|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

idleup

Joined: 06 Aug 2011

Posts: 19

|

|

| Back to top |

|

|

peter(at)sportingaero.com

Guest

|

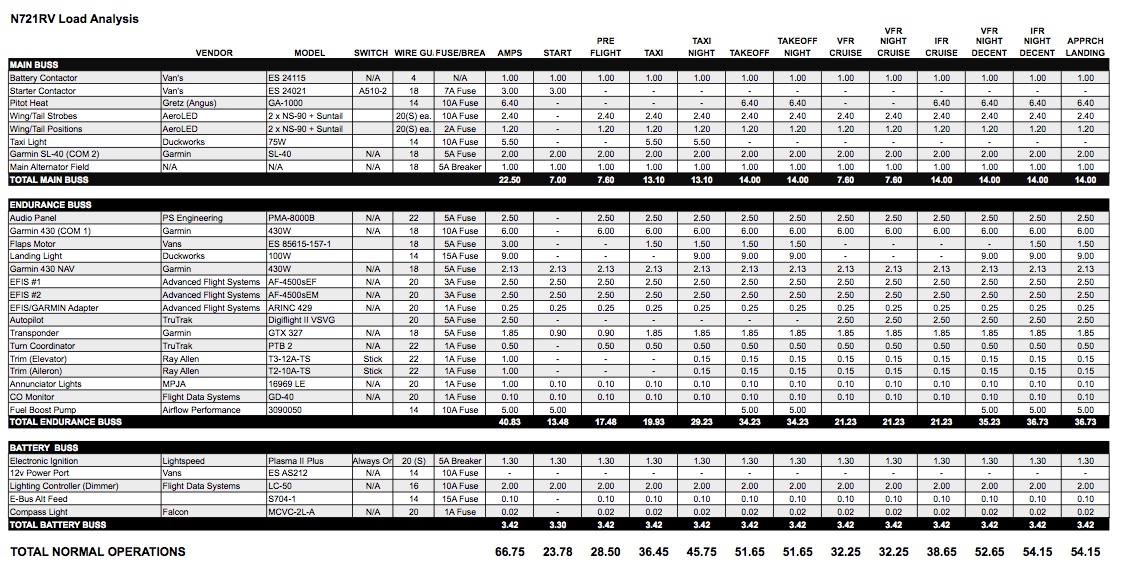

Posted: Sat Dec 29, 2012 1:06 am Post subject: Load Analysis Feedback Please... Posted: Sat Dec 29, 2012 1:06 am Post subject: Load Analysis Feedback Please... |

|

|

Hi Matt,

The only issue that might cause you a problem is the equipment on the

battery buss - if you cannot switch most of those items off with the

master switch you will drain the battery quickly. Are you sure the EI

should not be switched? Are you sure you will always turn off the

instrument & compass lights? The remaining comments are details.

When I construct a loading table I use the steady state load as the

value I'm interested in for load assessment, and the max draw to size

the fuse and wire. A wiring diagram showing the feeds to the busbars

(not to the individual loads) would also be useful. You appear to have

listed the peak load only, for example you have listed an SL-40 taking

2A and a 430 taking 6A, these are probably transmit currents and would

be pulled for only short periods. I would use the steady state figure

for all the devices for load calculation, but use the peak load to size

fuse and wire size. It is usually assumed that the battery will handle

any transient loads, such as radio transmit, flap motor, trim or gear

motor (if you had one), otherwise the alternator becomes huge. When

calculating the size of the battery for alternator out purposes the

increase in draw of large loads at the reduced battery voltage can be

significant (landing/taxi light, pitot heat) so may be worth listing

separately - your battery at 72% charge should be able to support the

endurance & battery loads for 30 minutes. As written a PC-680 would not

meet this requirement (12Ah available, 22Ah required).

Some of your fuse sizes seem low (3A fuse on a 2.5A load, for example

EFIS). Fuses protect the wire, double the load at least. Some also seem

high (10A fuse on a 2.4A load on the strobes). Wire sizes seem

inconsistent, the SL-40, a 2A load, has an 18g wire, but the audio

panel, a 2.5A load, has a 22g wire, CO monitor, a 0.1A load, has a 20g

wire.

Some specific points,

- Why 4ga wire of the battery connector, it only pulls 1 amp? If that is

the main battery feed is 4ga large enough (2 or 0 is common)? There

should be a switch to pull in the battery contactor, often wired with 18ga.

- Starter, does that starter contactor take a different load from the

battery contactor?

- Does the audio panel really pull 2.5A continuously?

- Flap motor load is not consistent

- Landing light load is high, are you sure it is 100W? If so it will

draw 7A on the alternator or 8A on the battery.

- Do you not have a back-up battery on at least one of your EFISs?

Hope this helps,

Peter

On 29/12/2012 06:08, idleup wrote:

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Tundra10

Joined: 14 Jun 2010

Posts: 102

Location: Scarborough, Ontario

|

Posted: Sat Dec 29, 2012 8:15 am Post subject: Load Analysis Feedback Please... Posted: Sat Dec 29, 2012 8:15 am Post subject: Load Analysis Feedback Please... |

|

|

Matt,

You definitely put a lot of work into this

You have used maximum currents, although in many cases, actual runtime

currents will be much lower. The radios are a good example. The

SL-40 is about 0.4A during receive. The Garmin 430 is about 2A for

receive + nav. The audio panel probably uses less than 2A too.

You decide what really needs to be on the endurance buss, but I would

suggest moving the flap motor and landing light to the main buss.

Once you have successfully arrived at the airport, you can turn the

main buss back on and use the battery reserve to lower the flaps and

maybe use the landing light (or just land without it).

I would put the lighting controller and compass light on the endurance

buss. You are less likely to leave them on accidentally draining the

battery. More importantly, if you have an electrical fire, you want

to be able to disconnect everything (except the ignition) by turning

off the master switch.

Using more typical currents, your endurance buss will be below 18A,

allowing extended flight with a 20A backup alternator. You didn't

mention what your architecture is.

Jeff Page

Dream Aircraft Tundra #10

| Quote: | From: "idleup" <matt(at)mattandmel.com>

Would you guys be so kind as to review my Load Analysis worksheet

and tell me if

you see anything that looks incorrect or have recommendations to

make it better?

I have spent quite a bit of time on this but at the end of the day still

question whether I know what I am doing and would appreciate some

peer review...

Thanks.

Of if you would prefer to download the PDF:

http://www.mattandmel.com/rv/Master_Load_Analysis_v1.pdf

Thank you much.

Matt

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

idleup

Joined: 06 Aug 2011

Posts: 19

|

Posted: Wed Jan 09, 2013 11:14 am Post subject: Re: Load Analysis Feedback Please... Posted: Wed Jan 09, 2013 11:14 am Post subject: Re: Load Analysis Feedback Please... |

|

|

Peter (and others),

It has taken me a while to address the items in your post. Thanks for reviewing my load analysis so thoroughly I appreciate it⦠I ended up moving the compass light completely since it should be connected through the lighting controller and I moved the controller to the endurance bus.

I understand what you are saying about the peak vs. transient loads. The loads that I used were based on other load analysis worksheets that others have posted and the documentation that I can find. When you said that a PC-680 would not meet the requirement of 30 minutes you said that 22Ah would be be required, where on my loan analysis did you get the 22Ah number from?

As for the fuse loads, I agree that it seems inconsistent. The 3A on a 2.5A load seems too low to me as well, I was using the manufacturer recommended fuse size in the worksheet. The EFIS's are AF-4500's and in the manual (v7.4) on page 69 it states to use a 3A fuse. Should I disregard this and go with say a 5A fuse instead? maybe someone with these same EFIS's can tell me what they did?

The reason the strobe fuse is 10A is because the manual states that each strobe uses 2.25A at peak for 0.33 seconds. Now, I remember reading about how quick peaks do not require larger fuses but I guess this case I was being cautious because I did not know. Based on this specification, what do you believe is a sufficiently sized fuse for the strobe circuit if not 10A?

As for the wire sizes for the SL-40, Audio Panel, and CO Monitor, what size would you recommend? I realize they are not consistent. Should I always use the same size wire for a given fuse size on the circuit? if so, is there a chart somewhere that says which size wire to always use for 5A or 1A fuses?

The 4AWG wire on the battery is in fact the main feed. I am using Bob's Figure Z-13/8 as a reference which states that "All wires marked 2AWG may be downsized to 4AWG depending on the size of engine and location of batteries". Should I instead keep this at 2AWG based on my loads in your opinion?

Also, on my wiring schematic I have a 22AWG wire going from panel ground to the Master Switch and then to the battery contractor, do you think this should be 18AWG instead based on your comment?

If I understand your question correctly then yes, the starter contractor takes a different load than the battery contactor. The two contractors are wired together with a 4AWG wire for the main load, but the starter contactor has a 3A load coming off the main power bus to the switch. So I guess the starter contractor has two power sources and the one off the bus is protected with a 7A fuse. Is this what you were asking?

The audio panel is a PMA-8000B and the only current it shows in the specifications is the maximum current of 2.5A on page 1-2. I have no idea what the transient load is.

I am not sure what you mean by the flap motor load is not consistent. Are you saying I should use the 3A for all phases of flight instead of using 1.5A? I figured that it was not going to use peak load all the time but maybe I am wrong?

The landing light is a PAR-36 style Duckworks light. In the manual on page 7 it says if you use a 100W bulb then use at least 10A fuse with 16AWG wire. However, I bumped it up to 14AWG since I already will be using 14 elsewhere and do not want to buy 16 just for this run. I changed the load to 7.5A per your recommendation. In all reality, I may change this before I am done to a lower drawing landing light (like 55W) but I want to plan it for what I purchased and what I know is the worst case.

I do not currently have a back-up battery for either of my EFIS's. I know this is an option that I can purchase from AFS but I believe it hooks directly into the back of the EFIS and would not affect my load analysis worksheet at all.

Again, thank you for taking the time to review this. I would appreciate if you also took the time to respond to my questions above. Thanks.

- Matt

| peter(at)sportingaero.com wrote: | Hi Matt,

The only issue that might cause you a problem is the equipment on the

battery buss - if you cannot switch most of those items off with the

master switch you will drain the battery quickly. Are you sure the EI

should not be switched? Are you sure you will always turn off the

instrument & compass lights? The remaining comments are details.

When I construct a loading table I use the steady state load as the

value I'm interested in for load assessment, and the max draw to size

the fuse and wire. A wiring diagram showing the feeds to the busbars

(not to the individual loads) would also be useful. You appear to have

listed the peak load only, for example you have listed an SL-40 taking

2A and a 430 taking 6A, these are probably transmit currents and would

be pulled for only short periods. I would use the steady state figure

for all the devices for load calculation, but use the peak load to size

fuse and wire size. It is usually assumed that the battery will handle

any transient loads, such as radio transmit, flap motor, trim or gear

motor (if you had one), otherwise the alternator becomes huge. When

calculating the size of the battery for alternator out purposes the

increase in draw of large loads at the reduced battery voltage can be

significant (landing/taxi light, pitot heat) so may be worth listing

separately - your battery at 72% charge should be able to support the

endurance & battery loads for 30 minutes. As written a PC-680 would not

meet this requirement (12Ah available, 22Ah required).

Some of your fuse sizes seem low (3A fuse on a 2.5A load, for example

EFIS). Fuses protect the wire, double the load at least. Some also seem

high (10A fuse on a 2.4A load on the strobes). Wire sizes seem

inconsistent, the SL-40, a 2A load, has an 18g wire, but the audio

panel, a 2.5A load, has a 22g wire, CO monitor, a 0.1A load, has a 20g

wire.

Some specific points,

- Why 4ga wire of the battery connector, it only pulls 1 amp? If that is

the main battery feed is 4ga large enough (2 or 0 is common)? There

should be a switch to pull in the battery contactor, often wired with 18ga.

- Starter, does that starter contactor take a different load from the

battery contactor?

- Does the audio panel really pull 2.5A continuously?

- Flap motor load is not consistent

- Landing light load is high, are you sure it is 100W? If so it will

draw 7A on the alternator or 8A on the battery.

- Do you not have a back-up battery on at least one of your EFISs?

Hope this helps,

Peter

On 29/12/2012 06:08, idleup wrote:

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

idleup

Joined: 06 Aug 2011

Posts: 19

|

Posted: Wed Jan 09, 2013 11:30 am Post subject: Re: Load Analysis Feedback Please... Posted: Wed Jan 09, 2013 11:30 am Post subject: Re: Load Analysis Feedback Please... |

|

|

Jeff,

I did end up moving the lighting off the battery bus and onto the endurance bus. I also moved the landing light and flaps to the main bus as per your suggestions. I was thinking in an electrical emergency at night I would need the landing light and flaps, but you are correct that those really are not needed during the "endurance" phase of flight, just the landing. Hopefully there would not be a problem that turning back on the master switch would aggrevate when I do need them.

The main reason I used the maximum currents is because I was trying to plan for worst case scenarios. As per Peter's recommendation I really should have two sheets (or multiple columns) so one set of loads can be used to determine battery endurance and the other for fuse and wire sizing. I have not seen this however in any of the templates I used for the load analysis so I did not do it that way.

Also, my architecture is using Bobs Z-13/8.

Thanks,

Matt

| Tundra10 wrote: | Matt,

You definitely put a lot of work into this

You have used maximum currents, although in many cases, actual runtime

currents will be much lower. The radios are a good example. The

SL-40 is about 0.4A during receive. The Garmin 430 is about 2A for

receive + nav. The audio panel probably uses less than 2A too.

You decide what really needs to be on the endurance buss, but I would

suggest moving the flap motor and landing light to the main buss.

Once you have successfully arrived at the airport, you can turn the

main buss back on and use the battery reserve to lower the flaps and

maybe use the landing light (or just land without it).

I would put the lighting controller and compass light on the endurance

buss. You are less likely to leave them on accidentally draining the

battery. More importantly, if you have an electrical fire, you want

to be able to disconnect everything (except the ignition) by turning

off the master switch.

Using more typical currents, your endurance buss will be below 18A,

allowing extended flight with a 20A backup alternator. You didn't

mention what your architecture is.

Jeff Page

Dream Aircraft Tundra #10

| Quote: | From: "idleup" <matt>

Would you guys be so kind as to review my Load Analysis worksheet

and tell me if

you see anything that looks incorrect or have recommendations to

make it better?

I have spent quite a bit of time on this but at the end of the day still

question whether I know what I am doing and would appreciate some

peer review...

Thanks.

Of if you would prefer to download the PDF:

http://www.mattandmel.com/rv/Master_Load_Analysis_v1.pdf

Thank you much.

Matt

|

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

peter(at)sportingaero.com

Guest

|

Posted: Wed Jan 09, 2013 1:58 pm Post subject: Load Analysis Feedback Please... Posted: Wed Jan 09, 2013 1:58 pm Post subject: Load Analysis Feedback Please... |

|

|

Hi Matt,

> where on my loan analysis did you get the 22Ah number from?

I simply added the total loads on the Endurance and Battery busses

(40.83 + 3.42), which in retrospect is probably pessimistic. I should

have used any of the night descent numbers - but they are all

significantly above that is available. If you look at the steady state

currents for night IFR cruise and then 10 minutes of descent I wonder

what the number is? There are many people using a PC680 as their only

battery, so I would guess it is possible.

>The EFIS's are AF-4500's and in the manual (v7.4) on page 69 it states

to use a 3A fuse. Should I disregard this and go with say a 5A fuse

instead? maybe someone with these same EFIS's can tell me what they did?

I have an AF-4500 in my aeroplane and used a 5A fuse. Bear in mind the

fuses protect the wiring more than anything.

>As for the wire sizes for the SL-40, Audio Panel, and CO Monitor, what

size would you recommend? I realize they are not consistent. Should I

always use the same size wire for a given fuse size on the circuit? if

so, is there a chart somewhere that says which size wire to always use

for 5A or 1A fuses?

Wire sizes are the subject of much debate (I'm sure others will chime

in), but there are really only 4 or 5 choices 22, 20, 18, 16 or 14g for

most runs. The only penalty in using 14g everywhere is weight (you would

be surprised just how much) and cost. You're right, there is no point in

buying 20' of one size for just one run. I use 22g everywhere I can -

particularly for radio and avionics feeds where the current draw is low

and the wire length (from fuse panel) is short. There is a chart which

equates current draw and wire length to gauge size - I think its in AC43.13

> The 4AWG wire on the battery is in fact the main feed. ... Should I

instead keep this at 2AWG based on my loads in your opinion?

Either will work, I tend to go for the larger diameter to ensure the are

no starting problems, particularly are a couple of years in service. If

you planning a permanent magnet starter the larger wire may be more

desirable as they take 2x current of slightly heavier starters.

>Also, on my wiring schematic I have a 22AWG wire going from panel

ground to the Master Switch and then to the battery contractor, do you

think this should be 18AWG instead based on your comment?

I was only pointing out you plan was inconsistent, it does not really

matter for short runs. For the last panel I wired up I bought 100' of

black 20g and used that for all the panel grounds.

>If I understand your question correctly then yes, the starter

contractor takes a different load than the battery contactor.

OK

>The two contractors are wired together with a 4AWG wire for the main

load, but the starter contactor has a 3A load coming off the main power

bus to the switch.

Could I suggest you look into the main contactor wiring in more detail -

what kind of OV protection are you using?

> The audio panel is a PMA-8000B and the only current it shows in the

specifications is the maximum current of 2.5A on page 1-2. I have no

idea what the transient load is.

2.5A is the transient load, as a guess the steady state load is probably

around 0.5A (no external speaker).

>I am not sure what you mean by the flap motor load is not consistent.

Are you saying I should use the 3A for all phases of flight instead of

using 1.5A?

Yes, if the flap motor takes 3A then use that - you could possibly use

1.5A for retract (wind is helping) and 3 for extension. However, I would

use 3A for fuse and wire sizing, but ignore from the rest of the load

sheet as the duration is very short.

In my AF-4500 the battery is internal and was fitted when I bought it.

As a further level of redundancy when something you haven't thought of

has stolen all of your electrons I think its worthwhile.

Hope this helps,

Peter

On 09/01/2013 19:15, idleup wrote:

| Quote: |

Peter (and others),

Peter,

It has taken me a while to address the items in your post. Thanks for reviewing my load analysis so thoroughly I appreciate it⦠I ended up moving the compass light completely since it should be connected through the lighting controller and I moved the controller to the endurance bus.

I understand what you are saying about the peak vs. transient loads. The loads that I used were based on other load analysis worksheets that others have posted and the documentation that I can find. When you said that a PC-680 would not meet the requirement of 30 minutes you said that 22Ah would be be required, where on my loan analysis did you get the 22Ah number from?

As for the fuse loads, I agree that it seems inconsistent. The 3A on a 2.5A load seems too low to me as well, I was using the manufacturer recommended fuse size in the worksheet. The EFIS's are AF-4500's and in the manual (v7.4) on page 69 it states to use a 3A fuse. Should I disregard this and go with say a 5A fuse instead? maybe someone with these same EFIS's can tell me what they did?

The reason the strobe fuse is 10A is because the manual states that each strobe uses 2.25A at peak for 0.33 seconds. Now, I remember reading about how quick peaks do not require larger fuses but I guess this case I was being cautious because I did not know. Based on this specification, what do you believe is a sufficiently sized fuse for the strobe circuit if not 10A?

As for the wire sizes for the SL-40, Audio Panel, and CO Monitor, what size would you recommend? I realize they are not consistent. Should I always use the same size wire for a given fuse size on the circuit? if so, is there a chart somewhere that says which size wire to always use for 5A or 1A fuses?

The 4AWG wire on the battery is in fact the main feed. I am using Bob's Figure Z-13/8 as a reference which states that "All wires marked 2AWG may be downsized to 4AWG depending on the size of engine and location of batteries". Should I instead keep this at 2AWG based on my loads in your opinion?

Also, on my wiring schematic I have a 22AWG wire going from panel ground to the Master Switch and then to the battery contractor, do you think this should be 18AWG instead based on your comment?

If I understand your question correctly then yes, the starter contractor takes a different load than the battery contactor. The two contractors are wired together with a 4AWG wire for the main load, but the starter contactor has a 3A load coming off the main power bus to the switch. So I guess the starter contractor has two power sources and the one off the bus is protected with a 7A fuse. Is this what you were asking?

The audio panel is a PMA-8000B and the only current it shows in the specifications is the maximum current of 2.5A on page 1-2. I have no idea what the transient load is.

I am not sure what you mean by the flap motor load is not consistent. Are you saying I should use the 3A for all phases of flight instead of using 1.5A? I figured that it was not going to use peak load all the time but maybe I am wrong?

The landing light is a PAR-36 style Duckworks light. In the manual on page 7 it says if you use a 100W bulb then use at least 10A fuse with 16AWG wire. However, I bumped it up to 14AWG since I already will be using 14 elsewhere and do not want to buy 16 just for this run. I changed the load to 7.5A per your recommendation. In all reality, I may change this before I am done to a lower drawing landing light (like 55W) but I want to plan it for what I purchased and what I know is the worst case.

I do not currently have a back-up battery for either of my EFIS's. I know this is an option that I can purchase from AFS but I believe it hooks directly into the back of the EFIS and would not affect my load analysis worksheet at all.

Again, thank you for taking the time to review this. I would appreciate if you also took the time to respond to my questions above. Thanks.

- Matt

peter(at)sportingaero.com wrote:

> Hi Matt,

>

> The only issue that might cause you a problem is the equipment on the

> battery buss - if you cannot switch most of those items off with the

> master switch you will drain the battery quickly. Are you sure the EI

> should not be switched? Are you sure you will always turn off the

> instrument & compass lights? The remaining comments are details.

>

> When I construct a loading table I use the steady state load as the

> value I'm interested in for load assessment, and the max draw to size

> the fuse and wire. A wiring diagram showing the feeds to the busbars

> (not to the individual loads) would also be useful. You appear to have

> listed the peak load only, for example you have listed an SL-40 taking

> 2A and a 430 taking 6A, these are probably transmit currents and would

> be pulled for only short periods. I would use the steady state figure

> for all the devices for load calculation, but use the peak load to size

> fuse and wire size. It is usually assumed that the battery will handle

> any transient loads, such as radio transmit, flap motor, trim or gear

> motor (if you had one), otherwise the alternator becomes huge. When

> calculating the size of the battery for alternator out purposes the

> increase in draw of large loads at the reduced battery voltage can be

> significant (landing/taxi light, pitot heat) so may be worth listing

> separately - your battery at 72% charge should be able to support the

> endurance & battery loads for 30 minutes. As written a PC-680 would not

> meet this requirement (12Ah available, 22Ah required).

> Some of your fuse sizes seem low (3A fuse on a 2.5A load, for example

> EFIS). Fuses protect the wire, double the load at least. Some also seem

> high (10A fuse on a 2.4A load on the strobes). Wire sizes seem

> inconsistent, the SL-40, a 2A load, has an 18g wire, but the audio

> panel, a 2.5A load, has a 22g wire, CO monitor, a 0.1A load, has a 20g

> wire.

>

> Some specific points,

> - Why 4ga wire of the battery connector, it only pulls 1 amp? If that is

> the main battery feed is 4ga large enough (2 or 0 is common)? There

> should be a switch to pull in the battery contactor, often wired with 18ga.

> - Starter, does that starter contactor take a different load from the

> battery contactor?

> - Does the audio panel really pull 2.5A continuously?

> - Flap motor load is not consistent

> - Landing light load is high, are you sure it is 100W? If so it will

> draw 7A on the alternator or 8A on the battery.

> - Do you not have a back-up battery on at least one of your EFISs?

>

> Hope this helps,

>

> Peter

> On 29/12/2012 06:08, idleup wrote:

>

>>

>>

>> Would you guys be so kind as to review my Load Analysis worksheet and tell me if you see anything that looks incorrect or have recommendations to make it better? I have spent quite a bit of time on this but at the end of the day still question whether I know what I am doing and would appreciate some peer review... Thanks.

>>

>>

>>

>> Of if you would prefer to download the PDF: http://www.mattandmel.com/rv/Master_Load_Analysis_v1.pdf

>>

>> Thank you much.

>>

>> Matt

>>

>>

>>

>>

>> Read this topic online here:

>>

>> http://forums.matronics.com/viewtopic.php?p=391129#391129

>>

>>

>>

>>

>>

>>

>>

>>

>>

>>

>>

>>

>>

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=391926#391926

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Tundra10

Joined: 14 Jun 2010

Posts: 102

Location: Scarborough, Ontario

|

Posted: Fri Jan 11, 2013 3:20 pm Post subject: Load Analysis Feedback Please... Posted: Fri Jan 11, 2013 3:20 pm Post subject: Load Analysis Feedback Please... |

|

|

Matt,

I am also using the Z13-8 architecture as the basis for my design.

From a load analysis perspective, the interesting value is the longer

term average load. This tells you whether the backup alternator (eg.

SD-20 on the vacuum pad) is sufficient to carry the reduced load for

the remainder of the flight, or to predict the discharge time of the

battery with that load. So realistic current consumption is of

interest, and is often much less than brief surge currents, such as

when you activate the transmitter to talk with ATC. If necessary, try

to measure your devices, if the specifications provide only maximum

ratings.

If you have a backup alternator, then the battery discharge time is of

less concern, since it will not be discharged during the remainder of

the flight and should have lots of juice for gear or landing lights

when you arrive at the destination. If you don't plan a backup

alternator, then selecting a battery and a test/maintenance schedule

for it is important, so when the main alternator dies, you can switch

to endurance loads only and start your stopwatch, knowing how long you

have electrical functions before landing.

If you rely on your EFIS for flight instruments, and perhaps

electronic ignition, those can be powered by the standby alternator if

you have one. If not, the battery sizing, test and maintenance

schedule become critically important. Since you have many electrical

goodies, I am assuming you are planning on a 20A standby alternator.

So My load analysis was based on what was on which bus, and did not go

into detail for phases of flight. With everything working, the

alternator can meet the load in any phase of flight. I consider the

failure of the main alternator an emergency situation if I am flying

IFR. I have enough equipment on the endurance bus to finish the

flight, although in hard IMC I would elect to land at a much earlier

time, since the pilot workload is higher with less equipment (eg.

autopilot). A low voltage indicator will warn me if the standby

alternator is not keeping up. You can look at my load analysis here:

http://www.qenesis.com/tundra/Electrical/Load_Analysis.pdf

Sizing wiring and fuses is done differently. Average loads indicate

how much heat might be created in the wires during use. Wires are

sized to be well below melting the insulation. For a surge current,

such as running a flap motor, it won't be run long enough to be

expected to overheat a wire (expect perhaps in the event of a fault).

However, the resistance of the wire factors into it as well, since

sufficient size the wire is necessary to ensure that sufficient

voltage arrives at the motor. The wasted drop along the wire is based

on the current and the resistance of the wire.

You can't change the current draw (expect perhaps by purchasing a more

efficient motor), but you can reduce the resistance of the wire by

changing to a thicker one. This is discussed in The Aero-Electric

Connection chapter 8.

Rather than recalculate for every circuit, I created a little table

that listed the currents for 5 degree temperature rise (for continuous

loads) and 10 degree rise (for intermittent loads), and what the

maximum wire lengths are for that size wire for a 5% voltage drop.

This is the chart I used:

http://www.qenesis.com/tundra/Electrical/WireSizes.pdf

I looked at the current in each circuit and what the length of the

wire was expected to be and selected the size from my chart. Most of

the wires were going very short distances, so size was related only to

temperature for the current. In a few cases (HID lights at the ends

of the wing and hydraulic gear pump) the size of the wire was related

to the voltage drop instead.

Once the appropriate wire size has been selected, then selecting the

appropriate rating for the circuit protection is straightforward,

since it is based on the size of the wire that is being protected (not

the load). People worry about fuses blowing at inappropriate times.

However, with sufficient size wire, the fuse rating can be easily high

enough that this is very unlikely to be a problem, even using

conservative currents to produce 10 degree rise temperatures. I used

the current for a 35 degree rise to select my fuses.

Jeff

| Quote: | Time: 11:30:59 AM PST US

Subject: Re: Load Analysis Feedback Please...

From: "idleup" <matt(at)mattandmel.com>

Jeff,

I did end up moving the lighting off the battery bus and onto the

endurance bus.

I also moved the landing light and flaps to the main bus as per your

suggestions.

I was thinking in an electrical emergency at night I would need the landing

light and flaps, but you are correct that those really are not needed during

the "endurance" phase of flight, just the landing. Hopefully there would not

be a problem that turning back on the master switch would aggrevate when I do

need them.

The main reason I used the maximum currents is because I was trying

to plan for

worst case scenarios. As per Peter's recommendation I really should have two

sheets (or multiple columns) so one set of loads can be used to

determine battery

endurance and the other for fuse and wire sizing. I have not seen

this however

in any of the templates I used for the load analysis so I did not do it that

way.

Also, my architecture is using Bobs Z-13/8.

Thanks,

Matt

Tundra10 wrote:

> Matt,

>

> You definitely put a lot of work into this

>

> You have used maximum currents, although in many cases, actual runtime

> currents will be much lower. The radios are a good example. The

> SL-40 is about 0.4A during receive. The Garmin 430 is about 2A for

> receive + nav. The audio panel probably uses less than 2A too.

>

> You decide what really needs to be on the endurance buss, but I would

> suggest moving the flap motor and landing light to the main buss.

> Once you have successfully arrived at the airport, you can turn the

> main buss back on and use the battery reserve to lower the flaps and

> maybe use the landing light (or just land without it).

>

> I would put the lighting controller and compass light on the endurance

> buss. You are less likely to leave them on accidentally draining the

> battery. More importantly, if you have an electrical fire, you want

> to be able to disconnect everything (except the ignition) by turning

> off the master switch.

>

> Using more typical currents, your endurance buss will be below 18A,

> allowing extended flight with a 20A backup alternator. You didn't

> mention what your architecture is.

>

> Jeff Page

> Dream Aircraft Tundra #10

>

> > From: "idleup"

> >

> > Would you guys be so kind as to review my Load Analysis worksheet

> > and tell me if

> > you see anything that looks incorrect or have recommendations to

> > make it better?

> > I have spent quite a bit of time on this but at the end of the day still

> > question whether I know what I am doing and would appreciate some

> > peer review...

> > Thanks.

> >

> >

> > Of if you would prefer to download the PDF:

> > http://www.mattandmel.com/rv/Master_Load_Analysis_v1.pdf

> >

> > Thank you much.

> >

> > Matt

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Paul Valovich

Joined: 11 Jan 2006

Posts: 75

|

Posted: Sat Jan 12, 2013 9:10 am Post subject: Load Analysis Feedback Please... Posted: Sat Jan 12, 2013 9:10 am Post subject: Load Analysis Feedback Please... |

|

|

I spent a lot of time analyzing electrical requirements during my -8A build, and initially seemed to apply overkill to every requirement. A few points that led me to Z 13/8 and a 40 amp B&C alternator and an SD8 backup:

<![if !supportLists]>· <![endif]>It really is steady state loads – not transients

<![if !supportLists]>· <![endif]>Endurance bus is just that – something to comfortably get you on the ground after a main alternator gliche; it doesn’t need to include all the nice to haves: strobes, #2 radio, most interior lighting, pitot heat, (if required turn it on for short periods), aux power plug. Again, you can wire these to the endurance bus but turn them on only when required

<![if !supportLists]>· <![endif]>Backup batteries in the Garmin and AFS 4500 relieve a lot of the requirements

<![if !supportLists]>· <![endif]>Minimize equipment on Battery Bus

280 hours and 20 months later, the electrical system has worked flawlessly. Normal load – strobes, 496, SL30, PMA7000B, GTX 327, AFS 4500 – is 15 amps. The extra $ for B&C products – and attention to detail in wiring the Z13/8 architecture - does instill confidence. Two switches to get the SD8 and Endurance Bus online; turn off the Batt/Alt switch and it’s mostly business as usual

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|