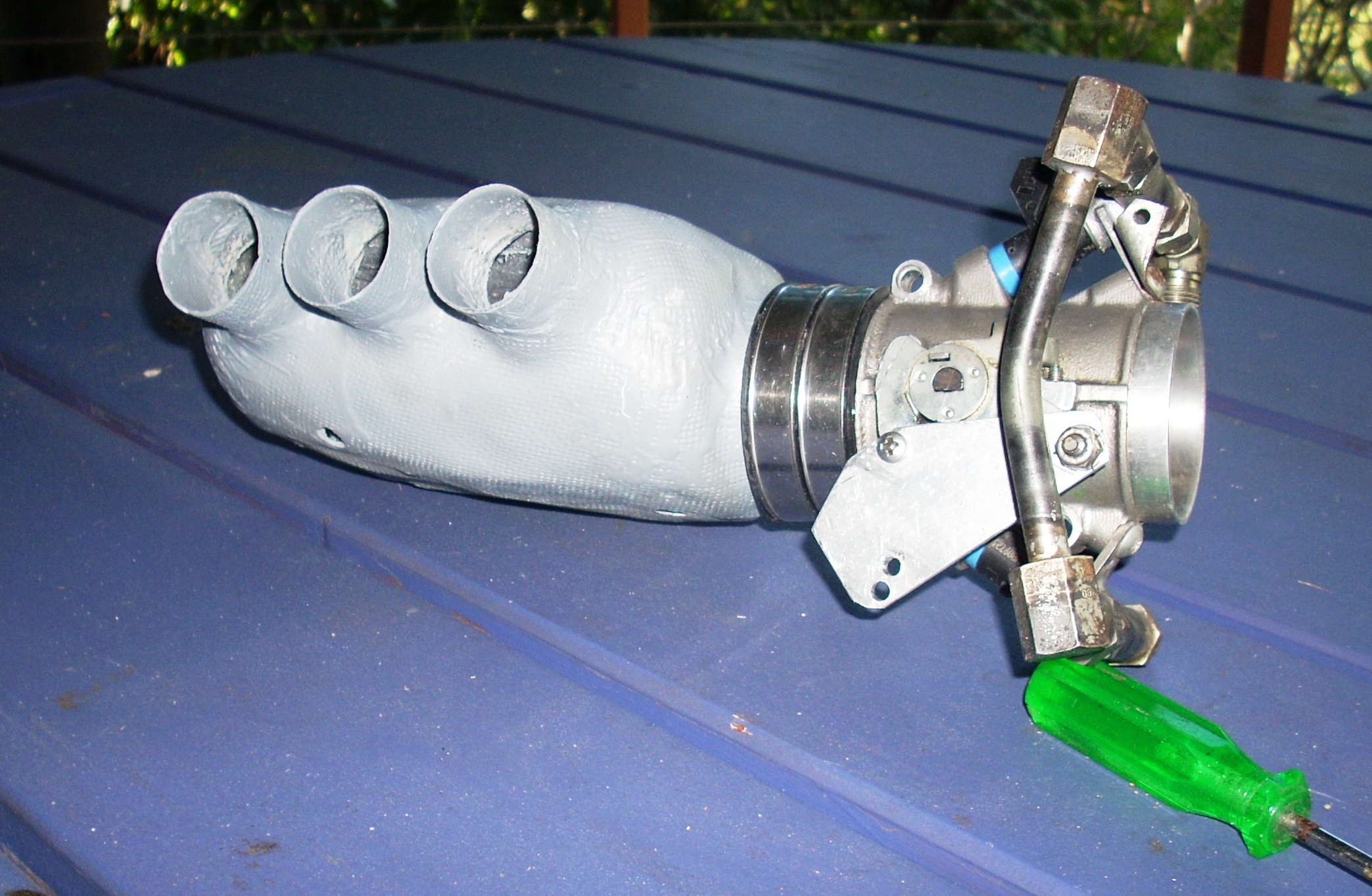

Do you mean the thing that sits between the upper and the lower

halves of the manifold? I refer to this part as the splitter, and

when I spoke with Pete about its shape, he said that Jabiru had done

some testing and found the present shape to be the best. Here is a

picture of that part and as you can see, it is already teardrop

shaped when viewed from above. I had a notion to carve it into an

hour-glass shape, (as seen viewed straight on, as in the picture I

sent previously) and I still might, the next time I have the manifold

off the engine. The only problem with that idea is that there is an

(unused) threaded hole back at the narrow part of the teardrop, that

would be exposed if I carved it to an hour glass shape. I thought of

simply screwing an aluminum bolt into this hole, then proceeding with

the shaping of it, but decided not to...guess I chickened out. That

rear hole could also be filled with some structural adhesive/epoxy/

whatever, and then it would just be carved away as the shape took

place. The front hole...the only one that gets used in the actual

assembly...has enough meat around it, that it would allow some

carving away on either side of it. Just to make sure we're on the

same page here, this shot shows that splitter from above, and I would

cut away on each side of the splitter such that the plan view of the

splitter remains the same shape, but when viewed vertically, the

sides are narrowed...like a good-lookin' babe in great shape when

viewed from the front (minus a few of the "accessories" of course).

And of course when I say the "rear hole" it is actually toward the

front of the engine in a tractor environment, but it is in the rear

of the airflow.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 760.3 hrs

Sensenich 62"x46" Wood prop

Electroair direct-fire ignition system

Rotec TBI-40 injection

Status: flying

On Sep 7, 2009, at 10:07 AM, zeprep251(at)aol.com wrote:

| Quote: | Lynn,

Is there any way to change the shape of the support bolt housing

to tear drop?The round tube has to create a lot of turbulence down

stream.

Gary Aman Jabiru 2200A 475 hrs

|

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

| Description: |

|

| Filesize: |

359.27 KB |

| Viewed: |

16425 Time(s) |

|

_________________

Lynn

Kitfox IV-Jabiru 2200

N369LM |

|

| Back to top |

|

|

Lynn Matteson

Joined: 10 Jan 2006

Posts: 2778

Location: Grass Lake, Michigan

|

Posted: Mon Sep 07, 2009 8:42 am Post subject: Here's an idea that DIDN'T work Posted: Mon Sep 07, 2009 8:42 am Post subject: Here's an idea that DIDN'T work |

|

|

Thanks for your thoughts, Don. It might just be that the better

atomization of the Rotec TBI is what is making my EGT's and CHT's

more even than with the Bing. Smaller droplets, therefore less

inertia. I seem to recall that Pete said that the factory tried

several different shapes of that divider/splitter and could find

nothing better than the present teardrop shape. He said they tried a

more blunt shape as well. I can't believe they didn't try leaving it

out, and they very well could have, but I don't recall whether Pete

said that or not.

Speaking of "heated to the point of vaporization before entering the

manifold", I have found that if I pull on the carb heat, my rpm's go

up about 60-80, the fuel flow goes up about point-2 to point-3

gallons per hour, and the plane turns slightly to the left, due to

the increase in rpm/torque. This is during straight and level flight

running about 2750 rpm's and using about 3.0 gph, during "lean of

peak EGT" operation. When I push the carb heat off, the plane returns

to the original flight direction, and the rpm's drop, as well as the

fuel usage. Talk about sensitive! Now this turn to the left is not

dramatic, just noticeable.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 760.3 hrs

Sensenich 62"x46" Wood prop

Electroair direct-fire ignition system

Rotec TBI-40 injection

Status: flying

On Sep 7, 2009, at 11:48 AM, dons701 wrote:

| Quote: |

<burdon1(at)comcast.net>

Hi Lynn and All

Just a few thoughts, a device that takes the "wet" flow of air

and fuel and imparts a centrifuge effect will tend to throw the

heavier droplets to the outside. I also remember a device that used

four counter rotating vortices, created by bending metal tabs

protruding inward from the inside of a large hole in sheet metal

and claimed to solve the separation problem. I thought it was

called Swarrup, or something like that, but when I tried to search

the net I found nothing.

Thank you for the pictures of your manifold. Heavier droplets of

fuel retain their kinetic energy and do not want to turn with the

air only to slam to the front for 1&2. One could wonder what would

happen if the center divider was completely removed, what

encouragement would the high velocity fuel and air have to

alternately flow to the rear cylinders (3&4).

If the fuel and air were heated to the point of vaporization

before entering the manifold you could have the even distribution

needed to run leaner because the current system is rich to

compromise the factory design. Don

--------

Zenith 701 #76120

Jabiru #2456 51 hours

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p 61870#261870

|

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

_________________

Lynn

Kitfox IV-Jabiru 2200

N369LM |

|

| Back to top |

|

|

Jim McCormick

Joined: 19 Mar 2007

Posts: 18

Location: Fresno, CA

|

Posted: Mon Sep 07, 2009 10:57 am Post subject: Here's an idea that DIDN'T work Posted: Mon Sep 07, 2009 10:57 am Post subject: Here's an idea that DIDN'T work |

|

|

Hi Lynn

Something you may want to try is to replace the "splitter wing" with a round

bar stock 12mm in dia. I have had some customers try this with good results.

The theory behind the round stock it it cause's turbulence in the plenum for

better fuel distribution? But the guys that have done this report the EGT's

are more uniform between the cyl's..

Jim McCormick

Jabiru Pacific LLC

255 W Fallbrook Suite 202B

Fresno, Ca 93711

P 559.431.1701

F 559.233.3676

www.jabirupacific.com

On 9/7/09 9:35 AM, "Lynn Matteson" <lynnmatt(at)jps.net> wrote:

| Quote: |

Thanks for your thoughts, Don. It might just be that the better

atomization of the Rotec TBI is what is making my EGT's and CHT's

more even than with the Bing. Smaller droplets, therefore less

inertia. I seem to recall that Pete said that the factory tried

several different shapes of that divider/splitter and could find

nothing better than the present teardrop shape. He said they tried a

more blunt shape as well. I can't believe they didn't try leaving it

out, and they very well could have, but I don't recall whether Pete

said that or not.

Speaking of "heated to the point of vaporization before entering the

manifold", I have found that if I pull on the carb heat, my rpm's go

up about 60-80, the fuel flow goes up about point-2 to point-3

gallons per hour, and the plane turns slightly to the left, due to

the increase in rpm/torque. This is during straight and level flight

running about 2750 rpm's and using about 3.0 gph, during "lean of

peak EGT" operation. When I push the carb heat off, the plane returns

to the original flight direction, and the rpm's drop, as well as the

fuel usage. Talk about sensitive! Now this turn to the left is not

dramatic, just noticeable.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 760.3 hrs

Sensenich 62"x46" Wood prop

Electroair direct-fire ignition system

Rotec TBI-40 injection

Status: flying

On Sep 7, 2009, at 11:48 AM, dons701 wrote:

>

> <burdon1(at)comcast.net>

>

> Hi Lynn and All

> Just a few thoughts, a device that takes the "wet" flow of air

> and fuel and imparts a centrifuge effect will tend to throw the

> heavier droplets to the outside. I also remember a device that used

> four counter rotating vortices, created by bending metal tabs

> protruding inward from the inside of a large hole in sheet metal

> and claimed to solve the separation problem. I thought it was

> called Swarrup, or something like that, but when I tried to search

> the net I found nothing.

> Thank you for the pictures of your manifold. Heavier droplets of

> fuel retain their kinetic energy and do not want to turn with the

> air only to slam to the front for 1&2. One could wonder what would

> happen if the center divider was completely removed, what

> encouragement would the high velocity fuel and air have to

> alternately flow to the rear cylinders (3&4).

> If the fuel and air were heated to the point of vaporization

> before entering the manifold you could have the even distribution

> needed to run leaner because the current system is rich to

> compromise the factory design. Don

>

> --------

> Zenith 701 #76120

> Jabiru #2456 51 hours

>

>

>

>

> Read this topic online here:

>

> http://forums.matronics.com/viewtopic.php?p 61870#261870

>

>

>

>

>

>

>

>

>

>

|

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

Peter H

Joined: 20 Mar 2007

Posts: 197

|

Posted: Mon Sep 07, 2009 1:54 pm Post subject: Here's an idea that DIDN'T work Posted: Mon Sep 07, 2009 1:54 pm Post subject: Here's an idea that DIDN'T work |

|

|

Looks like good work Lynn. Maybe you have got the splitter as good as it can

be.

I am interested in your test to WOT especially to see if you find no

increase in power for the last inch of throttle. I have taken this effect to

be an indication of losses in the collector (as proven by my test with the

baffle plate inserted) but it may be that my prop is overloading the system.

I am getting 2760RPM static with all of my ground tests.

The prop is 55X72 as used on my Quickie and I get 170KTS CAS at 2900RPM WOT

in level flight at 3000ft.It would be nice to find that extra power and

maybe set a record for this type.

Peter

--

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

Peter H

Joined: 20 Mar 2007

Posts: 197

|

Posted: Mon Sep 07, 2009 1:54 pm Post subject: Here's an idea that DIDN'T work Posted: Mon Sep 07, 2009 1:54 pm Post subject: Here's an idea that DIDN'T work |

|

|

Hi Lynn,

Yes it was a product called "Hiclone" overpriced at AUD160 and very heavily

promoted as a boost to power and economy.It has a double row of vanes in SS.

The idea is probably OK but I think any benefit is offset by the choking

effect as the device limits airflow.

I think it would work better if the diameter was much larger, then perhaps

tapered to the TB entry. This would accelerate the swirling air with limited

obstruction to the flow.

BTW I found it useful to conduct some tests using a high pressure spray of

water from a spray gun.

Peter

--

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

Peter H

Joined: 20 Mar 2007

Posts: 197

|

Posted: Mon Sep 07, 2009 2:02 pm Post subject: Here's an idea that DIDN'T work Posted: Mon Sep 07, 2009 2:02 pm Post subject: Here's an idea that DIDN'T work |

|

|

Don,

The induction collector is bolted flat to the sump.

When I discussed this with the Jabiru design engineer he admitted it was a

compromise. Heating the charge reduces efficiency but improves the

distribution as you suggest.

Peter

--

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

Peter H

Joined: 20 Mar 2007

Posts: 197

|

Posted: Mon Sep 07, 2009 2:03 pm Post subject: Here's an idea that DIDN'T work Posted: Mon Sep 07, 2009 2:03 pm Post subject: Here's an idea that DIDN'T work |

|

|

Jim,

Afriend of mine has replaced this part with a half round shape with the flat

at rear and he claims an improvement in distribution.

But I intend to continue with experiments for a bottom fed symmetrical

plenum.

Peter

--

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|