|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Oct 31, 2012 12:12 pm Post subject: single vs. 3-phase alternators (forgot the picture!) Posted: Wed Oct 31, 2012 12:12 pm Post subject: single vs. 3-phase alternators (forgot the picture!) |

|

|

At 01:02 PM 10/31/2012, you wrote:

--> AeroElectric-List message posted by: "user9253" <fran4sew(at)banyanol.com>

> do you know why these brushless alternator designs didn't use three

> phases like a modern BLDC motor?

This is pure speculation on my part; so correct me if wrong.

If the coils of a single phase alternator were rewired to make a 3 phase alternator, then voltage output would be only 1/3 of the single phase voltage. In order for a 3 phase alternator to have the same voltage output as a single phase alternator, it would have to have two more windings of the same size. Then it would weigh more and cost more.

Joe

--------

Joe Gores

The power output from an AC device is roughly proportional

to the weight of the active magnetic material (core), magnetic

strength and speed (rpm). I'm recalling from memory now but

back when I was winding my own transformers, a 1 pound core

was good for about 60 watts at 60 Hz. The same weight of core

in a 400 Hz system was good for 6.5 times that power . . .

400 watts. This assumes similar levels of magnetic flux

that can be carried in the core without saturation or

increases losses at higher frequencies.

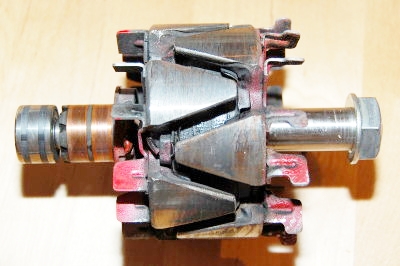

An automotive alternator is already crafted as a 3-phase

device. The configuration requires that pole-pairs on the

rotating magnet come in some multiple of 3 (usually

6 pairs but can be more on larger machines).

[img]cid:7.1.0.9.0.20121031151100.01e2d220(at)aeroelectric.com.0[/img]

The output voltage of any given winding is proportional

to speed x flux value x number of turns. When you 'rewind'

to get more voltage, it generally has to be done with

smaller wire . . . the winding window in the core is fixed.

The practical power output is not a linear function because

of heating effects of I-squared x R in the wires and the

windings ability to reject heat into the core and end turns.

There's not a great deal to be gained in power by going from

single to three-phase . . . it's that weight,flux,speed thing.

The BIG toe-stubber is pole piece configuration. The magnets

glued to the inside of the popular PM alternator shells (or

wound-field machines) are already optimized for their as-

manufactured condition. It takes more than a 'rewinding'

to morph from single to 3-phase configuration. But assuming

all other things are held the same, the watts-per-pound-per-

velocity will be the same for both configurations.

The BIG advantage of 3-phase is the smoother output with

simple full-wave rectification . . . about 5% ripple as

compared to 100% ripple for single-phase. But if the designer

sets out to do a clean piece of paper, 3-phase design it

will be only moderately more expensive. The power can be

a little better because the windings share duties . . . i.e.

there is never a time when current goes to zero in more than

one winding.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

73.52 KB |

| Viewed: |

1269 Time(s) |

|

|

|

| Back to top |

|

|

jbr79r(at)yahoo.com

Guest

|

Posted: Wed Oct 31, 2012 1:40 pm Post subject: single vs. 3-phase alternators (forgot the picture!) Posted: Wed Oct 31, 2012 1:40 pm Post subject: single vs. 3-phase alternators (forgot the picture!) |

|

|

Hi Bob

Is the small Walmart battery tender a good deal. It is quite a bit less expensive than the battery tender brand, Your opinion?

Jim Robinson

Sent from my iPad

On Oct 31, 2012, at 3:11 PM, "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

[quote] At 01:02 PM 10/31/2012, you wrote:

--> AeroElectric-List message posted by: "user9253" <fran4sew(at)banyanol.com (fran4sew(at)banyanol.com)>

> do you know why these brushless alternator designs didn't use three

> phases like a modern BLDC motor?

This is pure speculation on my part; so correct me if wrong.

If the coils of a single phase alternator were rewired to make a 3 phase alternator, then voltage output would be only 1/3 of the single phase voltage. In order for a 3 phase alternator to have the same voltage output as a single phase alternator, it would have to have two more windings of the same size. Then it would weigh more and cost more.

Joe

--------

Joe Gores

The power output from an AC device is roughly proportional

to the weight of the active magnetic material (core), magnetic

strength and speed (rpm). I'm recalling from memory now but

back when I was winding my own transformers, a 1 pound core

was good for about 60 watts at 60 Hz. The same weight of core

in a 400 Hz system was good for 6.5 times that power . . .

400 watts. This assumes similar levels of magnetic flux

that can be carried in the core without saturation or

increases losses at higher frequencies.

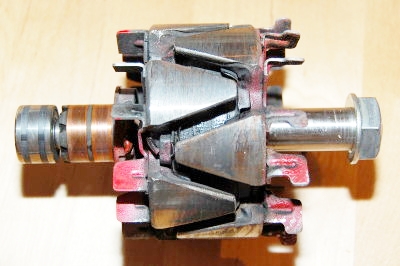

An automotive alternator is already crafted as a 3-phase

device. The configuration requires that pole-pairs on the

rotating magnet come in some multiple of 3 (usually

6 pairs but can be more on larger machines).

<1ddd5eb8.jpg>

The output voltage of any given winding is proportional

to speed x flux value x number of turns. When you 'rewind'

to get more voltage, it generally has to be done with

smaller wire . . . the winding window in the core is fixed.

The practical power output is not a linear function because

of heating effects of I-squared x R in the wires and the

windings ability to reject heat into the core and end turns.

There's not a great deal to be gained in power by going from

single to three-phase . . . it's that weight,flux,speed thing.

The BIG toe-stubber is pole piece configuration. The magnets

glued to the inside of the popular PM alternator shells (or

wound-field machines) are already optimized for their as-

manufactured condition. It takes more than a 'rewinding'

to morph from single to 3-phase configuration. But assuming

all other things are held the same, the watts-per-pound-per-

velocity will be the same for both configurations.

The BIG advantage of 3-phase is the smoother output with

simple full-wave rectification . . . about 5% ripple as

compared to 100% ripple for single-phase. But if the designer

sets out to do a clean piece of paper, 3-phase design it

will be only moderately more expensive. The power can be

a little better because the windings share duties . . . i.e.

there is never a time when current goes to zero in more than

one winding.

Bob . . .

[b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|