|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

jill(at)m-14p.com

Guest

|

Posted: Sat Apr 20, 2013 7:08 am Post subject: Hydraulic Lock Posted: Sat Apr 20, 2013 7:08 am Post subject: Hydraulic Lock |

|

|

Group,

A lot of good comments this morning. I have a couple of items to add:

A link to an article that Carl wrote in 1995; which is relevant to any

radial engine owner: http://www.m-14p.com/hydraulic_lock_cwh_1995.pdf .

We recommend against replacement of a link rod in the field. The rod may

not be the only damage to the engine. Typically, the rear cheekplate on the

crank will turn. (This is secured with a pinch bolt.) If the engine is not

torn down with this existing condition, you will be flying with a wobble on

the front end of the crank. In turn, the cam drive gear will bind and the

teeth will shear. The dual drive gear also typically fails. You have now set

yourself up for a catastrophic engine failure. If you sell your airplane to

someone and do not reveal and perform a field repair of replacement of the

link rod only, you are putting them in harm's way. (My opinion.)

Besides overhauling the M-14P, we do a lot of hydraulic lock and prop strike

teardowns. We see more accessory shaft damage with hydraulic lock than with

a prop strike teardown.

I think pulling a prop through 50-60 times may be great aerobic exercise,

but unnecessary. Yes, fear is good motivator and insurance against

hydraulic lock. It does not take many blades on a 2- or 3-bladed prop to

make sure you do not have hydraulic lock. If the cylinders are full of oil,

of course, it will take more to clear them.

Jill

M-14P, Inc.

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

samira.h(at)shaw.ca

Guest

|

Posted: Sun Apr 21, 2013 12:15 am Post subject: Hydraulic Lock Posted: Sun Apr 21, 2013 12:15 am Post subject: Hydraulic Lock |

|

|

The other day someone told me that

one actually can bend a rod on those

radials by just using the air start system

with the magnetos in off position and the

booster coil disconnected.

I doubt it very much that the air pressure

alone will have enough energy to damage

the engine in the event of a hydraulic lock,

the prop will merely stop turning.

Just my 2 cents.

cheers

Elmar

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

richard.goode(at)russiana

Guest

|

Posted: Sun Apr 21, 2013 12:55 am Post subject: Hydraulic Lock Posted: Sun Apr 21, 2013 12:55 am Post subject: Hydraulic Lock |

|

|

I would be very sure that you can bend a rod just with the air start, as

long as the engine has built up a little momentum. I have heard it said that

you can also do it by pulling the propeller through by hand, but this I

personally doubt, and I have never heard of an actual case where it has been

done!

Richard Goode

Rhodds Farm

Lyonshall

Hereford

HR5 3LW

United Kingdom

†Tel: +94 (0) 81 241 5137 (Sri Lanka)

Tel:†† +44 (0) 1544 340120

Fax:† +44 (0) 1544 340129

www.russianaeros.com

Iím currently in Sri Lanka but this Mail is working,and my local phone is

+94 779 132 160.

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

coolade2(at)gmail.com

Guest

|

Posted: Sun Apr 21, 2013 8:31 am Post subject: Hydraulic Lock Posted: Sun Apr 21, 2013 8:31 am Post subject: Hydraulic Lock |

|

|

elmar--you are incorrect--if you determine the area of the piston it is around 12 square inches--the air pressure is 50 to 70 atmospheres, so you get over 7000 pounds of pressure on the rod----It will bend!

On Apr 21, 2013, at 3:11 AM, Elmar & Manuela Hegenauer wrote:

| Quote: |

The other day someone told me that

one actually can bend a rod on those

radials by just using the air start system

with the magnetos in off position and the

booster coil disconnected.

I doubt it very much that the air pressure

alone will have enough energy to damage

the engine in the event of a hydraulic lock,

the prop will merely stop turning.

Just my 2 cents.

cheers

Elmar

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

mark.bitterlich(at)navy.m

Guest

|

Posted: Mon Apr 22, 2013 8:29 am Post subject: Hydraulic Lock Posted: Mon Apr 22, 2013 8:29 am Post subject: Hydraulic Lock |

|

|

YAK-52 at New Bern N.C. Inexperienced pilot did exactly that. Piston

Rod let go on the same flight taking a big chunk out of the case and

cylinder. Flew home on 8 out of 9 and landed safely.

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

mark.bitterlich(at)navy.m

Guest

|

Posted: Mon Apr 22, 2013 8:29 am Post subject: Hydraulic Lock Posted: Mon Apr 22, 2013 8:29 am Post subject: Hydraulic Lock |

|

|

Jill, you said:

"We see more accessory shaft damage with hydraulic lock than with a prop

strike teardown."

Are you sure you did not mean it the other way around? When the engine

is turning over during a start process it is turning over very slowly.

If there is too much oil in a cylinder, you end up with the piston being

between a rock and a hard place, meaning that the link rod is pushing

it, and it simply can't move any further "up" because the oil cannot

compress, so something has to "give", and that typically is the piston

rod, and it BENDS. There does not have to be any sudden change in

rotation speed during this process. With no sudden change in rotation

of the crankshaft, I fail to see how the accessory shaft would be

damaged at all.

On the other hand, during a hard prop strike, there is a lot of MASS

moving at high speed and any sudden change in crankshaft RPM will most

certainly damage the accessory shaft. In fact, the first inspection

that should ever be done on an engine that suffered a prop strike is to

see if the timing of the MAGS has shifted. It timing has changed, then

most certainly the accessory shaft has been twisted, and a complete

engine tear-down is mandatory.

Of course, every once in awhile a hydraulic lock situation will result

in the rod being bent enough where the bottom piston ring drops out of

the cylinder itself and "jams" the engine. In this one specific case, I

could see where stress would be imposed on the accessory shaft, but

again nowhere near as much as would be the case in a sudden change in

engine RPM caused by a Prop Strike, or sudden engine stoppage at speed.

Energy = mass times speed. The accessory shaft bends as a function of

the spinning mass it is driving versus the change in speed of the force

driving IT. If the speed of the driving force changes very suddenly,

the output mass energy will cause the shaft to twist.

The short version is this is: The faster the RPM of the engine when it

has a sudden change in speed, the more likely the accessory shaft will

twist.

You're saying that bending a piston rod will cause this (twisting the

accessory shaft) more often at starting RPM, than a prop strike

occurring with the engine developing power at running speeds? If you

say so OK, but it is hard to fathom.

Mark Bitterlich

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

mark.bitterlich(at)navy.m

Guest

|

Posted: Mon Apr 22, 2013 8:29 am Post subject: Hydraulic Lock Posted: Mon Apr 22, 2013 8:29 am Post subject: Hydraulic Lock |

|

|

Just a comment about bending a rod by hand-propping:

When I hand prop the M-14P, I am making that engine move through a compression stroke FAR faster than the normal compressed air starter ever could.

Lever arm length (prop) with big guy on the end equals one heck of a lot of force. Of course, I am rather "big".

Then we have to talk about being stupid. Let's say the prop is pulled through by hand and then just stops because there is oil in the cylinder and the piston now is in a hyd. lock condition. Which do you think would put more force on a link rod at this point? Hitting the starter and putting compressed air into the engine, or a 250 pound man hanging from the end of the prop?

I believe there is no question that a rod could be bent by "hand" (per se). I believe the reason we don't see if happen that often (if at all) is because most of us don't hand prop and are also educated enough not to do something quite this dumb.

Of course with the engine in the Yak-52 where it happened here, the guy who was flying it forgot to pull it through, so he asked someone else to do it for him. When the gent pulling it through said: "Hey, the prop won't turn anymore", the pilot said: "Stand Back, I'll clear it with the starter!".

Like I said, sometimes we have to talk about being stupid.

Mark

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

jill(at)m-14p.com

Guest

|

Posted: Tue Apr 23, 2013 12:58 pm Post subject: Hydraulic Lock Posted: Tue Apr 23, 2013 12:58 pm Post subject: Hydraulic Lock |

|

|

Good feedback, Mark.

Most prop strikes occur with wood composite or carbon fiber blades. (We

haven't had a prop strike teardown with a metal prop, yet.) The inertia of

energy is absorbed by the blades disintegrating or being shaved off.

I agree with your assessment of a hydraulic lock on startup, but not when

the engine fires and it pulls fuel or oil in from the intake tubes. If it

fires, there is a good likelihood that the accessory shaft will twist.

At landing speed, the aircraft travels 3.5 feet for each blade in contact

with the ground at initial point of contact. As the engine slows, this

increases. Consequently, the rearward deflection of a very thin blade

exceeds the rotational shearing. Additionally, the reduction of blade

length per rotation with a normal flare landing is less than a tenth of an

inch. In other words, the wood fails well before any engine parts are

stressed to the +400 foot/lbs of torque design load.

Jill

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

mark.bitterlich(at)navy.m

Guest

|

Posted: Wed Apr 24, 2013 7:24 am Post subject: Hydraulic Lock Posted: Wed Apr 24, 2013 7:24 am Post subject: Hydraulic Lock |

|

|

Actually this is very good information to keep in mind, and I am going

to chew on the physics of that answer for a day or two. It poses a very

interesting study in the stresses involved and should make for a rather

intense dinner table debate!  (Not you, my engineering friends!) (Not you, my engineering friends!)

Thanks for writing back Jill.

So given this information, what is the advice of M14P.com regarding prop

strikes and what should be done to the engine afterwards?

Mark

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

jill(at)m-14p.com

Guest

|

Posted: Fri Apr 26, 2013 9:32 am Post subject: Hydraulic lock Posted: Fri Apr 26, 2013 9:32 am Post subject: Hydraulic lock |

|

|

Additionally, the calculations for torque at full power are 641 ft/lbs on

the crankshaft and 936 ft/lbs on the prop shaft. (Double-check of the

calculations are welcome.)

The numbers in the previous post were for a typical prop strike which is at

near idle on an "Oh, %*&$!" gear up landing. We have had some sudden

stoppage prop strikes where we fully expected damage to the accessory shaft

and there was no damage. This comes back to design limit loads on the

individual components and how much over those limits the parts are

engineered to. I do not have that engineering data.

Mark, the prop strike teardown boils down to the insurance companies and

also, the ultimate peace of mind of the owner and subsequent buyers of the

aircraft. This is a judgment call; which we handle on a case by case basis.

For practical discussion, much of what dictates the prop strike teardown -

in the U.S. - is liability.

Jill

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

mark.bitterlich(at)navy.m

Guest

|

Posted: Fri Apr 26, 2013 11:02 am Post subject: Hydraulic lock Posted: Fri Apr 26, 2013 11:02 am Post subject: Hydraulic lock |

|

|

Good answer again Jill. Thank you.

I wrote a separate message about an engine that had a prop strike when

the left gear collapsed after touch-down. It took off after about a

foot on either end of the stock prop was ground off, then flew around

the pattern and landed. The engine was at idle, and the pilot stated

that he never even knew it happened until after he finally landed. I.E.

No sudden stop.

The engine has since had about 300 hours put on it with no problem

what-so-ever. Which is not to say it was not inspected, it was.

However, it was not totally torn down, only partially. Some of the

decisions were based on what your company published some time ago

concerning prop strikes based on the training they had received in

Russia. It seems it turned out to be the proper decision based on good

information.

The problem with replacing the engine is that you really don't know what

you're going to end up with there either. Hope for the best, but train

for the worst as they say.

In the end, my opinion is that there is a term called "PROP STRIKE!"

that we try to quantify into something that requires an exact action, no

matter what. This is what the FAA leans towards and if specific

information on the engine is unknown, they will also tend to apply

information made for other engines that they consider similar. This is

of course in many cases totally incorrect. Is the engine geared? What

about specific weak points (Accessory Shaft for instance)? These are

not the same from engine type to engine type even if they do both happen

to be "Radials". So EVERY case is unique and the actions taken can

vary within a fairly large margin, insurance companies and liabilities

excepted.

The other take-away from discussions like this is to realize that the

FAA reads the YAK LIST. This is not a guess. I know it for a fact. I

was confronted by an FAA Inspector for what I said on this list one time

and while some may say "so what, FREE SPEECH!", the fact is that when

confronted by these guys, it is not a fun experience no matter how much

"in the right" you might happen to be. Giving credit where credit is

due, I've eventually seen them make some good decisions, but the time

span in the interim is not something anyone wants to experience.

So while sharing good information is what this list is all about, I

would offer this one tiny suggestion: "WALLS HAVE EARS" Be careful

not to make arguments in public that could turn around and bite you in

the tail later on. Of course this is the "Pot calling the Kettle

Black", but hey, I'm learning.

Mark

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

jill(at)m-14p.com

Guest

|

Posted: Sat Apr 27, 2013 6:13 am Post subject: Hydraulic lock Posted: Sat Apr 27, 2013 6:13 am Post subject: Hydraulic lock |

|

|

Mark & Group,

What is critical in assessing the potential for damage to the accessory

shaft on a prop strike is the rate of deceleration. If you have a 3-bladed

metal Hartzell prop on your plane and hit a fire hydrant at idle, the

potential for damage is much greater than a high speed pass down the runway,

shave the tips of the blades on a wood or composite prop.

| Quote: | From the AI-14RA Engine Maintenance Manual:

|

"In case of propeller blade damage/broken or cracked/ at distance exceeding

1m/3.3 ft./ from the engine axis without sharp braking due to striking

against ground irregularities - the engine may be used after replacement of

propeller. In other cases send the engine to manufacturing plant or

specialized workshop for inspection."

Bear in mind, this is referring to the wood, composite Wilga blades. The

AI-14 also has a weaker planetary system than the M-14P.

And then you have the Service Bulletin issued by OKBM:

http://www.termikas.com/engines/M-14P/direktyva_angl.jpg (One must ask

what motivated the factory to issue this bulletin. The repair factory in

Shakhty did most of the overhauls on the M-14P, not OKBM.)

Have a great weekend, group!

Jill

________________________________ Message 7

_____________________________________

Time: 12:02:54 PM PST US

Subject: RE: RE: Hydraulic lock

From: "Bitterlich, Mark G CIV NAVAIR, WD" <mark.bitterlich(at)navy.mil>

Good answer again Jill. Thank you.

I wrote a separate message about an engine that had a prop strike when the

left gear collapsed after touch-down. It took off after about a foot on

either end of the stock prop was ground off, then flew around the pattern

and landed. The engine was at idle, and the pilot stated that he never even

knew it happened until after he finally landed. I.E.

No sudden stop.

The engine has since had about 300 hours put on it with no problem

what-so-ever. Which is not to say it was not inspected, it was.

However, it was not totally torn down, only partially. Some of the

decisions were based on what your company published some time ago concerning

prop strikes based on the training they had received in Russia. It seems it

turned out to be the proper decision based on good information.

The problem with replacing the engine is that you really don't know what

you're going to end up with there either. Hope for the best, but train for

the worst as they say.

In the end, my opinion is that there is a term called "PROP STRIKE!"

that we try to quantify into something that requires an exact action, no

matter what. This is what the FAA leans towards and if specific information

on the engine is unknown, they will also tend to apply information made for

other engines that they consider similar. This is of course in many cases

totally incorrect. Is the engine geared? What about specific weak points

(Accessory Shaft for instance)? These are not the same from engine type to

engine type even if they do both happen

to be "Radials". So EVERY case is unique and the actions taken can

vary within a fairly large margin, insurance companies and liabilities

excepted.

The other take-away from discussions like this is to realize that the FAA

reads the YAK LIST. This is not a guess. I know it for a fact. I was

confronted by an FAA Inspector for what I said on this list one time and

while some may say "so what, FREE SPEECH!", the fact is that when confronted

by these guys, it is not a fun experience no matter how much "in the right"

you might happen to be. Giving credit where credit is due, I've eventually

seen them make some good decisions, but the time span in the interim is not

something anyone wants to experience.

So while sharing good information is what this list is all about, I

would offer this one tiny suggestion: "WALLS HAVE EARS" Be careful

not to make arguments in public that could turn around and bite you in the

tail later on. Of course this is the "Pot calling the Kettle Black", but

hey, I'm learning.

Mark

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

Mozam

Joined: 24 Nov 2006

Posts: 85

|

Posted: Mon Apr 29, 2013 4:27 am Post subject: Re: Hydraulic Lock Posted: Mon Apr 29, 2013 4:27 am Post subject: Re: Hydraulic Lock |

|

|

A couple years ago I watched as one of our NE guys tried to make a left turn onto a taxiway in his -52TD just as his right brake froze up. The nose went over, with a high power setting, and the prop hit the pavement.

The last 12 inches or so of every blade was reduced to a million splinters in about one second! (Hence, his new callsign.) A broom and dustpan was used to sweep up what used to be three prop blades.

I don't believe the engine was damaged at all.

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

ReadeG(at)cairnwood.com

Guest

|

Posted: Mon Apr 29, 2013 6:10 am Post subject: Hydraulic Lock Posted: Mon Apr 29, 2013 6:10 am Post subject: Hydraulic Lock |

|

|

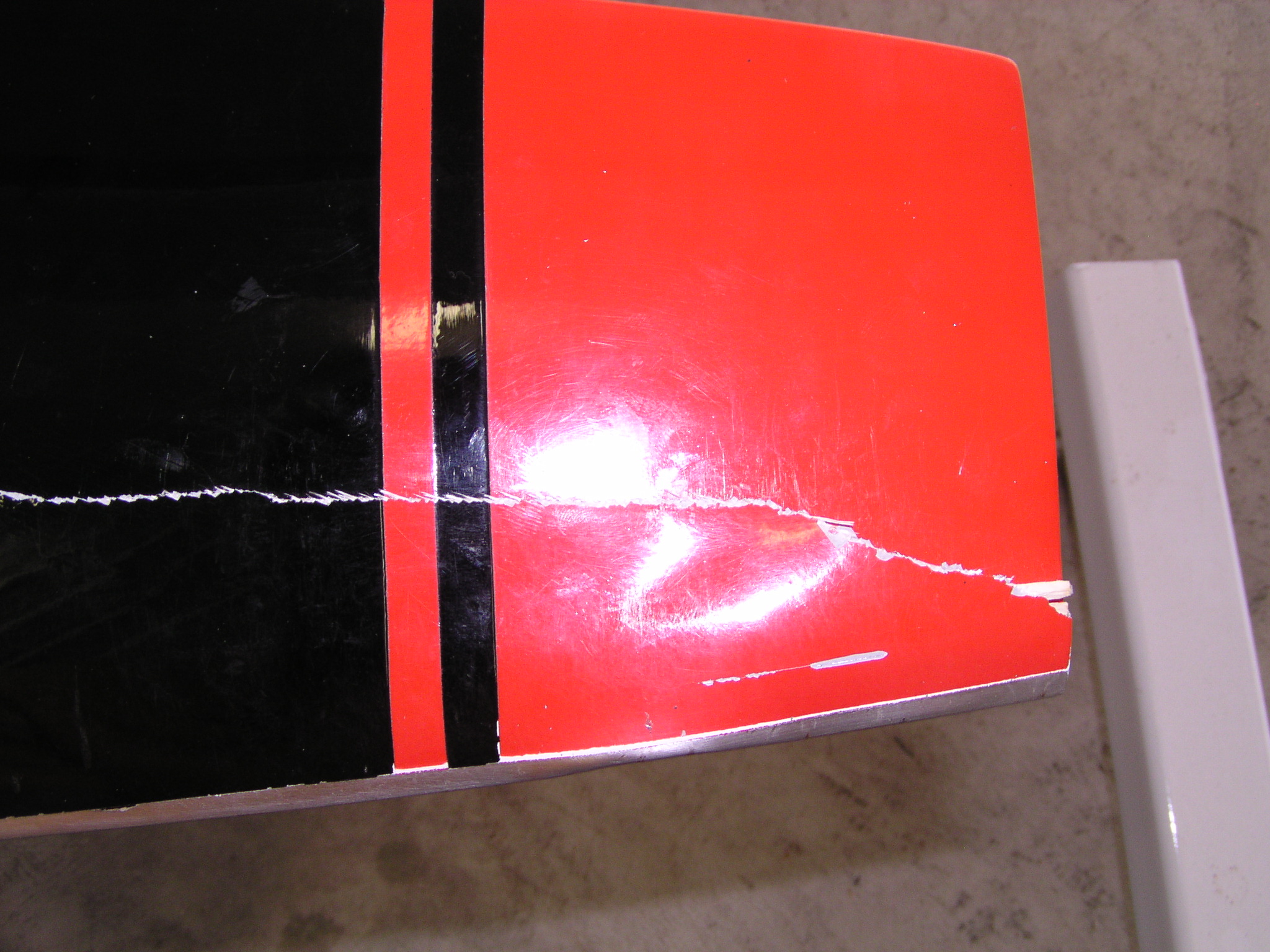

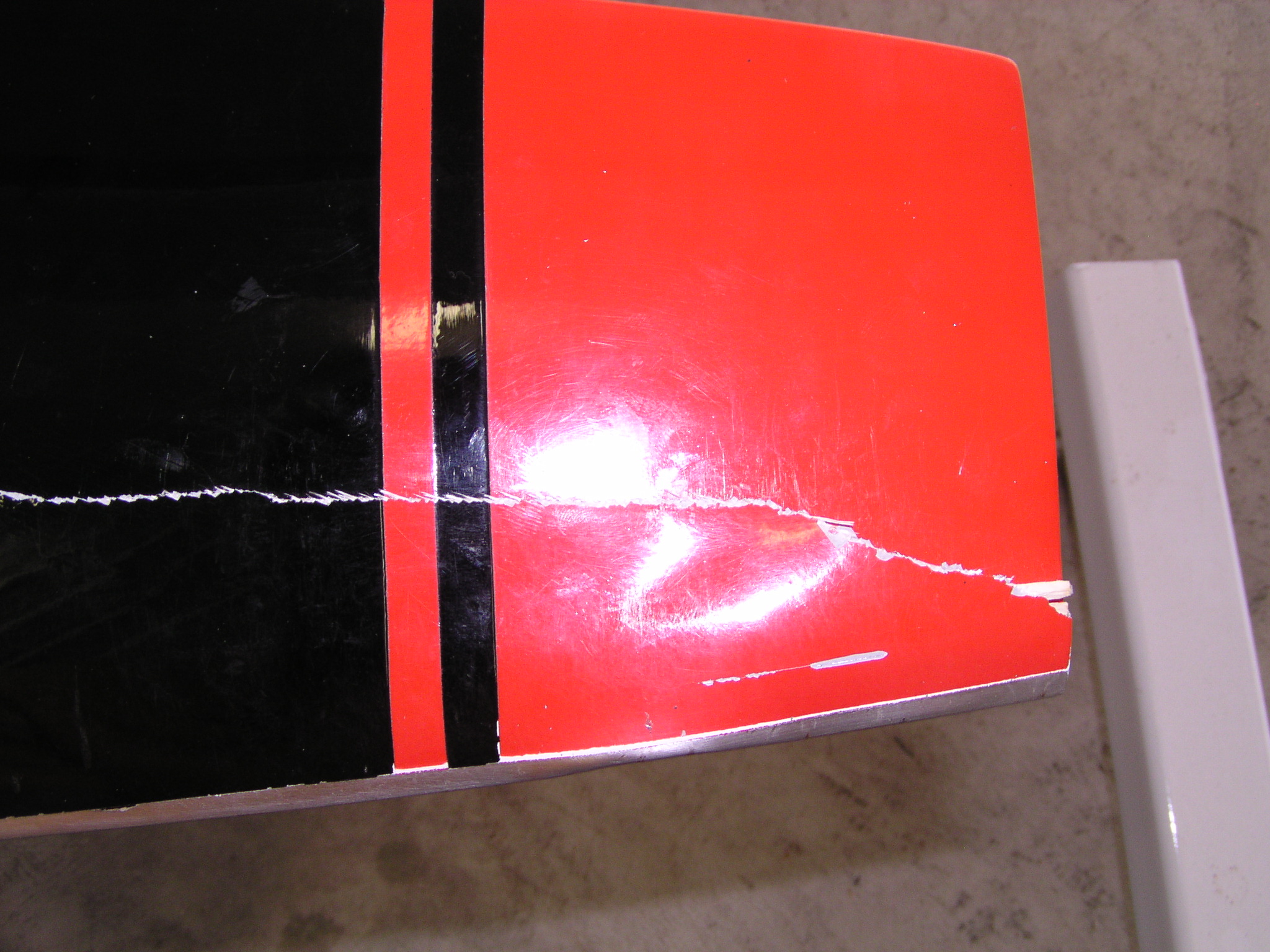

This is true - it was an amazing shower of sawdust! It did not tip up

very fast - it was a slow motion kind of thing which meant that I knew

exactly what was about to happen even with stick full aft and pulling

the power. We tore down the nose case and had the components tested

however they needed to be tested and nothing was out of order. We had

other tests done that were either prescribed in the manuals or deemed

appropriate for the situation. Results were all nominal. We put it

back together and that was probably 200 hours ago.

Splinter

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

| Description: |

|

| Filesize: |

676.16 KB |

| Viewed: |

8393 Time(s) |

|

| Description: |

|

| Filesize: |

654.38 KB |

| Viewed: |

8393 Time(s) |

|

|

|

| Back to top |

|

|

richard.goode(at)russiana

Guest

|

Posted: Mon Apr 29, 2013 6:39 am Post subject: Hydraulic Lock Posted: Mon Apr 29, 2013 6:39 am Post subject: Hydraulic Lock |

|

|

Was the engine checked in any way, or was it just assumed it was fine and a

new prop bolted on before continuing to fly?

Richard Goode Aerobatics

Rhodds Farm

Lyonshall

Hereford

HR5 3LW

Tel: +44 (0) 1544 340120

Fax: +44 (0) 1544 340129

www.russianaeros.com

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

drc(at)wscare.com

Guest

|

Posted: Mon Apr 29, 2013 10:22 am Post subject: Hydraulic Lock Posted: Mon Apr 29, 2013 10:22 am Post subject: Hydraulic Lock |

|

|

Reade, Holy shit what a picture !! I would have been sick I think.

I was worried about mine - happened in 2005, taxing at OSH prior to air venture - hit something with only one blade. They were establishing all the alternative ground taxi patterns. Other 2 blades ok.

Now 300 hours later no issues.

Dr. Herb Coussons, MD

drc(at)wscare.com

2641 Development Drive

Green Bay, WI 54311

Cell 920-639-8434

Work 920-338-6868

Fax 920-338-6869

On Apr 29, 2013, at 9:07 AM, "Genzlinger, Reade" <ReadeG(at)Cairnwood.com> wrote:

[quote] This is true - it was an amazing shower of sawdust! It did not tip up

very fast - it was a slow motion kind of thing which meant that I knew

exactly what was about to happen even with stick full aft and pulling

the power. We tore down the nose case and had the components tested

however they needed to be tested and nothing was out of order. We had

other tests done that were either prescribed in the manuals or deemed

appropriate for the situation. Results were all nominal. We put it

back together and that was probably 200 hours ago.

Splinter

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

| Description: |

|

| Filesize: |

694.46 KB |

| Viewed: |

8392 Time(s) |

|

| Description: |

|

| Filesize: |

665.31 KB |

| Viewed: |

8392 Time(s) |

|

|

|

| Back to top |

|

|

ReadeG(at)cairnwood.com

Guest

|

Posted: Mon Apr 29, 2013 10:58 am Post subject: Hydraulic Lock Posted: Mon Apr 29, 2013 10:58 am Post subject: Hydraulic Lock |

|

|

Yeah - it was not a great way to end the day. It was the last flight of

the day - I was doing a practice 4 ship flight as lead. As I was

taxiing I could not get it to turn left. I stopped and tried to taxing

again attempting a left turn and all it wanted to do was go straight

-but it did seem to exhibit some left braking. I stopped again and then

tried once more trying a little extra power to use the rudder to help.

As I began to move forward cycling the brake handle about the third

squeeze the brakes just locked up and the tail began to rise from power

and momentum. I pulled it back but too late. The one fortunate thing

is that the engine stopped with one of the blades on the ground - in

other words the blade held the cowl off the ground. After the Oscar

Sierra moment I shut everything down, a couple of buddies came over and

pulled the tail out of the sky and we got out and promptly pushed it out

of the way and into a hangar. As noted by Mozam, just a lot of

splinters on the ground. Not one mark out of the pavement.

Interestingly, the FAA was at this event. I had to provide my paperwork

(she looked at everything - program letter, registration, AC, parachute

repack date - all was in order!) and she wrote up a report. The next

day an inspector came out and determined that no property was damaged

and he simply called it an incident and not an accident. I had to let

them know when it was made airworthy again and that was it.

The MT prop is wonderful. But it is crazy expensive and the lead times

are awful. Insurance less deductible worked as expected. Needless to

say, the out of pocket still had some sting to it. The brake reduction

valve was replaced and all has been fine ever since. One expensive and

humbling way to get a call sign!

Reade Genzlinger

Cairnwood Cooperative Corporation

215.914.0370

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|