|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

Turbo_Boss

Joined: 14 Jul 2009

Posts: 10

Location: Panama Rep. of Panama - Central America

|

|

| Back to top |

|

|

K Dilks

Joined: 22 Sep 2008

Posts: 108

Location: UK

|

Posted: Tue Jul 14, 2009 9:47 pm Post subject: Re: Rotax 582 Quit in the air :-( Posted: Tue Jul 14, 2009 9:47 pm Post subject: Re: Rotax 582 Quit in the air :-( |

|

|

Copper part is the conrod side thrust washer from the crank shaft.

Bet you find the conrod blue from heat.

Usually caused by corrosion on the needle rollers then run. Engine sat in a humid hanger ?

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

Back home ................. |

|

| Back to top |

|

|

Turbo_Boss

Joined: 14 Jul 2009

Posts: 10

Location: Panama Rep. of Panama - Central America

|

Posted: Wed Jul 15, 2009 2:47 pm Post subject: Re: Rotax 582 Quit in the air :-( Posted: Wed Jul 15, 2009 2:47 pm Post subject: Re: Rotax 582 Quit in the air :-( |

|

|

| K Dilks wrote: | Copper part is the conrod side thrust washer from the crank shaft.

Bet you find the conrod blue from heat.

Usually caused by corrosion on the needle rollers then run. Engine sat in a humid hanger ? |

Hey K Dilks,

This Quicksilver belong to a guy that fly it almost every weekend.

The hangar is not humid but here in Central America the weather is almost 100% humidity Since this country is like inside a Rainforest BUT on the club there are like five Quicks with 582 with more hours and they have not fail this way.

I hope this next weekend I will open the crank case and I will check for that color on the rod and will take pics.

Thx for your time and help,

Isaac

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

kmccune

Joined: 22 Sep 2007

Posts: 577

Location: Wisconsin, USA

|

Posted: Sun Oct 04, 2009 5:14 am Post subject: Re: Rotax 582 Quit in the air :-( Posted: Sun Oct 04, 2009 5:14 am Post subject: Re: Rotax 582 Quit in the air :-( |

|

|

Did you ever figure out what happened?

Kevin

| Turbo_Boss wrote: | | K Dilks wrote: | Copper part is the conrod side thrust washer from the crank shaft.

Bet you find the conrod blue from heat.

Usually caused by corrosion on the needle rollers then run. Engine sat in a humid hanger ? |

Hey K Dilks,

This Quicksilver belong to a guy that fly it almost every weekend.

The hangar is not humid but here in Central America the weather is almost 100% humidity Since this country is like inside a Rainforest BUT on the club there are like five Quicks with 582 with more hours and they have not fail this way.

I hope this next weekend I will open the crank case and I will check for that color on the rod and will take pics.

Thx for your time and help,

Isaac |

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

“Always do what you are afraid to do.”

R.W. Emerson (1803-1882)

"Real freedom is the sustained act of being an individual." WW - 2009

"Life is a good deal...it's worth it" Feb 1969

Dorothy McCune |

|

| Back to top |

|

|

lucien

Joined: 03 Jun 2007

Posts: 721

Location: santa fe, NM

|

Posted: Sun Oct 04, 2009 8:40 am Post subject: Re: Rotax 582 Quit in the air :-( Posted: Sun Oct 04, 2009 8:40 am Post subject: Re: Rotax 582 Quit in the air :-( |

|

|

FWIW, a good friend of mine in TX had a similar failure with his 582 after about 150 hours. The parts didn't make it into the rest of the engine but the big end of the PTO rod had more or less almost welded itself to the crank. The thrust washers had melted and the remains had squished out the sides (like the washer had been made of thick mud)....

In that case the runout on the PTO end of the crank was way way out. What we think happened in that case was the excessive runout was causing the rod to ride on the ends of the needles rather than on the center. Perhaps everything just got too hot finally and just melted the works down.

The replacement crank - a factory new - also failed shortly after that, again with the excessive runout that was caught at the next 150 hour before the engine quit. The runout was within new everywhere on the crank when he put it in, but had gone out at some point in the next 150 hours.

This is the main reason I'm not real thrilled with the 582. It does seem to spool up the cranks a little more often than the other 2-strokes (which seem to hardly ever give crank problems).....

LS

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

LS

Titan II SS |

|

| Back to top |

|

|

Turbo_Boss

Joined: 14 Jul 2009

Posts: 10

Location: Panama Rep. of Panama - Central America

|

Posted: Sun Oct 04, 2009 5:20 pm Post subject: Re: Rotax 582 Quit in the air :-( Posted: Sun Oct 04, 2009 5:20 pm Post subject: Re: Rotax 582 Quit in the air :-( |

|

|

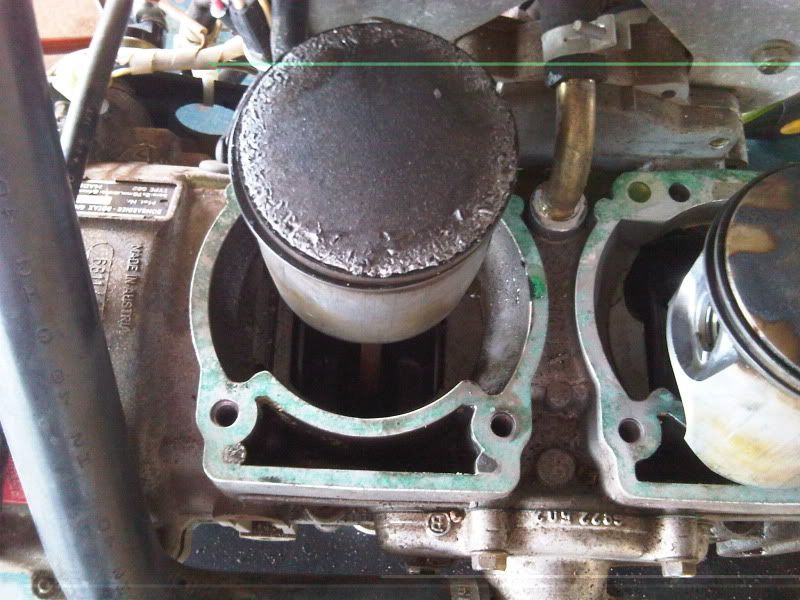

Ok, here are the pics of the bad crankshaf area were you can see that both cooper washer are missing. Also look the dark black color meaning overheating..................You can see also a lot of metal debriss.

http://i85.photobucket.com/albums/k57/Turbo_Boss/Ultralights/Missingwasher.jpg

This other pic, is from the Crankshaft area from the piston that was in good condition. You can see both cooper washers.

http://i85.photobucket.com/albums/k57/Turbo_Boss/Ultralights/CooperWashers.jpg

Thx,

Isaac

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

occom

Joined: 26 Aug 2006

Posts: 404

|

Posted: Mon Oct 05, 2009 3:16 am Post subject: Rotax 582 Quit in the air :-( Posted: Mon Oct 05, 2009 3:16 am Post subject: Rotax 582 Quit in the air :-( |

|

|

I notice surface corrosion on the "good" rod. It may be that a closer

examination of the bearing will reveal that it too is not in great shape.

The 582 suffers from corrosion because it can be totally open to the

environment depending on how the rotary valve stops. I plug both carbs on

mine. I hope it will prevent moisture getting in.

---

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|