|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

nuckolls.bob(at)aeroelect

Guest

|

Posted: Fri Sep 09, 2011 3:19 pm Post subject: Halogen bulbs with wig wag circuitry....failure mode Posted: Fri Sep 09, 2011 3:19 pm Post subject: Halogen bulbs with wig wag circuitry....failure mode |

|

|

I have H7604 lamps in my wing tips that aid landing and traffic

recognition. They are controlled by a solid state switcher that is

either OFF-ON-PULSED. ( I do not know the turn-on ramp characteristics..)

They fail in less than 10 hrs of operation. Interesting both seem to

fail nearly at the same time. The "pulse" mode for traffic

recognition is the major use.

My ignorant guess is that halogen bulbs do not like to be pulsed or

ramped up too quickly during pulse mode. If the rapid power ramp up

is the primary cause, I am wondering if an appropriate choke

(induction) would slow that ramping down and return normal life to

these devices.

If I were to do a WAG . . . I'm guessing that you're

getting repetitive stress cracks in the filaments.

These things operate somewhat hotter than their older

cousins . . . most seem to have heavier filaments too.

There are two things that erode filament integrity . . .

evaporation (total operating hours issue) and stress

cracks (combination of vibration and temperature cycling).

I'm wondering if the halogens are not more highly stressed

during each illumination cycle. Since a wig-wag operates

on the order of 2 flashes per second, 10 hours of flashing

would offer 72,000 or so temperature cycles. Far more cycles

than would be expected in automotive applications. Just

assuming 200 cycles per day in a high-beam lamp for night

highway driving would take 360 straight days of such service

to equal 10 hours of wig-wag.

Any insight, suggestions into the failure mode and how to work around

it would be greatly appreciated.

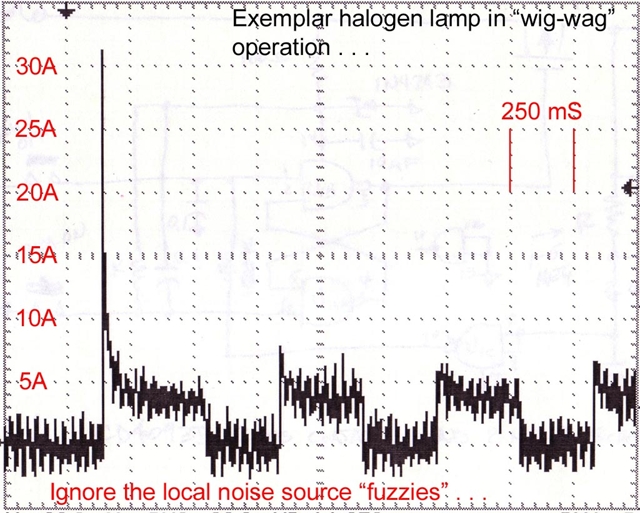

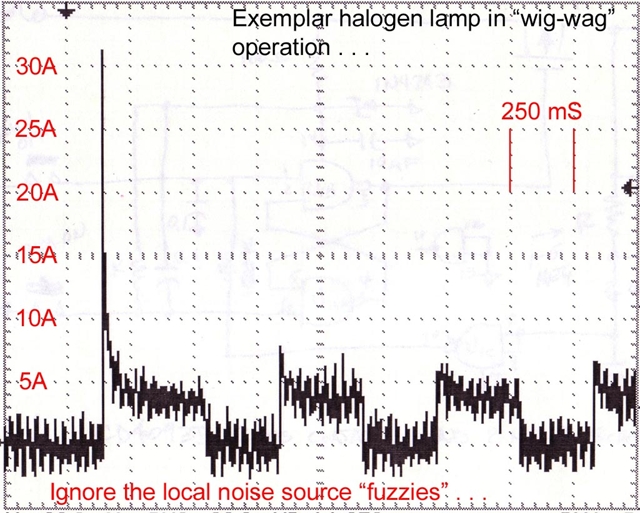

Not sure 'current ramping' would have a very useful effect.

Some of you may recall an experiment we did some years back

to evaluate the usefulness of inrush-limiters in wig-wagged

landing lights. Remember this plot?

http://www.aeroelectric.com/Pictures/Curves/Wig_Wag_Currents.jpg

We discovered that the lamp temperature stays pretty warm

during a 250 mS off-cycle such that you don't see the typical

cold-filament inrush each time the lamp is powered up. But

the temperature excursions between no-visible light and full

intensity is still significant. It may well be that the very

thing that makes the halogen a stellar illuminator amongst

incandescent lamps is it's Achilles Heel as well.

Just a guess . . . but until I hear/get a better idea, I'm

sticking with it.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

skywagon

Joined: 11 Feb 2006

Posts: 184

|

Posted: Fri Sep 09, 2011 4:52 pm Post subject: Halogen bulbs with wig wag circuitry....failure mode Posted: Fri Sep 09, 2011 4:52 pm Post subject: Halogen bulbs with wig wag circuitry....failure mode |

|

|

Bob,

I think that you are totally correct concerning the thermo rapid cycle being

the stress failure mode.

When viewing the filaments with a mag. lens they look completely normal and

intact until you look carefully at one end of the filament. They are broken

at the very end.

Odd that I have not run into others that are having the same problem as

these bulbs are used in a lot of recognition applications.

I suspect that if I left them ON continually, they would last a normal life.

And, as you outline, in PULSE mode the thermo aspect is too much stress. I

wonder now, if there is a heavy duty version of this bulb with bullet proof

filament structure.

I am installing new bulbs when delivered and will report back when I have a

similar failure. Hopefully, I may have learned more.

Thanks, David

___________________________________________________________________________

---

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

sprocket(at)vx-aviation.c

Guest

|

Posted: Fri Sep 09, 2011 7:03 pm Post subject: Halogen bulbs with wig wag circuitry....failure mode Posted: Fri Sep 09, 2011 7:03 pm Post subject: Halogen bulbs with wig wag circuitry....failure mode |

|

|

I used inrush current limiters on my halogens (450+ hours so far). Since

this also causes the lamps to take more time to reach full brightness, I

modified the B&C flasher to slow it down by doubling the capacitance of the

electrolytic capacitor inside the can. Double the resistor value would also

work.

V

--

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

skywagon

Joined: 11 Feb 2006

Posts: 184

|

Posted: Fri Sep 09, 2011 10:02 pm Post subject: Halogen bulbs with wig wag circuitry....failure mode Posted: Fri Sep 09, 2011 10:02 pm Post subject: Halogen bulbs with wig wag circuitry....failure mode |

|

|

Vern,

I am unfamiliar with the "current limiters" that you mention.

Your solution looks great. Please give a bit more detail...

I will check for my solid state flasher model and if it can be

modified...(not potted, etc.)

It was part of the RMD wing tip system.

David

============================================================

---

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

andrew.d.zachar(at)gmail.

Guest

|

Posted: Sat Sep 10, 2011 3:09 am Post subject: Halogen bulbs with wig wag circuitry....failure mode Posted: Sat Sep 10, 2011 3:09 am Post subject: Halogen bulbs with wig wag circuitry....failure mode |

|

|

Awhile back, I did a post about this exact modification. http://n999za.com/2010/11/07/hacking-the-wig-wag-flasher/

Of course, I was only successful because if this list's gracious help and advice. Hoping the pictures assist the discussion...

__

Andrew Zachar

andrew.d.zachar(at)gmail.com

On Sep 9, 2011, at 10:57 PM, "Vern Little" <sprocket(at)vx-aviation.com> wrote:

[quote]

I used inrush current limiters on my halogens (450+ hours so far). Since this also causes the lamps to take more time to reach full brightness, I modified the B&C flasher to slow it down by doubling the capacitance of the electrolytic capacitor inside the can. Double the resistor value would also work.

V

--

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

sprocket(at)vx-aviation.c

Guest

|

|

| Back to top |

|

|

sprocket(at)vx-aviation.c

Guest

|

Posted: Sat Sep 10, 2011 8:24 am Post subject: Halogen bulbs with wig wag circuitry....failure mode Posted: Sat Sep 10, 2011 8:24 am Post subject: Halogen bulbs with wig wag circuitry....failure mode |

|

|

.. this is a circular reference... your quoting my own posts on your site!

Nice to see you documented it properly.

Cheers, V

--

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Eric M. Jones

Joined: 10 Jan 2006

Posts: 565

Location: Massachusetts

|

Posted: Sat Sep 10, 2011 9:19 am Post subject: Re: Wig Wags etc. Posted: Sat Sep 10, 2011 9:19 am Post subject: Re: Wig Wags etc. |

|

|

I've been selling Wig-wags for many years. Our wig-wags do not depend on lamp resistance. They consist of two big mosfets driven by a mosfet driver and some simple internal timer. They cost more than the automotive type, and they are 100% solid state, so in theory that will last forever.

Early on, it was discovered that HIDs would destroy them for two reasons: 1) the starting current surge on an HID is very large (okay, short but tall), and the lamp and the + line sees a HV pulse at the same time. The solution to these issues was to supply a surge arrestor and an HV suppressor for those who wanted to wig-wag their HIDs. There are additional issues--these vary by lamp and ballast manufacturer--but people seem to be having very few problems.

Wig-wagging LEDs is trivial, but some LEDs require a voltage booster or constant current supply to function well. These employ little switch-mode power supplies that frequently make noise on the audio or HF transmitter lines. Bob published a fix for these, but I am not convinced.

Wig-wagging really big halogen lamps is also easy providing a current surge protector is used. I have demonstrated 2X 250 watt lamps wig-wagging happily with our WW(c) or WW(d).

After using these on my white LED tail lights, I finally had to give up and return to a simple, reliable (but not as efficient) LM317 current regulator (which I offer as a free design if you want to roll your own).

One final note: BMW is now testing white LASER auto headlamps. No, the lasers won't poke holes in things--lasers are used because they can be made to be several times more efficient (Lumens/Watt) than LEDs.

But LEDs are not slackers either...Cree has demonstrated a white LED of 231 Lumens Per Watt. And it keeps going up and up.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Eric M. Jones

www.PerihelionDesign.com

113 Brentwood Drive

Southbridge, MA 01550

(508) 764-2072

emjones(at)charter.net |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Sep 11, 2011 7:57 am Post subject: Halogen bulbs with wig wag circuitry....failure mode Posted: Sun Sep 11, 2011 7:57 am Post subject: Halogen bulbs with wig wag circuitry....failure mode |

|

|

| Quote: | | Wig-wagging really big halogen lamps is also easy providing a current surge protector is used. I have demonstrated 2X 250 watt lamps wig-wagging happily with our WW(c) or WW(d). |

Inrush current beyond the initial cold

start is not an issue for incandescent lamps.

The reason I plotted the this data . . .

[img]cid:.0[/img]

was to show that while the first, cold start inrush was the typical

30+ amps, subsequent start up currents were quite nominal. The lamp

being tested had a nominal on current of 4A (55w) but as you can see here,

the average start up current in the wig-wag mode was a tad above 5A.

This is because the filament doesn't cool off enough between flashes

to push the inrush even close to a cold-start value.

It isn't inrush killing these lamps by flashing them, it has to

be temperature cycling . . . for which there is no mitigating 'fix'.

After all, the reason these filaments produce white light is because

they've been elevated from below a dull red glow to the white light

produced by a metal glowing at 5000 degrees F. THATS a big temperature

shift.

I need to re-plot that trace above. There was some very strong

noise source going on at the time that produced the fuzzy spikes

on my data.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

257.77 KB |

| Viewed: |

10050 Time(s) |

|

|

|

| Back to top |

|

|

Eric M. Jones

Joined: 10 Jan 2006

Posts: 565

Location: Massachusetts

|

Posted: Sun Sep 11, 2011 9:27 am Post subject: Re: Halogen bulbs with wig wag circuitry....failure mode Posted: Sun Sep 11, 2011 9:27 am Post subject: Re: Halogen bulbs with wig wag circuitry....failure mode |

|

|

| Quote: | Inrush current beyond the initial cold

start is not an issue for incandescent lamps.

The reason I plotted the this data . . . |

Quite true Bob, however I tried not having a first cycle, but it never seemed to work. You ALWAYS have a first pulse.

Also, most timers using a 555 have an initial 1.5X times longer pulse than the second pulse. I no longer use the 555 for this reason. What I do now is have a faster r/c oscillator and a divider to get the correct timing. I'd be glad to share the schematic with interested parties.

Nice graph of the pulses.

I'd still bet that many halogen lamps have declined in quality. I've seen this first-hand. There are many variables in the making of halogen lamps.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Eric M. Jones

www.PerihelionDesign.com

113 Brentwood Drive

Southbridge, MA 01550

(508) 764-2072

emjones(at)charter.net |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Sep 12, 2011 6:06 am Post subject: Halogen bulbs with wig wag circuitry....failure mode Posted: Mon Sep 12, 2011 6:06 am Post subject: Halogen bulbs with wig wag circuitry....failure mode |

|

|

At 12:27 PM 9/11/2011, you wrote:

| Quote: |

> Inrush current beyond the initial cold

> start is not an issue for incandescent lamps.

> The reason I plotted the this data . . .

Quite true Bob, however I tried not having a first cycle, but it

never seemed to work. You ALWAYS have a first pulse.

|

Sure . . . The purpose of study was to support a

discussion about the NTC thermistor style current limiters.

These things 'work' when allowed to heat up past the

resistance vs. temperature break point where the

device's resistance falls to some low, tolerable value

of series resistance.

I think we were talking about the CL series limiters

http://search.digikey.com/scripts/DkSearch/dksus.dll?Detail&name=KC023L-ND

http://www.ge-mcs.com/download/temperature/920_325a.pdf

These stay in a low resistance state by a sustained

current flow and have a 'cool down' requirement of

2 to 20 seconds for them to 'reset' and be capable

of limited the next inrush event.

The discussion concluded that the thermistor style

device would perform as needed for the initial cold-

start transient but was too slow to help for closely

space repeat transients. The data plot showed that

second and subsequent events in an incandescent wig-wag

system were insignificant.

| Quote: | Also, most timers using a 555 have an initial 1.5X times longer

pulse than the second pulse. I no longer use the 555 for this

reason. What I do now is have a faster r/c oscillator and a divider

to get the correct timing. I'd be glad to share the schematic with

interested parties.

|

Yeah, my favorite is the CD4060 oscillator/divider.

Hope these don't go obsolete soon. I'm putting one

into a high school electronics class project. The

critters are 40 years old and still great ol' work

horses.

An alternative (if you can live in a 5v world) is

a PIC microcontroller. I keep the 8-pin flash devices

around to emulate more complex logic and timing

functions. It's a jelly bean part at about 75 cents

and capable of dropping into a bunch of applications

with the right code. I used one to generate a pair

of 17 Khz outputs to drive a push-pull, dc/dc converter

design. The single chip replaced 4 parts in the next-best

choice and was more stable to boot.

| Quote: | Nice graph of the pulses.

|

That's a plotting feature of even the low cost lines

of most 'scopes these days. I can plug a thumbdrive

into my TEK TDS220 scope and dump the screen to a

.jpg file. I can also get a dump of the numbers for

use in other analysis.

| Quote: | I'd still bet that many halogen lamps have declined in quality. I've

seen this first-hand. There are many variables in the making of halogen lamps.

|

You got that right. But I'll bet it's cyclical too.

Suppliers are always wrestling for contracts but

price cannot be the sole driver. I think the value

trends are generally upward.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

shenglu

Joined: 10 Oct 2011

Posts: 3

|

Posted: Tue Oct 11, 2011 6:25 pm Post subject: Re: Halogen bulbs with wig wag circuitry....failure mode Posted: Tue Oct 11, 2011 6:25 pm Post subject: Re: Halogen bulbs with wig wag circuitry....failure mode |

|

|

Light resistance is not dependent on our wig grow up. They include the MOSFET drivers and some simple two large internal timer-driven MOSFET. They cost more than the type of car.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Gadgets | Flash Memory |

|

| Back to top |

|

|

skywagon

Joined: 11 Feb 2006

Posts: 184

|

Posted: Wed Oct 12, 2011 9:17 am Post subject: Re: Halogen bulbs with wig wag circuitry....failure mode Posted: Wed Oct 12, 2011 9:17 am Post subject: Re: Halogen bulbs with wig wag circuitry....failure mode |

|

|

Since this bulb failure issue was my original message and problem, I can add only another piece of mechanical evidence that may or may not have anything to do with the H7604 filament failures....

1. Under magnification, both filaments separated not in the coil section, but, on the short straight ends just before their connection post.

2. I do not know if the filaments (bulbs) were originally installed in the vertical or horizontal orientation. Rumor has it, that installing with the filaments vertically removes some of the mechanical stress from wing vibration and landing stresses.

3. I have installed the new H7604's with the filaments in the vertical orientation and will report in the future if this seems to extend the bulb life.

David

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Fri Oct 14, 2011 7:35 am Post subject: Halogen bulbs with wig wag circuitry....failure mode Posted: Fri Oct 14, 2011 7:35 am Post subject: Halogen bulbs with wig wag circuitry....failure mode |

|

|

At 12:17 PM 10/12/2011, you wrote:

| Quote: |

Since this bulb failure issue was my original message and problem, I

can add only another piece of mechanical evidence that may or may

not have anything to do with the H7604 filament failures....

1. Under magnification, both filaments separated not in the coil

section, but, on the short straight ends just before their connection post.

2. I do not know if the filaments (bulbs) were originally installed

in the vertical or horizontal orientation. Rumor has it, that

installing with the filaments vertically removes some of the

mechanical stress from wing vibration and landing stresses.

3. I have installed the new H7604's with the filaments in the

vertical orientation and will report in the future if this seems to

extend the bulb life.

|

Hmmmm . . . I'm suspicious of any 'benefit' for

orientation of filaments to increase resistance

to vibration stresses. Most materials exhibit a

thing called a stress-to-events-ratio (S/N ratio)

where a number of events at a particular stress

level are required to structurally fail the

material. Further, the S/N curve is generally

not linear. In other words, raising the stress

level by a factor of 3 does not necessarily

result in failure at 1/3rd the number of cycles.

It might drop to 1/4th the number of cycles.

Stress transients on landing are short duration

but very few in number compared hours of in-flight

stimulus.

Tungsten has a unique metallurgical property where

the metal transforms from a brittle to a ductile

state at a rather low temperature. I think it was

on the order 500F. In any case, it was below the

dull-red-glow temperature. In the chapter on

lighting in the 'Connection, I described two

techniques for keeping a filament warm when the

light was OFF. Maintaining the brittle filament

at or above it's brittle-to-ductile transition

temperature has a marked effect on the S/N ratio.

It would be a very interesting experiment to

try some form of keep-warm system on an airplane

that exhibits a high failure rate for tungsten

filament lamps.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

skywagon

Joined: 11 Feb 2006

Posts: 184

|

Posted: Fri Oct 14, 2011 9:38 am Post subject: Halogen bulbs with wig wag circuitry....failure mode Posted: Fri Oct 14, 2011 9:38 am Post subject: Halogen bulbs with wig wag circuitry....failure mode |

|

|

Bob,

You are always surprising me with your knowledge background. My grey matter

stores a lot and I have a degree in electronics, however, I learn constantly

from your inputs to all these problems and questions.

Funny, I did not know that the halogen environment still included tungsten

filaments. I was assuming, some other mixture of metal was the basis for

these brighter lamps.

You bring up an interesting option...to keep the lamp filaments in their

flexible or ductile stage while in any none use state. I wonder what level

of current would be needed for that in a 12 - 14 v. system. And, an option

would have to be planned in the case of an alternator failure to cut the

background lamp current. Thanks, David

______________________________________________________________

---

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|