|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

AmphibFlyer

Joined: 29 Dec 2009

Posts: 25

|

Posted: Tue Dec 29, 2009 10:03 am Post subject: Rotax 914 Won't Start Posted: Tue Dec 29, 2009 10:03 am Post subject: Rotax 914 Won't Start |

|

|

A friend's Rotax 914 won't start--actually, it fires up, but won't get above about 900 rpm.

When the weather was warm, the engine started and ran smoothly. But it had trouble getting past 900 rpm on the last successful start, when the weather was starting to get cold. And now it just won't do it at all.

I have a theory, but before mentioning it to the owner, I'd like to ask what you guys think is the cause.

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

flyadive(at)gmail.com

Guest

|

Posted: Tue Dec 29, 2009 2:42 pm Post subject: Rotax 914 Won't Start Posted: Tue Dec 29, 2009 2:42 pm Post subject: Rotax 914 Won't Start |

|

|

SeaRay:

Ya gots to be more exact.

What OAT?

How long has the engine soaked at cold temps?

What OIL?

What viscosity oil?

Is the fuel fresh?

From what you say ... It DID get above 900 RPM just took a long time to get the engine warm?

Did you PRE-HEAT the engine?

Sure sounds like PRE-HEAT should of been the first step.

A fellow I know NEVER used pre-heat on his O-360 and the engine ran fine for many a year. He just had the engine rebuilt - TBO ya know. This being the first winter with the new engine (less than 25 hrs) the old no pre-heat procedure DID NOT WORK. It would not even turn over. Starter froze engaged. YET! As soon as the temps got to 50 F the thing kicked over in one blade.

So, what theory do you have?

Barry

On Tue, Dec 29, 2009 at 1:03 PM, AmphibFlyer <SeaRey(at)abstractconcreteworks.com (SeaRey(at)abstractconcreteworks.com)> wrote:

[quote]--> RotaxEngines-List message posted by: "AmphibFlyer" <SeaRey(at)AbstractConcreteWorks.com>

A friend's Rotax 914 won't start--actually, it fires up, but won't get above about 900 rpm.

When the weather was warm, the engine started and ran smoothly. But had trouble getting past 900 rpm on the last successful start, when the weather was starting to get cold. And now it just won't do it at all.

I have a theory, but before mentioning it to the owner, I'd like to ask what you guys think is the cause.

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=279115#279115

ber is the Annual List Fund Raiser. Click on

-= * AeroElectric www.aeroelectric.com

omebuiltHELP www.homebuilthelp.com

contribution" target="_blank">http://www.matronics.com/contribution

-Matt Dralle, Li - The RotaxEngines-List Email Forum -

:

axEngines-List" target="_blank">http://www.matronics.com/Navigator?RotaxE====================

http://forums.m===========

[b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

AmphibFlyer

Joined: 29 Dec 2009

Posts: 25

|

Posted: Tue Dec 29, 2009 3:57 pm Post subject: Re: Rotax 914 Won't Start Posted: Tue Dec 29, 2009 3:57 pm Post subject: Re: Rotax 914 Won't Start |

|

|

| flyadive(at)gmail.com wrote: |

From what you say ... It DID get above 900 RPM just took a long time to get the engine warm? |

Nope, it didn't get above 900 rpm. It maxed out there and wouldn't accelerate even to normal idle speed.

The last time it ran normally, the OAT was about 60 F. It had trouble getting past 900, but did after several seconds of chugging. At 45 F it would fire on all cylinders but couldn't break 900 rpm (approximately). I didn't pre-heat the engine, but I'm sure that low temperature is not the problem; it just makes the problem worse. These engines start just fine down to 0 F and below if the spark plug gaps are correct (.024, or less), which they were on this engine.

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

lucien

Joined: 03 Jun 2007

Posts: 721

Location: santa fe, NM

|

Posted: Tue Dec 29, 2009 4:25 pm Post subject: Re: Rotax 914 Won't Start Posted: Tue Dec 29, 2009 4:25 pm Post subject: Re: Rotax 914 Won't Start |

|

|

| AmphibFlyer wrote: | | flyadive(at)gmail.com wrote: |

From what you say ... It DID get above 900 RPM just took a long time to get the engine warm? |

Nope, it didn't get above 900 rpm. It maxed out there and wouldn't accelerate even to normal idle speed.

The last time it ran normally, the OAT was about 60 F. It had trouble getting past 900, but did after several seconds of chugging. At 45 F it would fire on all cylinders but couldn't break 900 rpm (approximately). I didn't pre-heat the engine, but I'm sure that low temperature is not the problem; it just makes the problem worse. These engines start just fine down to 0 F and below if the spark plug gaps are correct (.024, or less), which they were on this engine. |

Don't know if 2-stroke experience crosses over here, but two things that I've seen cause this kind of behavior are

- huge, massively heavy prop

- weak gearbox springs

It always amazes me the gigantic 2 ton props a lot of guys hang on these things - what prop, how big and how many blades? If it's way past the MOI limit on the 912 GB (6000 kg/cm3 last I looked in the manual, same as the 2-stroke C box) the engine simply may not be able to overcome it.

Same if the springs are worn and the preload is too weak. It'll be fighting the gearbox in that case too.

All that could be aggravated by a cold start as well...

If it's not that, I'm out of ideas and would like to know what it is once you finally figure out what it is...

LS

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

LS

Titan II SS |

|

| Back to top |

|

|

pasj66

Joined: 28 Jan 2009

Posts: 7

Location: Gothenburg, Sweden (ESGI)

|

Posted: Wed Dec 30, 2009 1:27 am Post subject: Re: Rotax 914 Won't Start Posted: Wed Dec 30, 2009 1:27 am Post subject: Re: Rotax 914 Won't Start |

|

|

Hello all,

fwiw check starting technique compared with the below document

http://www.rotax-aircraft-engines.com/pdf/dokus/d04645.pdf

throttle at idle and control rpm with choke until warm. I have a installation with 4 EGTs and the temp distribution is quite sensitive to the choke when cold.

Good luck

Best regards

Patrik

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

MCR R100, R914UL3 W/IC |

|

| Back to top |

|

|

flyadive(at)gmail.com

Guest

|

Posted: Thu Dec 31, 2009 8:48 am Post subject: Rotax 914 Won't Start Posted: Thu Dec 31, 2009 8:48 am Post subject: Rotax 914 Won't Start |

|

|

SeaRay:

I am a very single minded, serial input, data digesting machine.

Your response opens up many more questions:

[SeaRay]: Nope, it didn't get above 900 rpm. It maxed out there and wouldn't accelerate even to normal idle speed

1 - How long did you let the engine run in the 900 RPM range before calling it quits?

2 - What Oil Temps were you seeing while it was running in the 900 RPM range and before you shut it down?

[SeaRay]: The last time it ran normally, the OAT was about 60 F. It had trouble getting past 900, but did after several seconds of chugging.

3 - What is your definition of "RAN NORMALLY" ... IF it had trouble getting past 900 RPM?

[SeaRay]: At 45 F it would fire on all cylinders but couldn't break 900 rpm (approximately).

4 - Crazy question here .... How do you KNOW it was firing on ALL cylinders?

[SeaRay]: ... if the spark plug gaps are correct (.024, or less), which they were on this engine.

5 - I am at a disadvantage here, I do not know (now) the spark plug or gap requirement. but, 0.024" seems on the low side for a CDI. I run 0.035" on platum plugs in an O-360 with a CDI.

OK, lets see what ideas we can come up with with the available info:

a> Sure sounds like Pre-Heat would help a lot.

b> Also sounds like a vacuum leak on the intake.

c> Running too lean also fits the low RPM and inability to accelerate.

d> Incorrect routing of Spark Plug wires.

e> Incorrect Timing would produce the same results.

f> Does the ignition have Vacuum Advance? A leak there or totally disconnected ... Same results.

When you throw the book on the table there are MANY possibilities / variables, above are just starting points. Are there ANY situation that do produce acceptable results?

Let's take each individual item and eliminate it as a variable. Lets produce a list of KNOWN GOOD ITEMS.

Barry

On Tue, Dec 29, 2009 at 6:57 PM, AmphibFlyer <SeaRey(at)abstractconcreteworks.com (SeaRey(at)abstractconcreteworks.com)> wrote:

[quote]--> RotaxEngines-List message posted by: "AmphibFlyer" <SeaRey(at)AbstractConcreteWorks.com>

flyadive(at)gmail.com wrote:

| Quote: |

From what you say ... It DID get above 900 RPM just took a long time to get the engine warm?

|

Nope, it didn't get above 900 rpm. It maxed out there and wouldn't accelerate even to normal idle speed.

The last time it ran normally, the OAT was about 60 F. It had trouble getting past 900, but did after several seconds of chugging. At 45 F it would fire on all cylinders but couldn't break 900 rpm (approximately). I didn't pre-heat the engine, but I'm sure that low temperature is not the problem; it just makes the problem worse. These engines start just fine down to 0 F and below if the spark plug gaps are correct (.024, or less), which they were on this engine.

[b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

AmphibFlyer

Joined: 29 Dec 2009

Posts: 25

|

Posted: Thu Dec 31, 2009 9:26 am Post subject: Re: Rotax 914 Won't Start Posted: Thu Dec 31, 2009 9:26 am Post subject: Re: Rotax 914 Won't Start |

|

|

| lucien wrote: | Don't know if 2-stroke experience crosses over here, but two things that I've seen cause this kind of behavior are

- huge, massively heavy prop

- weak gearbox springs |

I think it's probably the gearbox springs, too. I didn't want to say so at first for fear of biasing any responses. This engine behaves a lot like mine did at about 400 hours: It would fire on all cylinders, but would not speed up past about 1,000 rpm. An aural indication was sort of a "chucka-chucka" sound as the engine tried to speed up. The remedy was to remove the gearbox and send it to Lockwood for replacement (and shimming) of the springs. On this engine, the sound is somewhat different than mine produced, and that's why I'm not sure I've diagnosed the problem correctly. But the other indications seem the same.

But there could be other causes as well (such as a bad sprag clutch), so if anyone has ideas, please let me know.

Also, if anyone knows why weak or worn springs prevent the engine from speeding up, I hope you'll explain it to me. I know that the ignition timing advances between about 600 and 900 rpm on these engines, but I don't really understand why the gearbox springs can affect the rpm, regardless of whether the timing is retarded for starting, or advanced for running.

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

lucien

Joined: 03 Jun 2007

Posts: 721

Location: santa fe, NM

|

Posted: Thu Dec 31, 2009 10:15 am Post subject: Re: Rotax 914 Won't Start Posted: Thu Dec 31, 2009 10:15 am Post subject: Re: Rotax 914 Won't Start |

|

|

| AmphibFlyer wrote: | | lucien wrote: | Don't know if 2-stroke experience crosses over here, but two things that I've seen cause this kind of behavior are

- huge, massively heavy prop

- weak gearbox springs |

I think it's probably the gearbox springs, too. I didn't want to say so at first for fear of biasing any responses. This engine behaves a lot like mine did at about 400 hours: It would fire on all cylinders, but would not speed up past about 1,000 rpm. An aural indication was sort of a "chucka-chucka" sound as the engine tried to speed up. The remedy was to remove the gearbox and send it to Lockwood for replacement (and shimming) of the springs. On this engine, the sound is somewhat different than mine produced, and that's why I'm not sure I've diagnosed the problem correctly. But the other indications seem the same.

But there could be other causes as well (such as a bad sprag clutch), so if anyone has ideas, please let me know.

Also, if anyone knows why weak or worn springs prevent the engine from speeding up, I hope you'll explain it to me. I know that the ignition timing advances between about 600 and 900 rpm on these engines, but I don't really understand why the gearbox springs can affect the rpm, regardless of whether the timing is retarded for starting, or advanced for running. |

Recip engines as you know rely on a flywheel effect in order to run. Some of the kinetic energy of the power stroke is stored in a flywheel to carry out the other 3 strokes (which necessarily don't produce power and in fact require power input to proceed).

Weak springs in the gearbox can decouple the prop from the crankshaft such that the flywheel effect needed for the engine to run correctly can be defeated in just the right way at certain, usually very low, rpm's. This is caused by the exessive slipping of the dog hub with the sudden reengagement as the hubs make contact at each side.

Years ago a friend of mine tried to design a prop extension on a 503 and he ran into the same problem but this time caused by the extension shaft itself. It was a narrow steel shaft that flexed torsionally. The engine would shake violently at a very low rpm until the crossbolt holding the shaft to the gearbox adapter plate he made snapped. Then the engine would run perfectly, albeit with the shaft slipping horribly.....

LS

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

LS

Titan II SS |

|

| Back to top |

|

|

AmphibFlyer

Joined: 29 Dec 2009

Posts: 25

|

Posted: Thu Dec 31, 2009 10:48 am Post subject: Re: Rotax 914 Won't Start Posted: Thu Dec 31, 2009 10:48 am Post subject: Re: Rotax 914 Won't Start |

|

|

| lucien wrote: | | Recip engines as you know rely on a flywheel effect in order to run... Weak springs in the gearbox can decouple the prop from the crankshaft such that the flywheel effect needed for the engine to run correctly can be defeated in just the right way at certain, usually very low, rpm's. This is caused by the exessive slipping of the dog hub with the sudden reengagement as the hubs make contact at each side. |

Thanks, Lucien! That makes sense, and now I realize that the springs must be in there at least partly to damp the lash in the gears at low rpm. These Rotax engines have a flywheel (and will run smoothly without a prop), so I hadn't considered the flywheel effect of the prop, resonance, and gear lash. Can't say I like the spring solution, but I guess it works most of the time.

What puzzles me is that Rotax apparently hasn't bothered to mention this condition in the maintenance or operator's manuals. At least, I haven't been able to find any mention of it. Nor indications of the sprag clutch problem.

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

Gilles.Thesee(at)ac-greno

Guest

|

Posted: Thu Dec 31, 2009 11:02 am Post subject: Rotax 914 Won't Start Posted: Thu Dec 31, 2009 11:02 am Post subject: Rotax 914 Won't Start |

|

|

AmphibFlyer a écrit :

| Quote: | Rotax engines have a flywheel

AmphibFlyer,

|

Rotax engines have NO flywheel.

| Quote: | (and will run smoothly without a prop)

Running a Rotax without a prop is a no-no.

|

Season's greetings

Best regards,

--

Gilles

http://contrails.free.fr

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

| Description: |

|

| Filesize: |

49.42 KB |

| Viewed: |

25550 Time(s) |

|

|

|

| Back to top |

|

|

AmphibFlyer

Joined: 29 Dec 2009

Posts: 25

|

Posted: Thu Dec 31, 2009 11:51 am Post subject: Re: Rotax 914 Won't Start Posted: Thu Dec 31, 2009 11:51 am Post subject: Re: Rotax 914 Won't Start |

|

|

| Gilles.Thesee(at)ac-greno wrote: | | Rotax engines have NO flywheel... Running a Rotax without a prop is a no-no. |

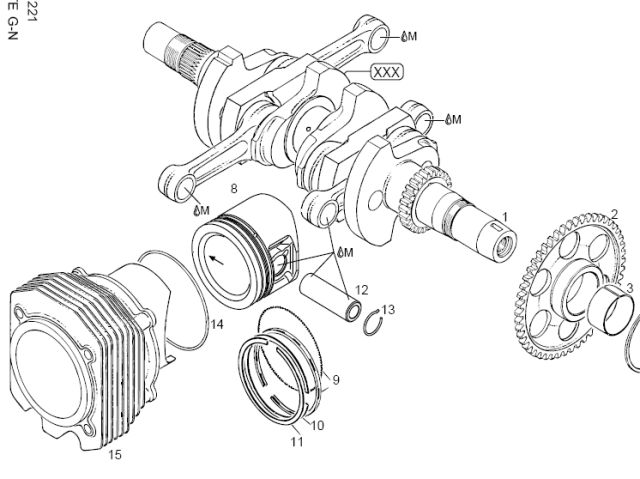

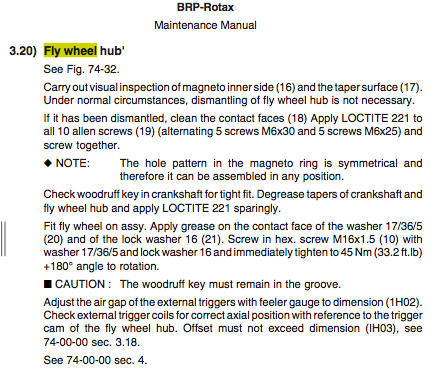

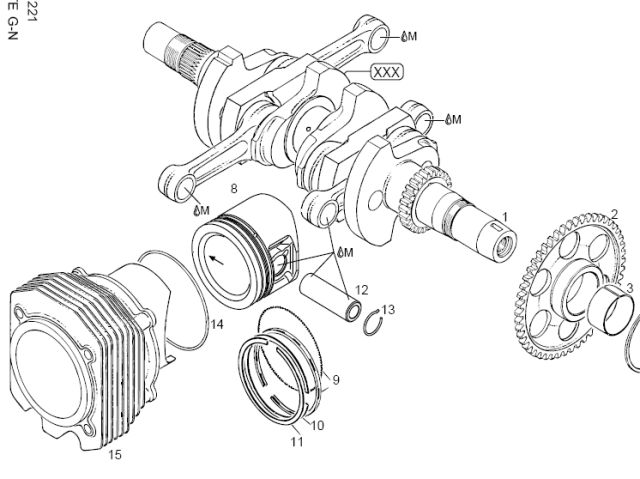

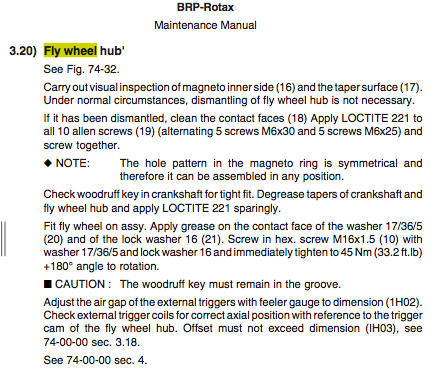

Well, you're right, mostly. I shouldn't have said that they do. On the other hand, the 912/914 Heavy Maintenance Manual discusses "flywheel hub" in several places (July 01/2008, 74-00-00, page 49, page 117, and page 25). It doesn't seem to show a clear diagram of an actual flywheel, though.

Also I should confess that I have never tried to run a 914 without a prop and relied on someone else's testimony, which I can't verify right now. So maybe it can be done and maybe it can't.

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

| Description: |

|

| Filesize: |

75.77 KB |

| Viewed: |

25542 Time(s) |

|

|

|

| Back to top |

|

|

flyadive(at)gmail.com

Guest

|

Posted: Thu Dec 31, 2009 12:32 pm Post subject: Rotax 914 Won't Start Posted: Thu Dec 31, 2009 12:32 pm Post subject: Rotax 914 Won't Start |

|

|

Gilles is right 100%!

You should NEVER run an engine without some form of flywheel. A prop IS a flywheel. And if your friend ran an engine without a flywheel and is alive to talk about it he is either lucky or a liar.

An engine run without a flywheel or the proper size flywheel can JUMP into a RUNAWAY condition and reach RPM's so high the engine will literally tear itself apart / explode.

Another question to throw into the pot: Is the prop properly CLOCKED? If it is not in the correct position you will get rough running and vibration.

Barry

On Thu, Dec 31, 2009 at 2:51 PM, AmphibFlyer <SeaRey(at)abstractconcreteworks.com (SeaRey(at)abstractconcreteworks.com)> wrote:

[quote]--> RotaxEngines-List message posted by: "AmphibFlyer" <SeaRey(at)AbstractConcreteWorks.com>

Gilles.Thesee(at)ac-greno wrote:

| Quote: | Rotax engines have NO flywheel... Running a Rotax without a prop is a no-no.

|

Well, you're right, mostly. I shouldn't have said that they do. On the other hand, the Heavy Maintenance Manual discusses "flywheel hub" in several places (July 01/2008, 74-00-00, page 49, page 117, and page 25). It doesn't seem to show a clear diagram of an actual flywheel, though.

Also I should confess that I have never tried to run a 914 without a prop and relied on someone else's testimony, which I can't verify right now. So maybe it can be done and maybe it can't.

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=279458#279458

Attachments:

http://forums.matronics.com//files/scr=======

he Contribution link below to find out more about

lder's Bookstore www.buildersbooks.com

href="http://www.howtocrimp.com/" target="_blank">www.howtocrimp.comhttp://www.matronics.com/Navigator?RotaxEngines-List

ronics.com/" target="_blank">http://forums.matronics.com

==============

[b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

rickofudall

Joined: 19 Sep 2009

Posts: 1392

Location: Udall, KS, USA

|

Posted: Thu Dec 31, 2009 12:44 pm Post subject: Rotax 914 Won't Start Posted: Thu Dec 31, 2009 12:44 pm Post subject: Rotax 914 Won't Start |

|

|

Amphibflyer, You've posed a "how long is a piece of string" question and there's just too much information missing to make any sort of reasonable guess.Has there ever been a time when this engine started and ran normally? How long ago was that? How many hours are on this engine? Like others I'd like to know what is known to be good.

Since it won't cost anything or require much in the way of disassembly, given the temperatures you're quoted, I'd take the exhaust pipe off the turbo and make sure there are no blockages in the turbine or the pipe. Rotax engines don't have enough of a pulse coming out the pipe to blow off a zip lock bag held on by a rubber band. I wouldn't be at all surprised if you had a mouse nest in the pipe somewhere.

As Beauford says, "Worth what you paid for it"

Rick Girard

On Thu, Dec 31, 2009 at 1:51 PM, AmphibFlyer <SeaRey(at)abstractconcreteworks.com (SeaRey(at)abstractconcreteworks.com)> wrote:

[quote]--> RotaxEngines-List message posted by: "AmphibFlyer" <SeaRey(at)AbstractConcreteWorks.com>

Gilles.Thesee(at)ac-greno wrote:

> Rotax engines have NO flywheel... Running a Rotax without a prop is a no-no.

Well, you're right, mostly. I shouldn't have said that they do. On the other hand, the Heavy Maintenance Manual discusses "flywheel hub" in several places (July 01/2008, 74-00-00, page 49, page 117, and page 25). It doesn't seem to show a clear diagram of an actual flywheel, though.

Also I should confess that I have never tried to run a 914 without a prop and relied on someone else's testimony, which I can't verify right now. So maybe it can be done and maybe it can't.

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=279458#279458

Attachments:

http://forums.matronics.com//files/screen_shot_2009_12_31_at_23239_pm_205.png

===========

="_blank">www.aeroelectric.com

ooks.com" target="_blank">www.buildersbooks.com

et="_blank">www.homebuilthelp.com

"_blank">www.howtocrimp.com

="_blank">http://www.matronics.com/contribution

le, List Admin.

===========

-List" target="_blank">http://www.matronics.com/Navigator?RotaxEngines-List

===========

http://forums.matronics.com

===========

[b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

The smallest miracle right in front of you is enough to make you happy.... |

|

| Back to top |

|

|

rickofudall

Joined: 19 Sep 2009

Posts: 1392

Location: Udall, KS, USA

|

Posted: Thu Dec 31, 2009 12:54 pm Post subject: Rotax 914 Won't Start Posted: Thu Dec 31, 2009 12:54 pm Post subject: Rotax 914 Won't Start |

|

|

Barry, Rotax engines run a gearbox of either 2.27 or 2.43 ratio. How exactly are you going to CLOCK it?

Rick Girard

On Thu, Dec 31, 2009 at 2:32 PM, FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)> wrote:

[quote]Gilles is right 100%!

You should NEVER run an engine without some form of flywheel. A prop IS a flywheel. And if your friend ran an engine without a flywheel and is alive to talk about it he is either lucky or a liar.

An engine run without a flywheel or the proper size flywheel can JUMP into a RUNAWAY condition and reach RPM's so high the engine will literally tear itself apart / explode.

Another question to throw into the pot: Is the prop properly CLOCKED? If it is not in the correct position you will get rough running and vibration.

Barry

On Thu, Dec 31, 2009 at 2:51 PM, AmphibFlyer <SeaRey(at)abstractconcreteworks.com (SeaRey(at)abstractconcreteworks.com)> wrote:

| Quote: | --> RotaxEngines-List message posted by: "AmphibFlyer" <SeaRey(at)AbstractConcreteWorks.com>

Gilles.Thesee(at)ac-greno wrote:

| Quote: | Rotax engines have NO flywheel... Running a Rotax without a prop is a no-no.

|

Well, you're right, mostly. I shouldn't have said that they do. On the other hand, the Heavy Maintenance Manual discusses "flywheel hub" in several places (July 01/2008, 74-00-00, page 49, page 117, and page 25). It doesn't seem to show a clear diagram of an actual flywheel, though.

Also I should confess that I have never tried to run a 914 without a prop and relied on someone else's testimony, which I can't verify right now. So maybe it can be done and maybe it can't.

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=279458#279458

Attachments:

http://forums.matronics.com//files/scr=======

he Contribution link below to find out more about

lder's Bookstore www.buildersbooks.com

href="http://www.howtocrimp.com/" target="_blank">www.howtocrimp.com iption,

www.matronics.com/Navigator?RotaxEngines-List" target="_blank">http://www.matronics.com/Navigator?RotaxEngines-List

ronics.com/" target="_blank">http://forums.matronics.com

==============

_blank">www.aeroelectric.com

.com" target="_blank">www.buildersbooks.com

="_blank">www.homebuilthelp.com

nk">www.howtocrimp.com

_blank">http://www.matronics.com/contribution

ist" target="_blank">http://www.matronics.com/Navigator?RotaxEngines-List

tp://forums.matronics.com

|

[b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

The smallest miracle right in front of you is enough to make you happy.... |

|

| Back to top |

|

|

rickofudall

Joined: 19 Sep 2009

Posts: 1392

Location: Udall, KS, USA

|

Posted: Thu Dec 31, 2009 1:03 pm Post subject: Rotax 914 Won't Start Posted: Thu Dec 31, 2009 1:03 pm Post subject: Rotax 914 Won't Start |

|

|

I should have specified the 912/914 series, The two strokes run 2.00, 2.58, 3.47 and 4.00 that I can remember off hand.

Rick

On Thu, Dec 31, 2009 at 2:54 PM, Richard Girard <aslsa.rng(at)gmail.com (aslsa.rng(at)gmail.com)> wrote:

[quote]Barry, Rotax engines run a gearbox of either 2.27 or 2.43 ratio. How exactly are you going to CLOCK it?

Rick Girard

On Thu, Dec 31, 2009 at 2:32 PM, FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)> wrote:

| Quote: | Gilles is right 100%!

You should NEVER run an engine without some form of flywheel. A prop IS a flywheel. And if your friend ran an engine without a flywheel and is alive to talk about it he is either lucky or a liar.

An engine run without a flywheel or the proper size flywheel can JUMP into a RUNAWAY condition and reach RPM's so high the engine will literally tear itself apart / explode.

Another question to throw into the pot: Is the prop properly CLOCKED? If it is not in the correct position you will get rough running and vibration.

Barry

On Thu, Dec 31, 2009 at 2:51 PM, AmphibFlyer <SeaRey(at)abstractconcreteworks.com (SeaRey(at)abstractconcreteworks.com)> wrote:

| Quote: | --> RotaxEngines-List message posted by: "AmphibFlyer" <SeaRey(at)AbstractConcreteWorks.com>

Gilles.Thesee(at)ac-greno wrote:

| Quote: | Rotax engines have NO flywheel... Running a Rotax without a prop is a no-no.

|

Well, you're right, mostly. I shouldn't have said that they do. On the other hand, the Heavy Maintenance Manual discusses "flywheel hub" in several places (July 01/2008, 74-00-00, page 49, page 117, and page 25). It doesn't seem to show a clear diagram of an actual flywheel, though.

Also I should confess that I have never tried to run a 914 without a prop and relied on someone else's testimony, which I can't verify right now. So maybe it can be done and maybe it can't.

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=279458#279458

Attachments:

http://forums.matronics.com//files/scr=======

he Contribution link below to find out more about

lder's Bookstore www.buildersbooks.com

href="http://www.howtocrimp.com/" target="_blank">www.howtocrimp.com iption,

www.matronics.com/Navigator?RotaxEngines-List" target="_blank">http://www.matronics.com/Navigator?RotaxEngines-List

ronics.com/" target="_blank">http://forums.matronics.com

==============

_blank">www.aeroelectric.com

.com" target="_blank">www.buildersbooks.com

="_blank">www.homebuilthelp.com

nk">www.howtocrimp.com

_blank">http://www.matronics.com/contribution

ist" target="_blank">http://www.matronics.com/Navigator?RotaxEngines-List

tp://forums.matronics.com

|

|

[b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

The smallest miracle right in front of you is enough to make you happy.... |

|

| Back to top |

|

|

AmphibFlyer

Joined: 29 Dec 2009

Posts: 25

|

Posted: Thu Dec 31, 2009 1:24 pm Post subject: Re: Rotax 914 Won't Start Posted: Thu Dec 31, 2009 1:24 pm Post subject: Re: Rotax 914 Won't Start |

|

|

| rickofudall wrote: | | Amphibflyer, ...Has there ever been a time when this engine started and ran normally? How long ago was that? How many hours are on this engine? |

Yes, yes, the engine has run almost 250 hours and it ran well a few weeks ago, when I flew the airplane several times. The last time I flew it was when the engine took a while to accelerate past about 900 rpm, and once it did the engine ran well and the airplane flew fine. When I tried to fly it a few days later, the temp was in the 40s F, and that time the engine would start but wouldn't accelerate to normal idle speed. The problem is not related to spark plug gap or the starting carburetors. I'm almost certain that it's caused by worn gearbox springs, exacerbated by the cool temperature. Just wanted to see if my diagnosis was likely to be correct, and Lucien's post seems to corroborate it.

In response to someone's observation about the narrow spark plug gap: Rotax says that the normal range for 914 plugs is .024" to .028" and that for cold weather they can be as tight as .020". My own 914 (with about 860 hours) always starts in cold weather if the gaps are .025" or less--except for the one time when the gearbox springs were shot. That was probably caused in part by too-low idle speeds. Both engines are on amphibians, and we routinely need very slow idle speed when docking. (Standard seaplane practice is to shut off one mag for even less thrust.) Since my gearbox springs were replaced I've kept the rpm up around 2,000 or faster, except for the few seconds that it's essential to idle slower, and that seems to have kept the washers from further excessive wear.

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

blackmore(at)platinum.ca

Guest

|

Posted: Thu Dec 31, 2009 1:38 pm Post subject: Rotax 914 Won't Start Posted: Thu Dec 31, 2009 1:38 pm Post subject: Rotax 914 Won't Start |

|

|

Take the intake off the turbo and see if it turns with your finger it should spin real easy, then if it does stay clear and try to start the engine with it off.. The intake to the turbo that is .... EPull a line off and make sure you are getting fuel and no junk on the screen in the tank. Check ignition system is behaving. Check choke is opening. Check starter is throwing out

That should keep you busy for the first ten mins! Check back with the right answer

Chris

[i]----

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

rparigoris

Joined: 24 Nov 2009

Posts: 796

|

Posted: Thu Dec 31, 2009 2:05 pm Post subject: Rotax 914 Won't Start Posted: Thu Dec 31, 2009 2:05 pm Post subject: Rotax 914 Won't Start |

|

|

I guess at 250 hours you can have gearbox problems. Off the cuff the first thing I would check is to make sure you have fresh gas, and clean the carb snot out of carbs. In my experiance with type 64 Bing carbs on my R100GS, the first thing that snots up is the enrichment jet located in the float bowl! I also find some snot in the main jets and other. Best replace gaskets on float bowl, and or any suspect O-rings. Any air leak on a 914 float bowl or other can negate ability to maintain between ~2 and ~5 PSI fuel pressure over airbox pressure. My gut feeling is a gearbox issue would not happen all of a sudden, clogged enrichmnet jet or lean mixture can happen all of a sudden. Jet could have been clogged for a while and you didn't notice till temp came down. The more alcohol in your fuel, the leaner the mixture, if you got a 20% batch..... BTW I have read a while back that for very cold weather operations of 91X, you can make enrichment circuit more rich. It was in a notice I recieved from Rotax, service bulletin, alert or other. Ripped diaphragm or any other leak that can cause a lean mixture will do you no good as well. Ron Parigoris [quote][b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

flyadive(at)gmail.com

Guest

|

Posted: Thu Dec 31, 2009 2:05 pm Post subject: Rotax 914 Won't Start Posted: Thu Dec 31, 2009 2:05 pm Post subject: Rotax 914 Won't Start |

|

|

Rich:

I asked the same question. The procedure is the same as for direct drives. Why you may ask?

Because the prop has more an effect as the FLYWHEEL having a much larger diameter than the gears.

The procedure is this:

1 - Take all safety precautions.

2 - Put the prop on with only a few bolts

3 - Remove the #1 Cyl Spark Plug.

4 - Rotate the prop so #1 piston is TDC on compression stroke.

5 - The prop #1 Blade ... Should be at the 1 O'clock position - LQQKing at it from the front of the engine.

6 - Position and reassemble as required.

Barry

On Thu, Dec 31, 2009 at 3:54 PM, Richard Girard <aslsa.rng(at)gmail.com (aslsa.rng(at)gmail.com)> wrote:

[quote]Barry, Rotax engines run a gearbox of either 2.27 or 2.43 ratio. How exactly are you going to CLOCK it?

Rick Girard

On Thu, Dec 31, 2009 at 2:32 PM, FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)> wrote:

| Quote: | Gilles is right 100%!

You should NEVER run an engine without some form of flywheel. A prop IS a flywheel. And if your friend ran an engine without a flywheel and is alive to talk about it he is either lucky or a liar.

An engine run without a flywheel or the proper size flywheel can JUMP into a RUNAWAY condition and reach RPM's so high the engine will literally tear itself apart / explode.

Another question to throw into the pot: Is the prop properly CLOCKED? If it is not in the correct position you will get rough running and vibration.

Barry

On Thu, Dec 31, 2009 at 2:51 PM, AmphibFlyer <SeaRey(at)abstractconcreteworks.com (SeaRey(at)abstractconcreteworks.com)> wrote:

| Quote: | --> RotaxEngines-List message posted by: "AmphibFlyer" <SeaRey(at)AbstractConcreteWorks.com>

Gilles.Thesee(at)ac-greno wrote:

| Quote: | Rotax engines have NO flywheel... Running a Rotax without a prop is a no-no.

|

Well, you're right, mostly. I shouldn't have said that they do. On the other hand, the Heavy Maintenance Manual discusses "flywheel hub" in several places (July 01/2008, 74-00-00, page 49, page 117, and page 25). It doesn't seem to show a clear diagram of an actual flywheel, though.

Also I should confess that I have never tried to run a 914 without a prop and relied on someone else's testimony, which I can't verify right now. So maybe it can be done and maybe it can't.

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=279458#279458

Attachments:

http://forums.matronics.com//files/scr=======

he Contribution link below to find out more about

lder's Bookstore www.buildersbooks.com

href="http://www.howtocrimp.com/" target="_blank">www.howtocrimp.com iption,

www.matronics.com/Navigator?RotaxEngines-List" target="_blank">http://www.matronics.com/Navigator?RotaxEngines-List

ronics.com/" target="_blank">http://forums.matronics.com

==============

_blank">www.aeroelectric.com

.com" target="_blank">www.buildersbooks.com

="_blank">www.homebuilthelp.com

nk">www.howtocrimp.com

_blank">http://www.matronics.com/contribution

ist" target="_blank">http://www.matronics.com/Navigator?RotaxEngines-List

tp://forums.matronics.com

|

|

| Quote: |

"_blank">www.aeroelectric.com

.com/" target="_blank">www.buildersbooks.com

="_blank">www.homebuilthelp.com

ank">www.howtocrimp.com

_blank">http://www.matronics.com/contribution

ist" target="_blank">http://www.matronics.com/Navigator?RotaxEngines-List

ttp://forums.matronics.com

|

[b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

rickofudall

Joined: 19 Sep 2009

Posts: 1392

Location: Udall, KS, USA

|

Posted: Thu Dec 31, 2009 5:21 pm Post subject: Rotax 914 Won't Start Posted: Thu Dec 31, 2009 5:21 pm Post subject: Rotax 914 Won't Start |

|

|

Once you reached operating temperature when the engine was running well, did you notice a lot of clatter when the engine was at idle?

Assuming there is a gearbox problem, there is a very easy way to check it. You'll need your engine fixation pin to lock the crank, a fishing scale, and a strap. The test is detailed in the manuals and I believe there's a SB on it, too. Adding to the suggestions concerning potential carb issues, have you checked the carb mounting flanges? There was a bad batch produced that cracked readily. The HKS uses the same part and mine lasted barely a year. I could not see the damage until I took them off the engine and looked at them in bright light, then the cracks were readily visible.

Rick Girard

On Thu, Dec 31, 2009 at 4:04 PM, <rparigor(at)suffolk.lib.ny.us (rparigor(at)suffolk.lib.ny.us)> wrote:

[quote]

I guess at 250 hours you can have gearbox problems. Off the cuff the first thing I would check is to make sure you have fresh gas, and clean the carb snot out of carbs. In my experiance with type 64 Bing carbs on my R100GS, the first thing that snots up is the enrichment jet located in the float bowl! I also find some snot in the main jets and other. Best replace gaskets on float bowl, and or any suspect O-rings. Any air leak on a 914 float bowl or other can negate ability to maintain between ~2 and ~5 PSI fuel pressure over airbox pressure. My gut feeling is a gearbox issue would not happen all of a sudden, clogged enrichmnet jet or lean mixture can happen all of a sudden. Jet could have been clogged for a while and you didn't notice till temp came down. The more alcohol in your fuel, the leaner the mixture, if you got a 20% batch..... BTW I have read a while back that for very cold weather operations of 91X, you can make enrichment circuit more rich. It was in a notice I recieved from Rotax, service bulletin, alert or other. Ripped diaphragm or any other leak that can cause a lean mixture will do you no good as well. Ron Parigoris

| Quote: |

_blank">www.aeroelectric.com

.com" target="_blank">www.buildersbooks.com

="_blank">www.homebuilthelp.com

nk">www.howtocrimp.com

_blank">http://www.matronics.com/contribution

ist" target="_blank">http://www.matronics.com/Navigator?RotaxEngines-List

tp://forums.matronics.com

|

[b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

The smallest miracle right in front of you is enough to make you happy.... |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|