|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

messydeer

Joined: 13 Feb 2006

Posts: 214

Location: Bellingham, WA

|

Posted: Fri Feb 19, 2010 1:14 pm Post subject: fuel pressure sender ground Posted: Fri Feb 19, 2010 1:14 pm Post subject: fuel pressure sender ground |

|

|

Hi!

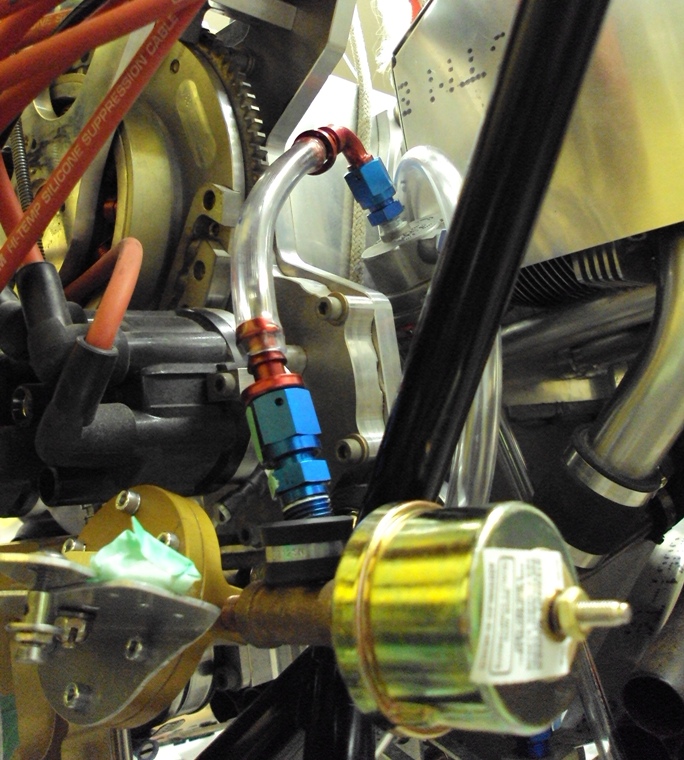

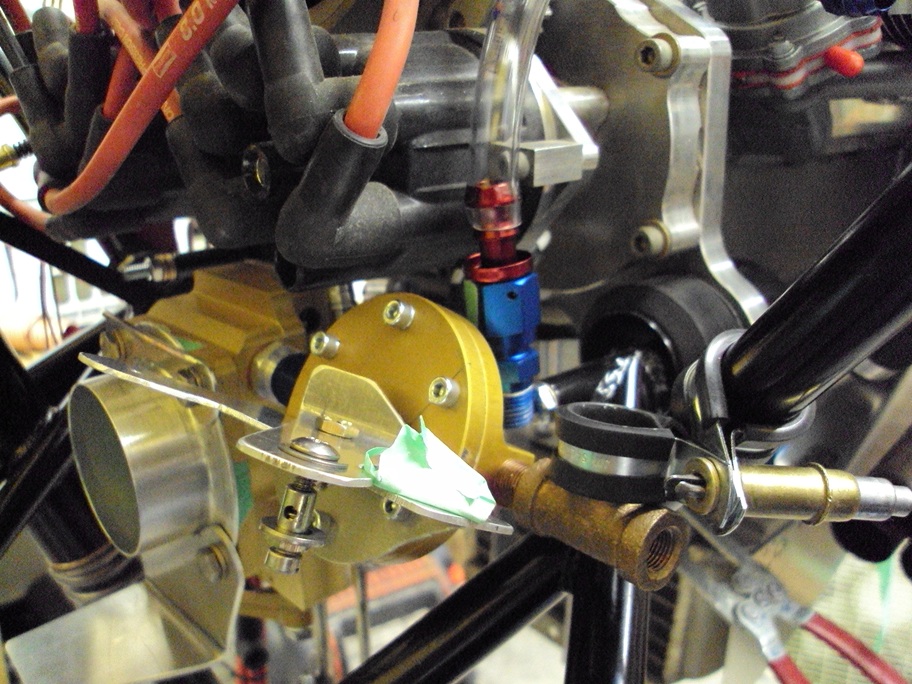

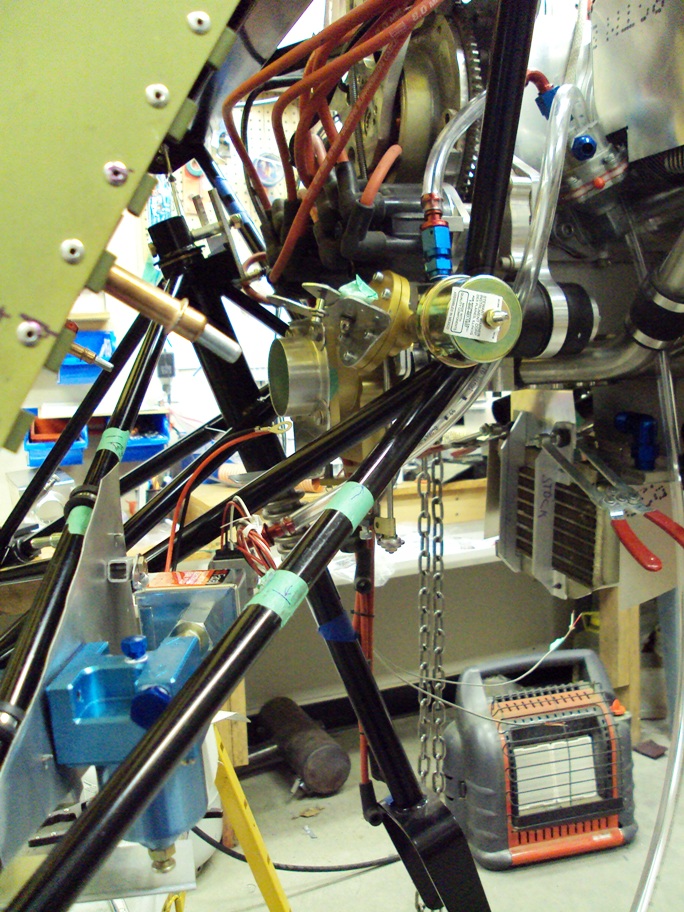

I just got my Steward Warner fuel pressure sender and am wondering what a good way to get a ground lead from it would be. The first pic shows its 1/8" npt stud threaded into a T fitting in my mockup. Tech support said to use the npt stud. But I can't imagine getting a tight fit with a ground ring that way, without making the actual fitting looser.

He also said if I needed to, the top of the can near the edge could be tapped.

Any ideas?

Thanks,

Dan

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

238.82 KB |

| Viewed: |

16451 Time(s) |

|

| Description: |

|

| Filesize: |

155.7 KB |

| Viewed: |

16451 Time(s) |

|

_________________

Dan |

|

| Back to top |

|

|

rampil

Joined: 04 May 2007

Posts: 870

|

Posted: Fri Feb 19, 2010 1:54 pm Post subject: Re: fuel pressure sender ground Posted: Fri Feb 19, 2010 1:54 pm Post subject: Re: fuel pressure sender ground |

|

|

What close fit?

the size of the ring is not important as long as it slides over the

NPT. If the NPT Tee does not compress the ring, put a jam nut

over the ring.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Ira N224XS |

|

| Back to top |

|

|

mprather(at)spro.net

Guest

|

Posted: Fri Feb 19, 2010 2:26 pm Post subject: fuel pressure sender ground Posted: Fri Feb 19, 2010 2:26 pm Post subject: fuel pressure sender ground |

|

|

Most NPT is tapered. As such, my thinking is that the threaded joint must

become tight by the binding of the taper, not by contacting facing

surfaces.. If the installed lug (or jam nut) causes contacting of the

facing surfaces, I might be a bit concerned about long term sealing of the

joint.

http://en.wikipedia.org/wiki/National_pipe_thread

Regards,

Matt-

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

messydeer

Joined: 13 Feb 2006

Posts: 214

Location: Bellingham, WA

|

|

| Back to top |

|

|

peter(at)sportingaero.com

Guest

|

Posted: Fri Feb 19, 2010 3:51 pm Post subject: fuel pressure sender ground Posted: Fri Feb 19, 2010 3:51 pm Post subject: fuel pressure sender ground |

|

|

Hose clamp around the sender to trap a ground wire? Solder a wire on to

the sender body? Bolt sender to a monifold bolted (and grounded) to the

firewall (or ground the mounting bolt)? Ground wire on the circular

metal thing?

BTW not sure I would use PVC pipe with push on fittings on a fuel line

under pressure! I use teflon braided pipe with integral firesleeve.

Peter

messydeer wrote:

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

rampil

Joined: 04 May 2007

Posts: 870

|

Posted: Fri Feb 19, 2010 4:13 pm Post subject: Re: fuel pressure sender ground Posted: Fri Feb 19, 2010 4:13 pm Post subject: Re: fuel pressure sender ground |

|

|

If worry about the sealing is your concern, use PTFE compound on the

joint.

If structural integrity is your issue, you should not be using the old

VDO automotive sensor in the first place as it has a huge moment arm

and NPT is not aerospace qualified. ANPT is better but is not compatible

with highest quality hose like Aeroquip 666.

If you are still wanting to use the VDO like Rotax used to for oil pressure,

strap it with a stainless hose clamp as suggested and safety wire it to

not rotate. Grounding at the clamp is optional but works if clean and the

sensor can is not corroded since under the clamp will not be as

anaerobic as under a jam nut to a ring terminal - i.e., more rust.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Ira N224XS |

|

| Back to top |

|

|

messydeer

Joined: 13 Feb 2006

Posts: 214

Location: Bellingham, WA

|

Posted: Fri Feb 19, 2010 4:52 pm Post subject: Re: fuel pressure sender ground Posted: Fri Feb 19, 2010 4:52 pm Post subject: Re: fuel pressure sender ground |

|

|

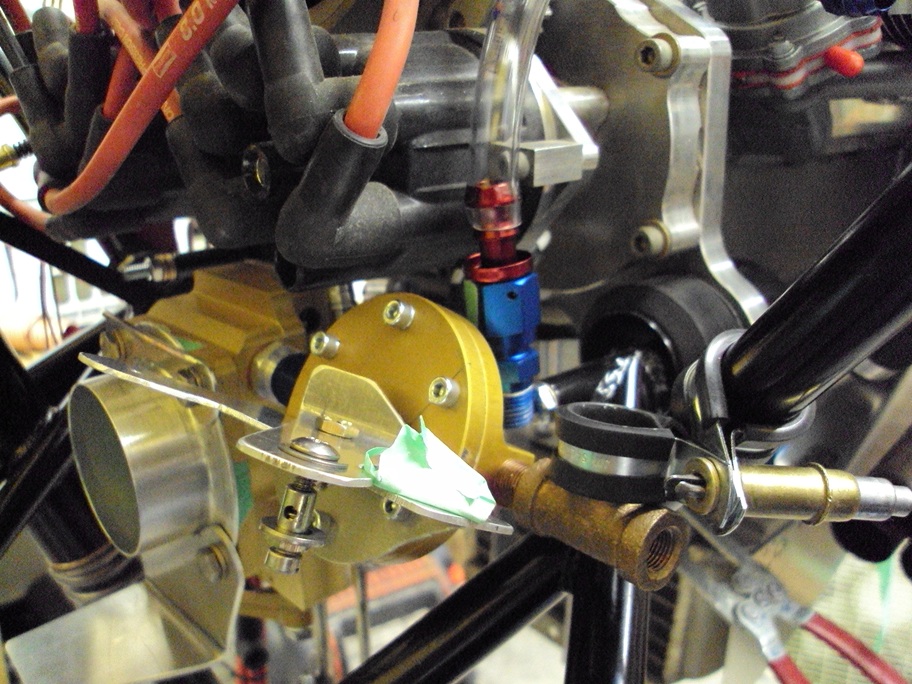

Thanks, guys

I could have mentioned this is mockup stuff, not the real McCoy. But $0.25/ft hose would be a better budget fit! The tee shown is a brass one from the hardware store. I'll replace it with an aluminum when it's delivered next week, along with a bunch of other fittings.

Grounding to the adel clamp sounds reasonable. I could take off the pad on the clamp holding the tee, then slip a ring over the bolt holding the two clamps together.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

259.56 KB |

| Viewed: |

16431 Time(s) |

|

_________________

Dan |

|

| Back to top |

|

|

al38kit

Joined: 13 Jul 2009

Posts: 21

|

Posted: Fri Feb 19, 2010 7:35 pm Post subject: Re: fuel pressure sender ground Posted: Fri Feb 19, 2010 7:35 pm Post subject: Re: fuel pressure sender ground |

|

|

First, to answer your question...If you check the resistance from the case of the transducer to the engine case and find it to be minimal, forget about a separate ground wire and ensure the case of the engine is common to your electrical system.

Now for the biggie...

I would scrap this entire installation of the transducer and mount it on a braided flexible line with a fitting having a flow restrictor.

It is a bad idea to mount any of these transducers in the manner you are attempting and many instrument manufacturers do NOT recommend hard mounting them to the engine...

I recall reading an accident report about a Questair Pilot who had mounted one on some tubing...it failed in flight and he got to spend some time in the mountains with a broken leg...alone.

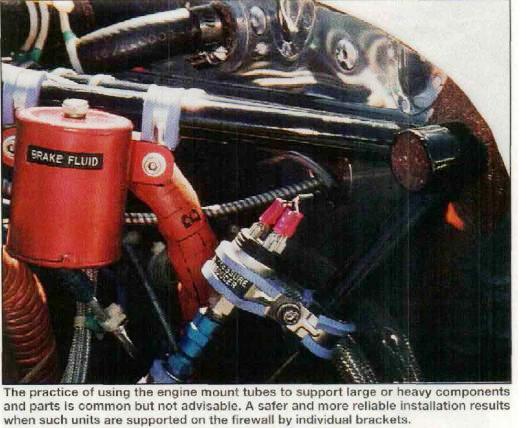

Fittings are not good mounts in a vibration environment.

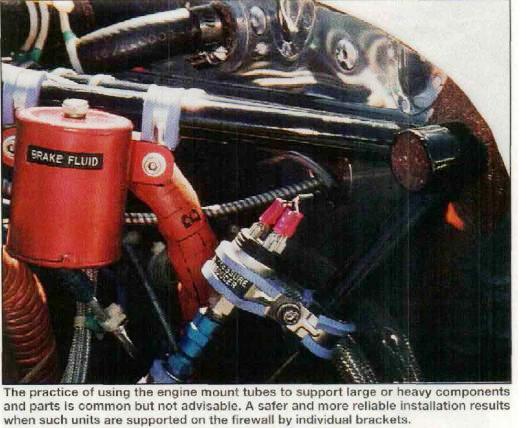

If that Adel clamp is mounted to the engine mount, it's an especially bad idea.

Just something to think about now...

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

messydeer

Joined: 13 Feb 2006

Posts: 214

Location: Bellingham, WA

|

Posted: Fri Feb 19, 2010 8:34 pm Post subject: Re: fuel pressure sender ground Posted: Fri Feb 19, 2010 8:34 pm Post subject: Re: fuel pressure sender ground |

|

|

Thanks A.

I understand your comments about the electrical ground.

As far as the chance of this type of unit mounted in this manner failing, I'd like some clarification. I take it you're saying this type of pressure sender is okay, but not the way it is installed/supported, right?

And the Questair had one 'on some tubing'. Was this rigid tubing or hose? Seems an installation that would fix the 1-lb sender to the engine mount would work, as long as flexible hose goes in and out of it.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Dan |

|

| Back to top |

|

|

rparigoris

Joined: 24 Nov 2009

Posts: 796

|

Posted: Fri Feb 19, 2010 9:15 pm Post subject: fuel pressure sender ground Posted: Fri Feb 19, 2010 9:15 pm Post subject: fuel pressure sender ground |

|

|

Hi Dan"I just got my Steward Warner fuel pressure sender and am wondering what a good way to get a ground lead from it would be."I have a remote oil sender that is attached to a non conductive line on my Rotax 914.One option is to put some sort of spacer that gets tightly squeezed between sender and fitting and attach to that. I have heard of just washers used, thin NPT nuts or you could be an idiot like I am going to be and turn a precision spacer and make it so I get a tight fit. Like Ira said it dosen't have to be a real tight fit on NPT, but I prefer that, but length is critical so you get enough tension and allow NPT to seal. To be a further idiot I am also considering installing a hose clamp on the OD of sender catching another ground to a piece of brass or copper held by clamp.I have other senders with fairly small brass hex. I will install senders leaving first few threads free of Loctite or sealant in hopes it gets a good ground to block, but will also install McMaster Carr small 3/8" wide stainless steel mini hose calmps (like automobile fuel injection fuel line clamps) grabbing a piece of copper or brass and use that as an aux. ground. Stupid, simple and looks very nice as well.Ron Parigoris [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

al38kit

Joined: 13 Jul 2009

Posts: 21

|

Posted: Sat Feb 20, 2010 6:50 am Post subject: Re: fuel pressure sender ground Posted: Sat Feb 20, 2010 6:50 am Post subject: Re: fuel pressure sender ground |

|

|

I think the sender is fine.

Regarding the failure I read about, yes it was on a rigid tube, and I believe the tubing failed...the mode of failure would be similar to what you could expect with a few fittings stacked together and the sender mounted to them.

From what I can see in your photos, using a large Adel clamp around the sender body and a second smaller clamp to the engine mount, mating the two together would be a good way to support the sender...

Then use a steel braided hose to connect the sender to the pressure port.

If there is a two conductor sender available (one with a ground), I'd look into getting one.

The good thing is that as this is a fuel pressure sender, if it fails and the engine is still running, it's just a system abnormal....

If it's an oil pressure sender and it indicates zero, you have a more complex situation.

Hope this helps.

Al

| messydeer wrote: | Thanks A.

I understand your comments about the electrical ground.

As far as the chance of this type of unit mounted in this manner failing, I'd like some clarification. I take it you're saying this type of pressure sender is okay, but not the way it is installed/supported, right?

And the Questair had one 'on some tubing'. Was this rigid tubing or hose? Seems an installation that would fix the 1-lb sender to the engine mount would work, as long as flexible hose goes in and out of it. |

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

messydeer

Joined: 13 Feb 2006

Posts: 214

Location: Bellingham, WA

|

Posted: Sat Feb 20, 2010 8:21 am Post subject: Re: fuel pressure sender ground Posted: Sat Feb 20, 2010 8:21 am Post subject: Re: fuel pressure sender ground |

|

|

Thanks, Al

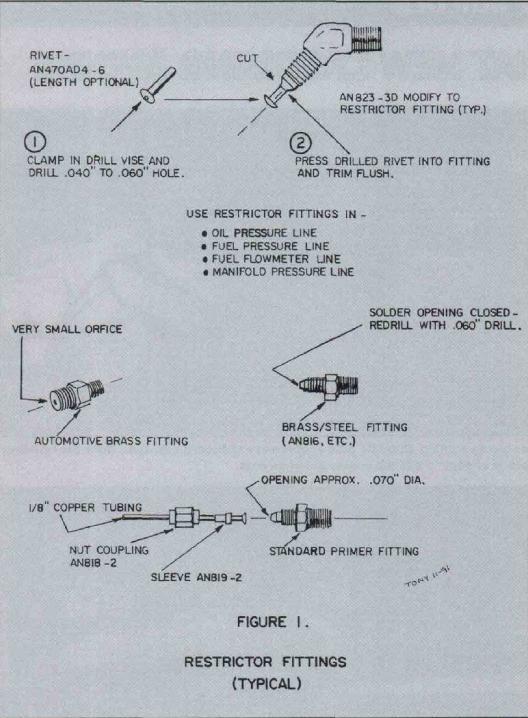

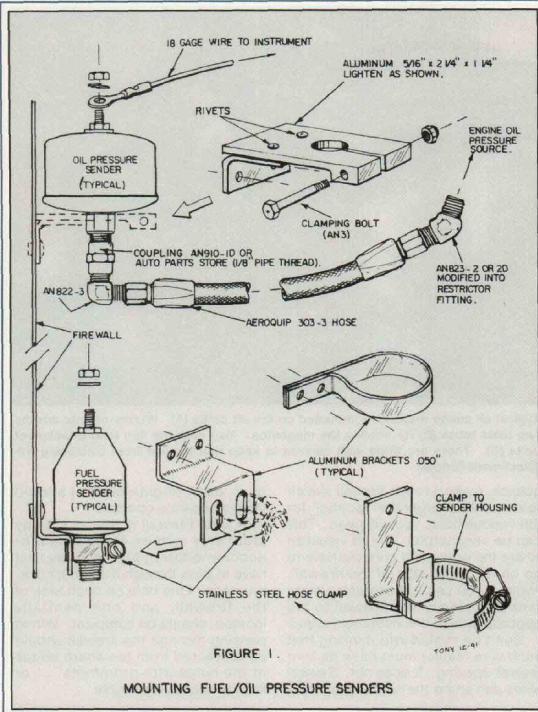

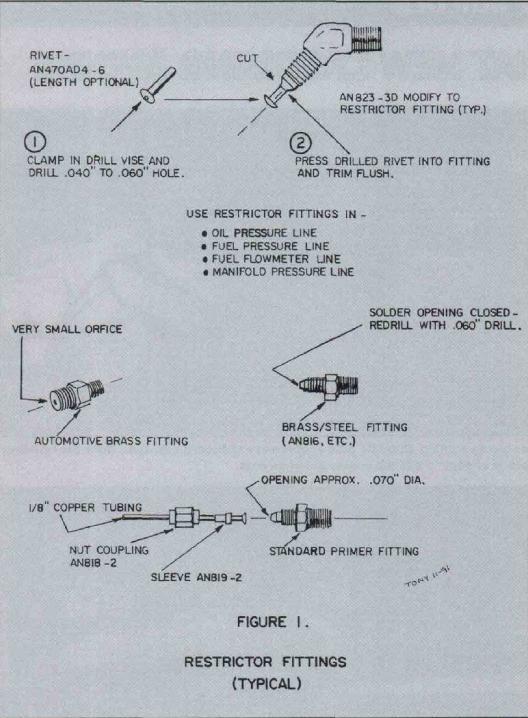

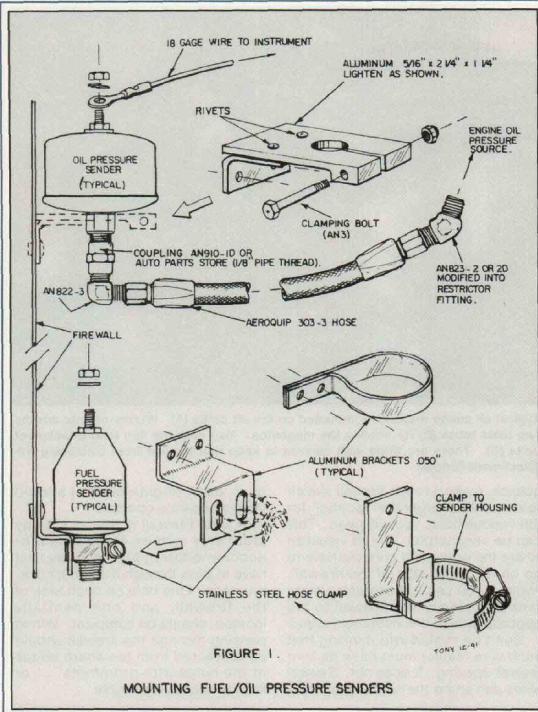

I searched the EAA archives and found a few articles by Tony B. about mounting fuel and oil pressure senders. He also recommends mounting the pressure sender to the firewall instead of the engine mount. That would be just as easy for me, if it's better.

In these articles (Feb and Mar 1992, I think) he also mentioned putting in custom made pressure reducers in both the oil and fuel lines.

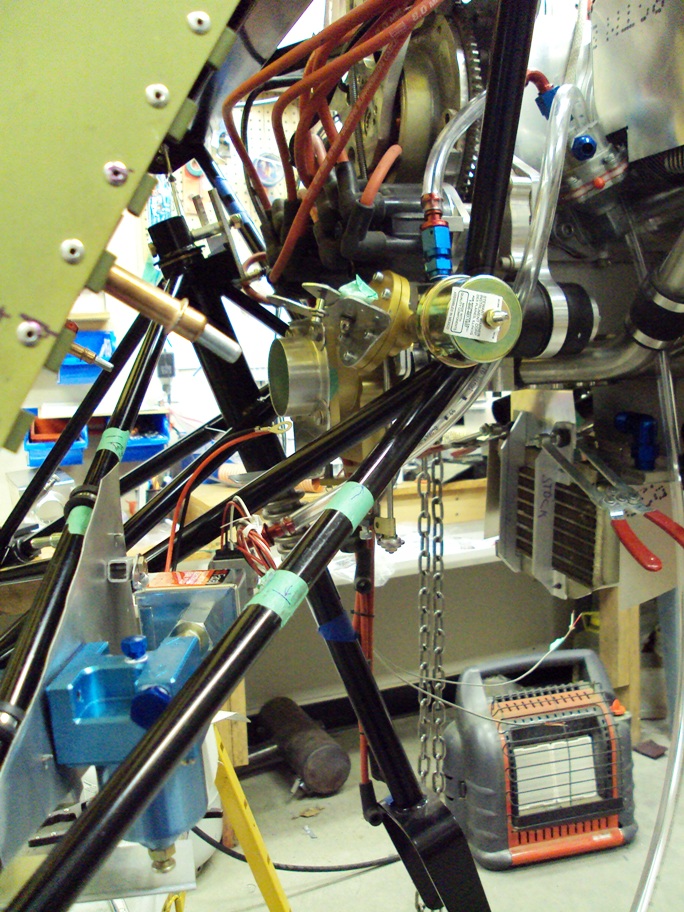

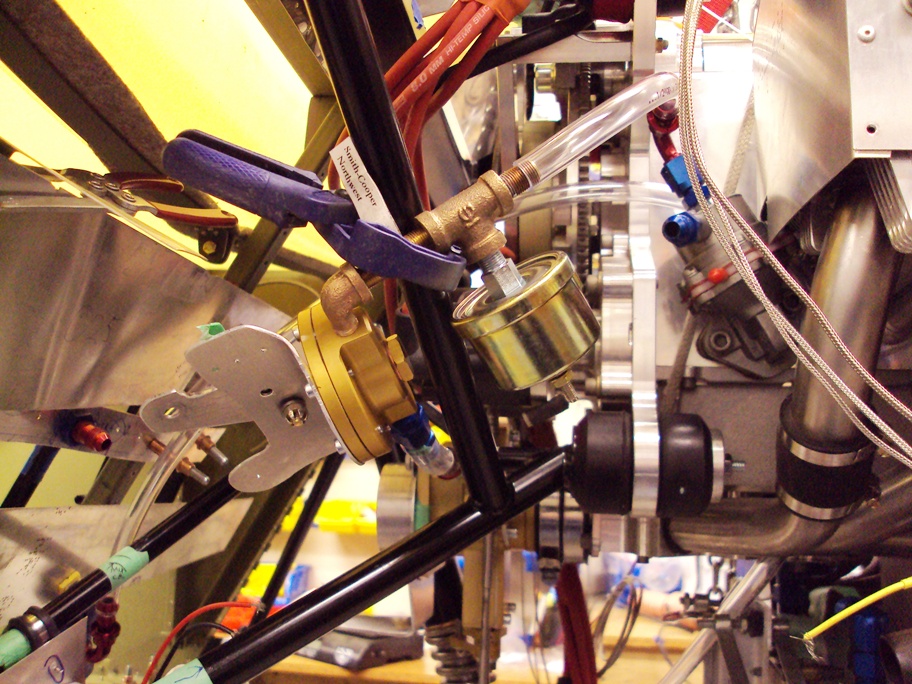

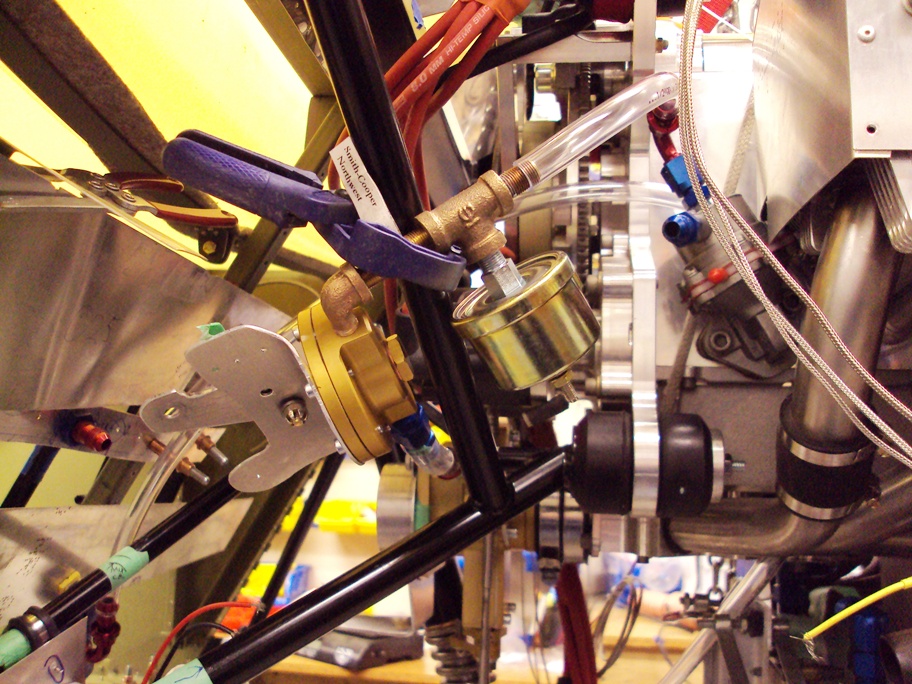

Your critique of the fuel pressure sender support makes me wonder about the support of the fuel regulator itself, the ~3" diameter yellow disc shaped object that the T goes into. The pic in my second post shows the Rotec TBI. It's supposedly nearly identical to the Ellison, but has the fuel regulator housed separately from the main unit. The main unit of the TBI has a male AN6 fitting and both ends of the fuel regulator have 1/8" FNPT ports. I have connected the two together with one aluminum AN-NPT adapter fitting. I was planning on supporting this regulator with the Adel clamps as shown in the pic, between the T fitting and engine mount. Maybe this is also a bad idea.

If so, I could fasten it instead to the engine with a bracket. You can see two cap screws that hold a plate to the engine mount flange, which is about 4-6" away. I could use the lower cap screw hole to secure a bracket made of 1/8" aluminum. It would go straight to the fuel regulator and fasten through on of its own cap screw holes.

The last structural question I have is regarding aluminum vs brass or steel fittings. I'm using aluminum wherever possible. The pics show some brass fittings, but I had planned to replace them with aluminum ones. Would it be better to not use the weaker aluminum for fittings going to the engine?

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

57.32 KB |

| Viewed: |

16378 Time(s) |

|

| Description: |

|

| Filesize: |

44.88 KB |

| Viewed: |

16378 Time(s) |

|

| Description: |

|

| Filesize: |

66.83 KB |

| Viewed: |

16378 Time(s) |

|

_________________

Dan |

|

| Back to top |

|

|

al38kit

Joined: 13 Jul 2009

Posts: 21

|

Posted: Sat Feb 20, 2010 1:37 pm Post subject: Re: fuel pressure sender ground Posted: Sat Feb 20, 2010 1:37 pm Post subject: Re: fuel pressure sender ground |

|

|

I think you're on the right track.

Is the thing that looks like a linkage on the regulator just mounted there to control the TBI, or is there a control on the regulator itself...?

If the regulator can be mounted elsewhere, consider doing that, perhaps on the firewall or the engine mount and then run the fuel line to the TBI via a flexible line. You could mount the transducer to the regulator, maybe directly and forget about any other fittings....You could then run a dedicated ground wire to the screws on the regulator and solve the transducer gounding thing.

Regarding the fittings, if there is a structural necessity I use steel. Putting a little silicone on the PT helps in assembly and may prevent galling the Al...Steel fittings fwd of the FW are a good idea...some will disagree with the added weight, but for the oz or two you save, it is still the fuel system.

Good luck.

Al

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

messydeer

Joined: 13 Feb 2006

Posts: 214

Location: Bellingham, WA

|

Posted: Sat Feb 20, 2010 2:53 pm Post subject: Re: fuel pressure sender ground Posted: Sat Feb 20, 2010 2:53 pm Post subject: Re: fuel pressure sender ground |

|

|

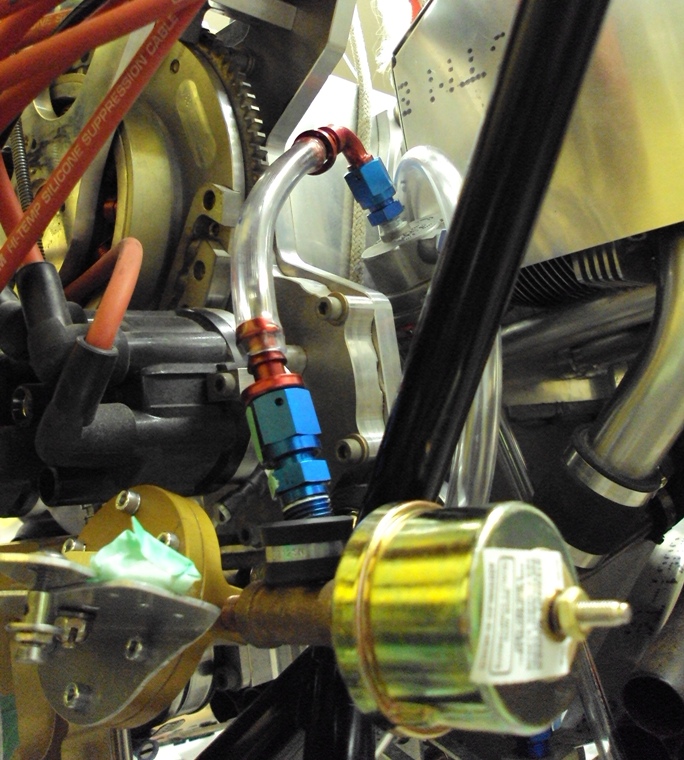

The linkage on the regulator is the primer lever. Pull the cable and it presses down on an a diaphragm override valve allowing fuel to spill into the TBI. So it goes wherever the regulator goes.

In case you or anybody has questions or comments about anything in the setup, the fuel line exits the slanted firewall a few inches above the gascolator, which is ~3" in front of the firewall. Then a hose connects into the back of the gascolator. The gascolator, Facet pump, and flow sensor are mounted to the 3 closest engine mount tubes. Two clips supporting the front of the gasco and the fuel flow sensor are not shown. Two brass 1/8-1/4 NPT reducer nipples connect these 3 components. Hose will exit the fuel flow sensor, then up to the mechanical pump (not connected in the pic).

| Quote: | | if the regulator can be mounted elsewhere, consider doing that, perhaps on the firewall or the engine mount and then run the fuel line to the TBI via a flexible line. You could mount the transducer to the regulator, maybe directly and forget about any other fittings.... |

Funny, I just posted a question about using a hose between the regulator and TBI on the Yahoo Jabiru Group. The regulator can be mounted pretty much anywhere else. Rotec says to keep it within a few inches up or down of the TBI. The further backwards it would go, the more of a head change there'd be in a climb or dive, which I guess would mean having to tweak the mixture. Same thing would happen if it were mounted much higher or lower than the intake. The firewall is ~8" behind the intake.

I don't know if mounting the regulator on the firewall would be the best. I'll get some more info about that. If it can be done, I'd rather mount both the regulator and the pressure sender on the firewall, cuz that would allow me to use a simple hard fitting between the two components. Then there'd be a single hose to the TBI, but it would mean ~16" of extra hose round trip.

From what TB wrote, it sounds he'd not want the pressure sender anywhere but the firewall. But you'd be okay with it on the engine mount, as long as hose connects it and not hard fittings?

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

296.74 KB |

| Viewed: |

16362 Time(s) |

|

_________________

Dan |

|

| Back to top |

|

|

al38kit

Joined: 13 Jul 2009

Posts: 21

|

Posted: Sat Feb 20, 2010 7:07 pm Post subject: Re: fuel pressure sender ground Posted: Sat Feb 20, 2010 7:07 pm Post subject: Re: fuel pressure sender ground |

|

|

I think you'd be fine mounting the regulator and transducer on the engine mount...consider the lower one and maybe you could get by with about a 9" sweeping line to the TB...that way putting a push-pull cable on it would be easy.

Good luck...

Al

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

messydeer

Joined: 13 Feb 2006

Posts: 214

Location: Bellingham, WA

|

Posted: Sat Feb 20, 2010 8:57 pm Post subject: Re: fuel pressure sender ground Posted: Sat Feb 20, 2010 8:57 pm Post subject: Re: fuel pressure sender ground |

|

|

Good to know. I reread the Rotec advice and they said mounting it level or 2" above would be fine, but don't mount it below the intake, if possible. So I think I've got a good spot on the upper tube. The hose between them is about 4-5" and with maybe 10-15 degrees curve.

Now I'll order some more fittings and work on the brackets.

Thanks for all your help, Al

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

301.21 KB |

| Viewed: |

16342 Time(s) |

|

_________________

Dan |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|