|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

flyv35b(at)minetfiber.com

Guest

|

Posted: Tue Nov 08, 2011 6:45 am Post subject: Oil Temperature Control Posted: Tue Nov 08, 2011 6:45 am Post subject: Oil Temperature Control |

|

|

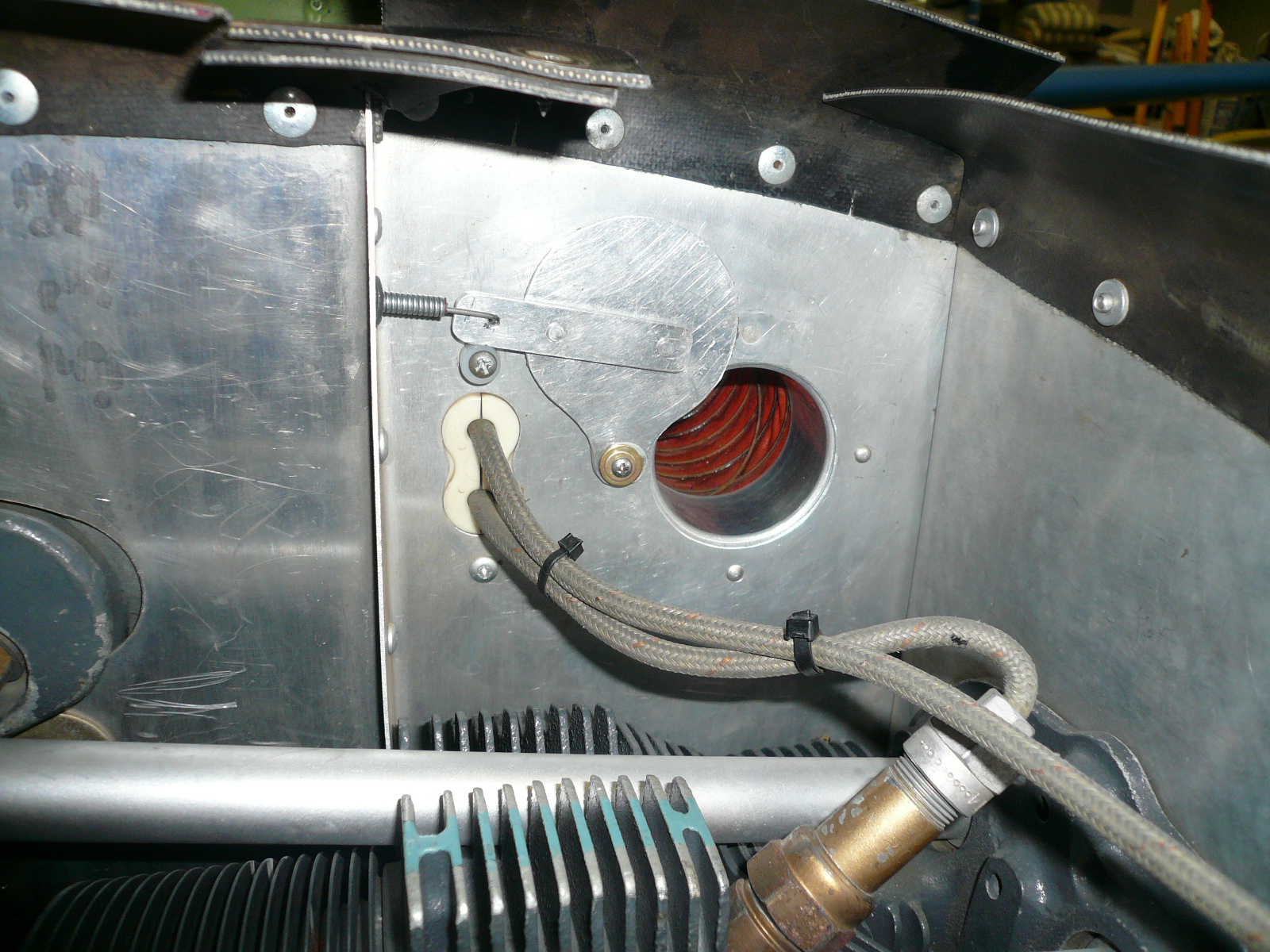

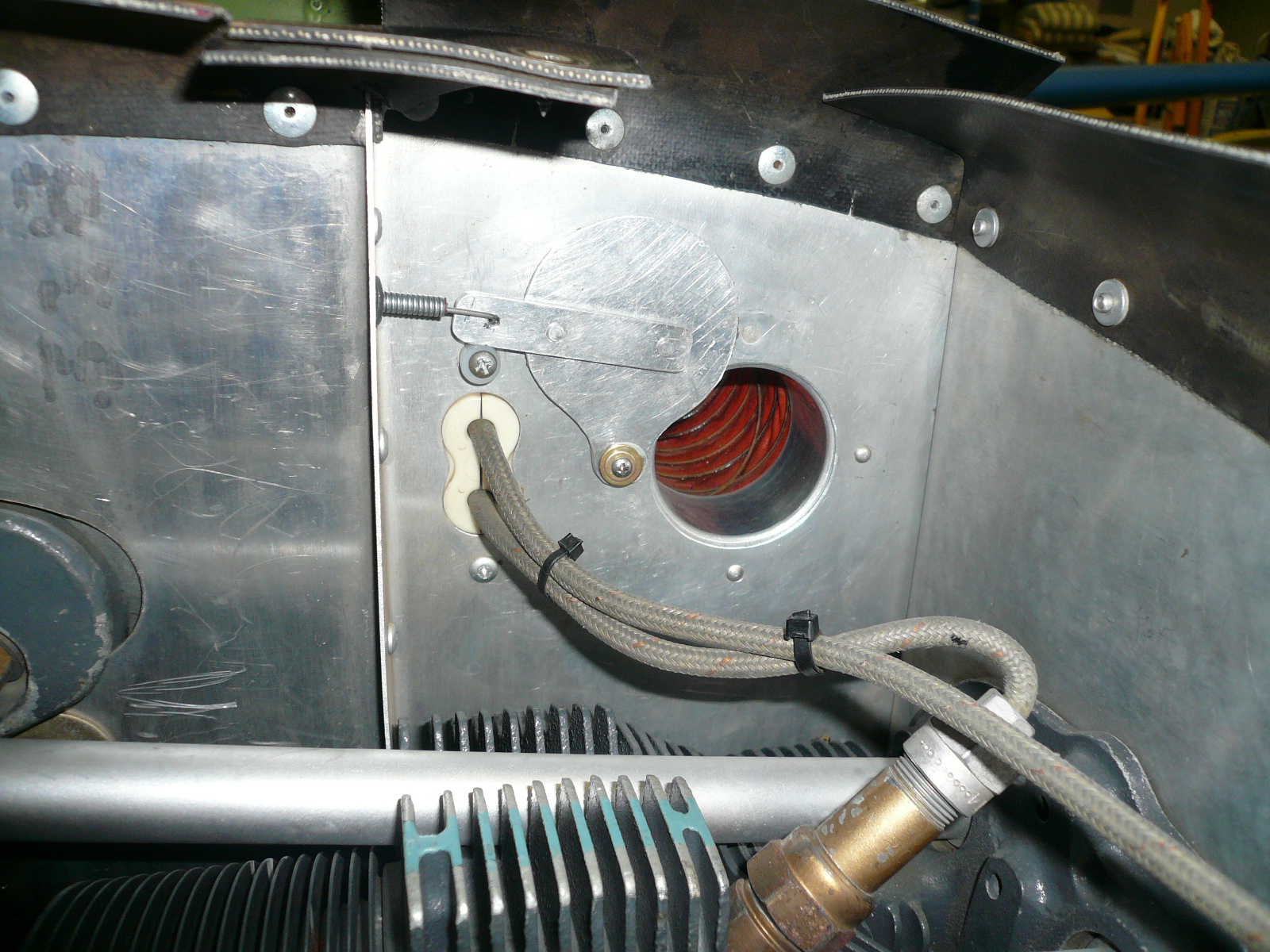

I hate to change the subject about oil level but I recently made and

installed a valve that will control the air flow to the inlet of the oil

cooler on my O-320 powered Lynx. When I installed this engine several

years ago I wondered if the small stock AA-1C cooler would be adequate

but decided to use it until testing proved otherwise. It has worked

well even at high ambient temperatures during extended climbs. But my

cooling with this engine is actually better than needed and during the

cool weather here in the NW the oil temperature will not get up even

close to 175F where there is half a chance of evaporating the moisture.

I got tired of taping over the inlet to block part of the air flow so I

fabricated a cockpit adjustable air valve to regulate the flow and

therefore the oil temperature. It's operated by a simple push-pull

cable with a ratchet lock, much like th stock mixture cable. A test

flight a couple of days ago showed a 20F temperature reduction from no

air flow through the cooler to maximum flow with a 2" diameter supply

duct. This was at about 80% power at 3000 msl and 40F OAT. Pretty good

for such a small cooler. But the real benefit is the ability to

regulate the oil temperature for operation in a more ideal range.

Larger coolers which are commonly used probably result in more like 30F

reduction.

Also, there was some discussion recently about how to route a manifold

pressure line. I did it very simply with a connector from the #3

cylinder and hose through a snap in bushing in the rear baffle to a

bulkhead fitting on the firewall. This may not work as well with the

normal baffling.

Cliff

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

| Description: |

|

| Filesize: |

841.33 KB |

| Viewed: |

868 Time(s) |

|

| Description: |

|

| Filesize: |

846.52 KB |

| Viewed: |

868 Time(s) |

|

| Description: |

|

| Filesize: |

855.91 KB |

| Viewed: |

868 Time(s) |

|

|

|

| Back to top |

|

|

teamgrumman(at)yahoo.com

Guest

|

Posted: Tue Nov 08, 2011 11:04 am Post subject: Oil Temperature Control Posted: Tue Nov 08, 2011 11:04 am Post subject: Oil Temperature Control |

|

|

Bill Kelly has the same experience with his O320-AA1C. He has some sort of manual controled valve.

From: flyv35b <flyv35b(at)minetfiber.com>

To: "teamgrumman-list(at)matronics.com" <teamgrumman-list(at)matronics.com>

Sent: Tuesday, November 8, 2011 6:41 AM

Subject: Oil Temperature Control

I hate to change the subject about oil level but I recently made and installed a valve that will control the air flow to the inlet of the oil cooler on my O-320 powered Lynx. When I installed this engine several years ago I wondered if the small stock AA-1C cooler would be adequate but decided to use it until testing proved otherwise. It has worked well even at high ambient temperatures during extended climbs. But my cooling with this engine is actually better than needed and during the cool weather here in the NW the oil temperature will not get up even close to 175F where there is half a chance of evaporating the moisture. I got tired of taping over the inlet to block part of the air flow so I fabricated a cockpit adjustable air valve to regulate the flow and therefore the oil temperature. It's operated by a simple push-pull cable with a ratchet lock, much like th stock mixture cable. A test flight a couple of days ago showed a 20F temperature reduction from no air flow through the cooler to maximum flow with a 2" diameter supply duct. This was at about 80% power at 3000 msl and 40F OAT. Pretty good for such a small cooler. But the real benefit is the ability to regulate the oil temperature for operation in a more ideal range. Larger coolers which are commonly used probably result in more like 30F reduction.

Also, there was some discussion recently about how to route a manifold pressure line. I did it very simply with a connector from the #3 cylinder and hose through a snap in bushing in the rear baffle to a bulkhead fitting on the firewall. This may not work as well with the normal baffling.

Cliff

[quote][b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|