|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

rickofudall

Joined: 19 Sep 2009

Posts: 1392

Location: Udall, KS, USA

|

Posted: Tue Nov 30, 2010 11:50 am Post subject: Construction Posted: Tue Nov 30, 2010 11:50 am Post subject: Construction |

|

|

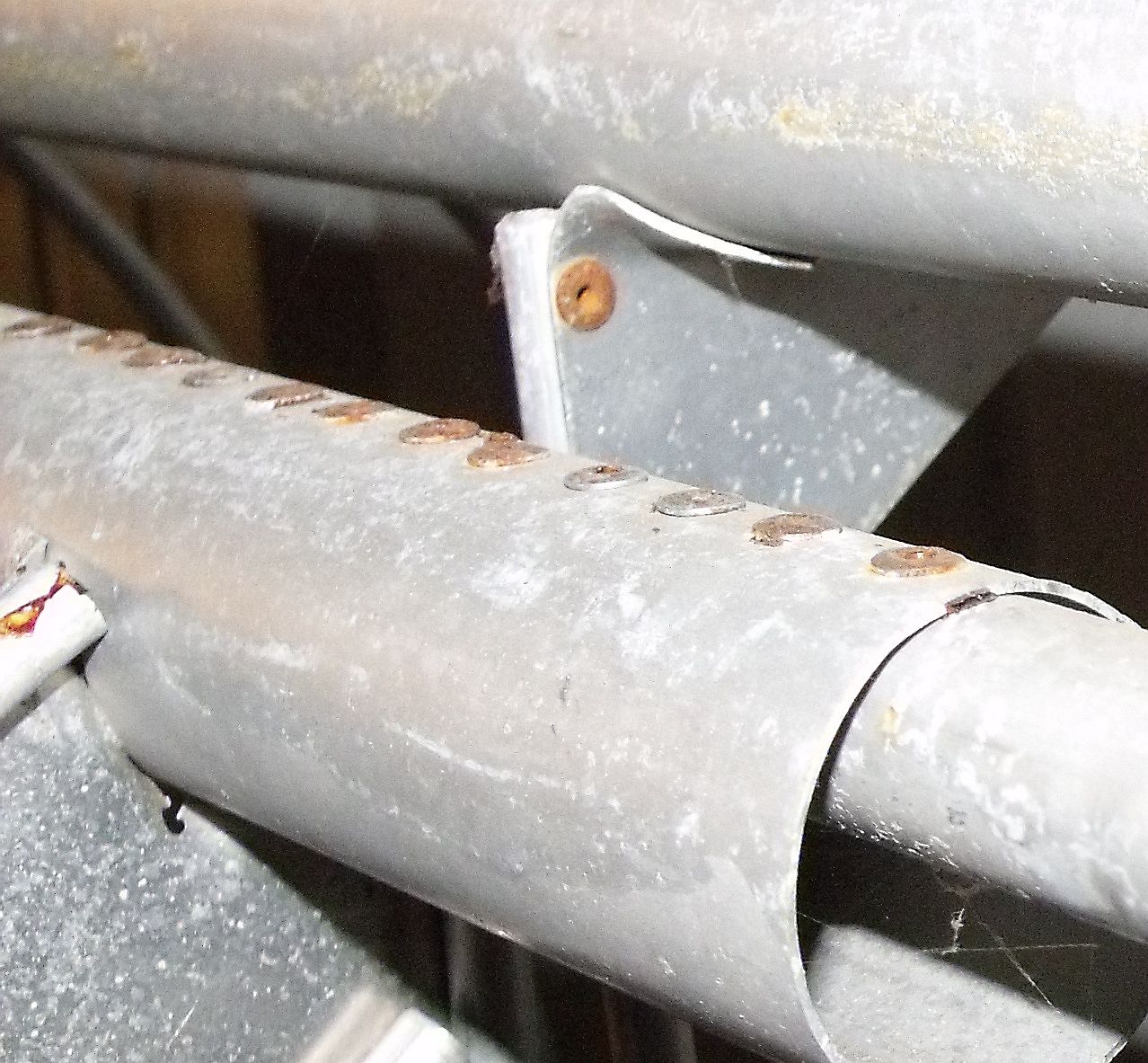

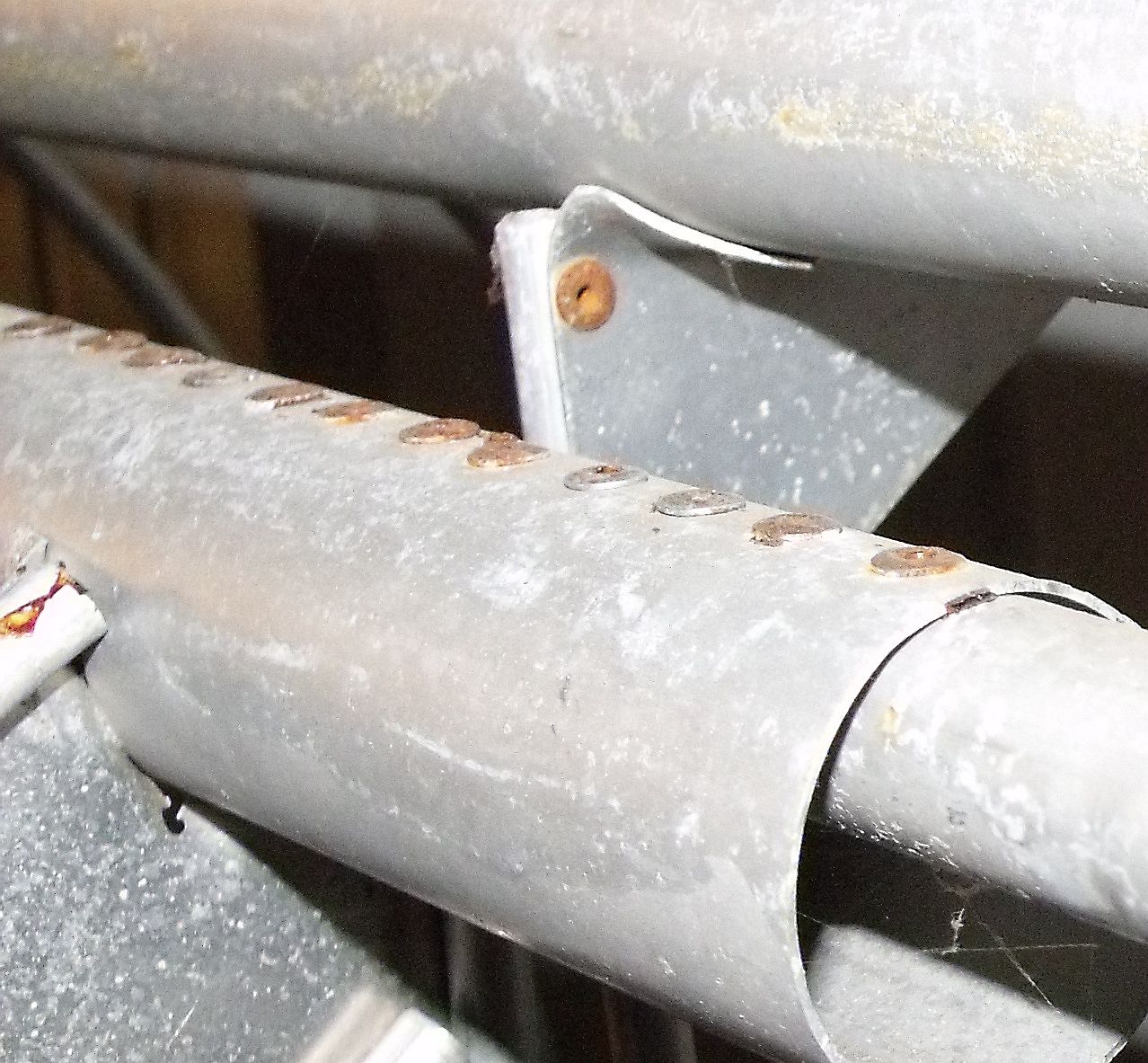

I realize that each Kolb built it the builder's experiment and you have the right to do as you wish, but you might want to consider this. The two things missing in the construction videos are: 1) No sign of any sort of corrosion protection on all that bare aluminum, and 2) no drain grommets or any way for water to get out of the covering. I know there will be comments from those who've never seen corrosion, or who don't believe in it, but the pictures show what condensation inside the wing of a 15 year old Firestar did to the aluminum. As Poor Richard said, "an ounce of prevention is worth a pound of cure".

If you think alodining new aluminum and painting with epoxy before covering is a PITA, add hours and hours of drilling out rivets, sanding and inspecting with a magnifying glass to the point of eyestrain, THEN acid etching, alodining, painting and reassembling for which you get more pains than just those in the posterior.

I didn't invent this, it's all right there in the Poly Fiber manual, so do as you think best.

Rick Girard

--

Zulu Delta

Kolb Mk IIIC

582 Gray head

4.00 C gearbox

3 blade WD

Thanks, Homer GBYM

It is not bigotry to be certain we are right; but it is bigotry to be unable to imagine how we might possibly have gone wrong.

- G.K. Chesterton

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

| Description: |

|

| Filesize: |

218.45 KB |

| Viewed: |

5613 Time(s) |

|

| Description: |

|

| Filesize: |

256.68 KB |

| Viewed: |

5613 Time(s) |

|

_________________

The smallest miracle right in front of you is enough to make you happy.... |

|

| Back to top |

|

|

Ralph B

Joined: 14 Apr 2007

Posts: 367

Location: Mound Minnesota

|

Posted: Tue Nov 30, 2010 12:16 pm Post subject: Re: Construction Posted: Tue Nov 30, 2010 12:16 pm Post subject: Re: Construction |

|

|

Rick, was this Firestar stored in a trailer?

I've heard that corrosion like this can happen

when the aircraft is stored in a trailer. I have

a 24-year-old Firestar and I'm sure there isn't

any corrosion on it and I store it in a garage. I

don't have any drain holes in the wing and I fly

during the winter and sometimes get salt on the

outside of the plane trailering it on those salted

Minnesota roads.

Ralph B

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

Ralph B

Kolb Kolbra 912uls

N20386

550 hours |

|

| Back to top |

|

|

rickofudall

Joined: 19 Sep 2009

Posts: 1392

Location: Udall, KS, USA

|

Posted: Tue Nov 30, 2010 12:58 pm Post subject: Construction Posted: Tue Nov 30, 2010 12:58 pm Post subject: Construction |

|

|

Ralph, I've only owned it for four years so I can't say. The fellow I bought it from had it stored in a workshop when I picked it up.

Rick

On Tue, Nov 30, 2010 at 2:16 PM, Ralph B <rstar447(at)gmail.com (rstar447(at)gmail.com)> wrote:

| Quote: | --> Kolb-List message posted by: "Ralph B" <rstar447(at)gmail.com (rstar447(at)gmail.com)>

Rick, was this Firestar stored in a trailer? I've heard that corrosion like this can happen when the aircraft is stored in a trailer. I have a 24 year old Firestar and I'm sure there isn't any corrosion on it and I store it in a garage.

Ralph B

--------

Ralph B

Original Firestar 447

N91493 E-AB

1000 hours

23 years flying it

Kolbra 912UL

N20386

2 years flying it

120 hrs

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=321829#321829

===========

="_blank">www.aeroelectric.com

ooks.com" target="_blank">www.buildersbooks.com

et="_blank">www.homebuilthelp.com

="_blank">http://www.matronics.com/contribution

le, List Admin.

===========

arget="_blank">http://www.matronics.com/Navigator?Kolb-List

===========

http://forums.matronics.com

===========

|

--

Zulu Delta

Kolb Mk IIIC

582 Gray head

4.00 C gearbox

3 blade WD

Thanks, Homer GBYM

It is not bigotry to be certain we are right; but it is bigotry to be unable to imagine how we might possibly have gone wrong.

- G.K. Chesterton

[quote][b]

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

The smallest miracle right in front of you is enough to make you happy.... |

|

| Back to top |

|

|

slyck(at)frontiernet.net

Guest

|

Posted: Tue Nov 30, 2010 1:55 pm Post subject: Construction Posted: Tue Nov 30, 2010 1:55 pm Post subject: Construction |

|

|

The climate you have it in has a lot to do with it. I doubt owners in northern VT have a lot of corrosion problems.Dry in the summer and zero corrosion in the bitter cold due to retarded chemical activity.

Personally I'm happy my wings have no access holes. there are no moving parts to inspect and no problems with

bees, mice, chipmunks and hickory nuts within.

The fuselage is in the basement for now but I am planning on a varmint free steel barn within the next two years.

BB

On 30, Nov 2010, at 3:54 PM, Richard Girard wrote:

[quote]Ralph, I've only owned it for four years so I can't say. The fellow I bought it from had it stored in a workshop when I picked it up.

Rick

On Tue, Nov 30, 2010 at 2:16 PM, Ralph B <rstar447(at)gmail.com (rstar447(at)gmail.com)> wrote:

| Quote: | --> Kolb-List message posted by: "Ralph B" <rstar447(at)gmail.com (rstar447(at)gmail.com)>

Rick, was this Firestar stored in a trailer? I've heard that corrosion like this can happen when the aircraft is stored in a trailer. I have a 24 year old Firestar and I'm sure there isn't any corrosion on it and I store it in a garage.

Ralph B

--------

Ralph B

Original Firestar 447

N91493 E-AB

1000 hours

23 years flying it

Kolbra 912UL

N20386

2 years flying it

120 hrs

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=321829#321829

===========

="_blank">www.aeroelectric.com

ooks.com" target="_blank">www.buildersbooks.com

et="_blank">www.homebuilthelp.com

="_blank">http://www.matronics.com/contribution

le, List Admin.

===========

arget="_blank">http://www.matronics.com/Navigator?Kolb-List

===========

http://forums.matronics.com

===========

|

--

Zulu Delta

Kolb Mk IIIC

582 Gray head

4.00 C gearbox

3 blade WD

Thanks, Homer GBYM

It is not bigotry to be certain we are right; but it is bigotry to be unable to imagine how we might possibly have gone wrong.

- G.K. Chesterton

| Quote: |

href="http://www.aeroelectric.com/">www.aeroelectric.com

href="http://www.buildersbooks.com/">www.buildersbooks.com

href="http://www.homebuilthelp.com/">www.homebuilthelp.com

href="http://www.matronics.com/contribution">http://www.matronics.com/contribution

href="http://www.matronics.com/Navigator?Kolb-List">http://www.matronics.com/Navigator?Kolb-List

href="http://forums.matronics.com/">http://forums.matronics.com

|

[b]

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

Rick Lewis

Joined: 03 Jul 2007

Posts: 122

Location: Kingston, Tn.

|

Posted: Wed Dec 01, 2010 5:41 am Post subject: Re: Construction Posted: Wed Dec 01, 2010 5:41 am Post subject: Re: Construction |

|

|

I absolutely agree with you on this. Every piece of aluminum in my plane has been corrosion proofed with the epoxy paint recommended in the poly fiber manual. Its easy to think everything is alright when you can't see it.

Rick Lewis

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

| Description: |

|

| Filesize: |

265.56 KB |

| Viewed: |

5581 Time(s) |

|

_________________

Rick Lewis

(VW Watercooled Engine) |

|

| Back to top |

|

|

herbgh(at)nctc.com

Guest

|

Posted: Wed Dec 01, 2010 6:00 am Post subject: Construction Posted: Wed Dec 01, 2010 6:00 am Post subject: Construction |

|

|

6061-T6 does not need corrosion protection in most applications..It

has its own oxidized layer that protects over time.. I would only be

concerned if I were flying near salt water...

I rebuilt an Ultrastar that had steel rivets and found everything

to be in good order...20 some odd years later...it had been on floats

at one time.. Herb

At 07:41 AM 12/1/2010, you wrote:

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

rickofudall

Joined: 19 Sep 2009

Posts: 1392

Location: Udall, KS, USA

|

Posted: Wed Dec 01, 2010 7:25 am Post subject: Construction Posted: Wed Dec 01, 2010 7:25 am Post subject: Construction |

|

|

Herb, No offense, but that's an old wives tale. 6061-T6's silicon alloy base makes it more resistant to corrosion than a copper based alloy like 2024-T3, but it doesn't give any magical powers. All aluminum gets an oxide layer the second it's exposed to oxygen and it does slow corrosion after that, but inside a sealed wing with a condensation cycle every day, unless of course you're Kolb is somewhere near Davis-Monthan AFB, provides all that's necessary for corrosion to continue. My Firestar came from mid Pennsylvania and now it's in Kansas. Not a lot of salt water around here.

Rick

On Wed, Dec 1, 2010 at 7:57 AM, Herb <herbgh(at)nctc.com (herbgh(at)nctc.com)> wrote:

| Quote: | --> Kolb-List message posted by: Herb <herbgh(at)nctc.com (herbgh(at)nctc.com)>

6061-T6 does not need corrosion protection in most applications..It has its own oxidized layer that protects over time.. I would only be concerned if I were flying near salt water...

I rebuilt an Ultrastar that had steel rivets and found everything to be in good order...20 some odd years later...it had been on floats at one time. Herb

At 07:41 AM 12/1/2010, you wrote:

===========

om" target="_blank">www.aeroelectric.com

ooks.com" target="_blank">www.buildersbooks.com

et="_blank">www.homebuilthelp.com

="_blank">http://www.matronics.com/contribution

le, List Admin.

===========

arget="_blank">http://www.matronics.com/Navigator?Kolb-List

===========

http://forums.matronics.com

===========

|

--

Zulu Delta

Kolb Mk IIIC

582 Gray head

4.00 C gearbox

3 blade WD

Thanks, Homer GBYM

It is not bigotry to be certain we are right; but it is bigotry to be unable to imagine how we might possibly have gone wrong.

- G.K. Chesterton

[quote][b]

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

The smallest miracle right in front of you is enough to make you happy.... |

|

| Back to top |

|

|

Dana

Joined: 13 Dec 2007

Posts: 1047

Location: Connecticut, USA

|

Posted: Wed Dec 01, 2010 10:27 am Post subject: Construction Posted: Wed Dec 01, 2010 10:27 am Post subject: Construction |

|

|

At 10:22 AM 12/1/2010, Richard Girard wrote:

| Quote: | Herb, No offense, but that's an old wives tale. 6061-T6's silicon alloy base makes it more resistant to corrosion than a copper based alloy like 2024-T3, but it doesn't give any magical powers. All aluminum gets an oxide layer the second it's exposed to oxygen and it does slow corrosion after that, but inside a sealed wing with a condensation cycle every day, unless of course you're Kolb is somewhere near Davis-Monthan AFB, provides all that's necessary for corrosion to continue.

My Firestar came from mid Pennsylvania and now it's in Kansas. Not a lot of salt water around here. |

Still, that seemed like _really_ bad corrosion! I have what's left of a project that started out as an ultralight in 1980, then a trailer some years later, that's sat outside my house for 23 years, laying on the ground, getting rained on. All 6061 tubing and AN bolts; it's still nowhere near as bad as that.

-Dana

--

Beam me up, Scotty, it ate my phaser. [quote][b]

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

herbgh(at)nctc.com

Guest

|

Posted: Wed Dec 01, 2010 11:44 am Post subject: Construction Posted: Wed Dec 01, 2010 11:44 am Post subject: Construction |

|

|

My other point was that I have rebuilt an Ultrastar and a MkIII ..91 MkIII and an older Us. No Corrosion...Herb

At 09:22 AM 12/1/2010, you wrote:

[quote]Herb, No offense, but that's an old wives tale. 6061-T6's silicon alloy base makes it more resistant to corrosion than a copper based alloy like 2024-T3, but it doesn't give any magical powers. All aluminum gets an oxide layer the second it's exposed to oxygen and it does slow corrosion after that, but inside a sealed wing with a condensation cycle every day, unless of course you're Kolb is somewhere near Davis-Monthan AFB, provides all that's necessary for corrosion to continue.

My Firestar came from mid Pennsylvania and now it's in Kansas. Not a lot of salt water around here.

Rick

On Wed, Dec 1, 2010 at 7:57 AM, Herb <herbgh(at)nctc.com (herbgh(at)nctc.com)> wrote:

--> Kolb-List message posted by: Herb <herbgh(at)nctc.com (herbgh(at)nctc.com)>

6061-T6 does not need corrosion protection in most applications..It has its own oxidized layer that protects over time.. I would only be concerned if I were flying near salt water...

I rebuilt an Ultrastar that had steel rivets and found everything to be in good order...20 some odd years later...it had been on floats at one time.. Herb

At 07:41 AM 12/1/2010, you wrote:

--> Kolb-List message posted by: "Rick Lewis" <cktman(at)hughes.net (cktman(at)hughes.net)>

I absolutely agree with you on this. Every piece of aluminum in my plane has been corrosion proofed with the epoxy paint recommended in the poly fiber manual. Its easy to think everything is alright when you can't see it.

Rick Lewis

--------

Rick Lewis

(VW Watercooled Engine)

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=321906#321906

Attachments:

http://forums.matronics.com//files/pic00005_182.jpg

===========

om" target="_blank">www.aeroelectric.com

ooks.com" target="_blank">www.buildersbooks.com

et="_blank">www.homebuilthelp.com

="_blank">http://www.matronics.com/contribution

le, List Admin.

===========

arget="_blank">http://www.matronics.com/Navigator?Kolb-List

===========

http://forums.matronics.com

===========

--

Zulu Delta

Kolb Mk IIIC

582 Gray head

4.00 C gearbox

3 blade WD

Thanks, Homer GBYM

It is not bigotry to be certain we are right; but it is bigotry to be unable to imagine how we might possibly have gone wrong.

- G.K. Chesterton

[b]

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

Eugene Zimmerman

Joined: 10 Jan 2006

Posts: 392

|

Posted: Wed Dec 01, 2010 12:09 pm Post subject: Construction Posted: Wed Dec 01, 2010 12:09 pm Post subject: Construction |

|

|

Rick,

What is the procedure you used for corrosion proofing the inside of the aluminum tubing used on a Kolb?

Gene

On Dec 1, 2010, at 8:41 AM, Rick Lewis wrote:

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

John Hauck

Joined: 09 Jan 2006

Posts: 4639

Location: Titus, Alabama (hauck's holler)

|

Posted: Wed Dec 01, 2010 1:14 pm Post subject: Construction Posted: Wed Dec 01, 2010 1:14 pm Post subject: Construction |

|

|

What is the procedure you used for corrosion proofing the inside of the

aluminum tubing used on a Kolb?

Gene

Gang:

Back in the old days, Kolb used carbon steel rivets with carbon steel

mandrels. They loved to rust.

I built my Ultrastar with carbon rivets and learned soon how quickly they

developed rust.

When I built my FS, I got Little Mike, Old Kolb Part Man, to get me SS pop

rivets to build the FS Kit. They worked much better, but they still used

carbon steel mandrels. I used to put a blob of Stitts 2 part expoxy on the

heads, but could do nothing with the tails of the rivets. However, this has

never been a problem. I am flying a MKIII I built in 1991, and has been

flying since 1992. That's a lot of hanger time, and a lot of time out under

the stars and rain/dew when I am flying overnight or longer cross country

flights.

I haven't had a problem with corrosion. My understanding was most aircraft

aluminum is "alclad". That is a thin coat of pure aluminum. If you get

aluminum that is not "alclad", it is more prone to corrode.

Based on the photos Rick G sent to the List of his Kolb project he picked up

in PA, I would have left it right where I found it. Never seen anything in

the junk pile out side that looked that bad, except when rodents peed on the

aluminum.

Rodent urine is highly corrosive, and they love Kolbs, especially the

tailboom. Occasionally I shoot some anticorrosion spray into my tailboom to

counteract rodent urine and water that gets in there from condensation, and

also from occasionally washing the airplane.

I am more concerned with the 4130 chromoly tubing. I have used tube seal in

all three Kolbs I have built.

I do have drain holes on wings, ailerons, horizontal stabilizers, elevators,

upper and lower vertical stabilizers, and rudder. Don't know if they do

more harm than good. They let out moisture, but allow dirt/mud daubers to

come inside. I had some corrosion in the trailing edge tube of the left

aileron when I rebuilt it in 2000. Undoubtedly, they have a lot of acid in

their nests and larvae.

john h

mkIII

Titus, Alabama

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

John Hauck

MKIII/912ULS

hauck's holler

Titus, Alabama |

|

| Back to top |

|

|

herbgh(at)nctc.com

Guest

|

Posted: Wed Dec 01, 2010 1:45 pm Post subject: Construction Posted: Wed Dec 01, 2010 1:45 pm Post subject: Construction |

|

|

John

The only alclad aluminum that I know is 2024...It is considered to

be a primary aircraft metal . .the core metal contains a fair amount

of copper..The trick it to lay a pure sheet of aluminum over both

sides of the ingot before it goes down the hot roll mill.. this bonds

a very thin layer to the core metal...

Guys with unpainted GA planes who like to polish will eventually

wear the soft cladding of aluminum through... then it is time to paint...Herb

6061 is a high Maganese/Magnesium alloy...from memory..The outer

surface corrodes into aluminum oxide which is hard and offers

corrosion protection from the normal elements...meaning ,,,no mouse

pee or salt water to name a couple..

At 03:11 PM 12/1/2010, you wrote:

| Quote: |

What is the procedure you used for corrosion proofing the inside of the

aluminum tubing used on a Kolb?

Gene

Gang:

Back in the old days, Kolb used carbon steel rivets with carbon steel

mandrels. They loved to rust.

I built my Ultrastar with carbon rivets and learned soon how quickly they

developed rust.

When I built my FS, I got Little Mike, Old Kolb Part Man, to get me SS pop

rivets to build the FS Kit. They worked much better, but they still used

carbon steel mandrels. I used to put a blob of Stitts 2 part expoxy on the

heads, but could do nothing with the tails of the rivets. However, this has

never been a problem. I am flying a MKIII I built in 1991, and has been

flying since 1992. That's a lot of hanger time, and a lot of time out under

the stars and rain/dew when I am flying overnight or longer cross country

flights.

I haven't had a problem with corrosion. My understanding was most aircraft

aluminum is "alclad". That is a thin coat of pure aluminum. If you get

aluminum that is not "alclad", it is more prone to corrode.

Based on the photos Rick G sent to the List of his Kolb project he picked up

in PA, I would have left it right where I found it. Never seen anything in

the junk pile out side that looked that bad, except when rodents peed on the

aluminum.

Rodent urine is highly corrosive, and they love Kolbs, especially the

tailboom. Occasionally I shoot some anticorrosion spray into my tailboom to

counteract rodent urine and water that gets in there from condensation, and

also from occasionally washing the airplane.

I am more concerned with the 4130 chromoly tubing. I have used tube seal in

all three Kolbs I have built.

I do have drain holes on wings, ailerons, horizontal stabilizers, elevators,

upper and lower vertical stabilizers, and rudder. Don't know if they do

more harm than good. They let out moisture, but allow dirt/mud daubers to

come inside. I had some corrosion in the trailing edge tube of the left

aileron when I rebuilt it in 2000. Undoubtedly, they have a lot of acid in

their nests and larvae.

john h

mkIII

Titus, Alabama

|

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

John Hauck

Joined: 09 Jan 2006

Posts: 4639

Location: Titus, Alabama (hauck's holler)

|

Posted: Wed Dec 01, 2010 1:58 pm Post subject: Construction Posted: Wed Dec 01, 2010 1:58 pm Post subject: Construction |

|

|

The only alclad aluminum that I know is 2024...It is considered to

be a primary aircraft metal . .the core metal contains a fair amount

of copper..The trick it to lay a pure sheet of aluminum over both

sides of the ingot before it goes down the hot roll mill.. this bonds

a very thin layer to the core metal...

Guys with unpainted GA planes who like to polish will eventually

wear the soft cladding of aluminum through... then it is time to

paint...Herb

6061 is a high Maganese/Magnesium alloy...from memory..The outer

surface corrodes into aluminum oxide which is hard and offers

corrosion protection from the normal elements...meaning ,,,no mouse

pee or salt water to name a couple..

Herb/Gang:

Thanks for correcting me. I remember reading about alclad somewhere many

years ago.

I've got old 6061 tubing hanging in the shop that has turned dark and old

looking, but when inspected, it is like surface dirt, extremely thin layer.

I don't hesitate to use this old tubing when necessary.

For items that should not be painted, like aluminum engine mounts on Kolbs

with 912's, I use alodine after giving them a phosphoric acid bath. This

works good. I learned from my first set of aluminum 912 engine mounts that

if primed and painted, where the engine case makes contact with the aluminum

mount, vibration and stress will soon wear away the primer and paint,

leaving four loose engine mount bolts. Of course one could prime and paint

the mounts, but mask off the areas where the engine case makes contact with

the mounts.

john h

mkIII

Titus, Alabama

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

John Hauck

MKIII/912ULS

hauck's holler

Titus, Alabama |

|

| Back to top |

|

|

slyck(at)frontiernet.net

Guest

|

Posted: Wed Dec 01, 2010 2:10 pm Post subject: Construction Posted: Wed Dec 01, 2010 2:10 pm Post subject: Construction |

|

|

Herb, quite right. If you go to buy an old airplane check to see how long it has been painted. Those polished antiques may look dandy

but all they are doing is harm. Better to paint it from the get go or leave the surface to chalk.

Even then I have heard about older airplanes that looked great on the surface but you could push a pencil through the skin. Mostly

the result of intergranular reaction due to dissimilar metals. A friend who refueled Air America gooneys in VN said he had to be careful

to not put a foot through the wing skin.

BB

On 1, Dec 2010, at 4:42 PM, Herb wrote:

| Quote: |

John

The only alclad aluminum that I know is 2024...It is considered to be a primary aircraft metal . .the core metal contains a fair amount of copper..The trick it to lay a pure sheet of aluminum over both sides of the ingot before it goes down the hot roll mill.. this bonds a very thin layer to the core metal...

Guys with unpainted GA planes who like to polish will eventually wear the soft cladding of aluminum through... then it is time to paint...Herb

6061 is a high Maganese/Magnesium alloy...from memory..The outer surface corrodes into aluminum oxide which is hard and offers corrosion protection from the normal elements...meaning ,,,no mouse pee or salt water to name a couple..

At 03:11 PM 12/1/2010, you wrote:

>

>

>

> What is the procedure you used for corrosion proofing the inside of the

> aluminum tubing used on a Kolb?

>

> Gene

>

>

> Gang:

>

> Back in the old days, Kolb used carbon steel rivets with carbon steel

> mandrels. They loved to rust.

>

> I built my Ultrastar with carbon rivets and learned soon how quickly they

> developed rust.

>

> When I built my FS, I got Little Mike, Old Kolb Part Man, to get me SS pop

> rivets to build the FS Kit. They worked much better, but they still used

> carbon steel mandrels. I used to put a blob of Stitts 2 part expoxy on the

> heads, but could do nothing with the tails of the rivets. However, this has

> never been a problem. I am flying a MKIII I built in 1991, and has been

> flying since 1992. That's a lot of hanger time, and a lot of time out under

> the stars and rain/dew when I am flying overnight or longer cross country

> flights.

>

> I haven't had a problem with corrosion. My understanding was most aircraft

> aluminum is "alclad". That is a thin coat of pure aluminum. If you get

> aluminum that is not "alclad", it is more prone to corrode.

>

> Based on the photos Rick G sent to the List of his Kolb project he picked up

> in PA, I would have left it right where I found it. Never seen anything in

> the junk pile out side that looked that bad, except when rodents peed on the

> aluminum.

>

> Rodent urine is highly corrosive, and they love Kolbs, especially the

> tailboom. Occasionally I shoot some anticorrosion spray into my tailboom to

> counteract rodent urine and water that gets in there from condensation, and

> also from occasionally washing the airplane.

>

> I am more concerned with the 4130 chromoly tubing. I have used tube seal in

> all three Kolbs I have built.

>

> I do have drain holes on wings, ailerons, horizontal stabilizers, elevators,

> upper and lower vertical stabilizers, and rudder. Don't know if they do

> more harm than good. They let out moisture, but allow dirt/mud daubers to

> come inside. I had some corrosion in the trailing edge tube of the left

> aileron when I rebuilt it in 2000. Undoubtedly, they have a lot of acid in

> their nests and larvae.

>

> john h

> mkIII

> Titus, Alabama

>

>

>

|

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

flykolb(at)pa.net

Guest

|

Posted: Wed Dec 01, 2010 4:30 pm Post subject: Construction Posted: Wed Dec 01, 2010 4:30 pm Post subject: Construction |

|

|

For those interested in painting the inside of tubes:

Years ago we built a float FS that was intended to be flown on the

Chesapeake where the water is brackish - somewhat salty.

We have always urged strong caution in flying Kolbs on salt water because

there are so many dissimilar metals. John Pitre in HI flew a TS for many

years but he went to great pains to protect and to rinse thoroughly with

fresh water after flying.

Getting back to the FS on the Chesapeake: We made a shallow pan and soaked

the ribs in lacquer thinner and swished it around to remove as much of the

oily coating on - and in - the tubing.

Then we immersed the ribs in a shallow pan of epoxy chromate primer and hung

them up to drip dry. For the spars we cleaned them inside and out with

lacquer thinner and then poured epoxy chromate paint thru them with the ends

capped off with plastic. The spars were then rotated and tilted to get the

inside thoroughly covered.

Then when the wing was assembled we sprayed epoxy chromate paint to paint

all the rivets and any missed areas. The tail surfaces, etc got even better

treatment because the tail typically receives spray from the floats.

I don't know how much of that was necessary, but we thought we were being as

thorough as we could.

I lost track of that FS, so ultimately I do not know how successful or

unsuccessful the preventative measures were.

Dennis

--

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|