|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

t41pilot

Joined: 05 Sep 2011

Posts: 38

Location: Howard City, Michigan

|

Posted: Tue Dec 27, 2011 7:48 am Post subject: Firefly Instrument panel Posted: Tue Dec 27, 2011 7:48 am Post subject: Firefly Instrument panel |

|

|

Regards to all on the Kolb list. I'm building a firefly and will be working on the instrument panel soon. I've looked at the hole saws at the big box stores and the teeth appear to be a bit on the coarse side. They seem geared for either wood or metal. I don't have fiberglass experience at all and am nervous about drilling the holes in the panel without cracking or badly chipping something. So any help here with types or brand names would be appreciated. My logic tells me a finer tooth pattern would be good for fiberglass. Also I see something called a flycutter but have no experience with that either. Also I need to make a drill jig for the H brace yet as well. Is a flat piece of stock with some predrilled holes as the plan suggests the best way to go, or has somebody invented a better way? A photo here would be helpful. My wings and tail are built but I live in Michigan and Winter is finally showing herself so my assembly and covering will have to wait till spring. I hope to be flying by early summer and hope to meet some of you at Oshkosh in July. Hope to get a ride from CES308 in the spring. Happy Holidays to all

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

Gregg Kaat

2011 Firefly |

|

| Back to top |

|

|

Mike Welch

Joined: 13 Feb 2011

Posts: 272

|

Posted: Tue Dec 27, 2011 11:20 am Post subject: Firefly Instrument panel Posted: Tue Dec 27, 2011 11:20 am Post subject: Firefly Instrument panel |

|

|

Gregg,

Here's a few of my thoughts regarding panels holes. (others may have different opinions/experiences)

If you want to go the "Cadillac' route...and you know exactly the instruments you are going to use,

you could find an outfit that would water-jet cut your panel. You could lay it out, and they'll do the rest.

This is likely to be the easiest (on you) and nicest looking.

The round holesaws wobble a hellava lot. They're not exactly made for precision circle cuts. Will they work?

Barely, providing you don't screw everything up. You have to clamp the panel down VERY securely.

The flycutters "can" do a fairly respectable job of cutting holes, but you REALLY have to get a high-quality

flycutter. I have one of those Harbour Freight pieces of crap. It hard to believe someone could make something so

worthless. I think I justy threw it away the last time I tried using it.

Same story for the holesaws. The chinese ones are crap, crap, crap!!! If you spend the money on some decent

Milwauckee or some USA made company ones, you have a better chance of doing an ok job.

For making your own panel holes, the "best" way is to call Aircraft Spruce, or other a/c parts houses. They sell

instrument panel hole punches. These are the ones where you tighten a bolt and the inner disc cuts out a precise

hole. This is the best method if you insist on doing it yourself.

Mike Welch

On Dec 27, 2011, at 9:48 AM, t41pilot wrote:

| Quote: |

Regards to all on the Kolb list. I'm building a firefly and will be working on the instrument panel soon. I've looked at the hole saws at the big box stores and the teeth appear to be a bit on the coarse side. They seem geared for either wood or metal. I don't have fiberglass experience at all and am nervous about drilling the holes in the panel without cracking or badly chipping something. So any help here with types or brand names would be appreciated. My logic tells me a finer tooth pattern would be good for fiberglass. Also I see something called a flycutter but have no experience with that either. Also I need to make a drill jig for the H brace yet as well. Is a flat piece of stock with some predrilled holes as the plan suggests the best way to go, or has somebody invented a better way? A photo here would be helpful. My wings and tail are built but I live in Michigan and Winter is finally showing herself so my assembly and covering will have to wait till spring. I hop!

e to be flying by early summer and hope to meet some of you at Oshkosh in July. Hope to get a ride from CES308 in the spring. Happy Holidays to all

--------

Gregg Kaat

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=361740#361740

|

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

byoungplumbing(at)gmail.c

Guest

|

Posted: Tue Dec 27, 2011 11:22 am Post subject: Firefly Instrument panel Posted: Tue Dec 27, 2011 11:22 am Post subject: Firefly Instrument panel |

|

|

Also I need to make a drill jig for the H brace yet as well. Is a flat piece of stock with some predrilled holes as the plan suggests the best way to go, or has somebody invented a better way? A photo here would be helpful.

--------

Gregg Kaat

| Quote: | >>>>>>>>>>>>>>>>>>>>>>>>>>

i found a piece of 1/4 in thick alum bar about 15 inch long. at 1/2 inch spacing i drilled 1/8 in holes in a perfect line the end holes were 1/2 inch and 3/8 inch. the 1/2 and 3/8 inch holes were for mounting the h sections in the wing and boom tube, by installing the h section bolt, through the pattern, and h section, i could predrill all the holes in the steel h section. then when the h section was installed and the 1/2 inch hole located and drilled in the spar,, i mounted the template on the side of the spar, and held in place with the bolt, i could line up and drill the spar through the jig., after getting one rivit at the far end drilled and held in place with a cleko, the rest drilled very easy and fast.

|

i hope it is as clear to you as it was to me.

boyd young

ps the 1/2 and 3/8 inch holes may have been 3/4 inch from the first 1/8 inch hole.

[img]C:\Users\user laptop\Desktop\2011-12 (Dec)\h-template.jpg[/img]

[quote][b]

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

phactor9

Joined: 16 Jun 2011

Posts: 78

|

Posted: Tue Dec 27, 2011 11:35 am Post subject: Firefly Instrument panel Posted: Tue Dec 27, 2011 11:35 am Post subject: Firefly Instrument panel |

|

|

I also have this task to look forward to; cutting large holes in Lexan. Some are suggesting a router with a very small diameter bit, following a circular jig.

A large hole-saw seems appropriate to me; but some are suggesting you start in reverse to score the surface before drilling forward. Apply masking tape firmly to the cut-line. I would think you'd need to drill slowly so's not to risk raising the temperature.

Another idea that seems feasible to me; firmly clamp the fiberglass/lexan in between two clean pieces of scrap plywood (not "plain" wood) and drill all three layers together. You probably wouldn't need to start in reverse in that case.

Phil H.

FF076

--- On Tue, 12/27/11, Richard Girard <aslsa.rng(at)gmail.com> wrote:

| Quote: |

From: Richard Girard <aslsa.rng(at)gmail.com>

Subject: Re: Firefly Instrument panel

To: kolb-list(at)matronics.com

Date: Tuesday, December 27, 2011, 1:25 PM

I wouldn't use the flycutter, if it catches as it breaks through it will tear the fiberglass and make a real mess. Hole saws work fine as long as you A) turn them slowly, B) pause every few seconds to allow the teeth to clear out the cutting debris, and C) use a backup block to support the panel as you cut.

One thing you might wish to consider is making a removable panel to make future maintenance much easier. If you mount the instruments directly into the fiberglass panel it becomes a real bear to work on after the nose is on the airplane.

Also, spend some time sitting in your plane strapped in as you would be when flying and see if you can reach the panel. If the Firefly is like the Firestar or the Mk III, you can't without unbuckling. Imagine how frustrating, and dangerous, it would be to have to unstrap to reach a switch in an emergency.

Rick Girard

On Tue, Dec 27, 2011 at 9:48 AM, t41pilot <t41pilot(at)frontier.com (t41pilot(at)frontier.com)> wrote:

| Quote: | --> Kolb-List message posted by: "t41pilot" <t41pilot(at)frontier.com (t41pilot(at)frontier.com)>

Regards to all on the Kolb list. I'm building a firefly and will be working on the instrument panel soon. I've looked at the hole saws at the big box stores and the teeth appear to be a bit on the coarse side. They seem geared for either wood or metal. I don't have fiberglass experience at all and am nervous about drilling the holes in the panel without cracking or badly chipping something. So any help here with types or brand names would be appreciated. My logic tells me a finer tooth pattern would be good for fiberglass. Also I see something called a flycutter but have no experience with that either. Also I need to make a drill jig for the H brace yet as well. Is a flat piece of stock with some predrilled holes as the plan suggests the best way to go, or has somebody invented a better way? A photo here would be helpful. My wings and tail are built but I live in Michigan and Winter is finally showing herself so my assembly and covering will have to wait till spring. I hop!

e to be flying by early summer and hope to meet some of you at Oshkosh in July. Hope to get a ride from CES308 in the spring. Happy Holidays to all

--------

Gregg Kaat

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=361740#361740

===========

="_blank">www.aeroelectric.com

ooks.com" target="_blank">www.buildersbooks.com

et="_blank">www.homebuilthelp.com

="_blank">http://www.matronics.com/contribution

le, List Admin.

===========

arget="_blank">http://www.matronics.com/Navigator?Kolb-List

===========

http://forums.matronics.com

===========

le, List Admin.

="_blank">http://www.matronics.com/contribution

===========

|

--

Zulu Delta

Mk IIIC

Thanks, Homer GBYM

It isn't necessary to have relatives in Kansas City in order to be unhappy.

- Groucho Marx

| Quote: |

ollow target=_blank>www.aeroelectric.com

/" rel=nofollow target=_blank>www.buildersbooks.com

ofollow target=_blank>www.homebuilthelp.com

llow target=_blank>http://www.matronics.com/contribution

=nofollow target=_blank>http://www.matronics.com/Navigator?Kolb-List

et=_blank>http://forums.matronics.com

llow target=_blank>http://www.matronics.com/contribution

|

|

[quote][b]

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

pc.king(at)comcast.net

Guest

|

Posted: Tue Dec 27, 2011 11:47 am Post subject: Firefly Instrument panel Posted: Tue Dec 27, 2011 11:47 am Post subject: Firefly Instrument panel |

|

|

Gregg,

Consider clamping plywood on the front and back of your fiberglass panel blank when you cut holes. That minimizes surface tearing.

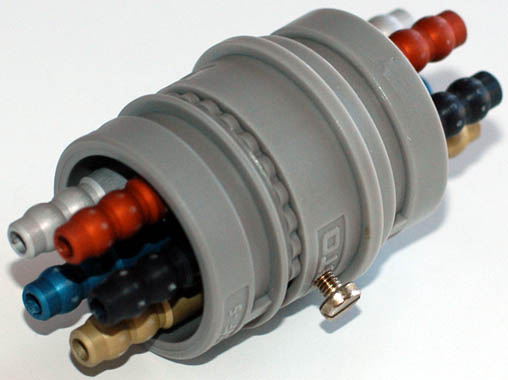

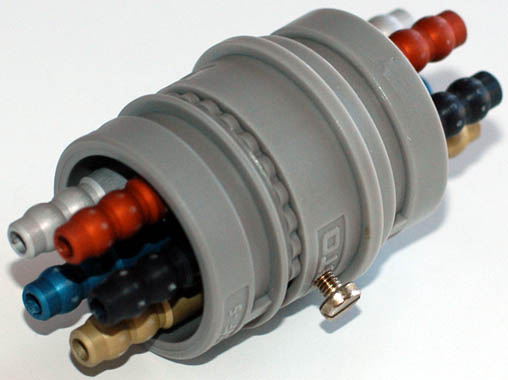

I second Rick's suggestion about a removable panel. They are common on sailplanes. Maintenance is easier and the instruments don't take a beating from riding in the trailer in the plane. The quick disconnect uses O-rings and works well. An electric plug or two, a BNC connector and the panel will pop in and out easily. Glider suppliers carry everything you need to build a panel.

Cumulus-Soaring,com is one supplier. Wingsandwheels.com is another.

Peter

Tubing connectors

http://www.cumulus-soaring.com/winter.htm#Tubing,_Connectors,_and_Miscellaneous

5-way tubing quick disconnect

http://www.cumulus-soaring.com/winter/connector-QD-2.jpg

[quote] ---

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

| Description: |

|

| Filesize: |

41.89 KB |

| Viewed: |

8111 Time(s) |

|

|

|

| Back to top |

|

|

williamtsullivan(at)att.n

Guest

|

Posted: Tue Dec 27, 2011 12:17 pm Post subject: Firefly Instrument panel Posted: Tue Dec 27, 2011 12:17 pm Post subject: Firefly Instrument panel |

|

|

I used a hand held cheap Black and Decker jigsaw with a hack saw blade to cut mine. I backed it up with plywood on the bottom. The blade guard held the top. Worked great. I drilled a starting hole away from the cutting area, and sawed into it.

Bill Sullivan

Windsor Locks, Ct.

FS 447

--- On Tue, 12/27/11, Phil <phactor9(at)yahoo.com> wrote:

| Quote: |

From: Phil <phactor9(at)yahoo.com>

Subject: Re: Firefly Instrument panel

To: kolb-list(at)matronics.com

Date: Tuesday, December 27, 2011, 2:32 PM

I also have this task to look forward to; cutting large holes in Lexan. Some are suggesting a router with a very small diameter bit, following a circular jig.

A large hole-saw seems appropriate to me; but some are suggesting you start in reverse to score the surface before drilling forward. Apply masking tape firmly to the cut-line. I would think you'd need to drill slowly so's not to risk raising the temperature.

Another idea that seems feasible to me; firmly clamp the fiberglass/lexan in between two clean pieces of scrap plywood (not "plain" wood) and drill all three layers together. You probably wouldn't need to start in reverse in that case.

Phil H.

FF076

--- On Tue, 12/27/11, Richard Girard <aslsa.rng(at)gmail.com> wrote:

| Quote: |

From: Richard Girard <aslsa.rng(at)gmail.com>

Subject: Re: Firefly Instrument panel

To: kolb-list(at)matronics.com

Date: Tuesday, December 27, 2011, 1:25 PM

I wouldn't use the flycutter, if it catches as it breaks through it will tear the fiberglass and make a real mess. Hole saws work fine as long as you A) turn them slowly, B) pause every few seconds to allow the teeth to clear out the cutting debris, and C) use a backup block to support the panel as you cut.

One thing you might wish to consider is making a removable panel to make future maintenance much easier. If you mount the instruments directly into the fiberglass panel it becomes a real bear to work on after the nose is on the airplane.

Also, spend some time sitting in your plane strapped in as you would be when flying and see if you can reach the panel. If the Firefly is like the Firestar or the Mk III, you can't without unbuckling. Imagine how frustrating, and dangerous, it would be to have to unstrap to reach a switch in an emergency.

Rick Girard

On Tue, Dec 27, 2011 at 9:48 AM, t41pilot <t41pilot(at)frontier.com> wrote:

| Quote: | --> Kolb-List message posted by: "t41pilot" <t41pilot(at)frontier.com>

Regards to all on the Kolb list. I'm building a firefly and will be working on the instrument panel soon. I've looked at the hole saws at the big box stores and the teeth appear to be a bit on the coarse side. They seem geared for either wood or metal. I don't have fiberglass experience at all and am nervous about drilling the holes in the panel without cracking or badly chipping something. So any help here with types or brand names would be appreciated. My logic tells me a finer tooth pattern would be good for fiberglass. Also I see something called a flycutter but have no experience with that either. Also I need to make a drill jig for the H brace yet as well. Is a flat piece of stock with some predrilled holes as the plan suggests the best way to go, or has somebody invented a better way? A photo here would be helpful. My wings and tail are built but I live in Michigan and Winter is finally showing herself so my assembly and covering will have to wait till spring. I hop!

e to be flying by early summer and hope to meet some of you at Oshkosh in July. Hope to get a ride from CES308 in the spring. Happy Holidays to all

--------

Gregg Kaat

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=361740#361740

===========

="_blank">www.aeroelectric.com

ooks.com" target="_blank">www.buildersbooks.com

et="_blank">www.homebuilthelp.com

="_blank">http://www.matronics.com/contribution

le, List Admin.

===========

arget="_blank">http://www.matronics.com/Navigator?Kolb-List

===========

http://forums.matronics.com

===========

le, List Admin.

="_blank">http://www.matronics.com/contribution

===========

|

--

Zulu Delta

Mk IIIC

Thanks, Homer GBYM

It isn't necessary to have relatives in Kansas City in order to be unhappy.

- Groucho Marx

| Quote: |

ollow target=_blank>www.aeroelectric.com

/" rel=nofollow target=_blank>www.buildersbooks.com

ofollow target=_blank>www.homebuilthelp.com

llow target=_blank>http://www.matronics.com/contribution

=nofollow target=_blank>http://www.matronics.com/Navigator?Kolb-List

et=_blank>http://forums.matronics.com

llow target=_blank>http://www.matronics.com/contribution

|

|

| Quote: | www.aeroelectric.co= * HomebuiltHELP http://www.matroblank" href="http://www.matronics.com/Navigator?Kolb-List">http://www.matfollow" target="_blank" href="http://forums.matronics.com">http://forum==========

|

|

[quote][b]

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

t41pilot

Joined: 05 Sep 2011

Posts: 38

Location: Howard City, Michigan

|

Posted: Tue Dec 27, 2011 12:57 pm Post subject: Re: Firefly Instrument panel Posted: Tue Dec 27, 2011 12:57 pm Post subject: Re: Firefly Instrument panel |

|

|

Thanks to all that have replied so far. The info is definately useful. Mike, I had suspicions that the hole saw may not cut a clean hole and I think you have confirmed that. I forgot that hole punches existed and I will look into that for sure. I don't have the instruments in my possesion yet so I don't know how much bezel is available to cover up a ragged edge on an imperfect cut if I do ultimately have to use a hole cutter for whatever reason but that would play into a decision as well. I like the removable panel idea but am concerned about the added weight. The firefly already approaches the weight limit of part 103 and I'm trying to stay within limits if possible. Are the detachable panels typically made of aluminum or wood? I already know that I can't reach the panel when seated so what I have in mind is similar to what degbot has. A grand rapids EIS and separate Alt, Aspd and compass in the panel. Switches mounted elsewhere. I'm a lightweight at 145 pounds so I'm expecting to have to have additional seat cushions to move me forward to get into the CG envelope. Good to hear from you again Phil. I know that you were thinking of going without a nosecone. How are you mounting your instruments? Also thanks to boyd for the H brace info.

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

Gregg Kaat

2011 Firefly |

|

| Back to top |

|

|

phactor9

Joined: 16 Jun 2011

Posts: 78

|

Posted: Tue Dec 27, 2011 1:47 pm Post subject: Firefly Instrument panel Posted: Tue Dec 27, 2011 1:47 pm Post subject: Firefly Instrument panel |

|

|

I'm not sure how I'll mount mine - perhaps a podium mount in front of the stick. I only have a dual CHT, dual EGT, TinyTach and a cheap Halls windmeter to figure out. My Garmin eTrex will Velcro to my leg for Alt and compass. A nose and windshield might be in my future, eventually.

Phil H.

2011 FF076

--- On Tue, 12/27/11, t41pilot <t41pilot(at)frontier.com> wrote:

| Quote: |

From: t41pilot <t41pilot(at)frontier.com>

Subject: Re: Firefly Instrument panel

To: kolb-list(at)matronics.com

Date: Tuesday, December 27, 2011, 3:57 PM

--> Kolb-List message posted by: "t41pilot" <t41pilot(at)frontier.com (t41pilot(at)frontier.com)>

Thanks to all that have replied so far. The info is definately useful. Mike, I had suspicions that the hole saw may not cut a clean hole and I think you have confirmed that. I forgot that hole punches existed and I will look into that for sure. I don't have the instruments in my possesion yet so I don't know how much bezel is available to cover up a ragged edge on an imperfect cut if I do ultimately have to use a hole cutter for whatever reason but that would play into a decision as well. I like the removable panel idea but am concerned about the added weight. The firefly already approaches the weight limit of part 103 and I'm trying to stay within limits if possible. Are the detachable panels typically made of aluminum or wood? I already know that I can't reach the panel when seated so what I have in mind is similar to what degbot has. A grand rapids EIS and separate Alt, Aspd and compass in the panel. Switches mounted elsewhere. I'm a lightweight at 145 pounds so I!

'm expecting to have to have additional seat cushions to move me forward to get into the CG envelope. Good to hear from you again Phil. I know that you were thinking of going without a nosecone. How are you mounting your instruments? Also thanks to boyd for the H brace info.

--------

Gregg Kaat

2011 Firefly

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=361784#361========================_-= the Contribution link below to find out more abouth -Matt Dralle, List --> http://www.matronics.com/Navigator?Kolb-List

sp; -->

|

[quote][b]

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

elleryweld(at)aol.com

Guest

|

Posted: Tue Dec 27, 2011 3:10 pm Post subject: Firefly Instrument panel Posted: Tue Dec 27, 2011 3:10 pm Post subject: Firefly Instrument panel |

|

|

FYI , a Fly cutter is designed to be used in a Milling machine or in a decent drill press not a hand held drill motor

do not archive

Ellery Batchelder Jr.

--

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

superjett(at)gmail.com

Guest

|

Posted: Tue Dec 27, 2011 3:22 pm Post subject: Firefly Instrument panel Posted: Tue Dec 27, 2011 3:22 pm Post subject: Firefly Instrument panel |

|

|

I'm new to the list (been lurking a while) but I do have a lot of

fiberglass experience. If you have steady hands a Dremel/etc with a

good spiral cut bit can cut accurately/smoothly. Start slightly

smaller than needed then slowly enlarge to your scribe mark. It works

great on fiberglass, carbon fiber, and even carbon/kevlar though that

will dull and the kevlar frays very finely.

All of the other suggestions are good too, especially the hole punch

which I've used also.

Darin

| Quote: | >

>

> Regards to all on the Kolb list. I'm building a firefly and will be

> working on

the instrument panel soon. I've looked at the hole saws at the big box

stores

and the teeth appear to be a bit on the coarse side. They seem geared for

either

wood or metal. I don't have fiberglass experience at all and am nervous

about

drilling the holes in the panel without cracking or badly chipping

something. So

any help here with types or brand names would be appreciated. My logic tells

me

a finer tooth pattern would be good for fiberglass. Also I see something

called

a flycutter but have no experience with that either. Also I need to make a

drill

jig for the H brace yet as well. Is a flat piece of stock with some

predrilled

holes as the plan suggests the best way to go, or has somebody invented a

better

way? A photo here would be helpful. My wings and tail are built but I live

in

Michigan and Winter is finally showing herself so my assembly and covering

will

have to wait till spring. I h!

op!

> e to be flying by early summer and hope to meet some of you at Oshkosh in

July. Hope to get a ride from CES308 in the spring. Happy Holidays to all

>

> --------

> Gregg Kaat

>

|

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

Mike Welch

Joined: 13 Feb 2011

Posts: 272

|

Posted: Tue Dec 27, 2011 4:26 pm Post subject: Firefly Instrument panel Posted: Tue Dec 27, 2011 4:26 pm Post subject: Firefly Instrument panel |

|

|

Ellery and other Kolbers,

I guess I took it for granted "of course" you would use a drill press for a hole saw or a flycutter!!

I assumed anybody wanting nice looking holes would at least start with decent drill press.

Mike Welch

On Dec 27, 2011, at 5:07 PM, Ellery Batchelder Jr wrote:

[quote] FYI , a Fly cutter is designed to be used in a Milling machine or in a decent drill press not a hand held drill motor

do not archive

Ellery Batchelder Jr.

--

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

t41pilot

Joined: 05 Sep 2011

Posts: 38

Location: Howard City, Michigan

|

Posted: Tue Dec 27, 2011 6:09 pm Post subject: Re: Firefly Instrument panel Posted: Tue Dec 27, 2011 6:09 pm Post subject: Re: Firefly Instrument panel |

|

|

Thanks for the tip Superjett. I do have a Dremel tool and have a steady hand when I haven't hit the coffee too hard. This idea is also cost effective as well and doesn't limit the hole to a circle. I thought of using my oscillating tool for the rectangle needed to mount the Grand Rapids EIS but this sounds better.

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

Gregg Kaat

2011 Firefly |

|

| Back to top |

|

|

johngilpin

Joined: 23 Mar 2011

Posts: 93

Location: 004

|

Posted: Wed Dec 28, 2011 1:11 am Post subject: Firefly Instrument panel Posted: Wed Dec 28, 2011 1:11 am Post subject: Firefly Instrument panel |

|

|

| Quote: | Also I see something called a flycutter but have no experience with that either.<

|

A flycutter works really well on fiberglass, plastic, or even .016 aluminum, if used by hand. Just drill the center hole, then work the flycutter by hand, scoring all round in overlapping sections. Very controllable and safe. Just keep working around deeper and deeper. Cleanest result is if you can do the last cuts from the backside.

Done it many times.

JG

[quote][b]

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

russkinne(at)mac.com

Guest

|

Posted: Sat Dec 31, 2011 5:22 am Post subject: Firefly Instrument panel Posted: Sat Dec 31, 2011 5:22 am Post subject: Firefly Instrument panel |

|

|

Just a suggestion -- the nearest EAA chapter may have, or know of, hole-punches you could borrow or rent.

Nearly every builder needs them at some point.

Russ K

On Dec 27, 2011, at 3:57 PM, t41pilot wrote:

| Quote: |

Thanks to all that have replied so far. The info is definately useful. Mike, I had suspicions that the hole saw may not cut a clean hole and I think you have confirmed that. I forgot that hole punches existed and I will look into that for sure. I don't have the instruments in my possesion yet so I don't know how much bezel is available to cover up a ragged edge on an imperfect cut if I do ultimately have to use a hole cutter for whatever reason but that would play into a decision as well. I like the removable panel idea but am concerned about the added weight. The firefly already approaches the weight limit of part 103 and I'm trying to stay within limits if possible. Are the detachable panels typically made of aluminum or wood? I already know that I can't reach the panel when seated so what I have in mind is similar to what degbot has. A grand rapids EIS and separate Alt, Aspd and compass in the panel. Switches mounted elsewhere. I'm a lightweight at 145 pounds so

I!

|

| Quote: | 'm expecting to have to have additional seat cushions to move me forward to get into the CG envelope. Good to hear from you again Phil. I know that you were thinking of going without a nosecone. How are you mounting your instruments? Also thanks to boyd for the H brace info.

--------

Gregg Kaat

2011 Firefly

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=361784#361784

|

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

phactor9

Joined: 16 Jun 2011

Posts: 78

|

Posted: Sat Dec 31, 2011 6:55 am Post subject: Firefly Instrument panel Posted: Sat Dec 31, 2011 6:55 am Post subject: Firefly Instrument panel |

|

|

But then you need something for the straight edges, if you have any...

You got me curious. Plus, as I said, I need to face this challenge soon. Therefore, I went to Ace and bought some 0.09" plex just to see if I could do it. Here are some pics:

http://phactor.com/Kolb/plexi_1.jpg

http://phactor.com/Kolb/plexi_2.jpg

For the round gauges, I started a 1/8" pilot hole and then used a rusty (but sharp) old 2" hole saw. I left the protective plastic on, but discovered it might be best to remove it; when I was drilling one of the small mounting screw holes later, the bit caught it and quickly wound up the entire protective sheet into one little ball wrapped around the bit (not fatal; rather funny, actually).

I also discovered you can NOT go fast with the hole saw; that's a lot of metal and friction and you do NOT want to melt the plastic any more than you have to. The saw got stuck in the first hole and I had to spend some time carefully unsticking it (came out just fine!).

The 2nd 2" hole was a breeze. 1/8" pilot hole, then SLOWLY drill with the 2" saw. The plexi disc pops out inside the saw (common with a hole saw) so you have to pop it out; not hard to do.

Straight edges: I tried a small Harbor Freight utility hobby saw 1 1/2" dia. but you can't take it to the corners with that. Then I tried drilling a 1/8" pilot hole in a corner and using my Dremel with a 1/8" RotoZip zip bit (it grinds on the sides, not the end of the bit) - if you do that (which worked well), then you ARE melting plastic (desired) and you have to get a reeeeally firm grip on the tool; it can travel quickly. I found the highest speed my Dremel would wind up to was best.

File the edges with metal files or sand paper. Keep in mind that edges are largely hidden by the gauges anyway. Whatever you get; plexi, lexan, I wouldn't be afraid of it being brittle; just be cautious of scratching where you don't want scratches. My sample seemed quite robust (isn't that by design nowadays?). And buy extra to practice on! The above was ONLY a test.

My 0.02

Phil H - 2011 FF76

--- On Sat, 12/31/11, russ kinne <russkinne(at)mac.com> wrote:

| Quote: |

From: russ kinne <russkinne(at)mac.com>

Subject: Re: Re: Firefly Instrument panel

To: kolb-list(at)matronics.com

Date: Saturday, December 31, 2011, 8:17 AM

--> Kolb-List message posted by: russ kinne <russkinne(at)mac.com (russkinne(at)mac.com)>

Just a suggestion -- the nearest EAA chapter may have, or know of, hole-punches you could borrow or rent.

Nearly every builder needs them at some point.

Russ K

On Dec 27, 2011, at 3:57 PM, t41pilot wrote:

| Quote: | --> Kolb-List message posted by: "t41pilot" <t41pilot(at)frontier.com (t41pilot(at)frontier.com)>

Thanks to all that have replied so far. The info is definately useful. Mike, I had suspicions that the hole saw may not cut a clean hole and I think you have confirmed that. I forgot that hole punches existed and I will look into that for sure. I don't have the instruments in my possesion yet so I don't know how much bezel is available to cover up a ragged edge on an imperfect cut if I do ultimately have to use a hole cutter for whatever reason but that would play into a decision as well. I like the removable panel idea but am concerned about the added weight. The firefly already approaches the weight limit of part 103 and I'm trying to stay within limits if possible. Are the detachable panels typically made of aluminum or wood? I already know that I can't reach the panel when seated so what I have in mind is similar to what degbot has. A grand rapids EIS and separate Alt, Aspd and compass in the panel. Switches mounted elsewhere. I'm a lightweight at 145 pounds so

I!

|

|

[quote][b]

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|