|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

rickofudall

Joined: 19 Sep 2009

Posts: 1392

Location: Udall, KS, USA

|

Posted: Fri Sep 25, 2009 5:10 pm Post subject: 2 stroke carb synchronizing Posted: Fri Sep 25, 2009 5:10 pm Post subject: 2 stroke carb synchronizing |

|

|

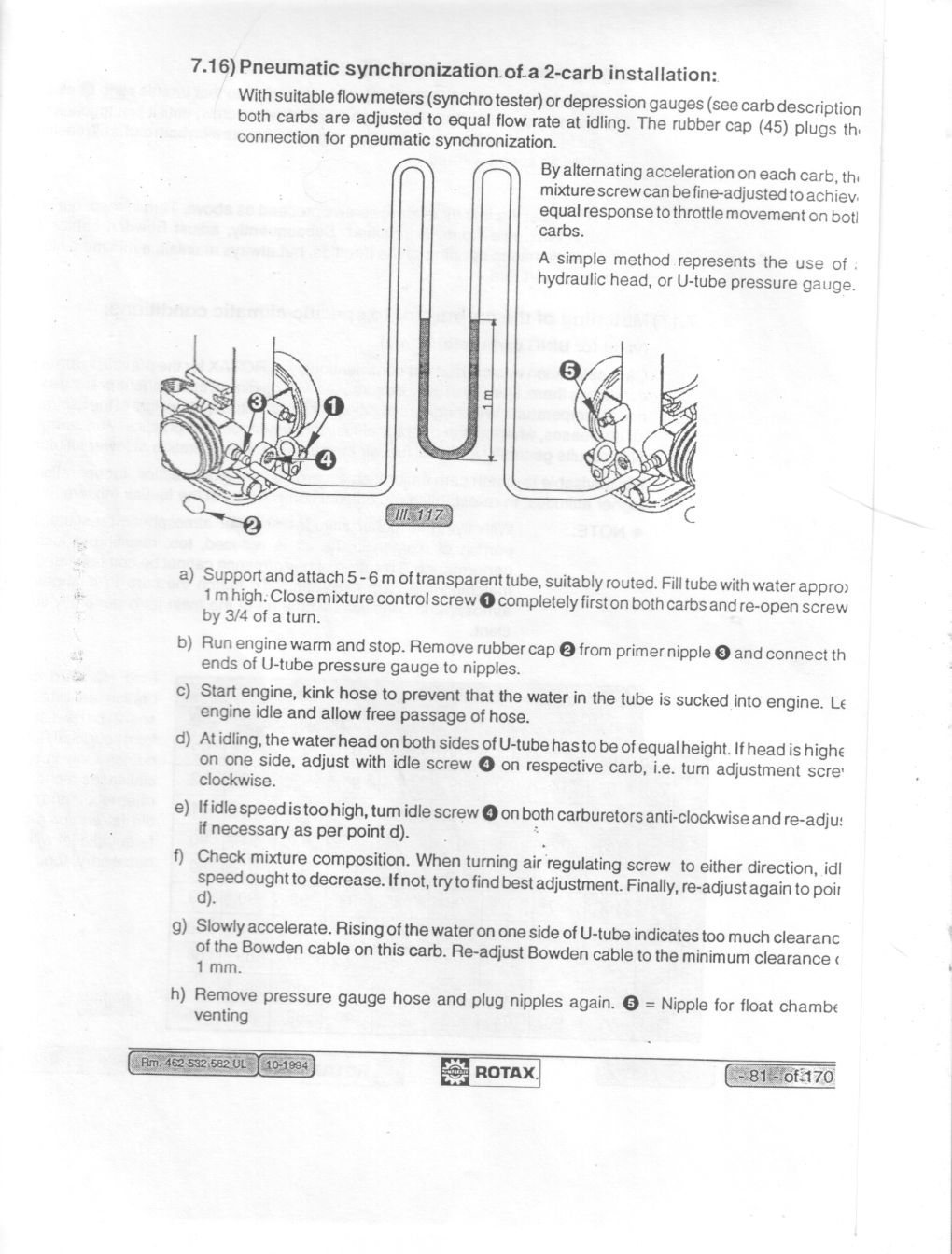

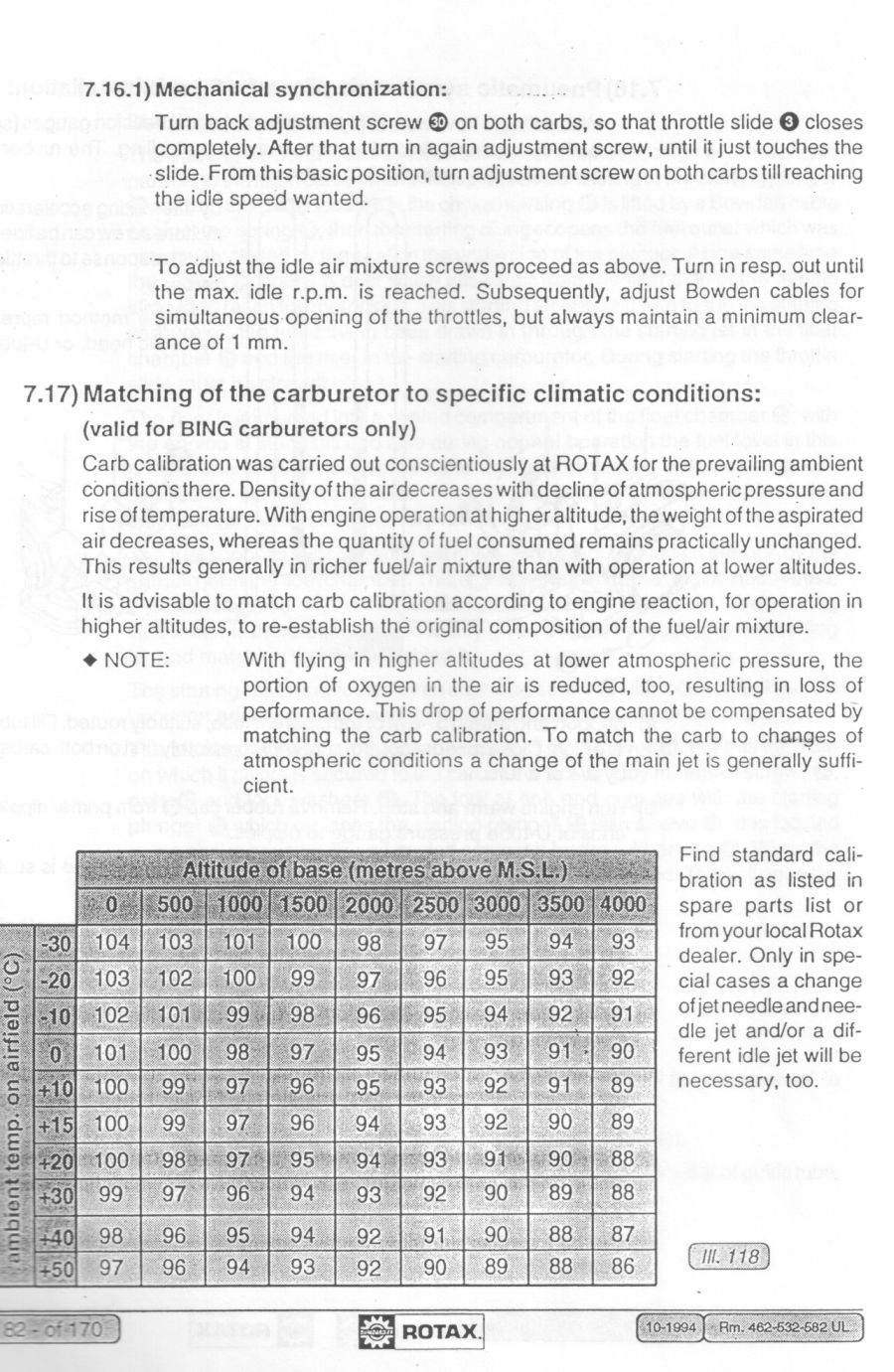

Here you go guys and gals. I'm not sure why Rotax has mechanical synching after pneumatic. I do it the other way, that's how it's spec'd for the 912 and my HKS.This is really so simple, it just seems intimidating until you do it once. As with all things done with a running engine, tie the plane down and have an assistant ready to hit mag switch(es) if required. Before you start raise throttle cable boots so you can get at the cable adjustment screw. Give each cable a tug to see how much slop there is. When you get to cable adjustment that's most likely the one that will have to be adjusted.

1. Adjust idle air screw per Rotax or Bing for your engine / carb combo.

2. Warm up engine to operating temperature

3. Hook up manometer (incidentally, someone on the list suggested two stroke oil instead of water, I used transmission fluid because I had it loaded into a pressure gun to fill the brake system on my trike. That is the easiest way to get the fluid into the tube. Using oil also makes the levels a little slower acting so you make an adjustment and wait a bit for the fluid column to react. It's also less likely to get sucked into the engine if one carb is severely out of synch to the other. To get the initial level set before you hook up to the primer port blow into the tube with the higher level until they're even.

4. Start engine and let idle. Screw in idle adjustment screw on carb connected to the fluid column with the lower level until the columns are even. If that makes your idle speed too high adjust each screw back out until you get the idle speed you want and both fluid columns are even. If you do have to back out an idle adjustment screw make sure you haven't brought the throttle cable up tight so that the carb piston is no longer setting on the adjustment screw.

5. Set RPM to 3000. Loosen adjustment screw on the top of the carb with the lower fluid column and screw out adjustment until columns are almost even and tighten lock nut (this will raise the column very slightly, which is why you don't want to get them exactly equal. It's not much but you are after perfection, after all).

6. Shut off engine, disconnect manometer lines and plug with an AN 3 screw so the manometer stays clean, replace primer plugs or lines.

I did my 582 while I had the wings off as spinning props make me nervous. I put an eyebolt (my local surplus store sells them cheap) in the board so I could safety wire the manometer to the aircraft, you could just as easily drill a hole and run safety wire through it.

That's it.

Rick Girard

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

| Description: |

|

| Filesize: |

166.58 KB |

| Viewed: |

6513 Time(s) |

|

| Description: |

|

| Filesize: |

245.5 KB |

| Viewed: |

6513 Time(s) |

|

| Description: |

|

| Filesize: |

69.92 KB |

| Viewed: |

6513 Time(s) |

|

_________________

The smallest miracle right in front of you is enough to make you happy.... |

|

| Back to top |

|

|

rickofudall

Joined: 19 Sep 2009

Posts: 1392

Location: Udall, KS, USA

|

Posted: Fri Oct 02, 2009 5:43 pm Post subject: 2 stroke carb synchronizing Posted: Fri Oct 02, 2009 5:43 pm Post subject: 2 stroke carb synchronizing |

|

|

Oops! Hopefully I caught this before someone goes out to their plane and tries using my version of the Rotax instructions.4, Screw in idle adjustment screw on carb connected to the fluid column with the lower level ....WRONG, should be higher level. Higher level means more vacuum, opening the throttle lowers vacuum.

Screw in idle adjustment screw on carb connected to the fluid column with the lower level ....Well, at least I'm consistent, again should be higher level, same reason.

Sorry guys and gals, typed faster than my brain could follow and confused manometer and vacuum gauges. Didn't catch it until I was expanding the email text for an article in the Chapter 88 newsletter this evening.

My apologies if I caused any confusion.

Rick Girard

On Fri, Sep 25, 2009 at 8:09 PM, Richard Girard <aslsa.rng(at)gmail.com (aslsa.rng(at)gmail.com)> wrote:

[quote]Here you go guys and gals. I'm not sure why Rotax has mechanical synching after pneumatic. I do it the other way, that's how it's spec'd for the 912 and my HKS. This is really so simple, it just seems intimidating until you do it once. As with all things done with a running engine, tie the plane down and have an assistant ready to hit mag switch(es) if required. Before you start raise throttle cable boots so you can get at the cable adjustment screw. Give each cable a tug to see how much slop there is. When you get to cable adjustment that's most likely the one that will have to be adjusted.

1. Adjust idle air screw per Rotax or Bing for your engine / carb combo.

2. Warm up engine to operating temperature

3. Hook up manometer (incidentally, someone on the list suggested two stroke oil instead of water, I used transmission fluid because I had it loaded into a pressure gun to fill the brake system on my trike. That is the easiest way to get the fluid into the tube. Using oil also makes the levels a little slower acting so you make an adjustment and wait a bit for the fluid column to react. It's also less likely to get sucked into the engine if one carb is severely out of synch to the other. To get the initial level set before you hook up to the primer port blow into the tube with the higher level until they're even.

4. Start engine and let idle. Screw in idle adjustment screw on carb connected to the fluid column with the lower level until the columns are even. If that makes your idle speed too high adjust each screw back out until you get the idle speed you want and both fluid columns are even. If you do have to back out an idle adjustment screw make sure you haven't brought the throttle cable up tight so that the carb piston is no longer setting on the adjustment screw.

5. Set RPM to 3000. Loosen adjustment screw on the top of the carb with the lower fluid column and screw out adjustment until columns are almost even and tighten lock nut (this will raise the column very slightly, which is why you don't want to get them exactly equal. It's not much but you are after perfection, after all).

6. Shut off engine, disconnect manometer lines and plug with an AN 3 screw so the manometer stays clean, replace primer plugs or lines.

I did my 582 while I had the wings off as spinning props make me nervous. I put an eyebolt (my local surplus store sells them cheap) in the board so I could safety wire the manometer to the aircraft, you could just as easily drill a hole and run safety wire through it.

That's it.

Rick Girard

[b]

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

The smallest miracle right in front of you is enough to make you happy.... |

|

| Back to top |

|

|

zeprep251(at)aol.com

Guest

|

Posted: Sat Oct 03, 2009 4:41 am Post subject: 2 stroke carb synchronizing Posted: Sat Oct 03, 2009 4:41 am Post subject: 2 stroke carb synchronizing |

|

|

The manometer has to be the most accurate method .But for me,two new round no.2 pencils worked fine.

G.Aman former 503dcdi carb synchronizer.My spell checker claims that we have invented a new word!

--

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

Jeffrey Dill

Joined: 23 Jul 2007

Posts: 52

Location: Pleasant view, TN

|

Posted: Wed Jul 11, 2012 8:50 am Post subject: Re: 2 stroke carb synchronizing Posted: Wed Jul 11, 2012 8:50 am Post subject: Re: 2 stroke carb synchronizing |

|

|

This is an old but excellent post. I don’t recall seeing the pasted Rotax synch procedure before. I have seen similar suggestions, just not the Rotax procedure; what book is it in?. I am running a 503 on a model 2 Kitfox and so far have not used a manometer. I guess you could say I was using a pencil jig to equal throttle position at idle, and then at high rpm. The engine has been running great except I saw somewhere that the EGTs are supposed to be within 40 degrees of each other. I am usually slightly outside of that window at high rpm. At low RPM the higher EGT is actually the opposite cylinder, does that make any sense? I operate at wide open throttle a lot. When I looked at my carbs at WOT, they were both beyond fully opened, so I don’t know what else I could do even if I put a manometer on it. If they are both open all the way, what else can be adjusted to balance the EGTs? Comments?

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

Jeff Dill

Model 2 |

|

| Back to top |

|

|

John Hauck

Joined: 09 Jan 2006

Posts: 4639

Location: Titus, Alabama (hauck's holler)

|

Posted: Wed Jul 11, 2012 9:55 am Post subject: 2 stroke carb synchronizing Posted: Wed Jul 11, 2012 9:55 am Post subject: 2 stroke carb synchronizing |

|

|

If they are both open all the way, what else can be adjusted to balance

the EGTs? Comments?

--------

Jeff Dill

Model 2

I wouldn't bet the farm on instrumentation found in Kolb Aircraft. They are

by no means precision instruments.

john h

mkIII

Titus, Alabama

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

John Hauck

MKIII/912ULS

hauck's holler

Titus, Alabama |

|

| Back to top |

|

|

zeprep251(at)aol.com

Guest

|

Posted: Wed Jul 11, 2012 5:25 pm Post subject: 2 stroke carb synchronizing Posted: Wed Jul 11, 2012 5:25 pm Post subject: 2 stroke carb synchronizing |

|

|

Jeff,

The slides clear the throttle bore by about 1/4" at full throttle.They can't let more air in by going past the bore but they allow the needles to be pulled out of the jets to the max,for richest mixture at full load.You can adjust for closed with slides bottomed with the screws backed out,then do the pencil thing to adjust cables to sync off idle movement after turning the idle speed screws in until they contact the slides.Then just turn the speed screws in the same amount for correct idle speed.I could get smooth idle below 1800rpm without using a manometer.The slow idle speed really shortened the landing distance,like having a drag chute on the FS-2

G.Aman FS-2 503dcdi MK-3 jabiru 2200A

--

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

|

|

| Back to top |

|

|

Richard Pike

Joined: 09 Jan 2006

Posts: 1671

Location: Blountville, Tennessee

|

Posted: Thu Jul 12, 2012 6:20 am Post subject: Re: 2 stroke carb synchronizing Posted: Thu Jul 12, 2012 6:20 am Post subject: Re: 2 stroke carb synchronizing |

|

|

Not wishing to hijack the thread, or sound like a know-it-all, but I have had very good results by pulling off the air cleaner and working the throttle lever until the top of the cut out in the back of the slide is even with the top of the carburetor throttle bore. This is typically at around 90 - 95% throttle.

If they are not identically aligned, turn the adjustment barrel at the top of the carb until they are. If the top surface edge of both slide cut outs are exactly aligned with their respective bores, then you will have EGT readings that are real close. Maybe not as perfect as using the manometer, but real close.

It is also extremely easy to see and do. And I like that.

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

Richard Pike

Kolb MKIII N420P (420ldPoops)

Kingsport, TN 3TN0

Forgiving is tough, being forgiven is wonderful, and God's grace really is amazing. |

|

| Back to top |

|

|

rickofudall

Joined: 19 Sep 2009

Posts: 1392

Location: Udall, KS, USA

|

Posted: Thu Jul 12, 2012 6:44 am Post subject: 2 stroke carb synchronizing Posted: Thu Jul 12, 2012 6:44 am Post subject: 2 stroke carb synchronizing |

|

|

Jeff, Somewhere in the archives is a post by me about how to make and use a manometer. You can find it by doing a search of my posts.You are right about the throttle slide going past full open, but it doesn't really matter. When you have your airplane staked down for setting the carbs run the engine up to full throttle by the tach, not the throttle position, hit the kill switches on the mags, and once the engine has stopped pull the aircleaners. The throttle slide will be about 1/4" BELOW the top of the carb bore. This is why it's important to use a manometer to balance the carbs. All of your flying is done with the throttle slide less than fully open so they need to be exact in their sychronization.

If your throttle linkage allows you to pull the slide to top of the bore I suggest you put a stop on your linkage to prevent it from opening further than the top of the carb bore. Pulling them further to the top of the slide bore only puts a strain on the throttle cables and can cause cable failure, which will make for a stressful day. As I recall Rotax has a service bulletin or instruction about this.

Rick Girard

do not archive

On Wed, Jul 11, 2012 at 8:24 PM, Gary Aman <zeprep251(at)aol.com (zeprep251(at)aol.com)> wrote:

[quote]Jeff,

The slides clear the throttle bore by about 1/4" at full throttle.They can't let more air in by going past the bore but they allow the needles to be pulled out of the jets to the max,for richest mixture at full load.You can adjust for closed with slides bottomed with the screws backed out,then do the pencil thing to adjust cables to sync off idle movement after turning the idle speed screws in until they contact the slides.Then just turn the speed screws in the same amount for correct idle speed.I could get smooth idle below 1800rpm without using a manometer.The slow idle speed really shortened the landing distance,like having a drag chute on the FS-2

G.Aman FS-2 503dcdi MK-3 jabiru 2200A

--

| | - The Matronics Kolb-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kolb-List |

|

_________________

The smallest miracle right in front of you is enough to make you happy.... |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|