|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

jspc78(at)yahoo.com

Guest

|

Posted: Fri Oct 26, 2012 1:13 pm Post subject: Pre-oiling 912ULS Posted: Fri Oct 26, 2012 1:13 pm Post subject: Pre-oiling 912ULS |

|

|

Greetings all:

I looked in the archives and didn't see an answer so here goes:

I have a 912ULS, in the crate I bought it in 2005. I just unwrapped it and would like to pressurize the oil system with engine oil since the engine has been sitting so long and I am very concerned about roating the engine (dry) to get the internal pump to move oil. I have a 12 volt oil pump, return tank and accessories to accomplish this, however I have a question:

Can I simply feed the oil pump inlet hose-barb with oil pressure to circulate oil throughout the gallery? I am concerned the pump will not pass oil if the engine is not turning.

Alternately I could remove the pressure sender and feed the gallery from there unless there is some reason not to. My preference is to feed through the larger oil pump inlet in the hipe of greater flow through the gallery.

I plan to return the oil by draining the crankcase through the return hosebarb and back into the return tank.

Any thoughts or suggestions to circulate oil through my engine?

Thanks, Jim

Kolb Mark3X

912ULS

80% completed

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

Roger Lee

Joined: 10 Jan 2006

Posts: 1464

Location: Tucson, Az.

|

Posted: Fri Oct 26, 2012 2:47 pm Post subject: Re: Pre-oiling 912ULS Posted: Fri Oct 26, 2012 2:47 pm Post subject: Re: Pre-oiling 912ULS |

|

|

Hi Jim,

You will need to do a good oil purge.

Here is the Rotax link to a video:

http://www.rotax-owner.com/information-reg/expanded-video-instructions-reg/33-exp-si-912-018

In the Installation manual section 13.10 page 78 (Oil Purge) are the same instructions.

I would advise that you go to the Rotax Owner website and download the 5 manuals you will need for your engine. They will be very helpful and almost all your answers will be there. You may even want to join the Rotax website as there are some good videos and experience for you to draw on there.

This is very important for this first start, but is easy to do. If It was my first start I would do it twice. It's very easy. twice just means rotating the prop twice as much.

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

Roger Lee

Tucson, Az.

Rotax Instructor & Rotax IRC

Light Sport Repairman

Home 520-574-1080 TRY HOME FIRST

Cell 520-349-7056 |

|

| Back to top |

|

|

jspc78(at)yahoo.com

Guest

|

Posted: Fri Oct 26, 2012 4:02 pm Post subject: Pre-oiling 912ULS Posted: Fri Oct 26, 2012 4:02 pm Post subject: Pre-oiling 912ULS |

|

|

Hi Roger,

Thanks for the response. I agree on the value of the Rotax Owner site. For years I got the updates, and am now reviewing the latest docs. I just joined the pay portion (is paying to play new?) and reviewed the video. The procedure does make sense, and I recall in the maintenance class they stressed the critical importance of purging. That said my question is can I pump oil into the engine *without* rotating it?

The procedure suggests air pressure against the tank to force oil into a turning engine. I am fortunate to have an electric oil pump so I don't need the air pressure.

I am several months from engine start, and have had the engine in its crate, wrapped in plastic for years. I want to circulate oil without rotating what I fear are dry (or nearly so) bearing journals.

When engine start comes I will follow this purging procedure to the letter.

Until then I wish to circulate oil, without first turning the engine.

I will re-examine the engine docs to look at the oil pump/bypass topology, but to save time I was asking if anyone on this list knew if oil can be pumped past a stationary oil pump.

My intent is to rig up my system and pump fresh oil through the gallery several times a month until engine installation. If I am lucky perhaps that will make up for having a new engine in mothballs so long.

Do you (or anyone else) know if a non-turning engine will allow oil under pressure past it?

Thanks, Jim

--- On Fri, 10/26/12, Roger Lee <ssadiver1(at)yahoo.com> wrote:

| Quote: | From: Roger Lee <ssadiver1(at)yahoo.com>

Subject: Re: Pre-oiling 912ULS

To: rotaxengines-list(at)matronics.com

Date: Friday, October 26, 2012, 3:47 PM

--> RotaxEngines-List message

posted by: "Roger Lee" <ssadiver1(at)yahoo.com>

Hi Jim,

You will need to do a good oil purge.

Here is the Rotax link to a video:

http://www.rotax-owner.com/information-reg/expanded-video-instructions-reg/33-exp-si-912-018

In the Installation manual section 13.10 page 78 (Oil Purge)

are the same instructions.

I would advise that you go to the Rotax Owner website and

download the 5 manuals you will need for your engine. They

will be very helpful and almost all your answers will be

there.

This is very important for this first start, but is easy to

do. If It was my first start I would do it twice. It's very

easy. twice just means rotating the prop twice as much.

--------

Roger Lee

Tucson, Az.

Light Sport Repairman - Maintenance Rated

Rotax Repair Center - Heavy Maint. Rated

Home 520-574-1080 TRY HOME FIRST

Cell 520-349-7056

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=386073#386073

RotaxEngines-List Email Forum -

- MATRONICS WEB FORUMS -

List Contribution Web Site -

-Matt

Dralle, List Admin.

|

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

Roger Lee

Joined: 10 Jan 2006

Posts: 1464

Location: Tucson, Az.

|

Posted: Fri Oct 26, 2012 5:33 pm Post subject: Re: Pre-oiling 912ULS Posted: Fri Oct 26, 2012 5:33 pm Post subject: Re: Pre-oiling 912ULS |

|

|

Your going to have to rotate the engine to get into critical areas and past the pump.

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

Roger Lee

Tucson, Az.

Rotax Instructor & Rotax IRC

Light Sport Repairman

Home 520-574-1080 TRY HOME FIRST

Cell 520-349-7056 |

|

| Back to top |

|

|

Thom Riddle

Joined: 10 Jan 2006

Posts: 1597

Location: Buffalo, NY, USA (9G0)

|

Posted: Sat Oct 27, 2012 4:14 am Post subject: Re: Pre-oiling 912ULS Posted: Sat Oct 27, 2012 4:14 am Post subject: Re: Pre-oiling 912ULS |

|

|

Jim,

Roger is correct that you must rotate the engine to get oil through the system even if externally pressurizing the inlet side of the pump. The reason is that the oil pump on the front of the engine is a positive displacement pump, which will allow very little oil (if any) to pass if it is not turning. BTW, when the engine is running, the inlet side of the oil pump is at lower than atmospheric pressure, never pressurized.

I'm not recommending this but you could pressurize the oil system on the outlet side of the pump through the oil pressure relief valve port. If you do this, make sure you remove the relief valve and spring and that the applied pressure is controlled within the allowable range. I don't think it is necessary to do this but in theory it could be done this way.

With a $20,000 engine, why not just follow the manufacturer's directions? It is certainly simpler and Rotax doesn't leave much to chance.

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

Thom Riddle

Buffalo, NY (9G0)

Don't worry about old age... it doesn't last very long.

- Anonymous |

|

| Back to top |

|

|

jspc78(at)yahoo.com

Guest

|

Posted: Sat Oct 27, 2012 9:08 am Post subject: Pre-oiling 912ULS Posted: Sat Oct 27, 2012 9:08 am Post subject: Pre-oiling 912ULS |

|

|

Thom, Roger:

Appreciate the confirmation and suggestions! Point certainly taken regarding adherence to the Rotax procedure. My problem is I waited so long to maintain this engine I am concerned the journals will score if I rotate the engine without adding oil first. I regret not following the Rotax procedure 5 years ago. I had the same though with regard to pressurizing the upstream side of the galley, and am studying the gallery details in the manual now.

Thanks all, and have a great weekend.

-Jim

--- On Sat, 10/27/12, Thom Riddle <riddletr(at)gmail.com> wrote:

| Quote: | From: Thom Riddle <riddletr(at)gmail.com>

Subject: Re: Pre-oiling 912ULS

To: rotaxengines-list(at)matronics.com

Date: Saturday, October 27, 2012, 5:14 AM

--> RotaxEngines-List message

posted by: "Thom Riddle" <riddletr(at)gmail.com>

Jim,

Roger is correct that you must rotate the engine to get oil

through the system even if externally pressurizing the inlet

side of the pump. The reason is that the oil pump on

the front of the engine is a positive displacement pump,

which will allow very little oil (if any) to pass if it is

not turning. BTW, when the engine is running, the inlet side

of the oil pump is at lower than atmospheric pressure, never

pressurized.

I'm not recommending this but you could pressurize the oil

system on the outlet side of the pump through the oil

pressure relief valve port. If you do this, make sure you

remove the relief valve and spring and that the applied

pressure is controlled within the allowable range. I don't

think it is necessary to do this but in theory it could be

done this way.

With a $20,000 engine, why not just follow the

manufacturer's directions? It is certainly simpler and Rotax

doesn't leave much to chance.

--------

Thom Riddle

Buffalo, NY (9G0)

Kolb Slingshot SS-021

Jabiru 2200A #1574

Diamond Katana DA20-A1

Rotax 912 F3

Don't worry about old age... it doesn't last very long.

- Anonymous

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=386100#386100

RotaxEngines-List Email Forum -

- MATRONICS WEB FORUMS -

List Contribution Web Site -

-Matt

Dralle, List Admin.

|

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Sun Oct 28, 2012 5:37 am Post subject: Pre-oiling 912ULS Posted: Sun Oct 28, 2012 5:37 am Post subject: Pre-oiling 912ULS |

|

|

Jim:

As they say your idea is Spot On. The entire idea of Pre-Oiling is to saturate and cover all the rotating parts PRIOR to rotating the the engine. To rotate the engine prior to pre-oiling or during pre-oiling is counter productive.

Since your engine is from 2005 the two questions that come up are:

1 - Where was the engine stored, was it kept in a low humidity area?

2 - Was the engine 'pickled', that is to say - Oiled with a preservative oil that does not run off the engine areas?

When it comes to 'pickling' a little research has to be done:

1 - Does Rotax make a storage oil? If so use it.

2 - If Rotax does NOT make a storage oil, use any storage oil you can obtain. Remember you are NOT running on this oil ONLY storing with it.

Yes - You do run the engine for a short time just to coat the insides of the engine BUT, that is a SHORT TIME and it is WITHOUT LOADS.

Special Note: Take a look at Page 8 - 2 Para 8.2

It states that preservation is for only one year and if stored for more than one year the preservation procedure should be repeated every year.

Have you been doing that?

If not - Start with that procedure prior to Pre-Oiling.

Why do i say that? Only because Pre-Oiling takes care of the engine NOT the gearbox gears. Do everything you can to get those gears wet with oil - SHORT of rotating them - Without oil.

So, how should you Pre-Oil?

1 - Take a look at the manual - Page 7-6 Figure 3 .

2 - Notice the Oil Flow Direction. It goes OUT of the Oil Cooler (item 5) - Into the Engine - Out of the engine and into the Oil Tank (item 4).

3 - I do not know if the picture I attached will get through. If it does not contact me directly and I will send it directly to you.

4 - This picture is of a Pre-Oiler I made. It can handle oil pressure up to 150 PSI. YOU pick the oil pressure your engine operates at and Pre-Oil at that pressure.

5 - Use the engine operating pressure so any valves will be opened by the pressure and the oil spray will cover the same areas as during normal operation.

6 - Since the engine has an Oil Pressure Regulator (item 1), you should pressure the pre-oiler higher than operating pressure and because the pressure drops in the pre-oilier quickly as volume of oil drops.

7 - Monitor the Oil Pressure Gauge of the plane/engine, since the Oil Pressure Sensor (item 2) is hooked up. There will probably be only a small deflection since the pre-oilier is applying pressure for only a short time.

8 - Now, here I have to ask a question. Does the Oil Pump (item 3) have a reverse flow check valve? If YES then you are limited to pre-oilier flow direction.

If NO then - Use the Pre-Oilier in BOTH directions - The IN and the OUT.

9 - When I Pre-Oil, it is done with one (1) quart of oil in each direction - From the Oil Cooler into the Engine and then Into the Engine on the OUTPUT side of the Engine. See note 8.

10 - Now, here you have some options:

a> You can leave the Oil Tank (item 4) attached and it will catch any oil that makes it to the exit of the engine. And remember to hook up a overflow tube to Vent Tube (item 7). I really doubt if this will ever happen, or...

b> Put a Plug on the Engine Exit line/hose so it develops a good pressure to spray the oil all around inside the engine.

The Pictures:

Pic #1 is a general overview

Pic #2 shows the fittings. One thing you can not see is the inside of the unit. From the oil line on the outside is a nylon pick-up tube that goes to the bottom of the unit.

You will see a Shrader valve on top. I hook up a 12VDC portable tire pump. Pressurize the unit to 125 PSI, you can leave the tire pump on and running when you open the valve.

This system is so easy that I pre-oil anytime the engine sits for a month or more.

Barry

On Fri, Oct 26, 2012 at 5:13 PM, Jim Clayton <jspc78(at)yahoo.com (jspc78(at)yahoo.com)> wrote:

| Quote: | --> RotaxEngines-List message posted by: Jim Clayton <jspc78(at)yahoo.com (jspc78(at)yahoo.com)>

Greetings all:

I looked in the archives and didn't see an answer so here goes:

I have a 912ULS, in the crate I bought it in 2005. I just unwrapped it and would like to pressurize the oil system with engine oil since the engine has been sitting so long and I am very concerned about roating the engine (dry) to get the internal pump to move oil. I have a 12 volt oil pump, return tank and accessories to accomplish this, however I have a question:

Can I simply feed the oil pump inlet hose-barb with oil pressure to circulate oil throughout the gallery? I am concerned the pump will not pass oil if the engine is not turning.

Alternately I could remove the pressure sender and feed the gallery from there unless there is some reason not to. My preference is to feed through the larger oil pump inlet in the hipe of greater flow through the gallery.

I plan to return the oil by draining the crankcase through the return hosebarb and back into the return tank.

Any thoughts or suggestions to circulate oil through my engine?

Thanks, Jim

Kolb Mark3X

912ULS

80% completed

===========

-List" target="_blank">http://www.matronics.com/Navigator?RotaxEngines-List

===========

http://forums.matronics.com

===========

le, List Admin.

="_blank">http://www.matronics.com/contribution

===========

|

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

| Description: |

|

| Filesize: |

219.29 KB |

| Viewed: |

11909 Time(s) |

|

| Description: |

|

| Filesize: |

274.87 KB |

| Viewed: |

11909 Time(s) |

|

|

|

| Back to top |

|

|

jspc78(at)yahoo.com

Guest

|

Posted: Mon Oct 29, 2012 2:57 pm Post subject: Pre-oiling 912ULS Posted: Mon Oct 29, 2012 2:57 pm Post subject: Pre-oiling 912ULS |

|

|

Hi Barry,

Thanks for the confirmation regarding a possibly dry engine being rotated to introduce oil. Your pvc pre-oiler is really cool! Thanks for the pics.

I purchased the engine around 2005. I peeled back the plastic, took a bunch of pictures and rewrapped it tightly sealing the plastic and reassembled the crate. The crate lived the next 7 plus years in my spare bedroom, temperature controlled. Fast forward to last week. I opened it and pulled the engine out of the crate. Close inspection showed the engine was still externally slightly oily, and the crankcase has remnants of the oil used during the test run at the factory. All good news I think.

After much consideration I decided to inject oil into the pressure sender port. As was confirmed by this list’s experts the oil pump is a positive displacement type (no surprise) so I needed to inject oil upstream of the pump if I desire gallery oil pressure without turning. I didn’t inject at the pressure regulator as suggested cause I didn’t have ready access to the metric fitting holding the spring, and I wasn’t sure if I would simply vent oil directly to the crankcase bypassing the gallery if I took the regulator apart. So I went with the pressure sensor port.

I removed the pressure sender and fed it oil (semi-syn motorcycle formulation since it will touch the wet clutch in the gearbox) at 40 to 55psi from a 12 volt pump. Added a tee in the pipe and 6 feet of sealed tubing (see pic) to act as a pressure accumulator so the pump doesn’t chatter. Worked out to 3 seconds of pump runtime to 12 seconds of resting. After running all day the pump wasn’t even warm. I opened the valve covers and saw oil coming out the pushrods, confirming the oil gallery is pressurized.

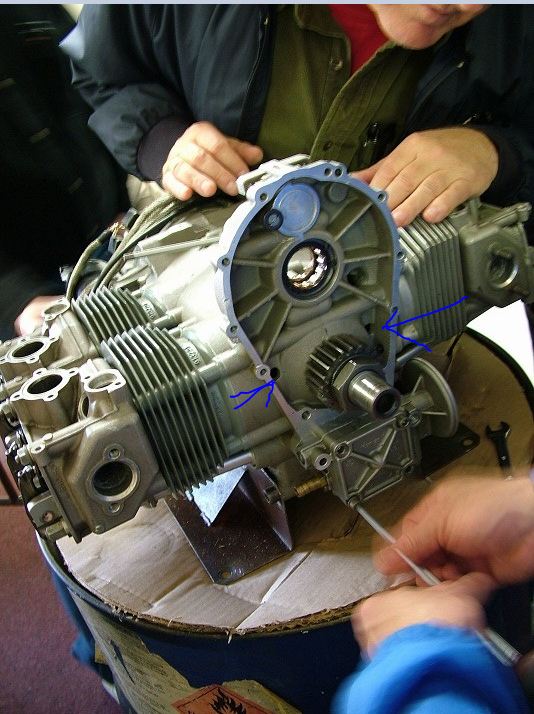

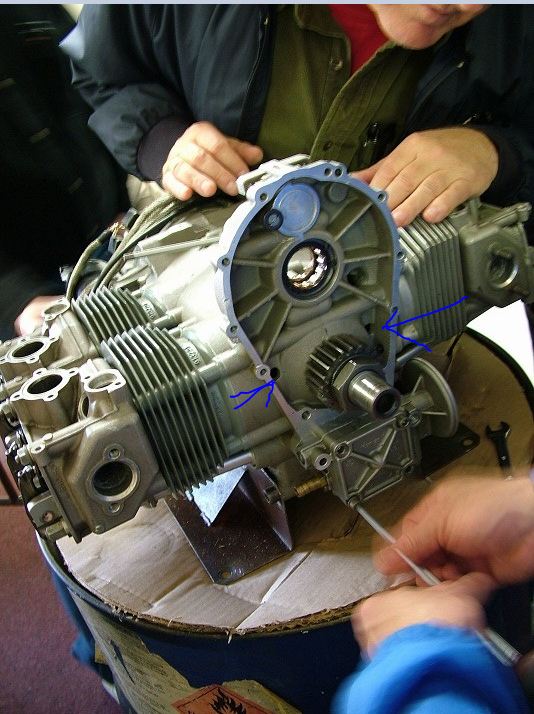

Next I raised the drain line to trap oil in the engine (see pic), and used it as a sight glass to predict the level in the crankcase. The level was also high enough to submerge the bottom passage to the gearbox (see pic of open gearbox from the servicing class). Then I leaned the engine left and right, forward and back to submerge the pistons/pins and slosh oil around in the gearbox. Drained the crankcase, put a couple of tablespoon of oil into each sparkplug hole. Finally, after hours of oil circulation I turned the engine over, plugs still out.

Note I was using a clean bucket for the oil supply. I seem to have misplaced my oil tank. I will look around for it a little longer before I worry about buying another!

I offer this only for entertainment purposes and don’t suggest anyone perform this procedure without approval from your Rotax dealer. My engine is long out of warranty and I alone am responsible for the outcome. I intend to keep the engine in this oiling regime until I am ready to start it; at which time I will purge the system and confirm lifter status per the Rotax procedure.

-Jim

--- On Sun, 10/28/12, FLYaDIVE <flyadive(at)gmail.com> wrote:

| Quote: |

From: FLYaDIVE <flyadive(at)gmail.com>

Subject: Re: RotaxEngines-List: Pre-oiling 912ULS

To: rotaxengines-list(at)matronics.com

Date: Sunday, October 28, 2012, 6:37 AM

Jim:

As they say your idea is Spot On. The entire idea of Pre-Oiling is to saturate and cover all the rotating parts PRIOR to rotating the the engine. To rotate the engine prior to pre-oiling or during pre-oiling is counter productive.

Since your engine is from 2005 the two questions that come up are:

1 - Where was the engine stored, was it kept in a low humidity area?

2 - Was the engine 'pickled', that is to say - Oiled with a preservative oil that does not run off the engine areas?

When it comes to 'pickling' a little research has to be done:

1 - Does Rotax make a storage oil? If so use it.

2 - If Rotax does NOT make a storage oil, use any storage oil you can obtain. Remember you are NOT running on this oil ONLY storing with it.

Yes - You do run the engine for a short time just to coat the insides of the engine BUT, that is a SHORT TIME and it is WITHOUT LOADS.

Special Note: Take a look at Page 8 - 2 Para 8.2

It states that preservation is for only one year and if stored for more than one year the preservation procedure should be repeated every year.

Have you been doing that?

If not - Start with that procedure prior to Pre-Oiling.

Why do i say that? Only because Pre-Oiling takes care of the engine NOT the gearbox gears. Do everything you can to get those gears wet with oil - SHORT of rotating them - Without oil.

So, how should you Pre-Oil?

1 - Take a look at the manual - Page 7-6 Figure 3 .

2 - Notice the Oil Flow Direction. It goes OUT of the Oil Cooler (item 5) - Into the Engine - Out of the engine and into the Oil Tank (item 4).

3 - I do not know if the picture I attached will get through. If it does not contact me directly and I will send it directly to you.

4 - This picture is of a Pre-Oiler I made. It can handle oil pressure up to 150 PSI. YOU pick the oil pressure your engine operates at and Pre-Oil at that pressure.

5 - Use the engine operating pressure so any valves will be opened by the pressure and the oil spray will cover the same areas as during normal operation.

6 - Since the engine has an Oil Pressure Regulator (item 1), you should pressure the pre-oiler higher than operating pressure and because the pressure drops in the pre-oilier quickly as volume of oil drops.

7 - Monitor the Oil Pressure Gauge of the plane/engine, since the Oil Pressure Sensor (item 2) is hooked up. There will probably be only a small deflection since the pre-oilier is applying pressure for only a short time.

8 - Now, here I have to ask a question. Does the Oil Pump (item 3) have a reverse flow check valve? If YES then you are limited to pre-oilier flow direction.

If NO then - Use the Pre-Oilier in BOTH directions - The IN and the OUT.

9 - When I Pre-Oil, it is done with one (1) quart of oil in each direction - From the Oil Cooler into the Engine and then Into the Engine on the OUTPUT side of the Engine. See note 8.

10 - Now, here you have some options:

a> You can leave the Oil Tank (item 4) attached and it will catch any oil that makes it to the exit of the engine. And remember to hook up a overflow tube to Vent Tube (item 7). I really doubt if this will ever happen, or...

b> Put a Plug on the Engine Exit line/hose so it develops a good pressure to spray the oil all around inside the engine.

The Pictures:

Pic #1 is a general overview

Pic #2 shows the fittings. One thing you can not see is the inside of the unit. From the oil line on the outside is a nylon pick-up tube that goes to the bottom of the unit.

You will see a Shrader valve on top. I hook up a 12VDC portable tire pump. Pressurize the unit to 125 PSI, you can leave the tire pump on and running when you open the valve.

This system is so easy that I pre-oil anytime the engine sits for a month or more.

Barry

On Fri, Oct 26, 2012 at 5:13 PM, Jim Clayton <[url=/mc/compose?to=jspc78(at)yahoo.com]jspc78(at)yahoo.com[/url]> wrote:

| Quote: | --> RotaxEngines-List message posted by: Jim Clayton <[url=/mc/compose?to=jspc78(at)yahoo.com]jspc78(at)yahoo.com[/url]>

Greetings all:

I looked in the archives and didn't see an answer so here goes:

I have a 912ULS, in the crate I bought it in 2005. I just unwrapped it and would like to pressurize the oil system with engine oil since the engine has been sitting so long and I am very concerned about roating the engine (dry) to get the internal pump to move oil. I have a 12 volt oil pump, return tank and accessories to accomplish this, however I have a question:

Can I simply feed the oil pump inlet hose-barb with oil pressure to circulate oil throughout the gallery? I am concerned the pump will not pass oil if the engine is not turning.

Alternately I could remove the pressure sender and feed the gallery from there unless there is some reason not to. My preference is to feed through the larger oil pump inlet in the hipe of greater flow through the gallery.

I plan to return the oil by draining the crankcase through the return hosebarb and back into the return tank.

Any thoughts or suggestions to circulate oil through my engine?

Thanks, Jim

Kolb Mark3X

912ULS

80% completed

===========

-List" target="_blank">http://www.matronics.com/Navigator?RotaxEngines-List

===========

http://forums.matronics.com

===========

le, List Admin.

="_blank">http://www.matronics.com/contribution

===========

|

|

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

| Description: |

|

| Filesize: |

87.77 KB |

| Viewed: |

11894 Time(s) |

|

| Description: |

|

| Filesize: |

263.34 KB |

| Viewed: |

11894 Time(s) |

|

| Description: |

|

| Filesize: |

271.34 KB |

| Viewed: |

11894 Time(s) |

|

|

|

| Back to top |

|

|

Gilles.Thesee(at)ac-greno

Guest

|

Posted: Mon Oct 29, 2012 3:33 pm Post subject: Pre-oiling 912ULS Posted: Mon Oct 29, 2012 3:33 pm Post subject: Pre-oiling 912ULS |

|

|

Jim Clayton a Ă©crit :

| Quote: |

I offer this only for entertainment purposes and don’t suggest anyone

perform this procedure without approval from your Rotax dealer. My

engine is long out of warranty and I alone am responsible for the

outcome. I intend to keep the engine in this oiling regime until I am

ready to start it; at which time I will purge the system and confirm

lifter status per the Rotax procedure.

Jim,

|

In my opinion, you did well, though it might be overkill. Nothing wrong

with having the engine thoroughly oiled before use.

Someone mentioned possible problems with the gearbox : you can't do much

harm to the gears by turning the engine by hand a few turns, even if

they happened to be dry.

Very few jounals in the Rotax, so the main issue migth be moving the

pistons in a dry cylinder. Not sure, but you certainly took care of this

by injecting some oil through the plug holes before turning anything.

Apart from this, no much risk with piston pins etc...

If correctly drained, too much oil will not harm the engine.

FWIW,

Best regards,

--

Gilles

http://contrails.free.fr

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

dashwood

Joined: 24 Jan 2009

Posts: 73

Location: sw ontario canada

|

Posted: Mon Oct 29, 2012 7:39 pm Post subject: Re: Pre-oiling 912ULS Posted: Mon Oct 29, 2012 7:39 pm Post subject: Re: Pre-oiling 912ULS |

|

|

just a thought on a bit off subject.. but looking at the pic of the back side of the gearbox...

has anyone thought of plugging the oil journal holes in a gearbox... tapping a plug hole in the top and filling it with 90 gear oil... would solve a lot of issues with 912 and the oil debates. and the problems with excessive wear.. i am not sure of effects of slipper clutching.. just talking bout gears only boxes....

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

Ross Alexander: CH701 driver 912ul 788tt

It only takes two things to fly, airspeed and money |

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Wed Oct 31, 2012 6:16 am Post subject: Pre-oiling 912ULS Posted: Wed Oct 31, 2012 6:16 am Post subject: Pre-oiling 912ULS |

|

|

Jim:

Sorry for the delay in responding, I'm in NJ and we lost power for the last

day or so.

HEY  Really great contraption. I love your set up. You have just Really great contraption. I love your set up. You have just

done a better job of oiling than Rotax ever would. The idea of the sight

tube (Egyptian Water Level) for oil level is a great idea. Now you now

know exactly the level oil and what was covered. Good Job Old Man.

Now, don't be surprised if you make a lot of smoke on your first start up.

It will last only a few seconds and only those outside the plane will

notice IF they pay attention. The prop blast will disperse things rapidly.

Getting oil to the gears is the next big issue. Lots of moving parts and

lots of metal on metal contact areas. If you were to:

1 - Remove the spark plugs.

2 - Ground the Mags.

3 - Totally flood the gear area - AND -

4 - Then turn the engine over by hand or with a heavy duty 1/2" Electric

Drill.

You will have covered all bases and will have that Totally Warm Fuzzy

Feeling.

5 - You could also squirt some oil in the cylinders prior to turning over

the engine by hand.

The only really rough Metal on Metal area is the rings and cylinder - Extra

oil there worn hurt.

Great Job - Keep us informed.

Barry

On Mon, Oct 29, 2012 at 6:56 PM, Jim Clayton <jspc78(at)yahoo.com> wrote:

[quote] Hi Barry,****

** **

Thanks for the confirmation regarding a possibly dry engine being rotated

to introduce oil. Your pvc pre-oiler is really cool! Thanks for the pics.

****

** **

I purchased the engine around 2005. I peeled back the plastic, took a

bunch of pictures and rewrapped it tightly sealing the plastic and

reassembled the crate. The crate lived the next 7 plus years in my spare

bedroom, temperature controlled. Fast forward to last week. I opened it

and pulled the engine out of the crate. Close inspection showed the engine

was still externally slightly oily, and the crankcase has remnants of the

oil used during the test run at the factory. All good news I think.****

** **

After much consideration I decided to inject oil into the pressure sender

port. As was confirmed by this list’s experts the oil pump is a positive

displacement type (no surprise) so I needed to inject oil upstream of the

pump if I desire gallery oil pressure without turning. I didn’t inject at

the pressure regulator as suggested cause I didn’t have ready access to the

metric fitting holding the spring, and I wasn’t sure if I would simply vent

oil directly to the crankcase bypassing the gallery if I took the regulator

apart. So I went with the pressure sensor port.****

** **

I removed the pressure sender and fed it oil (semi-syn motorcycle

formulation since it will touch the wet clutch in the gearbox) at 40 to

55psi from a 12 volt pump. Added a tee in the pipe and 6 feet of sealed

tubing (see pic) to act as a pressure accumulator so the pump doesn’t

chatter. Worked out to 3 seconds of pump runtime to 12 seconds of

resting. After running all day the pump wasn’t even warm. I opened the

valve covers and saw oil coming out the pushrods, confirming the oil

gallery is pressurized.****

** **

Next I raised the drain line to trap oil in the engine (see pic), and used

it as a sight glass to predict the level in the crankcase. The level was

also high enough to submerge the bottom passage to the gearbox (see pic of

open gearbox from the servicing class). Then I leaned the engine left and

right, forward and back to submerge the pistons/pins and slosh oil around

in the gearbox. Drained the crankcase, put a couple of tablespoon of oil

into each sparkplug hole. Finally, after hours of oil circulation I turned

the engine over, plugs still out. ****

** **

Note I was using a clean bucket for the oil supply. I seem to have

misplaced my oil tank. I will look around for it a little longer before I

worry about buying another!****

** **

I offer this only for entertainment purposes and don’t suggest anyone

perform this procedure without approval from your Rotax dealer. My engine

is long out of warranty and I alone am responsible for the outcome. I

intend to keep the engine in this oiling regime until I am ready to start

it; at which time I will purge the system and confirm lifter status per the

Rotax procedure. ****

** **

-Jim****

--- On *Sun, 10/28/12, FLYaDIVE <flyadive(at)gmail.com>* wrote:

From: FLYaDIVE <flyadive(at)gmail.com>

Subject: Re: Pre-oiling 912ULS

To: rotaxengines-list(at)matronics.com

Date: Sunday, October 28, 2012, 6:37 AM

Jim:

As they say your idea is Spot On. The entire idea of Pre-Oiling is to

saturate and cover all the rotating parts PRIOR to rotating the the engine.

To rotate the engine prior to pre-oiling or during pre-oiling is counter

productive.

Since your engine is from 2005 the two questions that come up are:

1 - Where was the engine stored, was it kept in a low humidity area?

2 - Was the engine 'pickled', that is to say - Oiled with

a preservative oil that does not run off the engine areas?

When it comes to 'pickling' a little research has to be done:

1 - Does Rotax make a storage oil? If so use it.

2 - If Rotax does NOT make a storage oil, use any storage oil you can

obtain. Remember you are NOT running on this oil ONLY storing with it.

Yes - You do run the engine for a short time just to coat the insides of

the engine BUT, that is a SHORT TIME and it is WITHOUT LOADS.

Special Note: Take a look at Page 8 - 2 Para 8.2

It states that preservation is for only one year and if stored for more

than one year the preservation procedure should be repeated every year.

Have you been doing that?

If not - Start with that procedure prior to Pre-Oiling.

Why do i say that? Only because Pre-Oiling takes care of the engine NOT

the gearbox gears. Do everything you can to get those gears wet with oil -

SHORT of rotating them - Without oil.

So, how should you Pre-Oil?

1 - Take a look at the manual - Page 7-6 Figure 3 .

2 - Notice the Oil Flow Direction. It goes OUT of the Oil Cooler (item 5)

- Into the Engine - Out of the engine and into the Oil Tank (item 4).

3 - I do not know if the picture I attached will get through. If it does

not contact me directly and I will send it directly to you.

4 - This picture is of a Pre-Oiler I made. It can handle oil pressure up

to 150 PSI. YOU pick the oil pressure your engine operates at and Pre-Oil

at that pressure.

5 - Use the engine operating pressure so any valves will be opened by the

pressure and the oil spray will cover the same areas as during normal

operation.

6 - Since the engine has an Oil Pressure Regulator (item 1), you should

pressure the pre-oiler higher than operating pressure and because the

pressure drops in the pre-oilier quickly as volume of oil drops.

7 - Monitor the Oil Pressure Gauge of the plane/engine, since the Oil

Pressure Sensor (item 2) is hooked up. There will probably be only a small

deflection since the pre-oilier is applying pressure for only a short time.

8 - Now, here I have to ask a question. Does the Oil Pump (item 3) have a

reverse flow check valve? If YES then you are limited to pre-oilier flow

direction.

If NO then - Use the Pre-Oilier in BOTH directions - The IN and the OUT.

9 - When I Pre-Oil, it is done with one (1) quart of oil in each direction

- From the Oil Cooler into the Engine and then Into the Engine on the

OUTPUT side of the Engine. See note 8.

10 - Now, here you have some options:

a> You can leave the Oil Tank (item 4) attached and it will catch any oil

that makes it to the exit of the engine. And remember to hook up a

overflow tube to Vent Tube (item 7). I really doubt if this will ever

happen, or...

b> Put a Plug on the Engine Exit line/hose so it develops a good pressure

to spray the oil all around inside the engine.

The Pictures:

Pic #1 is a general overview

Pic #2 shows the fittings. One thing you can not see is the inside of the

unit. From the oil line on the outside is a nylon pick-up tube that goes

to the bottom of the unit.

You will see a Shrader valve on top. I hook up a 12VDC portable tire

pump. Pressurize the unit to 125 PSI, you can leave the tire pump on and

running when you open the valve.

This system is so easy that I pre-oil anytime the engine sits for a month

or more.

Barry

On Fri, Oct 26, 2012 at 5:13 PM, Jim Clayton <jspc78(at)yahoo.com<http://mc/compose?to=jspc78(at)yahoo.com>

> wrote:

>

Greetings all:

I looked in the archives and didn't see an answer so here goes:

I have a 912ULS, in the crate I bought it in 2005. I just unwrapped it

and would like to pressurize the oil system with engine oil since the

engine has been sitting so long and I am very concerned about roating the

engine (dry) to get the internal pump to move oil. I have a 12 volt oil

pump, return tank and accessories to accomplish this, however I have a

question:

Can I simply feed the oil pump inlet hose-barb with oil pressure to

circulate oil throughout the gallery? I am concerned the pump will not

pass oil if the engine is not turning.

Alternately I could remove the pressure sender and feed the gallery from

there unless there is some reason not to. My preference is to feed through

the larger oil pump inlet in the hipe of greater flow through the gallery

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

jspc78(at)yahoo.com

Guest

|

Posted: Wed Oct 31, 2012 4:03 pm Post subject: Pre-oiling 912ULS Posted: Wed Oct 31, 2012 4:03 pm Post subject: Pre-oiling 912ULS |

|

|

Hi Barry/All:

Thanks! I am running the pump 30 minutes a day so the overkill makes me feel better about storing the engine for so long

I agree with respect to the gearbox. While I did lean the engine forward while the crankcase was full, I am concerned about the big bearings on the prop shaft. I was thinking of again removing the fuel pump, putting a couple of pints of oil in, and closing it up. Then with several helpers turning the engine upside down. This would trap oil at the prop-shaft end. Leave it upside down for perhaps a couple of hours to marinate two big bearings. Looking at the photos I took in the servicing class, I suspect those bearings need a bit of splash to keep those two lubed. I figure an hour or so marinating maybe soak in enough oil to suffice. Once done I will turn it right side up, and allow all the oil to drain.

I am several months from mounting the engine on the plane, so this system will stay in place awhile. Wish I could find the oil tank as the open bucket has to go. I will post separately asking if anyone has a spare oil tank (I know...not likely).

-Jim

--- On Wed, 10/31/12, FLYaDIVE <flyadive(at)gmail.com> wrote:

| Quote: |

From: FLYaDIVE <flyadive(at)gmail.com>

Subject: Re: Pre-oiling 912ULS

To: rotaxengines-list(at)matronics.com

Date: Wednesday, October 31, 2012, 7:15 AM

Jim:

Sorry for the delay in responding, I'm in NJ and we lost power for the last day or so.

HEY  Really great contraption. I love your set up. You have just done a better job of oiling than Rotax ever would. The idea of the sight tube (Egyptian Water Level) for oil level is a great idea. Now you now know exactly the level oil and what was covered. Good Job Old Man. Really great contraption. I love your set up. You have just done a better job of oiling than Rotax ever would. The idea of the sight tube (Egyptian Water Level) for oil level is a great idea. Now you now know exactly the level oil and what was covered. Good Job Old Man.

Now, don't be surprised if you make a lot of smoke on your first start up. It will last only a few seconds and only those outside the plane will notice IF they pay attention. The prop blast will disperse things rapidly.

Getting oil to the gears is the next big issue. Lots of moving parts and lots of metal on metal contact areas. If you were to:

1 - Remove the spark plugs.

2 - Ground the Mags.

3 - Totally flood the gear area - AND -

4 - Then turn the engine over by hand or with a heavy duty 1/2" Electric Drill.

You will have covered all bases and will have that Totally Warm Fuzzy Feeling.

5 - You could also squirt some oil in the cylinders prior to turning over the engine by hand.

The only really rough Metal on Metal area is the rings and cylinder - Extra oil there worn hurt.

Great Job - Keep us informed.

Barry

On Mon, Oct 29, 2012 at 6:56 PM, Jim Clayton <[url=/mc/compose?to=jspc78(at)yahoo.com]jspc78(at)yahoo.com[/url]> wrote:

| Quote: |

Hi Barry,

Thanks for the confirmation regarding a possibly dry engine being rotated to introduce oil. Your pvc pre-oiler is really cool! Thanks for the pics.

I purchased the engine around 2005. I peeled back the plastic, took a bunch of pictures and rewrapped it tightly sealing the plastic and reassembled the crate. The crate lived the next 7 plus years in my spare bedroom, temperature controlled. Fast forward to last week. I opened it and pulled the engine out of the crate. Close inspection showed the engine was still externally slightly oily, and the crankcase has remnants of the oil used during the test run at the factory. All good news I think.

After much consideration I decided to inject oil into the pressure sender port. As was confirmed by this list’s experts the oil pump is a positive displacement type (no surprise) so I needed to inject oil upstream of the pump if I desire gallery oil pressure without turning. I didn’t inject at the pressure regulator as suggested cause I didn’t have ready access to the metric fitting holding the spring, and I wasn’t sure if I would simply vent oil directly to the crankcase bypassing the gallery if I took the regulator apart. So I went with the pressure sensor port.

I removed the pressure sender and fed it oil (semi-syn motorcycle formulation since it will touch the wet clutch in the gearbox) at 40 to 55psi from a 12 volt pump. Added a tee in the pipe and 6 feet of sealed tubing (see pic) to act as a pressure accumulator so the pump doesn’t chatter. Worked out to 3 seconds of pump runtime to 12 seconds of resting. After running all day the pump wasn’t even warm. I opened the valve covers and saw oil coming out the pushrods, confirming the oil gallery is pressurized.

Next I raised the drain line to trap oil in the engine (see pic), and used it as a sight glass to predict the level in the crankcase. The level was also high enough to submerge the bottom passage to the gearbox (see pic of open gearbox from the servicing class). Then I leaned the engine left and right, forward and back to submerge the pistons/pins and slosh oil around in the gearbox. Drained the crankcase, put a couple of tablespoon of oil into each sparkplug hole. Finally, after hours of oil circulation I turned the engine over, plugs still out.

Note I was using a clean bucket for the oil supply. I seem to have misplaced my oil tank. I will look around for it a little longer before I worry about buying another!

I offer this only for entertainment purposes and don’t suggest anyone perform this procedure without approval from your Rotax dealer. My engine is long out of warranty and I alone am responsible for the outcome. I intend to keep the engine in this oiling regime until I am ready to start it; at which time I will purge the system and confirm lifter status per the Rotax procedure.

-Jim

--- On Sun, 10/28/12, FLYaDIVE <[url=/mc/compose?to=flyadive(at)gmail.com]flyadive(at)gmail.com[/url]> wrote:

| Quote: |

From: FLYaDIVE <[url=/mc/compose?to=flyadive(at)gmail.com]flyadive(at)gmail.com[/url]>

Subject: Re: Pre-oiling 912ULS

To: [url=/mc/compose?to=rotaxengines-list(at)matronics.com]rotaxengines-list(at)matronics.com[/url]

Date: Sunday, October 28, 2012, 6:37 AM

Jim:

As they say your idea is Spot On. The entire idea of Pre-Oiling is to saturate and cover all the rotating parts PRIOR to rotating the the engine. To rotate the engine prior to pre-oiling or during pre-oiling is counter productive.

Since your engine is from 2005 the two questions that come up are:

1 - Where was the engine stored, was it kept in a low humidity area?

2 - Was the engine 'pickled', that is to say - Oiled with a preservative oil that does not run off the engine areas?

When it comes to 'pickling' a little research has to be done:

1 - Does Rotax make a storage oil? If so use it.

2 - If Rotax does NOT make a storage oil, use any storage oil you can obtain. Remember you are NOT running on this oil ONLY storing with it.

Yes - You do run the engine for a short time just to coat the insides of the engine BUT, that is a SHORT TIME and it is WITHOUT LOADS.

Special Note: Take a look at Page 8 - 2 Para 8.2

It states that preservation is for only one year and if stored for more than one year the preservation procedure should be repeated every year.

Have you been doing that?

If not - Start with that procedure prior to Pre-Oiling.

Why do i say that? Only because Pre-Oiling takes care of the engine NOT the gearbox gears. Do everything you can to get those gears wet with oil - SHORT of rotating them - Without oil.

So, how should you Pre-Oil?

1 - Take a look at the manual - Page 7-6 Figure 3 .

2 - Notice the Oil Flow Direction. It goes OUT of the Oil Cooler (item 5) - Into the Engine - Out of the engine and into the Oil Tank (item 4).

3 - I do not know if the picture I attached will get through. If it does not contact me directly and I will send it directly to you.

4 - This picture is of a Pre-Oiler I made. It can handle oil pressure up to 150 PSI. YOU pick the oil pressure your engine operates at and Pre-Oil at that pressure.

5 - Use the engine operating pressure so any valves will be opened by the pressure and the oil spray will cover the same areas as during normal operation.

6 - Since the engine has an Oil Pressure Regulator (item 1), you should pressure the pre-oiler higher than operating pressure and because the pressure drops in the pre-oilier quickly as volume of oil drops.

7 - Monitor the Oil Pressure Gauge of the plane/engine, since the Oil Pressure Sensor (item 2) is hooked up. There will probably be only a small deflection since the pre-oilier is applying pressure for only a short time.

8 - Now, here I have to ask a question. Does the Oil Pump (item 3) have a reverse flow check valve? If YES then you are limited to pre-oilier flow direction.

If NO then - Use the Pre-Oilier in BOTH directions - The IN and the OUT.

9 - When I Pre-Oil, it is done with one (1) quart of oil in each direction - From the Oil Cooler into the Engine and then Into the Engine on the OUTPUT side of the Engine. See note 8.

10 - Now, here you have some options:

a> You can leave the Oil Tank (item 4) attached and it will catch any oil that makes it to the exit of the engine. And remember to hook up a overflow tube to Vent Tube (item 7). I really doubt if this will ever happen, or...

b> Put a Plug on the Engine Exit line/hose so it develops a good pressure to spray the oil all around inside the engine.

The Pictures:

Pic #1 is a general overview

Pic #2 shows the fittings. One thing you can not see is the inside of the unit. From the oil line on the outside is a nylon pick-up tube that goes to the bottom of the unit.

You will see a Shrader valve on top. I hook up a 12VDC portable tire pump. Pressurize the unit to 125 PSI, you can leave the tire pump on and running when you open the valve.

This system is so easy that I pre-oil anytime the engine sits for a month or more.

Barry

On Fri, Oct 26, 2012 at 5:13 PM, Jim Clayton <jspc78(at)yahoo.com> wrote:

| Quote: | --> RotaxEngines-List message posted by: Jim Clayton <jspc78(at)yahoo.com>

Greetings all:

I looked in the archives and didn't see an answer so here goes:

I have a 912ULS, in the crate I bought it in 2005. I just unwrapped it and would like to pressurize the oil system with engine oil since the engine has been sitting so long and I am very concerned about roating the engine (dry) to get the internal pump to move oil. I have a 12 volt oil pump, return tank and accessories to accomplish this, however I have a question:

Can I simply feed the oil pump inlet hose-barb with oil pressure to circulate oil throughout the gallery? I am concerned the pump will not pass oil if the engine is not turning.

Alternately I could remove the pressure sender and feed the gallery from there unless there is some reason not to. My preference is to feed through the larger oil pump inlet in the hipe of greater flow through the gallery.

I plan to return the oil by draining the crankcase through the return hosebarb and back into the return tank.

Any thoughts or suggestions to circulate oil through my engine?

Thanks, Jim

Kolb Mark3X

912ULS

80% completed

===========

-List" target="_blank">http://www.matronics.com/Navigator?RotaxEngines-List

===========

http://forums.matronics.com

===========

le, List Admin.

="_blank">http://www.matronics.com/contribution

===========

|

|

http://www.matronics.com/Navigator?RotaxEngine="nofollow" target="_blank" href="http://www.matronics.com/contributi==

|

|

[quote][b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

gcvisel

Joined: 23 Oct 2012

Posts: 11

Location: United States

|

Posted: Wed Oct 31, 2012 4:34 pm Post subject: Pre-oiling 912ULS Posted: Wed Oct 31, 2012 4:34 pm Post subject: Pre-oiling 912ULS |

|

|

Jim,

I've been following your re-oiling saga from the first, and really

can't quite figure out what you are trying to accomplish. You preserve

an engine or other metal part by giving it a coat of oil to keep water

off the metal, to keep it from rusting. Periodic re-coating renews this

protection. I assume you have the preservation spec from Rotax?

Extended soaking metal in oil does nothing for its long term wear

characteristics, as the oil does not "soak into" the metal. We used to

use metal containers to hold oil because they are impervious to the oil.

If your gears or bearings have rusted, no amount of oiling is going

to remove the rust. Much better to maybe just open it up and look to

see if you actually have rust, and remove it chemically or replace the

parts. Or if parts are seized, remove the dried oil with a solvent.

Or am I missing something? (I could see maybe soaking a dried out

seal in the hopes of reviving it, but again, I'd just figure on

replacing them if they leak.)

Gerry Visel

(ex-gearbox engineer for 30+ years, but now doing high tech toilets!)

On Wed, 2012-10-31 at 17:02 -0700, Jim Clayton wrote:

| Quote: | Hi Barry/All:

Thanks! I am running the pump 30 minutes a day so the overkill makes

me feel better about storing the engine for so long

I agree with respect to the gearbox. While I did lean the engine

forward while the crankcase was full, I am concerned about the big

bearings on the prop shaft. I was thinking of again removing the fuel

pump, putting a couple of pints of oil in, and closing it up. Then

with several helpers turning the engine upside down. This would trap

oil at the prop-shaft end. Leave it upside down for perhaps a couple

of hours to marinate two big bearings. Looking at the photos I took

in the servicing class, I suspect those bearings need a bit of splash

to keep those two lubed. I figure an hour or so marinating maybe soak

in enough oil to suffice. Once done I will turn it right side up, and

allow all the oil to drain.

I am several months from mounting the engine on the plane, so this

system will stay in place awhile. Wish I could find the oil tank as

the open bucket has to go. I will post separately asking if anyone

has a spare oil tank (I know...not likely).

-Jim

|

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

jspc78(at)yahoo.com

Guest

|

Posted: Thu Nov 01, 2012 11:16 am Post subject: Pre-oiling 912ULS Posted: Thu Nov 01, 2012 11:16 am Post subject: Pre-oiling 912ULS |

|

|

Hi Gerry,

Sorry, I may not have been clear. I am pretty handy in the material sciences, and do realize (for the purposes of this discussion) metals are not porous

The engine was internally (inside the valve covers), and externally oily, and there is no evidence anywhere of corrosion or moisture damage. It spent all its time in my care tightly wrapped in plastic and stored in a temperature controlled space.

I was using engineering slang to describe my desire to allow the the bearing races/rollers/balls and the plain bearing journals to flush away the old, possibly dried manufacturing oils and replace them with fresh Rotax approved oils. Another goal is to wet, as best I can, the backs of the many oil seals present. One of the Kolb builders, some years ago, was in my situation, and when the engine was finally started, it ran great, but all the seals began leaking requiring replacement within the first few months. My hope is to try and avoid that.

I am considering applying some kind of silicone spray to the external seal lips to further my goal to save whatever seals I can.

Specifically regarding the large bearings supporting the prop shaft, after studying my photos of the engine we messed with in the servicing class, I noticed the bearing cages and possibly some kind of wiper *might* slow the flow of replacement oil as detailed above in my goals. Clearly these structures are designed to work best in a running engine with much oil splash. I surmised, if that was true I could flood the area and allow oil to seep past any obstructing structures and complete the oil replacement.

As others on the list have correctly suggested this is a good time for a preservative oil. I chose to use standard approved oil for this engine instead for two reasons:

--I was concerned the clutch could be affected by a bad choice on my part, and I didn't want to wait and get possibly ambiguous guidance from Rotax

--The approved standard oil was locally available, and sure to work, however it would need periodic refreshing, something my oiling rig will address nicely.

My professional engineering experience has taught me the extra effort to prevent a problem is usually worth the time. Particularly in my case: I have big investment in brand new engine whose warranty has long since expired. So I cooked up all these steps to satisfy myself. As I mentioned before, I offer this purely for its entertainment value and reference. I don't suggest anyone follow suit.

Thanks, Jim

--- On Wed, 10/31/12, Gerry Visel <gcvisel(at)gmail.com> wrote:

| Quote: | From: Gerry Visel <gcvisel(at)gmail.com>

Subject: Re: Pre-oiling 912ULS

To: rotaxengines-list(at)matronics.com

Date: Wednesday, October 31, 2012, 5:34 PM

--> RotaxEngines-List message

posted by: Gerry Visel <gcvisel(at)gmail.com>

Jim,

I've been following your re-oiling saga

from the first, and really

can't quite figure out what you are trying to

accomplish. You preserve

an engine or other metal part by giving it a coat of oil to

keep water

off the metal, to keep it from rusting. Periodic

re-coating renews this

protection. I assume you have the preservation spec

from Rotax?

Extended soaking metal in oil does nothing

for its long term wear

characteristics, as the oil does not "soak into" the

metal. We used to

use metal containers to hold oil because they are impervious

to the oil.

If your gears or bearings have rusted, no

amount of oiling is going

to remove the rust. Much better to maybe just open it

up and look to

see if you actually have rust, and remove it chemically or

replace the

parts. Or if parts are seized, remove the dried oil

with a solvent.

Or am I missing something? (I could

see maybe soaking a dried out

seal in the hopes of reviving it, but again, I'd just figure

on

replacing them if they leak.)

Gerry Visel

(ex-gearbox engineer for 30+ years, but now doing high tech

toilets!)

On Wed, 2012-10-31 at 17:02 -0700, Jim Clayton wrote:

> Hi Barry/All:

>

> Thanks! I am running the pump 30 minutes a day so

the overkill makes

> me feel better about storing the engine for so long

>

> I agree with respect to the gearbox. While I did

lean the engine

> forward while the crankcase was full, I am concerned

about the big

> bearings on the prop shaft. I was thinking of

again removing the fuel

> pump, putting a couple of pints of oil in, and closing

it up. Then

> with several helpers turning the engine upside

down. This would trap

> oil at the prop-shaft end. Leave it upside down

for perhaps a couple

> of hours to marinate two big bearings. Looking at

the photos I took

> in the servicing class, I suspect those bearings need a

bit of splash

> to keep those two lubed. I figure an hour or so

marinating maybe soak

> in enough oil to suffice. Once done I will turn

it right side up, and

> allow all the oil to drain.

>

> I am several months from mounting the engine on the

plane, so this

> system will stay in place awhile. Wish I could

find the oil tank as

> the open bucket has to go. I will post separately

asking if anyone

> has a spare oil tank (I know...not likely).

>

> -Jim

RotaxEngines-List Email Forum -

- MATRONICS WEB FORUMS -

List Contribution Web Site -

-Matt

Dralle, List Admin.

|

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Thu Nov 01, 2012 12:32 pm Post subject: Pre-oiling 912ULS Posted: Thu Nov 01, 2012 12:32 pm Post subject: Pre-oiling 912ULS |

|

|

Jim:

You are right on about what you are saying and the procedure you are planing to use.

Two suggestions:

1 - On your gaskets - DO NOT tighten any Screws, Nuts or Bolts more than they already are. To do so could distort the shape of the gasket and creates a leak. Start from the known you have and run it for a while AND even if it does leak - LET IT. Let it leak for a while and see if temperature and hot oil bring back some life to the gaskets.

2 - I understand your idea of using silicone spray on the gaskets - But - I would run a test first. Take a piece of gasket material. Weigh it and measure the thickness and if you have the ability the diameter of a punched out hole such as where a bolt may go through. Then subject it to the silicone you plan on using. Most silicone's are very close in substance except for particle size. The big difference is in the mobilization agent. And what happens when the agent evaporates off. Better to know this before you address the engine itself.

Best of luck,

Barry

[quote]<Jim>

I am considering applying some kind of silicone spray to the external seal lips to further my goal to save whatever seals I can.

Specifically regarding the large bearings supporting the prop shaft, after studying my photos of the engine we messed with in the servicing class, I noticed the bearing cages and possibly some kind of wiper *might* slow the flow of replacement oil as detailed above in my goals. Clearly these structures are designed to work best in a running engine with much oil splash. I surmised, if that was true I could flood the area and allow oil to seep past any obstructing structures and complete the oil replacement.

As others on the list have correctly suggested this is a good time for a preservative oil. I chose to use standard approved oil for this engine instead for two reasons:

--I was concerned the clutch could be affected by a bad choice on my part, and I didn't want to wait and get possibly ambiguous guidance from Rotax

--The approved standard oil was locally available, and sure to work, however it would need periodic refreshing, something my oiling rig will address nicely.

My professional engineering experience has taught me the extra effort to prevent a problem is usually worth the time. Particularly in my case: I have big investment in brand new engine whose warranty has long since expired. So I cooked up all these steps to satisfy myself. As I mentioned before, I offer this purely for its entertainment value and reference. I don't suggest anyone follow suit.

Thanks, Jim

[b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

jspc78(at)yahoo.com

Guest

|

Posted: Thu Nov 01, 2012 4:36 pm Post subject: Pre-oiling 912ULS Posted: Thu Nov 01, 2012 4:36 pm Post subject: Pre-oiling 912ULS |

|

|

Great suggestions, Barry. Thanks! I will do some testing with the spray first.

In other news looked up a new oil tank on the Lockwood site....$800 something!! ok, back to searching my shop.

-Jim

--- On Thu, 11/1/12, FLYaDIVE <flyadive(at)gmail.com> wrote:

| Quote: |

From: FLYaDIVE <flyadive(at)gmail.com>

Subject: Re: Pre-oiling 912ULS

To: rotaxengines-list(at)matronics.com

Date: Thursday, November 1, 2012, 1:32 PM

Jim:

You are right on about what you are saying and the procedure you are planing to use.

Two suggestions:

1 - On your gaskets - DO NOT tighten any Screws, Nuts or Bolts more than they already are. To do so could distort the shape of the gasket and creates a leak. Start from the known you have and run it for a while AND even if it does leak - LET IT. Let it leak for a while and see if temperature and hot oil bring back some life to the gaskets.

2 - I understand your idea of using silicone spray on the gaskets - But - I would run a test first. Take a piece of gasket material. Weigh it and measure the thickness and if you have the ability the diameter of a punched out hole such as where a bolt may go through. Then subject it to the silicone you plan on using. Most silicone's are very close in substance except for particle size. The big difference is in the mobilization agent. And what happens when the agent evaporates off. Better to know this before you address the engine itself.

Best of luck,

Barry

| Quote: | <Jim>

I am considering applying some kind of silicone spray to the external seal lips to further my goal to save whatever seals I can.

Specifically regarding the large bearings supporting the prop shaft, after studying my photos of the engine we messed with in the servicing class, I noticed the bearing cages and possibly some kind of wiper *might* slow the flow of replacement oil as detailed above in my goals. Clearly these structures are designed to work best in a running engine with much oil splash. I surmised, if that was true I could flood the area and allow oil to seep past any obstructing structures and complete the oil replacement.

As others on the list have correctly suggested this is a good time for a preservative oil. I chose to use standard approved oil for this engine instead for two reasons:

--I was concerned the clutch could be affected by a bad choice on my part, and I didn't want to wait and get possibly ambiguous guidance from Rotax

--The approved standard oil was locally available, and sure to work, however it would need periodic refreshing, something my oiling rig will address nicely.

My professional engineering experience has taught me the extra effort to prevent a problem is usually worth the time. Particularly in my case: I have big investment in brand new engine whose warranty has long since expired. So I cooked up all these steps to satisfy myself. As I mentioned before, I offer this purely for its entertainment value and reference. I don't suggest anyone follow suit.

Thanks, Jim

www.ow" target="_blank" href="http://www.buildersbooks.com">www.buildersbooofollow" target="_blank" href="http://www.matronics.com/contribution">h="nofollow" target="_blank" href="http://www.matronics.com/Navigator?RotaxEngines-List">http://www.matronics.com/Navigator?RotaxEngines-List==========

|

|

[quote][b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Fri Nov 02, 2012 4:17 am Post subject: Pre-oiling 912ULS Posted: Fri Nov 02, 2012 4:17 am Post subject: Pre-oiling 912ULS |

|

|

Jim:

For testing you could make a tank from PVC piping. It will handle the pressure if any and also the temperature. You could also install a simple oil filter in line.

I know you will find the tank... Of course it will be in the last place you look.

Barry

On Thu, Nov 1, 2012 at 8:36 PM, Jim Clayton <jspc78(at)yahoo.com (jspc78(at)yahoo.com)> wrote:

| Quote: | Great suggestions, Barry. Thanks! I will do some testing with the spray first.

In other news looked up a new oil tank on the Lockwood site....$800 something!! ok, back to searching my shop.

-Jim

--- On Thu, 11/1/12, FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)> wrote:

| Quote: |

From: FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)>

Subject: Re: Pre-oiling 912ULS

To: rotaxengines-list(at)matronics.com (rotaxengines-list(at)matronics.com)

Date: Thursday, November 1, 2012, 1:32 PM

Jim:

You are right on about what you are saying and the procedure you are planing to use.

Two suggestions:

1 - On your gaskets - DO NOT tighten any Screws, Nuts or Bolts more than they already are. To do so could distort the shape of the gasket and creates a leak. Start from the known you have and run it for a while AND even if it does leak - LET IT. Let it leak for a while and see if temperature and hot oil bring back some life to the gaskets.

2 - I understand your idea of using silicone spray on the gaskets - But - I would run a test first. Take a piece of gasket material. Weigh it and measure the thickness and if you have the ability the diameter of a punched out hole such as where a bolt may go through. Then subject it to the silicone you plan on using. Most silicone's are very close in substance except for particle size. The big difference is in the mobilization agent. And what happens when the agent evaporates off. Better to know this before you address the engine itself.

Best of luck,

Barry

| Quote: | <Jim>

I am considering applying some kind of silicone spray to the external seal lips to further my goal to save whatever seals I can.

Specifically regarding the large bearings supporting the prop shaft, after studying my photos of the engine we messed with in the servicing class, I noticed the bearing cages and possibly some kind of wiper *might* slow the flow of replacement oil as detailed above in my goals. Clearly these structures are designed to work best in a running engine with much oil splash. I surmised, if that was true I could flood the area and allow oil to seep past any obstructing structures and complete the oil replacement.

As others on the list have correctly suggested this is a good time for a preservative oil. I chose to use standard approved oil for this engine instead for two reasons:

--I was concerned the clutch could be affected by a bad choice on my part, and I didn't want to wait and get possibly ambiguous guidance from Rotax

--The approved standard oil was locally available, and sure to work, however it would need periodic refreshing, something my oiling rig will address nicely.

My professional engineering experience has taught me the extra effort to prevent a problem is usually worth the time. Particularly in my case: I have big investment in brand new engine whose warranty has long since expired. So I cooked up all these steps to satisfy myself. As I mentioned before, I offer this purely for its entertainment value and reference. I don't suggest anyone follow suit.

Thanks, Jim

www.ow" target="_blank" href="http://www.buildersbooks.com">www.buildersbooofollow" target="_blank" href="http://www.matronics.com/contribution">h="nofollow" target="_blank" href="http://www.matronics.com/Navigator?RotaxEngines-List">http://www.matronics.com/Navigator?RotaxEngines-List==========

|

|

| Quote: |

_blank">www.aeroelectric.com

.com" target="_blank">www.buildersbooks.com

="_blank">www.homebuilthelp.com

_blank">http://www.matronics.com/contribution

ist" target="_blank">http://www.matronics.com/Navigator?RotaxEngines-List

tp://forums.matronics.com

|

|

--

Barry

“Chop’d Liver”

YOU ARE NOT

WE ARE

BECAUSE WE WERE

YOU ARE

The words to be inserted are VETERANS’ and FREE

Thank you Veterans!

[quote][b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

jspc78(at)yahoo.com

Guest

|

Posted: Fri Nov 02, 2012 12:37 pm Post subject: Pre-oiling 912ULS Posted: Fri Nov 02, 2012 12:37 pm Post subject: Pre-oiling 912ULS |

|

|

Hi Barry,

Good idea!

Thanks, Jim

--- On Fri, 11/2/12, FLYaDIVE <flyadive(at)gmail.com> wrote:

From: FLYaDIVE <flyadive(at)gmail.com>

Subject: Re: Pre-oiling 912ULS

To: rotaxengines-list(at)matronics.com

Date: Friday, November 2, 2012, 5:17 AM

Jim:

For testing you could make a tank from PVC piping. Â It will handle the pressure if any and also the temperature. Â You could also install a simple oil filter in line.I know you will find the tank... Of course it will be in the last place you look. Â

Barry

On Thu, Nov 1, 2012 at 8:36 PM, Jim Clayton <jspc78(at)yahoo.com> wrote:

Great suggestions, Barry. Â Thanks! Â I will do some testing with the spray first.

In other news  looked up a new oil tank on the Lockwood site....$800 something!!  ok, back to searching my shop.

-Jim

--- On Thu, 11/1/12, FLYaDIVE <flyadive(at)gmail.com> wrote:

From: FLYaDIVE <flyadive(at)gmail.com>

Subject: Re: Pre-oiling 912ULS

To: rotaxengines-list(at)matronics.com

Date: Thursday, November 1, 2012, 1:32 PM

Jim:

You are right on about what you are saying and the procedure you are planing to use.

Two suggestions:1 - On your gaskets - DO NOT tighten any Screws,

Nuts or Bolts more than they already are.  To do so could distort the shape of the gasket and creates a leak.  Start from the known you have and run it for a while AND even if it does leak - LET IT.  Let it leak for a while and see if temperature and hot oil bring back some life to the gaskets.

2 - I understand your idea of using silicone spray on the gaskets - But - I would run a test first.  Take a piece of gasket material.  Weigh it and measure the thickness and if you have the ability the diameter of a punched out hole such as where a bolt may go through.  Then subject it to the silicone you plan on using.  Most silicone's are very close in substance except for particle size.  The big difference is in the mobilization agent.  And what happens when the agent evaporates off.  Better to know this before you address the engine itself.

Best of luck,

Barry

<Jim>

I am considering applying some kind of silicone spray to the external seal lips to further my goal to save whatever seals I can.