|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

jhasbrouck(at)woh.rr.com

Guest

|

Posted: Sat Jun 10, 2006 12:22 pm Post subject: WD1002 and F1001B alignment Posted: Sat Jun 10, 2006 12:22 pm Post subject: WD1002 and F1001B alignment |

|

|

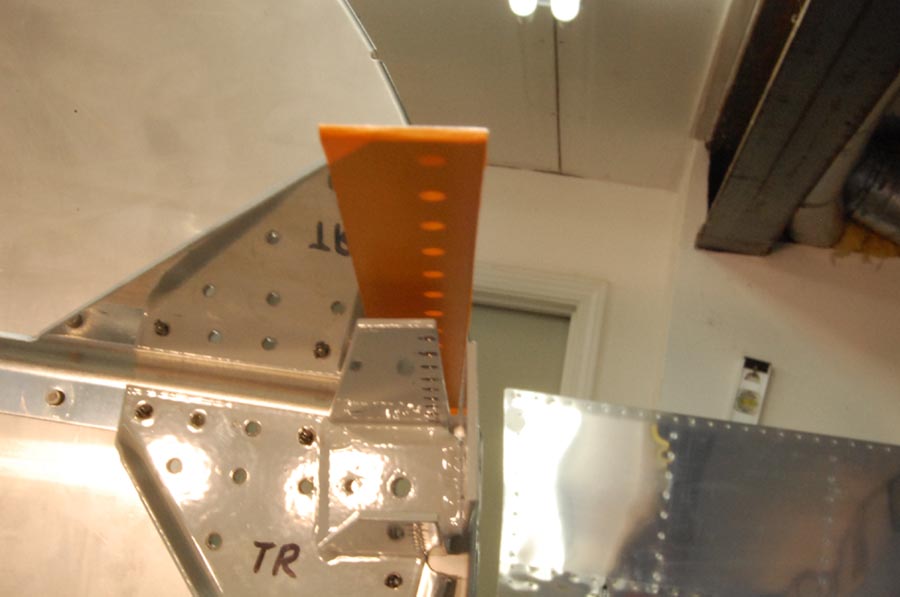

I searched the archive for this problem since I'd seen it before but

couldn't come up with a definite answer. Here's the question. When I look

at the pre-punched holes in the F1001B upper angle and compare to how they

line up with the undrilled upper flange of the WD1002, it's obvious that

I'll run off the edge of the WD1002 with the aft most holes. Pic. attached.

Know some of you contacted Vans about this but never heard the solution. I

can improve the situation a little by loading the bracket ( pulling it

outboard ) but still am not getting more than about 1/16" edge distance, not

enough I think. This is only on the left side, the right will be OK. Want

to solve this problem before going any further and it looks like a new

WD1002L may be that solution. Comments.

John Hasbrouck

#40264

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

27 KB |

| Viewed: |

630 Time(s) |

|

|

|

| Back to top |

|

|

Rick S.

Joined: 12 Feb 2006

Posts: 347

Location: Las Vegas

|

Posted: Sat Jun 10, 2006 1:31 pm Post subject: WD1002 and F1001B alignment Posted: Sat Jun 10, 2006 1:31 pm Post subject: WD1002 and F1001B alignment |

|

|

John,

I think there were a couple of different problems, 1) there were some bad 1002 brackets made and they needed to be exchanged. 2) Vans advised to clamp the leafs of the bracket in the proper orientation prior to drilling. 3) it's just plain very close to minimum edge distance. Your photos a bit blurry, maybe post one that provides a little better angle as to where your seeing the problem, the bracket may be Tango Uniform if the gap is really big compared to the right side where you say there is not a problem. Compare the two brackets to see where the difference might be in manufacture.

Rick S.

40185

Fuse/Finish

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Rick S.

RV-10

40185 |

|

| Back to top |

|

|

jhasbrouck(at)woh.rr.com

Guest

|

Posted: Sat Jun 10, 2006 2:15 pm Post subject: WD1002 and F1001B alignment Posted: Sat Jun 10, 2006 2:15 pm Post subject: WD1002 and F1001B alignment |

|

|

Rick,

I'm trying to get a good picture of this. I've outlined the rivets on

the flange of the WD1002L and R. On the left, the most aft rivet has a

distance to the edge of 1/16" and doesn't get to 1/8" until the 4th rivet

forward. On the right, the edge distance is at least 1/8" all the way. The

flanges of the weldment and the upper angle are not parallel on the left as

they are on the right. I could get better edge distance if I angled the

drill inboard when match drilling but the upper angle flange has a bend that

calls for a more outboard angle. john

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

32.88 KB |

| Viewed: |

602 Time(s) |

|

| Description: |

|

| Filesize: |

37.56 KB |

| Viewed: |

606 Time(s) |

|

|

|

| Back to top |

|

|

Albert Gardner

Joined: 10 Jan 2006

Posts: 455

Location: Yuma, AZ

|

Posted: Sat Jun 10, 2006 3:12 pm Post subject: WD1002 and F1001B alignment Posted: Sat Jun 10, 2006 3:12 pm Post subject: WD1002 and F1001B alignment |

|

|

I just went through this also. I used some clamps to pull the steel flange

fingers in toward the alum channels so that the edge distance would be OK.

Albert Gardner

40-422

Yuma, AZ

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

RV-9A N872RV

RV-10 N991RV |

|

| Back to top |

|

|

jesse(at)itecusa.org

Guest

|

Posted: Sat Jun 10, 2006 4:00 pm Post subject: WD1002 and F1001B alignment Posted: Sat Jun 10, 2006 4:00 pm Post subject: WD1002 and F1001B alignment |

|

|

We ran into very much the same problem on N256H and N415EC. On the latter,

we clamped the bracket to move it into position, then drilled and clecoed

every hole while check edge distance. It came out just fine.

Jesse Saint

I-TEC, Inc.

jesse(at)itecusa.org

www.itecusa.org

W: 352-465-4545

C: 352-427-0285

--

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

Deems Davis

Joined: 09 Jan 2006

Posts: 925

|

Posted: Sat Jun 10, 2006 6:40 pm Post subject: WD1002 and F1001B alignment Posted: Sat Jun 10, 2006 6:40 pm Post subject: WD1002 and F1001B alignment |

|

|

I did the same ( after screwing up the 1st one)

Deems Davis # 406

Fuse

http://deemsrv10.com/

Albert Gardner wrote:

| Quote: |

I just went through this also. I used some clamps to pull the steel flange

fingers in toward the alum channels so that the edge distance would be OK.

Albert Gardner

40-422

Yuma, AZ

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

jhasbrouck(at)woh.rr.com

Guest

|

Posted: Sun Jun 11, 2006 5:55 am Post subject: WD1002 and F1001B alignment Posted: Sun Jun 11, 2006 5:55 am Post subject: WD1002 and F1001B alignment |

|

|

Thanks for all the replies and especially to Rick for his telephone

consultation! Another example of how helpfull this list is. BTW: I primed

everything using a wallpaper paste and goat cheese blend. Seems to adhere

well but smells a little when it gets hot. I'm told that will go away over

time. Thanks again........john

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

Tim(at)MyRV10.com

Guest

|

Posted: Sun Jun 11, 2006 6:24 am Post subject: WD1002 and F1001B alignment Posted: Sun Jun 11, 2006 6:24 am Post subject: WD1002 and F1001B alignment |

|

|

John, I'd heard about the wallpaper paste + goat cheese primers, but

when I tried them on the Vertical Stab, I was not impressed with

their scent. It's truly awful. So I switched to something that worked

out real well for the rest of the build.... 80% used french fry grease,

10% Jello Gelatin (clear unscented), and 10% baking soda. It sticks

well, and flows into the little crannies and smells like a McDonalds.

I am having slight problems when I park outside unfenced airfields

though, as local wildlife is sometimes found inside the plane, licking

the interior.

Tim Olson - RV-10 N104CD - Flying

do not archive

John Hasbrouck wrote:

| Quote: |

Thanks for all the replies and especially to Rick for his telephone

consultation! Another example of how helpfull this list is. BTW: I

primed everything using a wallpaper paste and goat cheese blend. Seems

to adhere well but smells a little when it gets hot. I'm told that will

go away over time. Thanks again........john

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

rvbuilder(at)sausen.net

Guest

|

Posted: Sun Jun 11, 2006 8:50 am Post subject: WD1002 and F1001B alignment Posted: Sun Jun 11, 2006 8:50 am Post subject: WD1002 and F1001B alignment |

|

|

I had a better use for all that French fry grease I got to prime with, get a Deltahawk or Innodyn and convert to biodiesel. I figure I can get gig's flying over stadiums using the smell of my exhaust to increase sales of greasy foods. Oh wait, I forgot. Deltahawk, Innodyn, and flying over stadiums are all pipe dreams.

HEHE

Michael Sausen

RV-10 #352 Working on Fuselage

Do Not Archive

--

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

Andy Turner

Joined: 10 Jan 2006

Posts: 31

Location: Clarion, PA

|

Posted: Sat Sep 25, 2010 6:05 pm Post subject: Re: WD1002 and F1001B alignment Posted: Sat Sep 25, 2010 6:05 pm Post subject: Re: WD1002 and F1001B alignment |

|

|

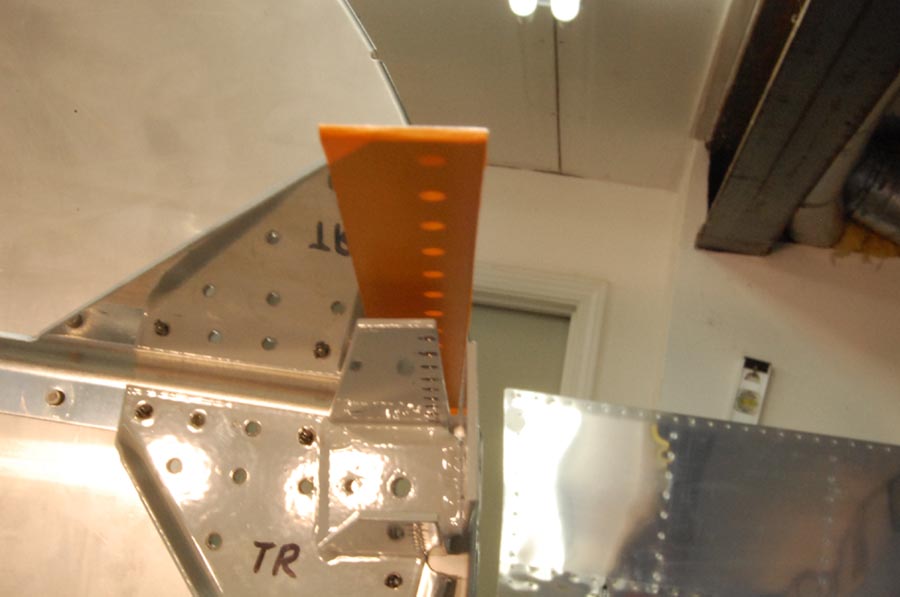

Bringing this old thread back to life in order to document my saga and solution. First time around drilling the firewall brackets, I ended up with insufficient edge distance on the upper flange of the upper (wd-1002) bracket - actually no edge distance. I removed the upper firewall brackets in order to replace them, but had a hard time figuring out what what went wrong. The base of wd-1002 sits on the firewall, partially on top of the base of f-1001b, so these two parts are tied tightly together. The flange of the wd-1002 isn't close to parallel to the f-1001b (see photo, orange tape added for contrast), and since they are rivited together at their bases, there isn't much scope for applying pressure to bring them in line without exerting substantial preloading to the firewall rivets.

Scott Risan was good enough to send me new brackets, so today I clecoed up the right side one, and it looked nice. Edge parallel to the F-1001B. I smiled and clecoed up the left side, only to find that it was quite non-parallel, and there would be no way to get good edge distance. Quit smiling. Eventually discovered, as I was playing with them on the table top, that the base of the W-1002L was ever so slightly rockered across the horizontal axis. Because all the rivet holes across the top are on one side of the rocker, it pitches the flange arm inboard. I threw the bracket into a vice and bent the base just a bit, then did a little filing of that thick powdercoat, till the base (forward side of the weldment) sat flat on the table. Re-clecoed it, and it looks good enough. The high spot on the forward face of the base that caused the rocker is associated with the welding on the aft side.

So, this problem is solved, I post here to alert other builders to be prepared to check the W-1002 for a flat base and tweak if necessary. I also note though that even though my W-1002 bracket arms are now parallel with the F-1001B, they sit 1/16 inboard of the outer edge of the F-1001B. The prepunched rivet holes in the F-1001B that serve as the drilling template are right at 2 edge diameters, so edge space is really at a premium here. Be careful!

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

61.61 KB |

| Viewed: |

7710 Time(s) |

|

_________________

Andy Turner |

|

| Back to top |

|

|

rv10flyer

Joined: 25 Aug 2009

Posts: 364

|

Posted: Sat Sep 25, 2010 7:41 pm Post subject: Re: WD1002 and F1001B alignment Posted: Sat Sep 25, 2010 7:41 pm Post subject: Re: WD1002 and F1001B alignment |

|

|

Thanks for the info guys. I will be doing this in a few days.

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Wayne G. |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|