|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

etienne.phillips(at)gmail

Guest

|

Posted: Thu Feb 16, 2012 5:59 pm Post subject: Servo problem Posted: Thu Feb 16, 2012 5:59 pm Post subject: Servo problem |

|

|

Hi All

I’m hoping that an RF greybeard will be able to offer some advice… I’ve built an elevator trim system for my aeroplane, using an RC servo mounted in the control surface, which is driven by a PIC18F microcontroller. This has worked flawlessly for 2 years.

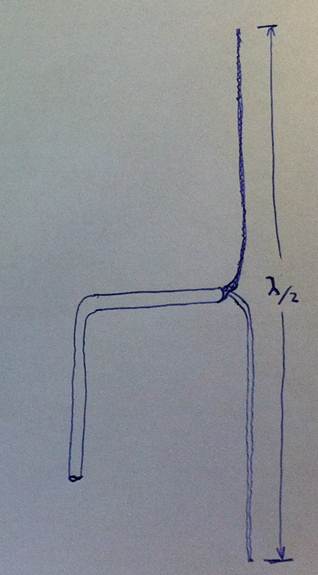

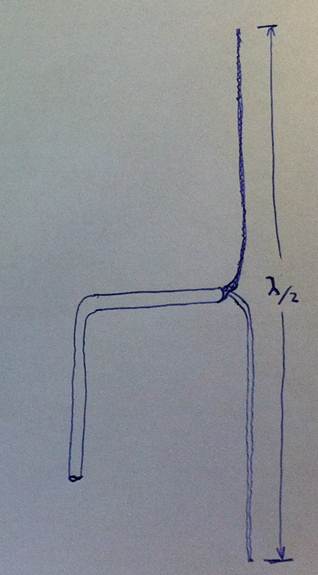

On the back of this success I built another identical one for a friend, and due to the difference in installation which I’ll explain shortly, I am being plagued by a fault that I haven’t been able to solve. The instigator for this problem is the RF emitted by the COM antenna, which on my aircraft is between the undercarriage (taildragger), and on the friends is inside the vertical stabiliser. The design of the friend’s antenna is as follows:

[img]cid:image002.jpg(at)01CCECBE.AF74CAB0[/img]

The braiding of the coax is stretched out in one direction whist the core is stretched out in the other. Since it’s a fiberglass aeroplane, the antenna is bonded to the skin of the vertical stab, without worry of electrical problems.

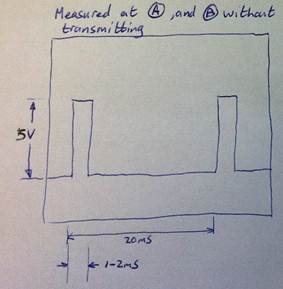

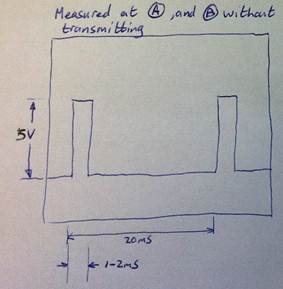

The design of the trim system is as follows:

[img]cid:image010.jpg(at)01CCECBE.AF74CAB0[/img]

Ship’s power is fed through a 7805 (with required smoothing caps) to the 18F4520, which generates the 1-2ms square pulse required by the servo. The output of the PIC is protected by a polyswitch and zener diode combo, resulting in a fairly low impedance output. Meanwhile, the power is fed into an off-the-shelf RC power converter, which has a 6V, 15Amp capable output. Signal and power is fed through a shielded 4-core tefzel wire to the back of the aeroplane where it breaks out into the connections required by the servo motor. The 6V power line is fed over two cores, whilst ground is connected via one core and the shield.

The problem: when transmitting on the radio at the low end of the airband spectrum 118Mhz, the servo goes bezerk. At 125MHz it twitches occasionally, but is mostly usable.

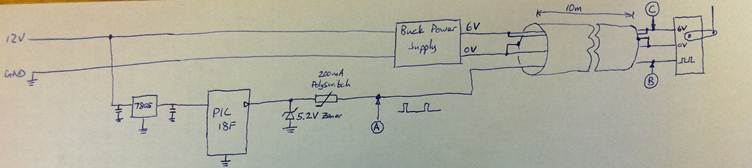

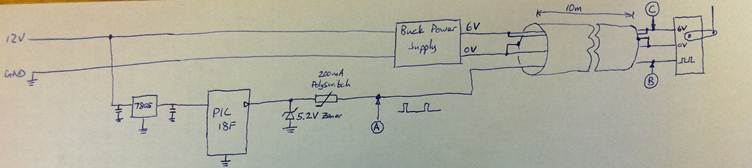

I took an oscilloscope out to the aeroplane, and tested at points “A”, “B” and “C” whilst both transmitting and not.

At “A”, the signal output by the PIC is clean, and unaffected by the noise induced by transmission. The same signal is measured at “B” whilst not transmitting:

[img]cid:image011.jpg(at)01CCECBE.AF74CAB0[/img]

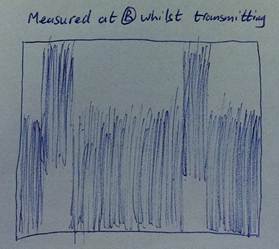

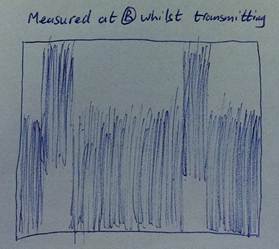

When transmitting, however, the signal at “B” becomes completely degraded:

[img]cid:image012.jpg(at)01CCECBE.AF74CAB0[/img]

The amplitude of the noise is approximately 5Vp-p, superimposed on the desired 5Vp-p signal. No wonder the servo doesn’t know what’s going on!

The power line is completely clean on both ends of the wire, at “C” and the output to the power converter.

I am aware that the suitability of using an RC servo in a real aircraft is a concern, but as has been proven in my aeroplane, mechanically and aerodynamically the system works well, providing enough authority to trim adequately without being so powerful that it cannot be over-ridden using excessive force. The microcontroller code and electrical design of the board has also proven to be reliable, and the installation in my aeroplane has been robust and able to withstand the noise generated from the com radio, although the distance to the antenna is much greater (not closer than 2 meters). We both have the same radio, an MGL VHF-10.

In the knowledgeable opinions of those who have RF experience, will I be able to implement a filter at the servo end of the wire to filter out the 120MHz-odd signal whilst retaining the integrity of the pulse? I tried using a 1uF electrolytic cap as a filter (this was the only cap I had on-hand, as the aeroplane is a 90min drive out of town), which had no effect on the noise, and only degraded the underlying signal further. I know that the cap isn’t rated at high frequencies, so I only include it as an anecdote. I’m concerned about putting a ceramic cap in a EM field – will this not act as an antenna and make the problem worse?

Any advice would be appreciated!

Thanks,

Etienne

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

15.96 KB |

| Viewed: |

20907 Time(s) |

|

| Description: |

|

| Filesize: |

9.62 KB |

| Viewed: |

20907 Time(s) |

|

| Description: |

|

| Filesize: |

13.68 KB |

| Viewed: |

20907 Time(s) |

|

| Description: |

|

| Filesize: |

10.52 KB |

| Viewed: |

20907 Time(s) |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Feb 16, 2012 7:27 pm Post subject: Servo problem Posted: Thu Feb 16, 2012 7:27 pm Post subject: Servo problem |

|

|

In the knowledgeable opinions of those who have

RF experience, will I be able to implement a

filter at the servo end of the wire to filter out

the 120MHz-odd signal whilst retaining the integrity of the pulse?

Absolutely. The variable position pulse is about a

half light-year away from the antagonistic signal . . .

well . . . maybe not light years but certainly separated

by many decades of RF spectrum separation.

We're talking sub killohertz versus 100 mHz or about

5 decades. A filter crafted to attenuate 100 mHz is

totally transparent to your signal-of-interest.

Based on your explorations and observations, it seems

likely that the RC servo is having problems with the

stronger RF field. RF, like all electro-magnetic

propagation attenuates based on the "square-law".

If you double the distance between emitting and

detecting devices, effects on the detector are

reduced to 1/4th of the original. That's a FAR FIELD

condition where there are no, distortions to the

field as it crosses the gap.

We know that the closer proximity of antenna

to servo can offer a profound increase in potential

interference. You also have NEAR-FIELD effects airplane

and wiring geometry. Far-field effects are only slightly

affected by frequency, near-field effects include

the effects of standing waves on airframe and wiring

which can be VERY sensitive to changes of frequency

for the antagonist signal. I can show you data

gathered in the hell-hole of a Hawker 800 were standing

waves generated by a poorly designed antenna system

would offer 1000:1 variations in interfering signal

while standing in one place and moving a probe around

within arm's reach. Further, the effects varied profoundly

from airplane to airplane.

I tried using a 1uF electrolytic cap as a

filter (this was the only cap I had on-hand, as

the aeroplane is a 90min drive out of town),

which had no effect on the noise, and only

degraded the underlying signal further. I know

that the cap isn’t rated at high frequencies, so

I only include it as an anecdote. I’m concerned

about putting a ceramic cap in a EM field – will

this not act as an antenna and make the problem worse?

Ceramic capacitors are not counter-indicated

for this task. The few R/C servos I've played

with all had plastic cases and ZERO provisions

for managing electro-magnetic compatibility.

Without taking your servos to the lab and doing

the full DO-160 work-up, I cannot offer anything

like an elegant, optimized solution.

I will suggest some sledge-and-crowbar techniques

with a high probability of success.

I would "wrap" the servo in copper tape to craft

a metallic enclosure. I would fabricate two, pi-

section filters on the outside surface right where

the wires come out of the actuator. The actuator

ground would tie to the outside copper shell.

Two capacitors for each of the two filters would also

solder directly to the shell. The schematic would

look something like this.

http://tinyurl.com/6vekr2o

The actual parts values are exceedingly un-critical.

Components spanning perhaps 1000:1 ratios of

value would do the job without degrading the

command signal. The elegant components are

driven more by physical characteristics that

lend themselves to "spider-webbing" onto the

side of a thin walled, copper box.

If you could send me one of the servos along with

a picture of the installed servo showing where

the envelope could grow some warts without hitting

anything in the airplane, I can pretty quickly

accomplish the proposed modification. I would

take pictures of the process and provide a bill

of materials.

If the mod proves successful, I'll publish the

solution to the AEC website. If there's a demand

for these filters, we could do an etched circuit

board layout and fab a Mk II filter from surface

mount components. More elegant yet.

If you'd like to take a whack at a DIY solution,

I'd start with inductors on the order of 1 uHy

and capacitors on the order of 1000 pF. And yes,

they could be ceramic disks . . . just keep the

leads short.

By the way, ferrite beads on the wires are exceedingly

unlikely to fix this. Benefits of ferrites as

over-the-bundle solutions to EMC problems are exceedingly

over-rated. Any device destined to fly on a TC aircraft

would have run the DO-160 gauntlet and enjoys necessary

filters INSIDE. Any installation instructions that

call for external fixes or prophylactics to be added

as part of the installation process says the designer

has not done their homework.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

etienne.phillips(at)gmail

Guest

|

Posted: Mon Feb 20, 2012 9:39 am Post subject: Servo problem Posted: Mon Feb 20, 2012 9:39 am Post subject: Servo problem |

|

|

Hi Bob

Thanks for the advice, and the solution! I installed a Pi filter only on the signal line, but with components of 100pF and 10uH, as that's what was available. The power line didn't seem to be affected by the noise, so I decided to try just the signal line first, then add the power line filter if required.

I also added a shield to the bottom of the servo using brass shimstock (I figured it was almost the same as copper foil, but somewhat more available - however not quite as solderable).

[img]cid:image005.png(at)01CCF006.F801CF80[/img]

The soldering in the photo doesn't appear to have flowed and stuck properly, but I gave it a good tug and it didn't come loose, so I just attributed it to the brass. The filter is inside the heatshrink, well supported from vibration.

The servo is a Turnigy HV-767 (http://www.hobbyking.com/hobbyking/store/uh_viewItem.asp?idProduct=9983) - a 31kg.cm monster, but is still the standard size, which makes it small enough to fit comfortably in the elevator. The casing is aluminium, save for the plastic cap at the bottom where all the electronics sits. At $60 a pop, it's a fairly cheap alternative to the Ray Allen servo, and capable of being used for much more than just trim.

The installation space is really tight, which meant that the filter had to sit outside the cavity, which limited my options for shielding hence the small strip over the bottom of the servo.

[img]cid:image002.png(at)01CCF006.95F456F0[/img]

[img]cid:image006.png(at)01CCF006.F801CF80[/img]

After adding the filter and the shielding, the signal going into the servo is absolutely clean, without a shred of noise visible on the signal line. The servo doesn't even notice the radio transmission now, so I'm very relieved!

This is what the controller up front looks like:

[img]cid:image007.png(at)01CCF006.F801CF80[/img]

There is also a stick-mounted rocker switch for easy trimming. The knob on the face allows you to save a position (such as the take-off trim), and return to it with a single click.

My current project is the autopilot side of this, which reads data in from an Efis and does the required maths, sending the resulting trimmer position to the trim controller over an RS-485 link (this is why I went for such big servos). So far, altitude hold works, whilst bank and yaw are waiting to be flight tested.

Thanks also for the offer of crafting a more elegant solution. Since the filter is so simple to fabricate, and seems to work in this really abusive environment, I wonder if it's even necessary…? With plugs and attachments it'll probably be unwieldy to install in such a small spot.

Once again, thanks!

Etienne

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

180.56 KB |

| Viewed: |

20894 Time(s) |

|

| Description: |

|

| Filesize: |

135.11 KB |

| Viewed: |

20894 Time(s) |

|

| Description: |

|

| Filesize: |

103.75 KB |

| Viewed: |

20894 Time(s) |

|

| Description: |

|

| Filesize: |

49.65 KB |

| Viewed: |

20894 Time(s) |

|

|

|

| Back to top |

|

|

jonlaury

Joined: 06 Nov 2006

Posts: 336

|

Posted: Mon Feb 20, 2012 10:16 pm Post subject: Re: Servo problem Posted: Mon Feb 20, 2012 10:16 pm Post subject: Re: Servo problem |

|

|

Bob,

This sounds like a similar situation that I'm encountering with an EyeBeam that uses capacitance for on/off and for dimming. It's housed in a small ceiling mounted enclosure with my cabin speaker.

Everytime I key the mike, the EB flashes uncontrollably and the on/off and dimming functions go inop. The only way to stop it is to pull the fuse.

Wishful thinking had me try ferrite clamps over the speaker wires or the EB twisted pair shielded cable to no effect. But you knew that  . .

Would the solution you devised for Etienne be germane to solving my problem?

Not sure how I would implement the copper shield as 1/2 of the EB is enclosed with the speaker and 1/2 is exposed to the cabin.

Thanks,

John

I really like the EB and the small tidy console that houses the speaker so I hope that I don't have to give it up to use a less EM/RF sensitive source of light.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

enginerdy(at)gmail.com

Guest

|

Posted: Mon Feb 20, 2012 11:03 pm Post subject: Servo problem Posted: Mon Feb 20, 2012 11:03 pm Post subject: Servo problem |

|

|

I'm sorry your ferrites didn't work.

Did you ever try to see if keying the mic without the comm radio on prevents the issue?

On Feb 21, 2012, at 12:16 AM, jonlaury wrote:

| Quote: |

Bob,

This sounds like a similar situation that I'm encountering with an EyeBeam that uses capacitance for on/off and for dimming. It's housed in a small ceiling mounted enclosure with my cabin speaker.

Everytime I key the mike, the EB flashes uncontrollably and the on/off and dimming functions go inop. The only way to stop it is to pull the fuse.

Wishful thinking had me try ferrite clamps over the speaker wires or the EB twisted pair shielded cable to no effect. But you knew that  . .

Would the solution you devised for Etienne be germane to solving my problem?

Not sure how I would implement the copper shield as 1/2 of the EB is enclosed with the speaker and 1/2 is exposed to the cabin.

Thanks,

John

I really like the EB and the small tidy console that houses the speaker so I hope that I don't have to give it up to use a less EM/RF sensitive source of light.

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=366804#366804

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue Feb 21, 2012 11:39 am Post subject: Servo problem Posted: Tue Feb 21, 2012 11:39 am Post subject: Servo problem |

|

|

At 12:16 AM 2/21/2012, you wrote:

| Quote: |

Bob,

This sounds like a similar situation that I'm encountering with an

EyeBeam that uses capacitance for on/off and for dimming. It's

housed in a small ceiling mounted enclosure with my cabin speaker.

Everytime I key the mike, the EB flashes uncontrollably and the

on/off and dimming functions go inop. The only way to stop it is to

pull the fuse.

Wishful thinking had me try ferrite clamps over the speaker wires or

the EB twisted pair shielded cable to no effect. But you knew that  . .

Would the solution you devised for Etienne be germane to solving my problem?

|

Probably not. Touch-buttons that sense body capacity

can be really twitchy in the presence of strong RF.

Can you send me a wiring diagram for your lighting

control system? I must admit that I'm not optimistic

but we can try. Need to see the installation manual

and wiring.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jonlaury

Joined: 06 Nov 2006

Posts: 336

|

Posted: Tue Feb 21, 2012 2:44 pm Post subject: Re: Servo problem Posted: Tue Feb 21, 2012 2:44 pm Post subject: Re: Servo problem |

|

|

Daniel,

No worries re the ferrites. It was easy and worth a shot. Thanks for trying. With the com off there's no problem with the EB. There's a 15' parallel run of speaker and EB wiring and that's where the problem is. When I run non-parallel wiring to power the EB, the problem disappears. Soo...see below.

Bob,

Thank you for your willingness to give it a go, but I've decided that the simplest fix is to re-route the wires to the EB. I didn't want to do that because it means pulling out some nice upholstery work to get 2 x 22 ga wires underneath it. But I know from experimentation that it will work.

That's going to be the best use of both yours and my time.

Cheers,

John

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Feb 22, 2012 7:12 am Post subject: Servo problem Posted: Wed Feb 22, 2012 7:12 am Post subject: Servo problem |

|

|

At 11:36 AM 2/20/2012, you wrote:

Hi Bob

Thanks for the advice, and the solution! I

installed a Pi filter only on the signal line,

but with components of 100pF and 10uH, as that's

what was available. The power line didn't seem to

be affected by the noise, so I decided to try

just the signal line first, then add the power line filter if required.

Good show.

<snip>

Thanks also for the offer of crafting a more

elegant solution. Since the filter is so simple

to fabricate, and seems to work in this really

abusive environment, I wonder if it's even

necessary…? With plugs and attachments it'll

probably be unwieldy to install in such a small spot.

It wouldn't necessarily have any plugs, only

attach pads for wires. I envision an ECB perhaps

0.7" x 1.0" that would accommodate surface mount

components on one side leaving the other flat.

Holes in the corners would let you solder-thru

to attach the board directly to the outside copper

foil on the actuator while simultaneously grounding

the filter to the foil.

Wires would come off each end. They would, of course,

be strain relieved with adhesive or perhaps tied

down with another layer of copper tape over the whole

filter/wiring installation.

Pretty small and low profile.

In any case, it looks like your dragon has been

held at bay.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jonlaury

Joined: 06 Nov 2006

Posts: 336

|

Posted: Thu Feb 23, 2012 2:25 pm Post subject: Re: Servo problem Posted: Thu Feb 23, 2012 2:25 pm Post subject: Re: Servo problem |

|

|

Bob,

Before I go ripping into my headliner, I put the question to the Aveo engineers about the interference that the EyeBeam was getting from somewhere.

They suggested this:

http://www.lineagepower.com/oem/pdf/FLT012A0Z.pdf

If you think this is the right track, does it go on the antagonist wiring or the EB wiring?

Cheers,

John

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Feb 23, 2012 3:00 pm Post subject: Servo problem Posted: Thu Feb 23, 2012 3:00 pm Post subject: Servo problem |

|

|

At 04:25 PM 2/23/2012, you wrote:

| Quote: |

Bob,

Before I go ripping into my headliner, I put the question to the

Aveo engineers about the interference that the EyeBeam was getting

from somewhere.

They suggested this:

http://www.lineagepower.com/oem/pdf/FLT012A0Z.pdf

If you think this is the right track, does it go on the antagonist

wiring or the EB wiring?

|

I looked up the product and found the wiring

diagrams. THAT filter is like killing fleas

with a 12 gauge . . .

How many of these devices are installed on your

airplane?

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Eric M. Jones

Joined: 10 Jan 2006

Posts: 565

Location: Massachusetts

|

Posted: Fri Feb 24, 2012 7:39 am Post subject: Re: T-antennae Posted: Fri Feb 24, 2012 7:39 am Post subject: Re: T-antennae |

|

|

Etienne drew a T-antenna on his discussion of the servo problem. This incluced stripping back the insulation on a coax, separating the shield and core, and stretching out each to form a Tee.

Clever. Actually too-clever-by-half. Would that it could be so easy! The problem lies in the termination, since the core and shield do not share the signal. In fact neither the core nor the shield even CARRY the signal.

See: periheliondesign.com/downloads/Dabbling%20with%20electricity.pdf

Then grab your SWR meter and Google any of the ham radio sites and see how to design a T-antenna.

Might it work the way Etienne shows? A little probably, but let's do it right.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Eric M. Jones

www.PerihelionDesign.com

113 Brentwood Drive

Southbridge, MA 01550

(508) 764-2072

emjones(at)charter.net |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sat Feb 25, 2012 5:55 am Post subject: Servo problem Posted: Sat Feb 25, 2012 5:55 am Post subject: Servo problem |

|

|

I looked up the product and found the wiring

diagrams. THAT filter is like killing fleas

with a 12 gauge . . .

How many of these devices are installed on your

airplane? How hard is it to remove them for

service/modification? If filtering the two

power lines is a solution to be explored, then

the filter components are quite small and

can be assembled right to the back of the

device were the wires emerge.

I'm disappointed but not surprised that the

folks who designed/built/marketed these

into aircraft did not fully appreciate

the potential for strong RF fields. Mobile

transmitters in vehicles of all kinds are

very strong locally . . . and they travel

around with the vehicle. You don't just

pass one occasionally.

In my earliest days of gainful employment

I worked for several two-way radio companies.

It was not uncommon to do installations of

transmitters having power outputs of 60

watts. Back then, the vehicle's other

systems were out of the copper-steel-

Bakelite (CSB) era. Exceedingly robust with

respect to RFI. In the silicon-software-

glass (SSG) era, virtually every active

component of a vehicles systems and accessories

is a potential victim for upset by local

radio energy fields.

Talk to the engineers that suggested the

boss-hog filters and see if they'll send

me a couple of these lights to play with.

If they would send a schematic of their

internals, it would be helpful too.

I'll craft a "scab-on" filter which they

can recommend for folks such as yourself

and consider for inclusion INSIDE future

production. You can encourage them to

contact me directly.

Barring their direct interest and response,

we can put the filters on your lights.

I suspect you could simply cut the lead wires

at the back of the dismounted units.

Leave me 1" pigtails. I'll send them

back with some sort of connector so

that you can re-install them in your

airplane.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jonlaury

Joined: 06 Nov 2006

Posts: 336

|

Posted: Sat Feb 25, 2012 8:15 am Post subject: Re: Servo problem Posted: Sat Feb 25, 2012 8:15 am Post subject: Re: Servo problem |

|

|

Bob,

I sent the following out this morning. Please let me know if they bite.

And thank you once AGAIN (and again, and again...!) for your generous offer to craft a solution to the RF problem with the EyeBeam. Hearing from you that this can be solved with an add-on filter, gives me confidence to go ahead and finally install the structural belly panel (with its 60+ screws, and covering the EB wiring) and move on to firing this thing up!

Cheers,

John

I regularly read, monitor and contribute to the Aerolectric List, which is monitored by Bob Nuckolls, a long time consulting electrical engineer for Piper, Beech, Cessna, Lear, Hawker, etc.

He is immensely generous and helpful to the experimental aircraft community in designing electrical architectures for the large variety of experimental aircraft and missions and enjoys solving challenging problems.

I submitted my RF problem with the EB and here is his response. I hope you will take him up on his offer. The discussion started out because someone had an RF problem with a servo, hence, "Post subject: Servo problem" I responded by asking if the solution he crafted for the servo might be appropriate for the RF problem with my EB.

Contact him directly here: http://www.aeroelectric.com/bob.nuckolls/

(Bob's response)

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|