|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

aarongleixner(at)sbcgloba

Guest

|

Posted: Mon Nov 16, 2009 5:35 pm Post subject: Tips on removal of front window and lessons learned Posted: Mon Nov 16, 2009 5:35 pm Post subject: Tips on removal of front window and lessons learned |

|

|

I just got off the phone with Van's after paying $470 for a new front window. I had approximately 50 small cracks starting at the glue joint, and extending about 1/8 inch beyond the glue joint. After reading all the warnings about not clamping when glueing the windows, I added a clamp in one location to hold the plexi tight, and all the cracks started under the clamp. While clamping pressure may not be the only variable for crack formation, it is definitely a strong contributing factor. So for those about to complete this step, avoid the clamps, and use plenty of glue to bridge any small gaps that might result.

Now for the question. Has anyone else had to remove a front window? At this point, I only need to remove the glue joint. How was it accomplished? Van's said someone routed out a window, but I was wondering if lots of heat from a heat gun, and a little prying might separate the glue from the fiberglass. Any suggestions would be greatly appreciated.

Aaron

[quote][b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

jeff(at)westcottpress.com

Guest

|

Posted: Mon Nov 16, 2009 5:58 pm Post subject: Tips on removal of front window and lessons learned Posted: Mon Nov 16, 2009 5:58 pm Post subject: Tips on removal of front window and lessons learned |

|

|

A router works well...

... at least for the windows in the doors.

don't ask me how I know.

Jeff Carpenter

40304

On Nov 16, 2009, at 5:34 PM, Aaron Gleixner wrote:

[quote]I just got off the phone with Van's after paying $470 for a new front window. I had approximately 50 small cracks starting at the glue joint, and extending about 1/8 inch beyond the glue joint. After reading all the warnings about not clamping when glueing the windows, I added a clamp in one location to hold the plexi tight, and all the cracks started under the clamp. While clamping pressure may not be the only variable for crack formation, it is definitely a strong contributing factor. So for those about to complete this step, avoid the clamps, and use plenty of glue to bridge any small gaps that might result.

Now for the question. Has anyone else had to remove a front window? At this point, I only need to remove the glue joint. How was it accomplished? Van's said someone routed out a window, but I was wondering if lots of heat from a heat gun, and a little prying might separate the glue from the fiberglass. Any suggestions would be greatly appreciated.

Aaron

| Quote: |

href="http://www.aeroelectric.com">www.aeroelectric.com

href="http://www.buildersbooks.com">www.buildersbooks.com

href="http://www.homebuilthelp.com">www.homebuilthelp.com

href="http://www.matronics.com/contribution">http://www.matronics.com/contribution

href="http://www.matronics.com/Navigator?RV10-List">http://www.matronics.com/Navigator?RV10-List

href="http://forums.matronics.com">http://forums.matronics.com

|

[b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

ricksked(at)embarqmail.co

Guest

|

Posted: Mon Nov 16, 2009 6:25 pm Post subject: Tips on removal of front window and lessons learned Posted: Mon Nov 16, 2009 6:25 pm Post subject: Tips on removal of front window and lessons learned |

|

|

<!DOCTYPE html PUBLIC "-//W3C//DTD HTML 4.0 Transitional//EN"> Aaron,Depends on how you glued it in. I used epoxy and flox and I'm sure heat and patience would work well Not sure about weld on. The fairing should be able to be removed with heat and some patience as well. IIRC, Jesse Saint may chime in, I think they swapped out a forward transparency...Dave Saylor will know for sure...he is the composite guru who's polished wings warped out his rear window....if it weren't such a pain to match paint I could swap out a front transparency in a week ready for paint....without using power tools except to clean up the cabin lip. And yes I've torn out a bunch of glass parts in my time.Rick SkedN246RS

Sent via BlackBerry by AT&TFrom: Aaron Gleixner <aarongleixner(at)sbcglobal.net>

Date: Mon, 16 Nov 2009 17:34:47 -0800 (PST)

To: <RV10-list(at)matronics.com>

Subject: RV10-List: Tips on removal of front window and lessons learned

I just got off the phone with Van's afte= r paying $470 for a new front window. I had approximately 50 small cr= acks starting at the glue joint, and extending about 1/8 inch beyond the gl= ue joint. After reading all the warnings about not clamping when glue= ing the windows, I added a clamp in one location to hold the plexi tight, a= nd all the cracks started under the clamp. While clamping pressure ma= y not be the only variable for crack formation, it is definitely a strong c= ontributing factor. So for those about to complete this step, avoid t= he clamps, and use plenty of glue to bridge any small gaps that might resul= t.

Now for the question. Has anyone else had to remove a front wind= ow? At this point, I only need to remove the glue joint. How wa= s it accomplished? Van's said someone routed out a window, but I was = wondering if lots of heat from a heat gun, and a little prying might separa= te the glue from the fiberglass. Any suggestions would be greatly app= reciated.

Aaron

[quote][b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

n223rv(at)wolflakeairport

Guest

|

Posted: Mon Nov 16, 2009 7:05 pm Post subject: Tips on removal of front window and lessons learned Posted: Mon Nov 16, 2009 7:05 pm Post subject: Tips on removal of front window and lessons learned |

|

|

I routed one out that was installed with weld on, same issue as you were explaining. Therefore I am not using weld on on my plane!! I set the depth to match the window thickness, it made a big mess but left a very nice and flat surface for the reinstall. BTW, we switched to Sikaflex and have been very happy with it. YMMV.

-Mike Kraus

Sent from my iPhone

On Nov 16, 2009, at 8:34 PM, Aaron Gleixner <aarongleixner(at)sbcglobal.net (aarongleixner(at)sbcglobal.net)> wrote:

[quote]I just got off the phone with Van's after paying $470 for a new front window. I had approximately 50 small cracks starting at the glue joint, and extending about 1/8 inch beyond the glue joint. After reading all the warnings about not clamping when glueing the windows, I added a clamp in one location to hold the plexi tight, and all the cracks started under the clamp. While clamping pressure may not be the only variable for crack formation, it is definitely a strong contributing factor. So for those about to complete this step, avoid the clamps, and use plenty of glue to bridge any small gaps that might result.

Now for the question. Has anyone else had to remove a front window? At this point, I only need to remove the glue joint. How was it accomplished? Van's said someone routed out a window, but I was wondering if lots of heat from a heat gun, and a little prying might separate the glue from the fiberglass. Any suggestions would be greatly appreciated.

Aaron

| Quote: |

href="http://www.aeroelectric.com">www.aeroelectric.com

href="http://www.buildersbooks.com">www.buildersbooks.com

href="http://www.homebuilthelp.com">www.homebuilthelp.com

href="http://www.matronics.com/contribution">http://www.matronics.com/contribution

href="http://www.matronics.com/Navigator?RV10-List">http://www.matronics.com/Navigator?RV10-List

href="http://forums.matronics.com">http://forums.matronics.com

|

[b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

kearney

Joined: 20 Sep 2008

Posts: 563

|

Posted: Mon Nov 16, 2009 7:45 pm Post subject: Tips on removal of front window and lessons learned Posted: Mon Nov 16, 2009 7:45 pm Post subject: Tips on removal of front window and lessons learned |

|

|

Mike

How did you use Sikaflex on the front window? Pix would be great. When you routed the old window out, did that effectively leave a bottom notch for the window?

Inquiring minds need to know.

Les

#40643

From: owner-rv10-list-server(at)matronics.com [mailto:owner-rv10-list-server(at)matronics.com] On Behalf Of Michael Kraus

Sent: November-16-09 8:02 PM

To: rv10-list(at)matronics.com

Subject: Re: Tips on removal of front window and lessons learned

I routed one out that was installed with weld on, same issue as you were explaining. Therefore I am not using weld on on my plane!! I set the depth to match the window thickness, it made a big mess but left a very nice and flat surface for the reinstall. BTW, we switched to Sikaflex and have been very happy with it. YMMV.

-Mike Kraus

Sent from my iPhone

On Nov 16, 2009, at 8:34 PM, Aaron Gleixner <aarongleixner(at)sbcglobal.net (aarongleixner(at)sbcglobal.net)> wrote:

| Quote: |

I just got off the phone with Van's after paying $470 for a new front window. I had approximately 50 small cracks starting at the glue joint, and extending about 1/8 inch beyond the glue joint. After reading all the warnings about not clamping when glueing the windows, I added a clamp in one location to hold the plexi tight, and all the cracks started under the clamp. While clamping pressure may not be the only variable for crack formation, it is definitely a strong contributing factor. So for those about to complete this step, avoid the clamps, and use plenty of glue to bridge any small gaps that might result.

Now for the question. Has anyone else had to remove a front window? At this point, I only need to remove the glue joint. How was it accomplished? Van's said someone routed out a window, but I was wondering if lots of heat from a heat gun, and a little prying might separate the glue from the fiberglass. Any suggestions would be greatly appreciated.

Aaron

| Quote: | | href="http://www.aeroelectric.com">www.aeroelectric.comhref="http://www.buildersbooks.com">www.buildersbooks.comhref="http://www.homebuilthelp.com">www.homebuilthelp.comhref="http://www.matronics.com/contribution">http://www.matronics.com/contribution href="http://www.matronics.com/Navigator?RV10-List">http://www.matronics.com/Navigator?RV10-Listhref="http://forums.matronics.com">http://forums.matronics.com |

|

0123456789 | Quote: | | href="http://www.aeroelectric.com">www.aeroelectric.com |

0 | Quote: | | href="http://www.aeroelectric.com">www.aeroelectric.com |

1 | Quote: | | href="http://www.aeroelectric.com">www.aeroelectric.com |

2 | Quote: | | href="http://www.aeroelectric.com">www.aeroelectric.com |

3 | Quote: | | href="http://www.aeroelectric.com">www.aeroelectric.com |

4 | Quote: | | href="http://www.aeroelectric.com">www.aeroelectric.com |

5 | Quote: | | href="http://www.aeroelectric.com">www.aeroelectric.com |

6 | Quote: | | href="http://www.aeroelectric.com">www.aeroelectric.com |

7 | Quote: | | href="http://www.aeroelectric.com">www.aeroelectric.com |

8 | Quote: | | href="http://www.aeroelectric.com">www.aeroelectric.com |

9 | Quote: | | href="http://www.buildersbooks.com">www.buildersbooks.com |

0 | Quote: | | href="http://www.buildersbooks.com">www.buildersbooks.com |

1 | Quote: | | href="http://www.buildersbooks.com">www.buildersbooks.com |

2 | Quote: | | href="http://www.buildersbooks.com">www.buildersbooks.com |

3 | Quote: | | href="http://www.buildersbooks.com">www.buildersbooks.com |

4 | Quote: | | href="http://www.buildersbooks.com">www.buildersbooks.com |

5 | Quote: | | href="http://www.buildersbooks.com">www.buildersbooks.com |

6 | Quote: | | href="http://www.buildersbooks.com">www.buildersbooks.com |

7

[quote][b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

rebrunk42(at)gmail.com

Guest

|

Posted: Mon Nov 16, 2009 7:47 pm Post subject: Tips on removal of front window and lessons learned Posted: Mon Nov 16, 2009 7:47 pm Post subject: Tips on removal of front window and lessons learned |

|

|

I had my window replaced by a professional chosen by my insurer. I believe he routed it out. Robert

Sent from my iPhone

Robert E. Brunkenhoefer

Brunkenhoefer Law Firm, P.C.

520 Lawrence St.

Corpus Christi, Texas 78401

Phone: 361-888-8808

Facsimile: 361-888-6753

robert(at)brunklaw.com (robert(at)brunklaw.com)

On Nov 16, 2009, at 7:34 PM, Aaron Gleixner <aarongleixner(at)sbcglobal.net (aarongleixner(at)sbcglobal.net)> wrote:

[quote]I just got off the phone with Van's after paying $470 for a new front window. I had approximately 50 small cracks starting at the glue joint, and extending about 1/8 inch beyond the glue joint. After reading all the warnings about not clamping when glueing the windows, I added a clamp in one location to hold the plexi tight, and all the cracks started under the clamp. While clamping pressure may not be the only variable for crack formation, it is definitely a strong contributing factor. So for those about to complete this step, avoid the clamps, and use plenty of glue to bridge any small gaps that might result.

Now for the question. Has anyone else had to remove a front window? At this point, I only need to remove the glue joint. How was it accomplished? Van's said someone routed out a window, but I was wondering if lots of heat from a heat gun, and a little prying might separate the glue from the fiberglass. Any suggestions would be greatly appreciated.

Aaron

| Quote: |

href="http://www.aeroelectric.com">www.aeroelectric.com

href="http://www.buildersbooks.com">www.buildersbooks.com

href="http://www.homebuilthelp.com">www.homebuilthelp.com

href="http://www.matronics.com/contribution">http://www.matronics.com/contribution

href="http://www.matronics.com/Navigator?RV10-List">http://www.matronics.com/Navigator?RV10-List

href="http://forums.matronics.com">http://forums.matronics.com

|

[b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

indigoonlatigo(at)msn.com

Guest

|

Posted: Mon Nov 16, 2009 9:35 pm Post subject: Tips on removal of front window and lessons learned Posted: Mon Nov 16, 2009 9:35 pm Post subject: Tips on removal of front window and lessons learned |

|

|

I can only imagine the feeling of having to redo a windscreen due to cracks C )^%&*^2208&^*66&769q!!!!

Thought i would post a few pict on how I glued in my windscreen. I had heard about all the craze line issues and I even went as far as to purchase five tubes of Sikaflex for the side windows. I never used the sikaflex so if anyone want to purchase the five tubes for a quarter of what it cost me C let me know.

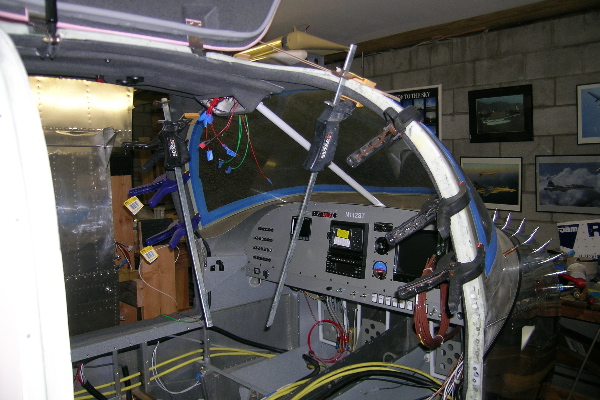

The key to clamping the windscreen IMO in is distribution of pressure. I used several laminations of 1/16" ply C aircraft modeling plywood to distribute the force. The pictures should tell the story. Also C I used wooden wedges to push down on the plexi where needed. Note the 3/4" ply used across the top of the canopy C clamped to the canopy C but it is the wedges which are pushing down on the plexi. This entire process is a two person process and it needs to be rehearsed. One person should spread the Weld On on the canopy rim while the other is doing the windscreen edge. Pressure to the windscreen should be applied at the top and then incrementally going out to the sides C each side at the same time. Tape should be placed on the inside of the windcreen and outside with the inside tape removed once the window is clamped. Get all the hairs of WeldOn off the plexi immediately.

Date: Mon C 16 Nov 2009 17:34:47 -0800

From: aarongleixner(at)sbcglobal.net

Subject: Tips on removal of front window and lessons learned

To: RV10-list(at)matronics.com

I just got off the phone with Van's after paying $470 for a new front window. I had approximately 50 small cracks starting at the glue joint C and extending about 1/8 inch beyond the glue joint. After reading all the warnings about not clamping when glueing the windows C I added a clamp in one location to hold the plexi tight C and all the cracks started under the clamp. While clamping pressure may not be the only variable for crack formation C it is definitely a strong contributing factor. So for those about to complete this step C avoid the clamps C and use plenty of glue to bridge any small gaps that might result.

Now for the question. Has anyone else had to remove a front window? At this point C I only need to remove the glue joint. How was it accomplished? Van's said someone routed out a window C but I was wondering if lots of heat from a heat gun C and a little prying might separate the glue from the fiberglass. Any suggestions would be greatly appreciated.

Aaron

| Quote: |

ectric.com

">www.buildersbooks.com

builthelp.com

tronics.com/contribution

/www.matronics.com/Navigator?RV10-List

.com

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

148.51 KB |

| Viewed: |

6820 Time(s) |

|

| Description: |

|

| Filesize: |

139.44 KB |

| Viewed: |

6820 Time(s) |

|

| Description: |

|

| Filesize: |

127.67 KB |

| Viewed: |

6820 Time(s) |

|

| Description: |

|

| Filesize: |

150.12 KB |

| Viewed: |

6820 Time(s) |

|

|

|

| Back to top |

|

|

dlm46007(at)cox.net

Guest

|

Posted: Tue Nov 17, 2009 5:05 am Post subject: Tips on removal of front window and lessons learned Posted: Tue Nov 17, 2009 5:05 am Post subject: Tips on removal of front window and lessons learned |

|

|

We have used the following technique successfully on two aircraft , Glastar and RV10. We use bent aluminum fingers; a 1/2" wide by 3 " by .040 strip has a cleco hole on one end and a masking tape wrap on the other. cleco holes for these "fingers" are drilled at 4-6" intervals around the glass. these are numbered and are placed when the window is glued. After curing, the fingers are removed and the edge of the window sanded smooth. Then two one inch strips of E-glass , cut on a 45 bias, are glued around the windows to secure the window in the frame and fill the mounting holes. More work but the neither the window or the frame crack. We learned this technique at Phoenix Composites who have been doing this for years with all manner of composite aircraft.

From: owner-rv10-list-server(at)matronics.com [mailto:owner-rv10-list-server(at)matronics.com] On Behalf Of John Gonzalez

Sent: Monday, November 16, 2009 10:24 PM

To: RV 10 group

Subject: RE: Tips on removal of front window and lessons learned

I can only imagine the feeling of having to redo a windscreen due to cracks, )^%&*^2208&^*66&769q!!!!

Thought i would post a few pict on how I glued in my windscreen. I had heard about all the craze line issues and I even went as far as to purchase five tubes of Sikaflex for the side windows. I never used the sikaflex so if anyone want to purchase the five tubes for a quarter of what it cost me, let me know.

The key to clamping the windscreen IMO in is distribution of pressure. I used several laminations of 1/16" ply, aircraft modeling plywood to distribute the force. The pictures should tell the story. Also, I used wooden wedges to push down on the plexi where needed. Note the 3/4" ply used across the top of the canopy, clamped to the canopy, but it is the wedges which are pushing down on the plexi. This entire process is a two person process and it needs to be rehearsed. One person should spread the Weld On on the canopy rim while the other is doing the windscreen edge. Pressure to the windscreen should be applied at the top and then incrementally going out to the sides, each side at the same time. Tape should be placed on the inside of the windcreen and outside with the inside tape removed once the window is clamped. Get all the hairs of WeldOn off the plexi immediately.

Date: Mon, 16 Nov 2009 17:34:47 -0800

From: aarongleixner(at)sbcglobal.net

Subject: Tips on removal of front window and lessons learned

To: RV10-list(at)matronics.com

I just got off the phone with Van's after paying $470 for a new front window. I had approximately 50 small cracks starting at the glue joint, and extending about 1/8 inch beyond the glue joint. After reading all the warnings about not clamping when glueing the windows, I added a clamp in one location to hold the plexi tight, and all the cracks started under the clamp. While clamping pressure may not be the only variable for crack formation, it is definitely a strong contributing factor. So for those about to complete this step, avoid the clamps, and use plenty of glue to bridge any small gaps that might result.

Now for the question. Has anyone else had to remove a front window? At this point, I only need to remove the glue joint. How was it accomplished? Van's said someone routed out a window, but I was wondering if lots of heat from a heat gun, and a little prying might separate the glue from the fiberglass. Any suggestions would be greatly appreciated.

Aaron

[quote]

ectric.com

">www.buildersbooks.com

builthelp.com

tronics.com/contribution

/www.matronics.com/Navigator?RV10-List

.com

[b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

jesse(at)saintaviation.co

Guest

|

Posted: Tue Nov 17, 2009 5:45 am Post subject: Tips on removal of front window and lessons learned Posted: Tue Nov 17, 2009 5:45 am Post subject: Tips on removal of front window and lessons learned |

|

|

I had to replace a windshield that was broken when a Columbia crashed into it. It was already actually broken, so it couldn't be removed in one piece anyway. I used a rubber mallet fairly gently to break the pieces loose from the glue (not weld-on) and then used a die grinder to remove the glue. For a whole window, I don't know what I would recommend, but probably a router or heat like others have mentioned would work well.

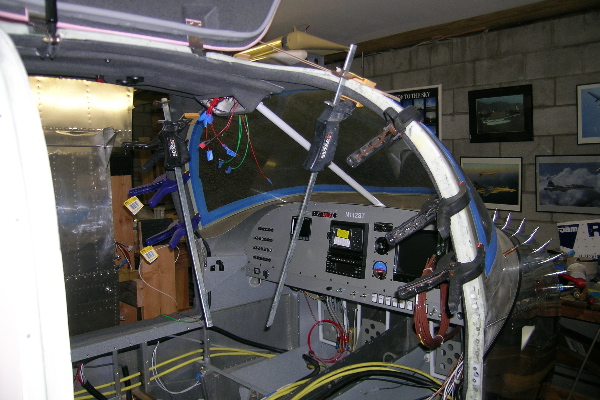

When installing, we put a piece of cardboard over the window and tie a rope from one spar center section over to the other to hold the lower part of the windshield in place and then drill some #40 holes and use little pieces of flat aluminum and clecos around the rest of the window. We've never had a crack. Attached is a picture with some of the clecos in place, but not the rope.

[img]cid:75940410-33D5-4C52-93A2-0F3E4247B107(at)WRVS4400N[/img]

Jesse Saint

Saint Aviation, Inc.

jesse(at)saintaviation.com (jesse(at)saintaviation.com)

Cell: 352-427-0285

Fax: 815-377-3694

On Nov 16, 2009, at 9:23 PM, ricksked(at)embarqmail.com (ricksked(at)embarqmail.com) wrote:

| Quote: | Aaron,

Depends on how you glued it in. I used epoxy and flox and I'm sure heat and patience would work well Not sure about weld on. The fairing should be able to be removed with heat and some patience as well. IIRC, Jesse Saint may chime in, I think they swapped out a forward transparency...Dave Saylor will know for sure...he is the composite guru who's polished wings warped out his rear window....if it weren't such a pain to match paint I could swap out a front transparency in a week ready for paint....without using power tools except to clean up the cabin lip. And yes I've torn out a bunch of glass parts in my time.

Rick Sked

N246RS

Sent via BlackBerry by AT&TFrom: Aaron Gleixner <aarongleixner(at)sbcglobal.net (aarongleixner(at)sbcglobal.net)>

Date: Mon, 16 Nov 2009 17:34:47 -0800 (PST)

To: <RV10-list(at)matronics.com (RV10-list(at)matronics.com)>

Subject: Tips on removal of front window and lessons learned

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

221.94 KB |

| Viewed: |

6810 Time(s) |

|

|

|

| Back to top |

|

|

tgesele(at)optonline.net

Guest

|

Posted: Tue Nov 17, 2009 6:16 am Post subject: Tips on removal of front window and lessons learned Posted: Tue Nov 17, 2009 6:16 am Post subject: Tips on removal of front window and lessons learned |

|

|

Aaron C

6nbsp; I had the exact problem and replaced my windscreen E The procedure I used (which worked very well) was to cut the windscreen just in front of the flange using the cutoff wheel E >From there C I used a heat gun to melt the weld-on and the remaining plexi peeled off easily E A lite sanding and I was good to go E If you go with this method C just be careful with the heat gun C you just want to heat it enough to lossen the plexi C not deform the fiberglass E Took about 2 hrs total if I remember correctly E

6nbsp;

Good luck E

6nbsp;

Tom Gesele N629RV

---

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

n223rv(at)wolflakeairport

Guest

|

Posted: Tue Nov 17, 2009 6:28 am Post subject: Tips on removal of front window and lessons learned Posted: Tue Nov 17, 2009 6:28 am Post subject: Tips on removal of front window and lessons learned |

|

|

I routed out the 2 sides and the top as discussed, then used an angled die grinder with sanding disks to grind away the lower fiberglass fairing flush with the windscreen. The windscreen then popped out and left a nice lip all around for the new one.

For the sikaflex, I used the primer on both surfaces then applied it with a caulk gun. I held the window in place with cleco's and aluminum tabs as others have discussed, but I used small weights to hold the bottom of the windscreen until dry.

Sent from my iPhone

On Nov 16, 2009, at 10:44 PM, "Les Kearney" <kearney(at)shaw.ca (kearney(at)shaw.ca)> wrote:

[quote] st1\:*{behavior:url(#default#ieooui) } <![endif]--> <![endif]--> <![endif]-->

Mike

How did you use Sikaflex on the front window? Pix would be great. When you routed the old window out, did that effectively leave a bottom notch for the window?

Inquiring minds need to know.

Les

#40643

From: owner-rv10-list-server(at)matronics.com (owner-rv10-list-server(at)matronics.com) [mailto:owner-rv10-list-server(at)matronics.com] On Behalf Of Michael Kraus

Sent: November-16-09 8:02 PM

To: rv10-list(at)matronics.com (rv10-list(at)matronics.com)

Subject: Re: Tips on removal of front window and lessons learned

I routed one out that was installed with weld on, same issue as you were explaining. Therefore I am not using weld on on my plane!! I set the depth to match the window thickness, it made a big mess but left a very nice and flat surface for the reinstall. BTW, we switched to Sikaflex and have been very happy with it. YMMV.

-Mike Kraus

Sent from my iPhone

On Nov 16, 2009, at 8:34 PM, Aaron Gleixner <[url=mailto:aarongleixner(at)sbcglobal.net]aarongleixner(at)sbcglobal.net (aarongleixner(at)sbcglobal.net)[/url]> wrote:

| Quote: |

I just got off the phone with Van's after paying $470 for a new front window. I had approximately 50 small cracks starting at the glue joint, and extending about 1/8 inch beyond the glue joint. After reading all the warnings about not clamping when glueing the windows, I added a clamp in one location to hold the plexi tight, and all the cracks started under the clamp. While clamping pressure may not be the only variable for crack formation, it is definitely a strong contributing factor. So for those about to complete this step, avoid the clamps, and use plenty of glue to bridge any small gaps that might result.

Now for the question. Has anyone else had to remove a front window? At this point, I only need to remove the glue joint. How was it accomplished? Van's said someone routed out a window, but I was wondering if lots of heat from a heat gun, and a little prying might separate the glue from the fiberglass. Any suggestions would be greatly appreciated.

Aaron

|

012345678901234

5

[b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

roxianmike(at)msn.com

Guest

|

Posted: Tue Nov 17, 2009 6:28 pm Post subject: Tips on removal of front window and lessons learned Posted: Tue Nov 17, 2009 6:28 pm Post subject: Tips on removal of front window and lessons learned |

|

|

David: did you do something similar like the fingers when doing the back windows? I am hoping to try those again on the next warm weekend day after having cracked one by clamping it.

From: dlm46007(at)cox.net

To: rv10-list(at)matronics.com

Subject: RE: RV10-List: Tips on removal of front window and lessons learned

Date: Tue C 17 Nov 2009 06:04:19 -0700

.ExternalClass .ecxhmmessage P {padding-bottom:0px;padding-left:0px;padding-right:0px;padding-top:0px;} .ExternalClass BODY.ecxhmmessage {font-family:Verdana;font-size:10pt;} We have used the following technique successfully on two aircraft C Glastar and RV10. We use bent aluminum fingers; a 1/2" wide by 3 " by .040 strip has a cleco hole on one end and a masking tape wrap on the other. cleco holes for these "fingers" are drilled at 4-6" intervals around the glass. these are numbered and are placed when the window is glued. After curing C the fingers are removed and the edge of the window sanded smooth. Then two one inch strips of E-glass C cut on a 45 bias C are glued around the windows to secure the window in the frame and fill the mounting holes. More work but the neither the window or the frame crack. We learned this technique at Phoenix Composites who have been doing this for years with all manner of composite aircraft.

From: owner-rv10-list-server(at)matronics.com [mailto:owner-rv10-list-server(at)matronics.com] On Behalf Of John Gonzalez

Sent: Monday C November 16 C 2009 10:24 PM

To: RV 10 group

Subject: RE: Tips on removal of front window and lessons learned

I can only imagine the feeling of having to redo a windscreen due to cracks C )^%&*^2208&^*66&769q!!!!

Thought i would post a few pict on how I glued in my windscreen. I had heard about all the craze line issues and I even went as far as to purchase five tubes of Sikaflex for the side windows. I never used the sikaflex so if anyone want to purchase the five tubes for a quarter of what it cost me C let me know.

The key to clamping the windscreen IMO in is distribution of pressure. I used several laminations of 1/16" ply C aircraft modeling plywood to distribute the force. The pictures should tell the story. Also C I used wooden wedges to push down on the plexi where needed. Note the 3/4" ply used across the top of the canopy C clamped to the canopy C but it is the wedges which are pushing down on the plexi. This entire process is a two person process and it needs to be rehearsed. One person should spread the Weld On on the canopy rim while the other is doing the windscreen edge. Pressure to the windscreen should be applied at the top and then incrementally going out to the sides C each side at the same time. Tape should be placed on the inside of the windcreen and outside with the inside tape removed once the window is clamped. Get all the hairs of WeldOn off the plexi immediately.

Date: Mon C 16 Nov 2009 17:34:47 -0800

From: aarongleixner(at)sbcglobal.net

Subject: Tips on removal of front window and lessons learned

To: RV10-list(at)matronics.com

I just got off the phone with Van's after paying $470 for a new front window. I had approximately 50 small cracks starting at the glue joint C and extending about 1/8 inch beyond the glue joint. After reading all the warnings about not clamping when glueing the windows C I added a clamp in one location to hold the plexi tight C and all the cracks started under the clamp. While clamping pressure may not be the only variable for crack formation C it is definitely a strong contributing factor. So for those about to complete this step C avoid the clamps C and use plenty of glue to bridge any small gaps that might result.

Now for the question. Has anyone else had to remove a front window? At this point C I only need to remove the glue joint. How was it accomplished? Van's said someone routed out a window C but I was wondering if lots of heat from a heat gun C and a little prying might separate the glue from the fiberglass. Any suggestions would be greatly appreciated.

Aaron

[quote]

ectric.com

">www.buildersbooks.com

builthelp.com

tronics.com/contribution

/www.matronics.com/Navigator?RV10-List

.com

lectric.com

/">www.buildersbooks.com

ebuilthelp.com

ww.matronics.com/contribution

ttp://www.matronics.com/Navigator?RV10-List

ronics.com

[b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

dlm46007(at)cox.net

Guest

|

Posted: Tue Nov 17, 2009 7:19 pm Post subject: Tips on removal of front window and lessons learned Posted: Tue Nov 17, 2009 7:19 pm Post subject: Tips on removal of front window and lessons learned |

|

|

we used the "fingers" on all windows. .An even gentle pressure is exerted all round. Check with Mike Andresan on Friday. I showed him the technique on his left rear window and he has used it on others. Or you can call me on 480-626-4048.

From: owner-rv10-list-server(at)matronics.com [mailto:owner-rv10-list-server(at)matronics.com] On Behalf Of Roxanne and Mike Lefever

Sent: Tuesday, November 17, 2009 7:27 PM

To: rv10-list(at)matronics.com

Subject: RE: Tips on removal of front window and lessons learned

David: did you do something similar like the fingers when doing the back windows? I am hoping to try those again on the next warm weekend day after having cracked one by clamping it.

From: dlm46007(at)cox.net

To: rv10-list(at)matronics.com

Subject: RE: RV10-List: Tips on removal of front window and lessons learned

Date: Tue, 17 Nov 2009 06:04:19 -0700

.ExternalClass .ecxhmmessage P { PADDING-BOTTOM: 0px; PADDING-LEFT: 0px; PADDING-RIGHT: 0px; PADDING-TOP: 0px } .ExternalClass BODY.ecxhmmessage { FONT-FAMILY: Verdana; FONT-SIZE: 10pt } We have used the following technique successfully on two aircraft , Glastar and RV10. We use bent aluminum fingers; a 1/2" wide by 3 " by .040 strip has a cleco hole on one end and a masking tape wrap on the other. cleco holes for these "fingers" are drilled at 4-6" intervals around the glass. these are numbered and are placed when the window is glued. After curing, the fingers are removed and the edge of the window sanded smooth. Then two one inch strips of E-glass , cut on a 45 bias, are glued around the windows to secure the window in the frame and fill the mounting holes. More work but the neither the window or the frame crack. We learned this technique at Phoenix Composites who have been doing this for years with all manner of composite aircraft.

From: owner-rv10-list-server(at)matronics.com [mailto:owner-rv10-list-server(at)matronics.com] On Behalf Of John Gonzalez

Sent: Monday, November 16, 2009 10:24 PM

To: RV 10 group

Subject: RE: Tips on removal of front window and lessons learned

I can only imagine the feeling of having to redo a windscreen due to cracks, )^%&*^2208&^*66&769q!!!!

Thought i would post a few pict on how I glued in my windscreen. I had heard about all the craze line issues and I even went as far as to purchase five tubes of Sikaflex for the side windows. I never used the sikaflex so if anyone want to purchase the five tubes for a quarter of what it cost me, let me know.

The key to clamping the windscreen IMO in is distribution of pressure. I used several laminations of 1/16" ply, aircraft modeling plywood to distribute the force. The pictures should tell the story. Also, I used wooden wedges to push down on the plexi where needed. Note the 3/4" ply used across the top of the canopy, clamped to the canopy, but it is the wedges which are pushing down on the plexi. This entire process is a two person process and it needs to be rehearsed. One person should spread the Weld On on the canopy rim while the other is doing the windscreen edge. Pressure to the windscreen should be applied at the top and then incrementally going out to the sides, each side at the same time. Tape should be placed on the inside of the windcreen and outside with the inside tape removed once the window is clamped. Get all the hairs of WeldOn off the plexi immediately.

Date: Mon, 16 Nov 2009 17:34:47 -0800

From: aarongleixner(at)sbcglobal.net

Subject: Tips on removal of front window and lessons learned

To: RV10-list(at)matronics.com

I just got off the phone with Van's after paying $470 for a new front window. I had approximately 50 small cracks starting at the glue joint, and extending about 1/8 inch beyond the glue joint. After reading all the warnings about not clamping when glueing the windows, I added a clamp in one location to hold the plexi tight, and all the cracks started under the clamp. While clamping pressure may not be the only variable for crack formation, it is definitely a strong contributing factor. So for those about to complete this step, avoid the clamps, and use plenty of glue to bridge any small gaps that might result.

Now for the question. Has anyone else had to remove a front window? At this point, I only need to remove the glue joint. How was it accomplished? Van's said someone routed out a window, but I was wondering if lots of heat from a heat gun, and a little prying might separate the glue from the fiberglass. Any suggestions would be greatly appreciated.

Aaron

[quote]

ectric.com

">www.buildersbooks.com

builthelp.com

tronics.com/contribution

/www.matronics.com/Navigator?RV10-List

.com

lectric.com

/">www.buildersbooks.com

ebuilthelp.com

ww.matronics.com/contribution

ttp://www.matronics.com/Navigator?RV10-List

ronics.com

href="http://www.aeroelectric.com">www.aeroelectric.com

href="http://www.buildersbooks.com">www.buildersbooks.com

href="http://www.homebuilthelp.com">www.homebuilthelp.com

href="http://www.matronics.com/contribution">http://www.matronics.com/chref="http://www.matronics.com/Navigator?RV10-List">http://www.matronics.com/Navigator?RV10-List

href="http://forums.matronics.com">http://forums.matronics.com

[b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

jump2(at)sbcglobal.net

Guest

|

Posted: Wed Nov 18, 2009 6:23 am Post subject: Tips on removal of front window and lessons learned Posted: Wed Nov 18, 2009 6:23 am Post subject: Tips on removal of front window and lessons learned |

|

|

I too just replaced my front window. Used a router and then cleand up as needed. I talked to weldon tech and they said if you do not get it all off (weldon) you should still get the same bond as before. I too used fingers but my problem did not occure from that, it was through out the window. Gues what Van had to say. Never seen or heard of that before. Try micro mesh. No thanks

Here's a couple of pic of my install and what it looked like.

Patrick Thyssen

At least I got a 100hr out of it.

--- On Tue, 11/17/09, David McNeill <dlm46007(at)cox.net> wrote:

| Quote: |

From: David McNeill <dlm46007(at)cox.net>

Subject: RE: Tips on removal of front window and lessons learned

To: rv10-list(at)matronics.com

Date: Tuesday, November 17, 2009, 9:19 PM

#yiv259553191 .hmmessage P { PADDING-BOTTOM:0px;MARGIN:0px;PADDING-LEFT:0px;PADDING-RIGHT:0px;PADDING-TOP:0px;} #yiv259553191 { FONT-FAMILY:Verdana;FONT-SIZE:10pt;} we used the "fingers" on all windows. .An even gentle pressure is exerted all round. Check with Mike Andresan on Friday. I showed him the technique on his left rear window and he has used it on others. Or you can call me on 480-626-4048.

From: owner-rv10-list-server(at)matronics.com [mailto:owner-rv10-list-server(at)matronics.com] On Behalf Of Roxanne and Mike Lefever

Sent: Tuesday, November 17, 2009 7:27 PM

To: rv10-list(at)matronics.com

Subject: RE: RV10-List: Tips on removal of front window and lessons learned

David: did you do something similar like the fingers when doing the back windows? I am hoping to try those again on the next warm weekend day after having cracked one by clamping it.

From: dlm46007(at)cox.net

To: rv10-list(at)matronics.com

Subject: RE: Tips on removal of front window and lessons learned

Date: Tue, 17 Nov 2009 06:04:19 -0700

#yiv259553191 .ExternalClass .ecxhmmessage P { PADDING-BOTTOM:0px;PADDING-LEFT:0px;PADDING-RIGHT:0px;PADDING-TOP:0px;} #yiv259553191 .ExternalClass BODY.ecxhmmessage { FONT-FAMILY:Verdana;FONT-SIZE:10pt;} We have used the following technique successfully on two aircraft , Glastar and RV10. We use bent aluminum fingers; a 1/2" wide by 3 " by .040 strip has a cleco hole on one end and a masking tape wrap on the other. cleco holes for these "fingers" are drilled at 4-6" intervals around the glass. these are numbered and are placed when the window is glued. After curing, the fingers are removed and the edge of the window sanded smooth. Then two one inch strips of E-glass , cut on a 45 bias, are glued around the windows to secure the window in the frame and fill the mounting holes. More work but the neither the window or the frame crack. We learned this technique at Phoenix Composites who have been doing this for years with all manner of composite aircraft.

From: owner-rv10-list-server(at)matronics.com [mailto:owner-rv10-list-server(at)matronics.com] On Behalf Of John Gonzalez

Sent: Monday, November 16, 2009 10:24 PM

To: RV 10 group

Subject: RE: Tips on removal of front window and lessons learned

I can only imagine the feeling of having to redo a windscreen due to cracks, )^%&*^2208&^*66&769q!!!!

Thought i would post a few pict on how I glued in my windscreen. I had heard about all the craze line issues and I even went as far as to purchase five tubes of Sikaflex for the side windows. I never used the sikaflex so if anyone want to purchase the five tubes for a quarter of what it cost me, let me know.

The key to clamping the windscreen IMO in is distribution of pressure. I used several laminations of 1/16" ply, aircraft modeling plywood to distribute the force. The pictures should tell the story. Also, I used wooden wedges to push down on the plexi where needed. Note the 3/4" ply used across the top of the canopy, clamped to the canopy, but it is the wedges which are pushing down on the plexi. This entire process is a two person process and it needs to be rehearsed. One person should spread the Weld On on the canopy rim while the other is doing the windscreen edge. Pressure to the windscreen should be applied at the top and then incrementally going out to the sides, each side at the same time. Tape should be placed on the inside of the windcreen and outside with the inside tape removed once the window is clamped. Get all the hairs of WeldOn off the plexi immediately.

Date: Mon, 16 Nov 2009 17:34:47 -0800

From: aarongleixner(at)sbcglobal.net

Subject: Tips on removal of front window and lessons learned

To: RV10-list(at)matronics.com

I just got off the phone with Van's after paying $470 for a new front window. I had approximately 50 small cracks starting at the glue joint, and extending about 1/8 inch beyond the glue joint. After reading all the warnings about not clamping when glueing the windows, I added a clamp in one location to hold the plexi tight, and all the cracks started under the clamp. While clamping pressure may not be the only variable for crack formation, it is definitely a strong contributing factor. So for those about to complete this step, avoid the clamps, and use plenty of glue to bridge any small gaps that might result.

Now for the question. Has anyone else had to remove a front window? At this point, I only need to remove the glue joint. How was it accomplished? Van's said someone routed out a window, but I was wondering if lots of heat from a heat gun, and a little prying might separate the glue from the fiberglass. Any suggestions would be greatly appreciated.

Aaron

| Quote: | ectric.com">www.buildersbooks.combuilthelp.comtronics.com/contribution/www.matronics.com/Navigator?RV10-List.comlectric.com/">www.buildersbooks.comebuilthelp.comww.matronics.com/contributionttp://www.matronics.com/Navigator?RV10-Listronics.comhref="http://www.aeroelectric.com">www.aeroelectric.comhref="http://www.buildersbooks.com">www.buildersbooks.comhref="http://www.homebuilthelp.com">www.homebuilthelp.comhref="http://www.matronics.com/contribution">http://www.matronics.com/chref="http://www.matronics.com/Navigator?RV10-List">http://www.matronics.com/Navigator?RV10-Listhref="http://forums.matronics.com">http://forums.matronics.comwww.aeroetarget="_blank" href="http://www.buildersbooks.com">www.buildersbooks.cfollow" target="_blank"

href="http://www.matronics.com/contribution">http://www.matronics.com/co_blank" href="http://www.matronics.com/Navigator?RV10-List">http://www.mal="nofollow" target="_blank"

============= |

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

1.66 MB |

| Viewed: |

6749 Time(s) |

|

| Description: |

|

| Filesize: |

1.63 MB |

| Viewed: |

6749 Time(s) |

|

|

|

| Back to top |

|

|

n223rv(at)wolflakeairport

Guest

|

Posted: Wed Nov 18, 2009 9:28 am Post subject: Tips on removal of front window and lessons learned Posted: Wed Nov 18, 2009 9:28 am Post subject: Tips on removal of front window and lessons learned |

|

|

Do Van's has selective amnesia then because I sent them a similar picture 2 years ago.....

Sent from my iPhone

On Nov 18, 2009, at 9:12 AM, Patrick Thyssen <[url=mailto:jump2(at)sbcglobal.net]jump2(at)sbcglobal.net (jump2(at)sbcglobal.net)[/url]> wrote:

| Quote: | I too just replaced my front window. Used a router and then cleand up as needed. I talked to weldon tech and they said if you do not get it all off (weldon) you should still get the same bond as before. I too used fingers but my problem did not occure from that, it was through out the window. Gues what Van had to say. Never seen or heard of that before. Try micro mesh. No thanks

Here's a couple of pic of my install and what it looked like.

Patrick Thyssen

At least I got a 100hr out of it.

--- On Tue, 11/17/09, David McNeill <[url=mailto:dlm46007(at)cox.net]dlm46007(at)cox.net (dlm46007(at)cox.net)[/url]> wrote:

| Quote: |

From: David McNeill <[url=mailto:dlm46007(at)cox.net]dlm46007(at)cox.net (dlm46007(at)cox.net)[/url]>

Subject: RE: Tips on removal of front window and lessons learned

To: (rv10-list(at)matronics.com)[url=mailto:rv10-list(at)matronics.com]rv10-list(at)matronics.com (rv10-list(at)matronics.com)[/url]

Date: Tuesday, November 17, 2009, 9:19 PM

#yiv259553191 .hmmessage P { PADDING-BOTTOM:0px;MARGIN:0px;PADDING-LEFT:0px;PADDING-RIGHT:0px;PADDING-TOP:0px;} #yiv259553191 { FONT-FAMILY:Verdana;FONT-SIZE:10pt;} we used the "fingers" on all windows. .An even gentle pressure is exerted all round. Check with Mike Andresan on Friday. I showed him the technique on his left rear window and he has used it on others. Or you can call me on 480-626-4048.

From: [url=mailto:owner-rv10-list-server(at)matronics.com]owner-rv10-list-server(at)matronics.com (owner-rv10-list-server(at)matronics.com)[/url] [mailto:owner-rv10-list-server(at)matronics.com] On Behalf Of Roxanne and Mike Lefever

Sent: Tuesday, November 17, 2009 7:27 PM

To: (rv10-list(at)matronics.com)[url=mailto:rv10-list(at)matronics.com]rv10-list(at)matronics.com (rv10-list(at)matronics.com)[/url]

Subject: RE: Tips on removal of front window and lessons learned

David: did you do something similar like the fingers when doing the back windows? I am hoping to try those again on the next warm weekend day after having cracked one by clamping it.

From: (dlm46007(at)cox.net)[url=mailto:dlm46007(at)cox.net]dlm46007(at)cox.net (dlm46007(at)cox.net)[/url]

To: (rv10-list(at)matronics.com)[url=mailto:rv10-list(at)matronics.com]rv10-list(at)matronics.com (rv10-list(at)matronics.com)[/url]

Subject: RE: RV10-List: Tips on removal of front window and lessons learned

Date: Tue, 17 Nov 2009 06:04:19 -0700

#yiv259553191 .ExternalClass .ecxhmmessage P { PADDING-BOTTOM:0px;PADDING-LEFT:0px;PADDING-RIGHT:0px;PADDING-TOP:0px;} #yiv259553191 .ExternalClass BODY.ecxhmmessage { FONT-FAMILY:Verdana;FONT-SIZE:10pt;} We have used the following technique successfully on two aircraft , Glastar and RV10. We use bent aluminum fingers; a 1/2" wide by 3 " by .040 strip has a cleco hole on one end and a masking tape wrap on the other. cleco holes for these "fingers" are drilled at 4-6" intervals around the glass. these are numbered and are placed when the window is glued. After curing, the fingers are removed and the edge of the window sanded smooth. Then two one inch strips of E-glass , cut on a 45 bias, are glued around the windows to secure the window in the frame and fill the mounting holes. More work but the neither the window or the frame crack. We learned this technique at Phoenix Composites who have been doing this for years with all manner of composite aircraft.

From: [url=mailto:owner-rv10-list-server(at)matronics.com]owner-rv10-list-server(at)matronics.com (owner-rv10-list-server(at)matronics.com)[/url] [mailto:owner-rv10-list-server(at)matronics.com] On Behalf Of John Gonzalez

Sent: Monday, November 16, 2009 10:24 PM

To: RV 10 group

Subject: RE: Tips on removal of front window and lessons learned

I can only imagine the feeling of having to redo a windscreen due to cracks, )^%&*^2208&^*66&769q!!!!

Thought i would post a few pict on how I glued in my windscreen. I had heard about all the craze line issues and I even went as far as to purchase five tubes of Sikaflex for the side windows. I never used the sikaflex so if anyone want to purchase the five tubes for a quarter of what it cost me, let me know.

The key to clamping the windscreen IMO in is distribution of pressure. I used several laminations of 1/16" ply, aircraft modeling plywood to distribute the force. The pictures should tell the story. Also, I used wooden wedges to push down on the plexi where needed. Note the 3/4" ply used across the top of the canopy, clamped to the canopy, but it is the wedges which are pushing down on the plexi. This entire process is a two person process and it needs to be rehearsed. One person should spread the Weld On on the canopy rim while the other is doing the windscreen edge. Pressure to the windscreen should be applied at the top and then incrementally going out to the sides, each side at the same time. Tape should be placed on the inside of the windcreen and outside with the inside tape removed once the window is clamped. Get all the hairs of WeldOn off the plexi immediately.

Date: Mon, 16 Nov 2009 17:34:47 -0800

From: (aarongleixner(at)sbcglobal.net)[url=mailto:aarongleixner(at)sbcglobal.net]aarongleixner(at)sbcglobal.net (aarongleixner(at)sbcglobal.net)[/url]

Subject: Tips on removal of front window and lessons learned

To: (RV10-list(at)matronics.com)[url=mailto:RV10-list(at)matronics.com]RV10-list(at)matronics.com (RV10-list(at)matronics.com)[/url]

I just got off the phone with Van's after paying $470 for a new front window. I had approximately 50 small cracks starting at the glue joint, and extending about 1/8 inch beyond the glue joint. After reading all the warnings about not clamping when glueing the windows, I added a clamp in one location to hold the plexi tight, and all the cracks started under the clamp. While clamping pressure may not be the only variable for crack formation, it is definitely a strong contributing factor. So for those about to complete this step, avoid the clamps, and use plenty of glue to bridge any small gaps that might result.

Now for the question. Has anyone else had to remove a front window? At this point, I only need to remove the glue joint. How was it accomplished? Van's said someone routed out a window, but I was wondering if lots of heat from a heat gun, and a little prying might separate the glue from the fiberglass. Any suggestions would be greatly appreciated.

Aaron

|

<IMG_2986.JPG>

<IMG_2437.JPG>

|

[quote][b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

MauleDriver(at)nc.rr.com

Guest

|

Posted: Wed Nov 18, 2009 10:33 am Post subject: Tips on removal of front window and lessons learned Posted: Wed Nov 18, 2009 10:33 am Post subject: Tips on removal of front window and lessons learned |

|

|

I'm ready to do all the glass but I don't completely get the issues

involved. Is there more than clamping that is a problem? The crazing

in the middle of the wind sheild doesn't seem like a clamping problem.

As I understand it, a warm shop, the right tools, the adhesive of your

choice, a good partner, and ? will lead to success.

Bill "all the glass by Christmas" Watson

40605

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

jeff(at)westcottpress.com

Guest

|

Posted: Wed Nov 18, 2009 11:20 am Post subject: Tips on removal of front window and lessons learned Posted: Wed Nov 18, 2009 11:20 am Post subject: Tips on removal of front window and lessons learned |

|

|

I'm in the middle of all this right now, and here's my thought (for

whatever it might be worth):

If the window does not sit flush with the mating surface and has to be

clamped to conform to the proper shape, then you risk crazing as a

result of the tension that you've bonded in to the plexi. It is

probably best to build up the mating surface prior to bonding to some

extent to minimize the need for any distortion of the window shape...

clamps, tape, weight, etc. should be used to hold the piece in place

while bonding, not to change the shape of the plexi.

Jeff Carpenter

40304

On Nov 18, 2009, at 10:32 AM, Bill Mauledriver Watson wrote:

| Quote: |

>

I'm ready to do all the glass but I don't completely get the issues

involved. Is there more than clamping that is a problem? The

crazing in the middle of the wind sheild doesn't seem like a

clamping problem.

As I understand it, a warm shop, the right tools, the adhesive of

your choice, a good partner, and ? will lead to success.

Bill "all the glass by Christmas" Watson

40605

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

bgill1(at)charter.net

Guest

|

Posted: Wed Nov 18, 2009 3:54 pm Post subject: Tips on removal of front window and lessons learned Posted: Wed Nov 18, 2009 3:54 pm Post subject: Tips on removal of front window and lessons learned |

|

|

I am actually surprised at the number of folks that have had to replace the windscreen already.. I went through the same issue earlier this year - before the first flight.

Mine was in the middle of the passenger side. As best I could tell it was probably self induced. I remember cleaning the windscreen a few years back so I could paint a good coat of spray latex for protection. It was before the numerous discussions on what not to use on the "glass". After removing the spray lat, I found crazing in 3 different areas that was not there prior. I used the micro polish kit and completely removed the defect. Unfortunately, the slight variation in thickness (when viewed at the sharp angle) was totally unacceptable. I cried a bit then forked over the cash and bought a new windscreen.

I had no issues around the perimeter. I used the aluminum fingers and some duct tape and had a good fit with no crazing. I did opt to pass on the Weld-on the second round and used FE6026 with very good results so far. The removal was a chore using heat and a chisel to remove. Time consuming and painful but do able. The re-installation was smooth and then back in business.

Hard lesson to take but the windscreens deserve a lot of respect. I did look at the thickness of my Cessna windscreen in comparison - WOW. If I hit a bird I would much rather be in the RV!

Byron

N253RV

--

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

indigoonlatigo(at)msn.com

Guest

|

Posted: Wed Nov 18, 2009 8:07 pm Post subject: Tips on removal of front window and lessons learned Posted: Wed Nov 18, 2009 8:07 pm Post subject: Tips on removal of front window and lessons learned |

|

|

One issue not explained is C "How are people cutting the windscreen?"

I used a cut off wheel. It melts the plastic infront of the cutting.

Next i used 50-60 grit sanding disk on my Bose electric grinder. This is the kind of grinder that cuts tile C it runs at high RPM. Again C it heats at the same time it taketh away. Watch out for a run away cut off wheel or sanding disk. DO NOT GET DISTRACTED!

As for getting the windscreen to fit exactly to the canopy frame and fuse C it will never happen. Indeed it takes like two to three hundred on/off sessions of taking little by little off each time.

One very important point that the manual does not show C ROUND THE CORNERS OFF THE EDGES TO GET RID OF THE POINT LOADS ON THE PLEXI. THE MANUAL SHOWS A SHARP 90 DEGREE ANGLE ON ALL EDGES...I DO NOT AGREE WITH THIS IMAGE.

John

[quote] Date: Wed C 18 Nov 2009 13:32:13 -0500

From: MauleDriver(at)nc.rr.com

To: rv10-list(at)matronics.com

Subject: Re: Tips on removal of front window and lessons learned

--> RV10-List message posted by: Bill Mauledriver Watson <MauleDriver(at)nc.rr.com>

I'm ready to do all the glass but I don't completely get the issues

involved. Is there more than clamping that is a problem? The crazing

in the middle of the wind sheild doesn't seem like a clamping problem.

As I understand it C a warm shop C the right tools C the adhesive of your

choice C a good partner C and ? will lead to success.

Bill "all the glass by Christmas" Wat=====================

_=

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

MauleDriver(at)nc.rr.com

Guest

|

Posted: Thu Nov 19, 2009 3:26 am Post subject: Tips on removal of front window and lessons learned Posted: Thu Nov 19, 2009 3:26 am Post subject: Tips on removal of front window and lessons learned |

|

|

John Gonzalez wrote:

I did my initial fit a couple of weeks ago using a thin cut off wheel on

a die grinder - yep, it melts and that seems like a good thing. The

dremel with the new mandrel and the little cutoff wheels works too but

real slow.

Rounding the corners, especially at the front edge makes a lot of

sense. One is tempted to try and flush fit it but Vans suggests that

isn't necessary - but rounding seems very right as a way to avoid point

loading.

That'll be my plan for the next fitting session. Thanks John!

Bill

| Quote: | One issue not explained is, "How are people cutting the windscreen?"

I used a cut off wheel. It melts the plastic infront of the cutting.

Next i used 50-60 grit sanding disk on my Bose electric grinder. This

is the kind of grinder that cuts tile, it runs at high RPM. Again, it

heats at the same time it taketh away. Watch out for a run away cut

off wheel or sanding disk. DO NOT GET DISTRACTED!

As for getting the windscreen to fit exactly to the canopy frame and

fuse, it will never happen. Indeed it takes like two to three

hundred on/off sessions of taking little by little off each time.

One very important point that the manual does not show, ROUND THE

CORNERS OFF THE EDGES TO GET RID OF THE POINT LOADS ON THE PLEXI. THE

MANUAL SHOWS A SHARP 90 DEGREE ANGLE ON ALL EDGES...I DO NOT AGREE

WITH THIS IMAGE.

John

> Date: Wed, 18 Nov 2009 13:32:13 -0500

> From: MauleDriver(at)nc.rr.com

> To: rv10-list(at)matronics.com

> Subject: Re: Tips on removal of front window and lessons

learned

>

>

<MauleDriver(at)nc.rr.com>

>

> I'm ready to do all the glass but I don't completely get the issues

> involved. Is there more than clamping that is a problem? The crazing

> in the middle of the wind sheild doesn't seem like a clamping problem.

>

> As I understand it, a warm shop, the right tools, the adhesive of your

> choice, a good partner, and ? will lead to success.

>

> Bill "all the glass by Christmas" Wat=====================

> _=

>

>

>

*

*

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|