|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

mdnanwelch7(at)hotmail.co

Guest

|

Posted: Tue Apr 13, 2010 9:35 am Post subject: copper foil groundplane Posted: Tue Apr 13, 2010 9:35 am Post subject: copper foil groundplane |

|

|

Hi guys,

I've just joined this group and have a couple of questions. I have searched the archives, but finding my particular answers is tough, to say the least.

I'm getting very close to installing the Icom A200 comm antenna in my tube & fabric airplane (Kolb MkIII). I think I've chosen to go underneath the fuselage, between the main gear legs, with the 23" steel rod mast pointing down and rearward.

Here's my first question; is the center solid wire RG58 antenna lead the one that point down and away? In other words, the shielding cable is the lead that I make the groundplane with, right? I also assume they are NOT interchangeable, true?

I can build a decent dipole antenna using a 1/8" welding rod using Dean Scott's design plans. But, the groundplane rod of the dipole would be inside the steel frame fuselage, which isn't good. I would include the Pawsey stub for the balun.

Second question; can I build a 1/2" copper tape "X" groundplane and attach it to the inside of the fabric at the center of the BNC connector. If it's possible to use this style of groundplane with the solid rod antenna, can a guy use 6 legs of the copper foil? Any advantage to more than just the (4) 23" strips?

Thanks for your help!

Mike Welch

PS. Here is the link to Dean Scott's antenna design I would probably be using.

http://forums.matronics.com//files/antenna_design_118.pdf

Hotmail is redefining busy with tools for the New Busy. Get more from your inbox. See how. [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

doug.ilg(at)verizon.net

Guest

|

Posted: Tue Apr 13, 2010 12:04 pm Post subject: copper foil groundplane Posted: Tue Apr 13, 2010 12:04 pm Post subject: copper foil groundplane |

|

|

Mike,

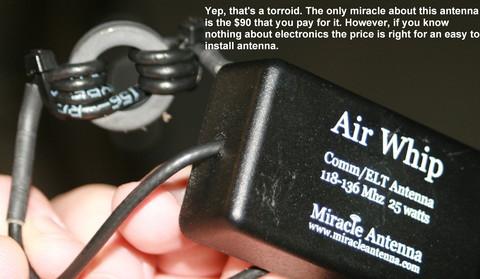

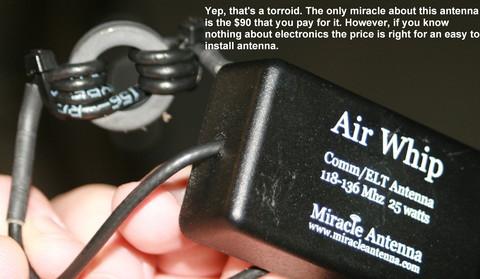

Have you looked at Miracle Antenna's Air Whip? http://www.miracleantenna.com/AirWhip.htm It's a full dipole antenna that's made completely of flexible wire. It's also end-fed, so you don't need access to the middle of the antenna for connection. You can put it anywhere in the fuselage that's not shielded by conductive parts.

I'm not flying yet, but mine seems to work very well on the ground. It fits quite well in the fiberglass nose cone of my Challenger. Based on a quick look at a picture of a Kolb M3X, I'd guess you could do something similar in your airplane. It might save you some of the hassle you're dealing with.

FYI.

-Doug

Doug Ilg

Grumman Tiger N74818, College Park Airport (KCGS), Maryland

Challenger II LSS LW (N641LG reserved) - kit underway at Laurel Suburban (W18)

| Quote: |

From: Mike Welch <mdnanwelch7(at)hotmail.com>

To: aeroelectric-list(at)matronics.com

Sent: Tue, April 13, 2010 1:15:25 PM

Subject: copper foil groundplane

Hi guys,

I've just joined this group and have a couple of questions. I have searched the archives, but finding my particular answers is tough, to say the least.

I'm getting very close to installing the Icom A200 comm antenna in my tube & fabric airplane (Kolb MkIII). I think I've chosen to go underneath the fuselage, between the main gear legs, with the 23" steel rod mast pointing down and rearward.

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

mdnanwelch7(at)hotmail.co

Guest

|

Posted: Tue Apr 13, 2010 1:48 pm Post subject: copper foil groundplane Posted: Tue Apr 13, 2010 1:48 pm Post subject: copper foil groundplane |

|

|

Doug,

No, I hadn't heard of this one. It sounds like this could be the perfect setup. Do you know how the wire is "oriented"? Can you just make a circular loop, or ????

I do like the idea of this antenna, but since I'm between jobs right now, funds are very scarce. Plus, I really wanted to make the antenna for my plane, just for the experience.

Does anyone know of a DIY plan for this type of dipole end-fed com antenna? What is in that little black box? (hopefully not some of that "special smoke" that leaks out when you touch two wrong wires together!!)

If anyone knows of a way to make one these single wire dipole end-fed antennas, I'd sure appreciate a drawing or two.

Thanks again, Doug, for the tip!!

Mike Welch

.ExternalClass DIV {;}

Mike,

Have you looked at Miracle Antenna's Air Whip? http://www.miracleantenna.com/AirWhip.htm It's a full dipole antenna that's made completely of flexible wire. It's also end-fed, so you don't need access to the middle of the antenna for connection. You can put it anywhere in the fuselage that's not shielded by conductive parts.

I'm not flying yet, but mine seems to work very well on the ground. It fits quite well in the fiberglass nose cone of my Challenger. Based on a quick look at a picture of a Kolb M3X, I'd guess you could do something similar in your airplane. It might save you some of the hassle you're dealing with.

FYI.

-Doug

Doug Ilg

Grumman Tiger N74818, College Park Airport (KCGS), Maryland

Challenger II LSS LW (N641LG reserved) - kit underway at Laurel Suburban (W18)

| Quote: |

From: Mike Welch <mdnanwelch7(at)hotmail.com>

To: aeroelectric-list(at)matronics.com

Sent: Tue, April 13, 2010 1:15:25 PM

Subject: copper foil groundplane

.ExternalClass .ecxhmmessage P {padding:0px;} .ExternalClass body.ecxhmmessage {font-size:10pt;font-family:Verdana;} Hi guys,

I've just joined this group and have a couple of questions. I have searched the archives, but finding my particular answers is tough, to say the least.

I'm getting very close to installing the Icom A200 comm antenna in my tube & fabric airplane (Kolb MkIII). I think I've chosen to go underneath the fuselage, between the main gear legs, with the 23" steel rod mast pointing down and rearward.

|

Hotmail is redefining busy with tools for the New Busy. Get more from your inbox. See how. [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue Apr 13, 2010 8:30 pm Post subject: copper foil groundplane Posted: Tue Apr 13, 2010 8:30 pm Post subject: copper foil groundplane |

|

|

At 01:15 PM 4/13/2010, you wrote:

Mike,

Have you looked at Miracle Antenna's Air Whip? http://www.miracleantenna.com/AirWhip.htm It's a full dipole antenna that's made completely of flexible wire. It's also end-fed, so you don't need access to the middle of the antenna for connection. You can put it anywhere in the fuselage that's not shielded by conductive parts.

I'm not flying yet, but mine seems to work very well on the ground. It fits quite well in the fiberglass nose cone of my Challenger. Based on a quick look at a picture of a Kolb M3X, I'd guess you could do something similar in your airplane. It might save you some of the hassle you're dealing with.

The end-fed half-wave antenna has been around

for a long time and is a popular topic of

discussion and debate in the amateur radio

antenna forums. There's a particularly lucid

study of these beasties to be found at:

http://www.aa5tb.com/efha.html

Of course, this article is dealing with the lower

HF frequencies of interest to amateurs but the

physics scales nicely into the higher VHF range.

My sense is that while they can be "tuned" to

accommodate effects of installation, they're not

your grandpa's plug-n-play buggy whip. It's unlikely

that an end-fed half-wave stuck inside the fuselage

of a composite aircraft will be optimized out of the

box for that particular installation.

Having said that, we also know that antenna efficiency

in airplanes can be all over the map and still provide

satisfactory performance. I have no doubt that the

antenna offered has many "satisfied" users.

If the builder is not DIY shy, a few dollars in

materials can be crafted into an quarter-wave

over ground-plane antenna that will certainly

perform as well with more predictable results

for SWR. Getting to the center of a half-wave

dipole isn't hard if you put the center

half way up on the side of the fuselage and

wrap around the inside surface.

Distorting from a straight antenna will have

the effect of electrically lengthening the

antenna so trimming after installation with

some form of SWR instrument would be useful

. . . but probably wouldn't produce observable

differences in performance

[/b]I've just joined this group and have a couple of questions.

I have searched the archives, but finding my particular

answers is tough, to say the least. I'm getting very close to

installing the Icom A200 comm antenna in my tube & fabric

airplane (Kolb MkIII). I think I've chosen to go underneath

the fuselage, between the main gear legs, with the 23" steel

rod mast pointing down and rearward.

That will probably work as well as anything else.

You can ground the feedline shield to the steel-tube

structure.

Bob . . .

[/b]

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

mdnanwelch7(at)hotmail.co

Guest

|

Posted: Wed Apr 14, 2010 5:14 am Post subject: copper foil groundplane Posted: Wed Apr 14, 2010 5:14 am Post subject: copper foil groundplane |

|

|

Hi Bob,

Thanks for the detailed and informative response. Yes, I am very much a DIY person.

I don't really have the $100 for the Miracle antenna (end-fed halfwave dipole), so I guess I'll have to stick with a homemade one.

So far, I'm still leaning toward the belly mount dipole, and making a spoke style grid of copper foil, where the steel rod mast mounts in the center of the grid. I'll sure to get a good ground of the groundplane to the tube frame.

Does more than four legs of a cu foil groundplane make it better? Or, is that just a waste of copper tape?

I'm curious. After I get this antenna constructed, mounted and finished, how does one check it's adjustment with a SWR meter. I mean, there aren't many things you could do to the mast, except cut off a little. But, what if you cut off too much?

Could you possibly explain the actual nuts and bolts of using an SWR meter, and how it can allow a guy to improve his antenna's performance?

One more thing.... I am also building a GlaStar, and bought the factory copper foil dipole antenna. I noticed it has triax cable, rather than regular RG58. I assume this is because the extra layer of the triax acts as a balun. I meant to check out how the triax connects at the junction of the two copper strips, but forgot, and mounted it in the tail and closed it up.

For fiberglass airplanes that might use this type of "triax cable copper foil dipole", how and where is the triax soldered, if it's soldered at all?

Thanks a lot!!

Mike Welch

The end-fed half-wave antenna has been around

for a long time and is a popular topic of

discussion and debate in the amateur radio

antenna forums. There's a particularly lucid

study of these beasties to be found at:

http://www.aa5tb.com/efha.html

Of course, this article is dealing with the lower

HF frequencies of interest to amateurs but the

physics scales nicely into the higher VHF range.

My sense is that while they can be "tuned" to

accommodate effects of installation, they're not

your grandpa's plug-n-play buggy whip. It's unlikely

that an end-fed half-wave stuck inside the fuselage

of a composite aircraft will be optimized out of the

box for that particular installation.

Having said that, we also know that antenna efficiency

in airplanes can be all over the map and still provide

satisfactory performance. I have no doubt that the

antenna offered has many "satisfied" users.

If the builder is not DIY shy, a few dollars in

materials can be crafted into an quarter-wave

over ground-plane antenna that will certainly

perform as well with more predictable results

for SWR. Getting to the center of a half-wave

dipole isn't hard if you put the center

half way up on the side of the fuselage and

wrap around the inside surface.

Distorting from a straight antenna will have

the effect of electrically lengthening the

antenna so trimming after installation with

some form of SWR instrument would be useful

. . . but probably wouldn't produce observable

differences in performance

[/b]I've just joined this group and have a couple of questions.

I have searched the archives, but finding my particular

answers is tough, to say the least. I'm getting very close to

installing the Icom A200 comm antenna in my tube & fabric

airplane (Kolb MkIII). I think I've chosen to go underneath

the fuselage, between the main gear legs, with the 23" steel

rod mast pointing down and rearward.

That will probably work as well as anything else.

You can ground the feedline shield to the steel-tube

structure.

Bob . . .

[/b]

| Quote: |

-List">http://www.matronics.com/Navigator?AeroElectric-List

ronics.com

ww.matronics.com/contribution

|

The New Busy think 9 to 5 is a cute idea. Combine multiple calendars with Hotmail. Get busy. [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

N20DG

Joined: 02 Jan 2008

Posts: 61

Location: lancaster, texas

|

Posted: Wed Apr 14, 2010 6:26 am Post subject: copper foil groundplane Posted: Wed Apr 14, 2010 6:26 am Post subject: copper foil groundplane |

|

|

Check this out

http://rst-engr.com/rst/catalog/airplane_antenna.html

Dick

In a message dated 4/14/2010 8:16:26 A.M. Central Daylight Time, mdnanwelch7(at)hotmail.com writes:

| Quote: | Hi Bob,

Thanks for the detailed and informative response. Yes, I am very much a DIY person.

I don't really have the $100 for the Miracle antenna (end-fed halfwave dipole), so I guess I'll have to stick with a homemade one.

So far, I'm still leaning toward the belly mount dipole, and making a spoke style grid of copper foil, where the steel rod mast mounts in the center of the grid. I'll sure to get a good ground of the groundplane to the tube frame.

Does more than four legs of a cu foil groundplane make it better? Or, is that just a waste of copper tape?

I'm curious. After I get this antenna constructed, mounted and finished, how does one check it's adjustment with a SWR meter. I mean, there aren't many things you could do to the mast, except cut off a little. But, what if you cut off too much?

Could you possibly explain the actual nuts and bolts of using an SWR meter, and how it can allow a guy to improve his antenna's performance?

One more thing.... I am also building a GlaStar, and bought the factory copper foil dipole antenna. I noticed it has triax cable, rather than regular RG58. I assume this is because the extra layer of the triax acts as a balun. I meant to check out how the triax connects at the junction of the two copper strips, but forgot, and mounted it in the tail and closed it up.

For fiberglass airplanes that might use this type of "triax cable copper foil dipole", how and where is the triax soldered, if it's soldered at all?

Thanks a lot!!

Mike Welch

The end-fed half-wave antenna has been around

for a long time and is a popular topic of

discussion and debate in the amateur radio

antenna forums. There's a particularly lucid

study of these beasties to be found at:

http://www.aa5tb.com/efha.html

Of course, this article is dealing with the lower

HF frequencies of interest to amateurs but the

physics scales nicely into the higher VHF range.

My sense is that while they can be "tuned" to

accommodate effects of installation, they're not

your grandpa's plug-n-play buggy whip. It's unlikely

that an end-fed half-wave stuck inside the fuselage

of a composite aircraft will be optimized out of the

box for that particular installation.

Having said that, we also know that antenna efficiency

in airplanes can be all over the map and still provide

satisfactory performance. I have no doubt that the

antenna offered has many "satisfied" users.

If the builder is not DIY shy, a few dollars in

materials can be crafted into an quarter-wave

over ground-plane antenna that will certainly

perform as well with more predictable results

for SWR. Getting to the center of a half-wave

dipole isn't hard if you put the center

half way up on the side of the fuselage and

wrap around the inside surface.

Distorting from a straight antenna will have

the effect of electrically lengthening the

antenna so trimming after installation with

some form of SWR instrument would be useful

. . . but probably wouldn't produce observable

differences in performance

[/b]I've just joined this group and have a couple of questions.

I have searched the archives, but finding my particular

answers is tough, to say the least. I'm getting very close to

installing the Icom A200 comm antenna in my tube & fabric

airplane (Kolb MkIII). I think I've chosen to go underneath

the fuselage, between the main gear legs, with the 23" steel

rod mast pointing down and rearward.

That will probably work as well as anything else.

You can ground the feedline shield to the steel-tube

structure.

Bob . . .

[/b]

| Quote: |

-List">http://www.matronics.com/Navigator?AeroElectric-List

ronics.com

ww.matronics.com/contribution

|

The New Busy think 9 to 5 is a cute idea. Combine multiple calendars with Hotmail. Get busy. | Quote: |

====================================

List href="http://www.matronics.com/Navigator?AeroElectric-List">http://www.matronics.com/Navigator?AeroElectric-List

====================================

ms.matronics.com/">http://forums.matronics.com

====================================

tp://www.matronics.com/contribution">http://www.matronics.com/contribution

====================================

|

|

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

mdnanwelch7(at)hotmail.co

Guest

|

Posted: Wed Apr 14, 2010 7:35 am Post subject: copper foil groundplane Posted: Wed Apr 14, 2010 7:35 am Post subject: copper foil groundplane |

|

|

Dick,

I'm very familiar with Bob Weir's stuff, and in fact, I built one of these copper foil antennas a few years ago. I haven't installed it yet. If I can find it, I think I'm going to go ahead and use it.

I built the mast out of fiberglass, with the copper foil sandwiched inside it. The mast is then soldered to a BNC connector, and faired in with more fiberglass. Finally, I sanded everything nice and smooth, and painted it grey.

Thanks for the reference, tho.

Mike Welch

From: RGent1224(at)aol.com

Date: Wed, 14 Apr 2010 10:19:48 -0400

Subject: Re: RE: copper foil groundplane

To: aeroelectric-list(at)matronics.com

Check this out

http://rst-engr.com/rst/catalog/airplane_antenna.html

Dick

In a message dated 4/14/2010 8:16:26 A.M. Central Daylight Time, mdnanwelch7(at)hotmail.com writes:

| Quote: | Hi Bob,

Thanks for the detailed and informative response. Yes, I am very much a DIY person.

I don't really have the $100 for the Miracle antenna (end-fed halfwave dipole), so I guess I'll have to stick with a homemade one.

So far, I'm still leaning toward the belly mount dipole, and making a spoke style grid of copper foil, where the steel rod mast mounts in the center of the grid. I'll sure to get a good ground of the groundplane to the tube frame.

Does more than four legs of a cu foil groundplane make it better? Or, is that just a waste of copper tape?

I'm curious. After I get this antenna constructed, mounted and finished, how does one check it's adjustment with a SWR meter. I mean, there aren't many things you could do to the mast, except cut off a little. But, what if you cut off too much?

Could you possibly explain the actual nuts and bolts of using an SWR meter, and how it can allow a guy to improve his antenna's performance?

One more thing.... I am also building a GlaStar, and bought the factory copper foil dipole antenna. I noticed it has triax cable, rather than regular RG58. I assume this is because the extra layer of the triax acts as a balun. I meant to check out how the triax connects at the junction of the two copper strips, but forgot, and mounted it in the tail and closed it up.

For fiberglass airplanes that might use this type of "triax cable copper foil dipole", how and where is the triax soldered, if it's soldered at all?

Thanks a lot!!

Mike Welch

The end-fed half-wave antenna has been around

for a long time and is a popular topic of

discussion and debate in the amateur radio

antenna forums. There's a particularly lucid

study of these beasties to be found at:

http://www.aa5tb.com/efha.html

Of course, this article is dealing with the lower

HF frequencies of interest to amateurs but the

physics scales nicely into the higher VHF range.

My sense is that while they can be "tuned" to

accommodate effects of installation, they're not

your grandpa's plug-n-play buggy whip. It's unlikely

that an end-fed half-wave stuck inside the fuselage

of a composite aircraft will be optimized out of the

box for that particular installation.

Having said that, we also know that antenna efficiency

in airplanes can be all over the map and still provide

satisfactory performance. I have no doubt that the

antenna offered has many "satisfied" users.

If the builder is not DIY shy, a few dollars in

materials can be crafted into an quarter-wave

over ground-plane antenna that will certainly

perform as well with more predictable results

for SWR. Getting to the center of a half-wave

dipole isn't hard if you put the center

half way up on the side of the fuselage and

wrap around the inside surface.

Distorting from a straight antenna will have

the effect of electrically lengthening the

antenna so trimming after installation with

some form of SWR instrument would be useful

. . . but probably wouldn't produce observable

differences in performance

[/b]I've just joined this group and have a couple of questions.

I have searched the archives, but finding my particular

answers is tough, to say the least. I'm getting very close to

installing the Icom A200 comm antenna in my tube & fabric

airplane (Kolb MkIII). I think I've chosen to go underneath

the fuselage, between the main gear legs, with the 23" steel

rod mast pointing down and rearward.

That will probably work as well as anything else.

You can ground the feedline shield to the steel-tube

structure.

Bob . . .

[/b]

| Quote: |

-List">http://www.matronics.com/Navigator?AeroElectric-List

ronics.com

ww.matronics.com/contribution

|

The New Busy think 9 to 5 is a cute idea. Combine multiple calendars with Hotmail. Get busy. |

| Quote: |

-List">http://www.matronics.com/Navigator?AeroElectric-List

ronics.com

ww.matronics.com/contribution

|

The New Busy think 9 to 5 is a cute idea. Combine multiple calendars with Hotmail. Get busy. [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Apr 14, 2010 7:48 am Post subject: copper foil groundplane Posted: Wed Apr 14, 2010 7:48 am Post subject: copper foil groundplane |

|

|

At 08:12 AM 4/14/2010, you wrote:

Hi Bob,

Thanks for the detailed and informative response. Yes, I am very

much a DIY person. I don't really have the $100 for the Miracle

antenna (end-fed halfwave dipole), so I guess I'll have to stick with

a homemade one.

I've had an antenna building article on my to-do list

for years. Unfortunately that list is long and the

antenna project is pretty far down. Suggest you start

with a manufactured "mount" like . . . .

http://tinyurl.com/y3a4lpf

This is an example of MANY similar products which

you can find at about any truck-stop on a major highway.

You can install the mating PL-259 coax connector

on your coax -OR- install a SO Male to BNC female

adapter to mate with your own installed BNC cable

male -OR- consider this pre-mfg assembly from

Radio Shack . . .

http://tinyurl.com/y7dzxpf

It has a PL-259 on one end that will mate with

your "truckers antenna mount". You can cut the

connector off the other end and install a cable

male to mate with your transceiver.

So far, I'm still leaning toward the belly mount dipole,

"dipole" or "vertical 1/4-wave"?

and making a spoke style grid of copper foil, where the steel rod

mast mounts in the center of the grid. I'll sure to get a good ground

of the groundplane to the tube frame. Does more than four legs of

a cu foil groundplane make it better? Or, is that just a waste of

copper tape?

Tests have shown that there's a diminishing return

on investment for adding radials to the ground plane.

To make a significant improvement one needs to double

the radials. The step from 4 is up to 8 . . . you can

see where that's taking us.

You'll need some sort of structural bracket

that grips a tube and supplies a suitable

flat against the inside surface of the fabric

for attaching the antenna. This bracket also be

suitable for grounding the coax shield to the

airframe. Getting robust connection to a ground

plane attached inside a fabric 'skin' is problematic.

The ship's existing metallic structure is a

reasonable substitute for the classic "spider

legs" ground plane.

I'm curious. After I get this antenna constructed, mounted and finished,

how does one check it's adjustment with a SWR meter. I mean, there

aren't many things you could do to the mast, except cut off a little.

Correct. If you were going to "go for the gold",

you'd make it extra long by about an inch and

then trim to length for best SWR at the selected

center frequency. The theroetical 1/4-wave centered

in the VHF comm band (129.5 Mhz) is 23.34 inches.

If you cut it to 22.34 inches the antenna is

calculated to center on 132.14 Mhz. So the

"tuning sensitivity" for this antenna is on the

order of 2.6 Mhz per inch of length. So trimming

say .1" at a time would let you "sneak up on it".

Alternatively, you can calculate a new length based

on measured center frequency using the 2.6"/MHz

sensitivity factor.

Now that we've fine tuned the theory, know also

that there are other factors that influence the

resonant frequency. An important one is a correction

for length/diameter ratio. I speak to this effect

in figure 13-6 of the 'Connection. If your antenna

rod is .125" diam stainless and is about 23" long,

then the l/d ratio is about 160. This translates

to an electrical "lengthening" of about 3.5% or

.81 inches. Gee, this translates to about 2 Mhz

shift in center frequency.

Further, bending your antenna aft for a rakish

appearance (or better ground clearance) has a

further lengthening effect. All this calculator

key-punching goes to demonstrate that the ideal

antenna is trimmed to length after installation

using some form of instrumentation.

Return on investment? The guy listening to your

transmitted signal wouldn't know the difference

between the "ideal" and "pretty close" antenna.

Further, DIRECTIONAL effects of airframe geometry

can have a PROFOUND effect on the very best of

antennas. This effect is discussed in the BALUN

construction article cited below.

Bottom line: 22" for a 1/4-wave stick is close

enough for government work. An SWR test at the

transceiver end of the feed line is most useful

as a gross check of antenna integrity. Check SWR

at say 1 Mhz steps from 118.0 to 135.0 and plot the

results. The "dip" in the plot shows the center

frequency of the antenna. The SWR shouldn't be

more than 3.0:1 over the full range of interest.

An antenna with a broken connection along the feed

line will have very high SWR numbers and probably

exhibit no clear "dip" in the plot.

But, what if you cut off too much?

That IS a problem only if you're pedantic about

getting the antenna performance centered on

129.5000000000 Mhz. If you "overshoot" a trimming

operation and the durn thing now centers at 131

Mhz, no big deal.

Could you possibly explain the actual nuts and bolts of using

an SWR meter, and how it can allow a guy to improve his antenna's

performance?

It's pretty simple. Use your ship's transmitter

as a signal source and plot measured SWR against

transmit frequency. When you're all done, the

SWR will be LOWEST at the design center. SWR

should not be more than 3:1 at the edges of

the band.

One more thing.... I am also building a GlaStar, and bought the

factory copper foil dipole antenna. I noticed it has triax cable,

rather than regular RG58. I assume this is because the extra layer

of the triax acts as a balun. I meant to check out how the triax

connects at the junction of the two copper strips, but forgot, and

mounted it in the tail and closed it up.

For fiberglass airplanes that might use this type of "triax cable

copper foil dipole", how and where is the triax soldered, if it's

soldered at all?

I've heard of this design but never had the opportunity

to run it through the lab. It's better than NO balun but

again, ROI is problematic. The outer shield could be

used two ways: Soldered to the inner shield 1/4-wave from

the antenna end only. This makes it a "bazooka" decoupling

sleeve.

http://tinyurl.com/y6xgese

Alternatively, it can solder to the inner shield 1/4-wave

away from the antenna as above. The other end of outer

shield solders to the center conductor at the antenna

end. This makes it a piece of transmission line. This

type of balun is easily synthesized without the use

of triaxial coax as shown here:

http://tinyurl.com/yytxwd3

I wouldn't discourage anyone from going for the best-

we-know-how-to-do in selection/fabrication, installation

and testing of antennas on the airplane. At the same

time, know that "missing the mark" by some small amount

is probably not a reason for ripping it out and starting

over.

Bob . . .

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

n81jg(at)aol.com

Guest

|

Posted: Wed Apr 14, 2010 10:02 am Post subject: copper foil groundplane Posted: Wed Apr 14, 2010 10:02 am Post subject: copper foil groundplane |

|

|

Check out Slim Jim and J-pole antennas on Google. They are end fed dipoles.

John Greaves

VariEze N81JG

Redding, CA

--

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

longg(at)pjm.com

Guest

|

Posted: Wed Apr 14, 2010 10:44 am Post subject: copper foil groundplane Posted: Wed Apr 14, 2010 10:44 am Post subject: copper foil groundplane |

|

|

Found this. Just put in the freq and it tells you how long to make it.

Does that mean the length we're shooting for is the middle of the band?

http://www.m0ukd.com/Calculators/Slim_Jim/index.php

Glenn

--

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

checkn6

Joined: 20 Feb 2010

Posts: 14

|

Posted: Wed Apr 14, 2010 1:32 pm Post subject: Re: copper foil groundplane Posted: Wed Apr 14, 2010 1:32 pm Post subject: Re: copper foil groundplane |

|

|

Inside the magic box

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

53.02 KB |

| Viewed: |

10972 Time(s) |

|

|

|

| Back to top |

|

|

longg(at)pjm.com

Guest

|

Posted: Thu Apr 15, 2010 5:56 am Post subject: copper foil groundplane Posted: Thu Apr 15, 2010 5:56 am Post subject: copper foil groundplane |

|

|

Thanks,

Actually I'd pay $90 just for the packaging. I've now seen some of the

homemade jobs and while I've not clue on how to build antennas, I have

less of clue how any of these folks got their inventions in the

airplane. Copper strips, pipe, soldering, 3 ft tall, etc. etc. I have a

Lancair not a Suburban.

$90.00 is a no brainer. Thanks for the reference.

Do Not Archive.

Glenn

--

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|