|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

Bob McC

Joined: 09 Jan 2006

Posts: 258

Location: Toronto, ON

|

Posted: Thu May 02, 2013 6:22 am Post subject: How to test engine ground? Posted: Thu May 02, 2013 6:22 am Post subject: How to test engine ground? |

|

|

Dan;

Connect your voltmeter between the battery negative post and the engine case/starter housing while cranking and see what the voltage drop is. Very low voltage reading = good ground. significant voltage reading = bad ground. If you also know what current you're drawing you can calculate total loop resistance using these readings.

Bob McC

Date: Thu, 2 May 2013 09:11:41 -0400

Subject: How to test engine ground?

From: dcheckoway(at)gmail.com

To: aeroelectric-list(at)matronics.com

This may seem like a ridiculous question, and hopefully I'll end up slapping my forehead when I hear the answer...but here goes anyway.

I'd like to quantify, or at least qualify my engine ground connection. That is, I have a 2 AWG wire connecting my engine to the ground block on the firewall. Suffice it to say, I have reason to suspect that one of the connections is less than perfect. I have an intermittent issue (probably another thread in the making), and I want to rule out ground as a culprit

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Bob McC

Falco #908

(just starting) |

|

| Back to top |

|

|

tim2542(at)sbcglobal.net

Guest

|

Posted: Thu May 02, 2013 7:08 am Post subject: How to test engine ground? Posted: Thu May 02, 2013 7:08 am Post subject: How to test engine ground? |

|

|

Dans idea is a good one, but I think he meant misspoke slightly when he said "voltage drop". You want to know the voltage between the engine case and the NEG battery terminal while cranking, in other words your volt meter is placed in parallel with the ground system. Anything more than 1~1-1/2 volts indicates the ground is not able to drain off the ohm-bugs fast enough and they are having to wait in line to get home  . Also if you do have a high reading (high resistance) you can then go point to point on the different terminals and find the one causing the problem. . Also if you do have a high reading (high resistance) you can then go point to point on the different terminals and find the one causing the problem.

Tim

Sent from my iPad

On May 2, 2013, at 7:22 AM, Bob McCallum <robert.mccallum2(at)sympatico.ca (robert.mccallum2(at)sympatico.ca)> wrote:

[quote] Dan;

Connect your voltmeter between the battery negative post and the engine case/starter housing while cranking and see what the voltage drop is. Very low voltage reading = good ground. significant voltage reading = bad ground. If you also know what current you're drawing you can calculate total loop resistance using these readings.

Bob McC

Date: Thu, 2 May 2013 09:11:41 -0400

Subject: How to test engine ground?

From: dcheckoway(at)gmail.com (dcheckoway(at)gmail.com)

To: aeroelectric-list(at)matronics.com (aeroelectric-list(at)matronics.com)

This may seem like a ridiculous question, and hopefully I'll end up slapping my forehead when I hear the answer...but here goes anyway.

I'd like to quantify, or at least qualify my engine ground connection. That is, I have a 2 AWG wire connecting my engine to the ground block on the firewall. Suffice it to say, I have reason to suspect that one of the connections is less than perfect. I have an intermittent issue (probably another thread in the making), and I want to rule out ground as a culprit.

When I throw an ohmmeter across, of course I see zero ohms. But that only tells me the obvious. It would probably read zero even if I had a 24 AWG wire in its place.  And what I'm concerned about is that maybe it's reading zero despite the engine side connection not making good enough contact. Probably not, but I'd like to rule it out. And what I'm concerned about is that maybe it's reading zero despite the engine side connection not making good enough contact. Probably not, but I'd like to rule it out.

Is there any way (something a doofus like me could do) to test the quality of this engine ground connection? i.e. when my starter is sucking 200 amps through that straw, I'd like to know if it's truly unimpeded so to speak.

Any tips or tricks? Or do we just trust that if the wire is fat enough, we *think* our connections are fine, the starter cranks and nothing smokes, then life is good enough?

Thanks,

Dan

[b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jluckey(at)pacbell.net

Guest

|

Posted: Thu May 02, 2013 7:28 am Post subject: How to test engine ground? Posted: Thu May 02, 2013 7:28 am Post subject: How to test engine ground? |

|

|

Tim , Bob's use of the term "Voltage Drop" is correct.

--- On Thu, 5/2/13, Tim Andres <tim2542(at)sbcglobal.net> wrote:

From: Tim Andres <tim2542(at)sbcglobal.net>

Subject: Re: How to test engine ground?

To: "aeroelectric-list(at)matronics.com" <aeroelectric-list(at)matronics.com>

Date: Thursday, May 2, 2013, 8:07 AM

Dans idea is a good one, but I think he meant misspoke slightly when he said "voltage drop". You want to know the voltage between the engine case and the NEG battery terminal while cranking, in other words your volt meter is placed in parallel with the ground system. Anything more than 1~1-1/2 volts indicates the ground is not able to drain off the ohm-bugs fast enough and they are having to wait in line to get home  . Also if you do have a high reading (high resistance) you can then go point to point on the different terminals and find the one causing the problem. Tim . Also if you do have a high reading (high resistance) you can then go point to point on the different terminals and find the one causing the problem. Tim

Sent from my iPad

On May 2, 2013, at 7:22 AM, Bob McCallum <robert.mccallum2(at)sympatico.ca> wrote:

Dan;

Connect your voltmeter between the battery negative post and the engine case/starter housing while cranking and see what the voltage drop is. Very low voltage reading = good ground. significant voltage reading = bad ground. If you also know what current you're drawing you can calculate total loop resistance using these readings.

Bob McC

Date: Thu, 2 May 2013 09:11:41 -0400

Subject: How to test engine ground?

From: dcheckoway(at)gmail.com

To: aeroelectric-list(at)matronics.com

This may seem like a ridiculous question, and hopefully I'll end up slapping my forehead when I hear the answer...but here goes anyway.

I'd like to quantify, or at least qualify my engine ground connection. That is, I have a 2 AWG wire connecting my engine to the ground block on the firewall. Suffice it to say, I have reason to suspect that one of the connections is less than perfect. I have an intermittent issue (probably another thread in the making), and I want to rule out ground as a culprit.

When I throw an ohmmeter across, of course I see zero ohms. But that only tells me the obvious. It would probably read zero even if I had a 24 AWG wire in its place.  And what I'm concerned about is that maybe it's reading zero despite the engine side connection not making good enough contact. Probably not, but I'd like to rule it out. And what I'm concerned about is that maybe it's reading zero despite the engine side connection not making good enough contact. Probably not, but I'd like to rule it out.

Is there any way (something a doofus like me could do) to test the quality of this engine ground connection? i.e. when my starter is sucking 200 amps through that straw, I'd like to know if it's truly unimpeded so to speak

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu May 02, 2013 7:50 am Post subject: How to test engine ground? Posted: Thu May 02, 2013 7:50 am Post subject: How to test engine ground? |

|

|

I'd like to quantify, or at least qualify my engine ground connection. That is, I have a 2 AWG wire connecting my engine to the ground block on the firewall. Suffice it to say, I have reason to suspect that one of the connections is less than perfect. I have an intermittent issue (probably another thread in the making), and I want to rule out ground as a culprit.

When I throw an ohmmeter across, of course I see zero ohms. But that only tells me the obvious. It would probably read zero even if I had a 24 AWG wire in its place.  And what I'm concerned about is that maybe it's reading zero despite the engine side connection not making good enough contact. Probably not, but I'd like to rule it out. And what I'm concerned about is that maybe it's reading zero despite the engine side connection not making good enough contact. Probably not, but I'd like to rule it out.

Your observation has roots in the ideas we've discussed in the past . . . ideas for quantifying the quality of electrical connections and components with very low resistance.

Is there any way (something a doofus like me could do) to test the quality of this engine ground connection? i.e. when my starter is sucking 200 amps through that straw, I'd like to know if it's truly unimpeded so to speak.

Any tips or tricks? Or do we just trust that if the wire is fat enough, we *think* our connections are fine, the starter cranks and nothing smokes, then life is good enough?

One fact that goes favorably to your question is that a really POOR joint or component will have a LOT of voltage drop with a commensurate concentration of high energy dissipation. For example, a common reason for alternators to be returned to B&C for repair is a burned b-lead terminal that was so loose as to allow arcing and much heat . . . the terminal melted. Some contactor failures present as a valiant effort to maintain useful conductivity but with attendant losses in the one volt or more range. 1 volt x 200 amps is 200 watts . . . dumping that kind of energy into the small area of a degraded contact heats things up rapidly and accelerates the failure. See http://tinyurl.com/qmk6gm

Thanks,

Dan

At 09:22 AM 5/2/2013, you wrote:

Dan;

Connect your voltmeter between the battery negative post and the engine case/starter housing while cranking and see what the voltage drop is. Very low voltage reading = good ground. significant voltage reading = bad ground. If you also know what current you're drawing you can calculate total loop resistance using these readings.

Bob McC

This is a good beginning . . . unfortunately, starters make very poor loads for the purpose of conducting diagnostics. Starter current is directly related to load . . . which varies wildly as the engine rotates through cylinder compression cycles. Taking a reading from a digital display watching voltage drops generated by a starter motor is difficult if not impossible. An analog meter will be a little better but not by much. Measuring voltage drop across various portions of the power loop under known load is fundamental to the low-ohms adapter hardware and articles offered on the website. The low-ohms adapter illustrated offers a maximum of 1 amp excitation current. A bit low for measuring starter circuit drops with commonly available instrumentation. One would LIKE to excite a path under analysis with a steady 10 or even 100 amps. This isn't as hard as it might seem.

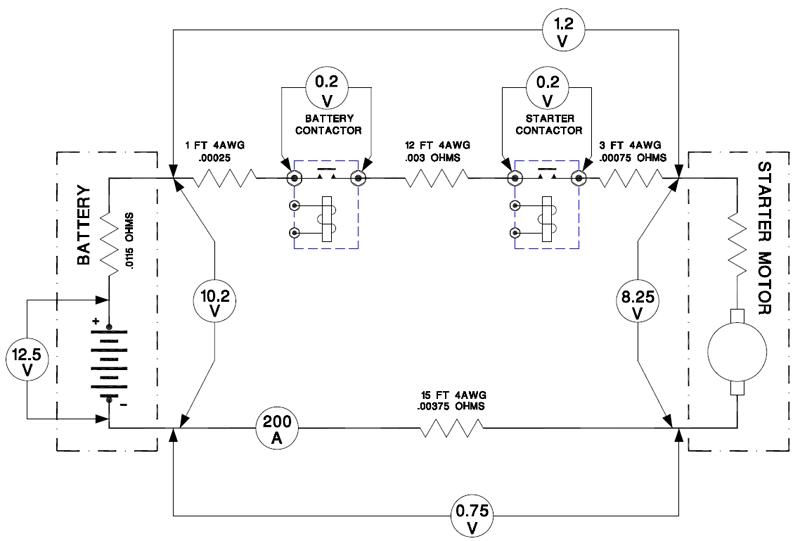

The folks over at Harbor Freight offer this carbon pile load battery tester which is capable of developing a reasonably steady state load at 200 amps or more.

[img]cid:.0[/img][/b] To use this device as a circuit quality tester, you need to wire it to your airplane such that it REPLACES the starter as a load on the system. This is BEST accomplished by adding short test-pigtails to the ship's wiring such that the 'test clamps' do not connect to the airplane's wiring. If these 'slip' or fail to make good contact throughout the test effort, they might arc and damage parts of the airplane. The BEST way to make these connections is to cut the clips off the test cables leaving about a 6' pigtail on the clip. Install ring terminals that can be used to bolt the cable back together later thus restoring the original functionality of the tester. With the clips 'unbolted' you can attach tester wires to the crankcase and the starter power terminal. For this test, remove the jumper on the starter's pinion gear engagement solenoid to disable the starter. You might also wish to fabricate a hand held 'pickle switch' to energize the ship's starter contactor. The lead wires for this piece of equipment needs to be long enough so that you can control the load from any place you're observing your voltmeter.

Now, you may need to enlist the help of someone to 'manage the load' . . . tell your assistant to crank the load knob up to achieve the desired test current, 100A is probably enough. With a little practice, you can easily hold a test current to within 5 amps or so.

Now, as you probe various portions of the (+) or (-) starter circuit with a voltmeter, you can hit the system with a test load likely to produce useful readings for voltage drop on your plain-vanilla multimeter . . . either digital or analog. Most off-the-shelf meters have a 200 mV full scale reading. With voltmeter and pickle-switch in hand, you can explore the cranking circuit in its entirety. Any portion of the circuit with compromised integrity will probably manifest with rather striking voltage drop. Your starter contactor is an intermittent duty device; you want to make the readings rather quickly.

One of the future AEC products being considered is a processor based integrator adapter for a digital voltmeter. The device would have two inputs: one for voltage drop, the other for battery voltage. A very rapid sampling of current (voltage drop) compared with excitation voltage (battery terminal voltage) would be evaluated and integrated over time such that a technician could analyze system integrity using the engine's starter as a load.

In the mean time, you can modify the HF battery tester into a steady-state load that will yield very useful data for evaluating the integrity of your system's fat wire circuits.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

92.36 KB |

| Viewed: |

11287 Time(s) |

|

|

|

| Back to top |

|

|

skywagon

Joined: 11 Feb 2006

Posts: 184

|

Posted: Thu May 02, 2013 8:02 am Post subject: How to test engine ground? Posted: Thu May 02, 2013 8:02 am Post subject: How to test engine ground? |

|

|

Key words in Bob's answer are "post" and "starter housing"; where the test instrument probes for voltage connection must be made. Don't test at any point on the cable(s).

You want the test for loss to include all of the cable-to-terminal connections. There could be corrosion, oxidation, looseness in those cable joints that are invisible, but, will show up in the test Bob outlines. If a voltage (loss) is found in that pathway somewhere, then, you can switch your test leads and march down the cable length to track down where the loss, cable resistance, is located and fix it.

....Dave

[quote] ---

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Mark(at)wessonair.com

Guest

|

Posted: Thu May 02, 2013 8:37 am Post subject: How to test engine ground? Posted: Thu May 02, 2013 8:37 am Post subject: How to test engine ground? |

|

|

I agree with everything said, however.

Before reading anyone else's post my check would have been to check the voltage at the starter load stud and starter case ground while starting.

If you have a good ground and positive cable your voltage drop will be minimal. (Sorry I don't know what the baseline for good would be)

You could then take a jumper cable and run from the battery negative and starter case and do the check again to compare the two.

If the drop is less then the jumper cable made a better ground. If the same then your ground system works as well.

With a 12.8v battery I would expect somewhere around 10 - 11 volts during starting. I would assume somewhere less than that could mean that one of the cables/connections is deficient.

Mark Wesson<?xml:namespace prefix = o ns = "urn:schemas-microsoft-com:office:office" />

From: owner-aeroelectric-list-server(at)matronics.com [mailto:owner-aeroelectric-list-server(at)matronics.com] On Behalf Of Dan Checkoway

Sent: Thursday, May 02, 2013 12:00 PM

To: aeroelectric-list(at)matronics.com

Subject: Re: How to test engine ground?

Thanks guys, that makes total sense...will give it a shot! (sound of hand slapping forehead)

Dan

On Thu, May 2, 2013 at 11:27 AM, Jeff Luckey <jluckey(at)pacbell.net (jluckey(at)pacbell.net)> wrote:

[quote] Tim , Bob's use of the term "Voltage Drop" is correct.

--- On Thu, 5/2/13, Tim Andres <tim2542(at)sbcglobal.net (tim2542(at)sbcglobal.net)> wrote:

| Quote: |

From: Tim Andres <tim2542(at)sbcglobal.net (tim2542(at)sbcglobal.net)>

Subject: Re: How to test engine ground?

To: "aeroelectric-list(at)matronics.com (aeroelectric-list(at)matronics.com)" <aeroelectric-list(at)matronics.com (aeroelectric-list(at)matronics.com)>

Date: Thursday, May 2, 2013, 8:07 AM

Dans idea is a good one, but I think he meant misspoke slightly when he said "voltage drop". You want to know the voltage between the engine case and the NEG battery terminal while cranking, in other words your volt meter is placed in parallel with the ground system. Anything more than 1~1-1/2 volts indicates the ground is not able to drain off the ohm-bugs fast enough and they are having to wait in line to get home  . Also if you do have a high reading (high resistance) you can then go point to point on the different terminals and find the one causing the problem. . Also if you do have a high reading (high resistance) you can then go point to point on the different terminals and find the one causing the problem.

Tim

Sent from my iPad

On May 2, 2013, at 7:22 AM, Bob McCallum <robert.mccallum2(at)sympatico.ca> wrote:

| Quote: | Dan;

Connect your voltmeter between the battery negative post and the engine case/starter housing while cranking and see what the voltage drop is. Very low voltage reading = good ground. significant voltage reading = bad ground. If you also know what current you're drawing you can calculate total loop resistance using these readings.

Bob McC

Date: Thu, 2 May 2013 09:11:41 -0400

Subject: AeroElectric-List: How to test engine ground?

From: dcheckoway(at)gmail.com

To: aeroelectric-list(at)matronics.com

This may seem like a ridiculous question, and hopefully I'll end up slapping my forehead when I hear the answer...but here goes anyway.

I'd like to quantify, or at least qualify my engine ground connection. That is, I have a 2 AWG wire connecting my engine to the ground block on the firewall. Suffice it to say, I have reason to suspect that one of the connections is less than perfect. I have an intermittent issue (probably another thread in the making), and I want to rule out ground as a culprit.

When I throw an ohmmeter across, of course I see zero ohms. But that only tells me the obvious. It would probably read zero even if I had a 24 AWG wire in its place.  And what I'm concerned about is that maybe it's reading zero despite the engine side connection not making good enough contact. Probably not, but I'd like to rule it out. And what I'm concerned about is that maybe it's reading zero despite the engine side connection not making good enough contact. Probably not, but I'd like to rule it out.

Is there any way (something a doofus like me could do) to test the quality of this engine ground connection? i.e. when my starter is sucking 200 amps through that straw, I'd like to know if it's truly unimpeded so to speak.

Any tips or tricks? Or do we just trust that if the wire is fat enough, we *think* our connections are fine, the starter cranks and nothing smokes, then life is good enough?

Thanks,

Dan

ank" href="http://www.matronics.com/Navigator?AeroElectric-List">http://wt; http://www.matronics.com/contrib===============

|

|

| Quote: |

ist" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

tp://forums.matronics.com

_blank">http://www.matronics.com/contribution

|

href="http://www.matronics.com/Navigator?AeroElectric-List">http://www.matronics.com/Navigator?AeroElectric-List

href="http://forums.matronics.com">http://forums.matronics.com

href="http://www.matronics.com/contribution">http://www.matronics.com/c

[b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

tim2542(at)sbcglobal.net

Guest

|

Posted: Thu May 02, 2013 10:38 am Post subject: How to test engine ground? Posted: Thu May 02, 2013 10:38 am Post subject: How to test engine ground? |

|

|

Your right, and apologies to Bob, I just thought it might be a confusing term, since what he's looking for is a voltage increase from zero.

Tim

Sent from my iPad

On May 2, 2013, at 8:27 AM, Jeff Luckey <jluckey(at)pacbell.net (jluckey(at)pacbell.net)> wrote:

[quote]Tim , Bob's use of the term "Voltage Drop" is correct.

--- On Thu, 5/2/13, Tim Andres <tim2542(at)sbcglobal.net (tim2542(at)sbcglobal.net)> wrote:

| Quote: |

From: Tim Andres <tim2542(at)sbcglobal.net (tim2542(at)sbcglobal.net)>

Subject: Re: How to test engine ground?

To: "aeroelectric-list(at)matronics.com (aeroelectric-list(at)matronics.com)" <aeroelectric-list(at)matronics.com (aeroelectric-list(at)matronics.com)>

Date: Thursday, May 2, 2013, 8:07 AM

Dans idea is a good one, but I think he meant misspoke slightly when he said "voltage drop". You want to know the voltage between the engine case and the NEG battery terminal while cranking, in other words your volt meter is placed in parallel with the ground system. Anything more than 1~1-1/2 volts indicates the ground is not able to drain off the ohm-bugs fast enough and they are having to wait in line to get home  . Also if you do have a high reading (high resistance) you can then go point to point on the different terminals and find the one causing the problem. . Also if you do have a high reading (high resistance) you can then go point to point on the different terminals and find the one causing the problem.

Tim

Sent from my iPad

On May 2, 2013, at 7:22 AM, Bob McCallum <[url=/mc/compose?to=robert.mccallum2(at)sympatico.ca]robert.mccallum2(at)sympatico.ca[/url]> wrote:

| Quote: | Dan;

Connect your voltmeter between the battery negative post and the engine case/starter housing while cranking and see what the voltage drop is. Very low voltage reading = good ground. significant voltage reading = bad ground. If you also know what current you're drawing you can calculate total loop resistance using these readings.

Bob McC

Date: Thu, 2 May 2013 09:11:41 -0400

Subject: How to test engine ground?

From: [url=/mc/compose?to=dcheckoway(at)gmail.com]dcheckoway(at)gmail.com[/url]

To: [url=/mc/compose?to=aeroelectric-list(at)matronics.com]aeroelectric-list(at)matronics.com[/url]

This may seem like a ridiculous question, and hopefully I'll end up slapping my forehead when I hear the answer...but here goes anyway.

I'd like to quantify, or at least qualify my engine ground connection. That is, I have a 2 AWG wire connecting my engine to the ground block on the firewall. Suffice it to say, I have reason to suspect that one of the connections is less than perfect. I have an intermittent issue (probably another thread in the making), and I want to rule out ground as a culprit.

When I throw an ohmmeter across, of course I see zero ohms. But that only tells me the obvious. It would probably read zero even if I had a 24 AWG wire in its place.  And what I'm concerned about is that maybe it's reading zero despite the engine side connection not making good enough contact. Probably not, but I'd like to rule it out. And what I'm concerned about is that maybe it's reading zero despite the engine side connection not making good enough contact. Probably not, but I'd like to rule it out.

Is there any way (something a doofus like me could do) to test the quality of this engine ground connection? i.e. when my starter is sucking 200 amps through that straw, I'd like to know if it's truly unimpeded so to speak.

Any tips or tricks? Or do we just trust that if the wire is fat enough, we *think* our connections are fine, the starter cranks and nothing smokes, then life is good enough?

Thanks,

Dan

ank" href="http://www.matronics.com/Navigator?AeroElectric-List">http://wt; http://www.matronics.com/contrib===============

|

|

| Quote: |

===================================

st">http://www.matronics.com/Navigator?AeroElectric-List

===================================

cs.com

===================================

matronics.com/contribution

===================================

|

[b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

fly4grins(at)gmail.com

Guest

|

Posted: Fri May 03, 2013 6:40 am Post subject: How to test engine ground? Posted: Fri May 03, 2013 6:40 am Post subject: How to test engine ground? |

|

|

Hi Dan-

There is another highly technical way to test the thermal side of your (potential) problem: Leave the ignition off and cowl opened, crank for a while, and see if your ground strap connections get warm or hot to the touch. That's not extremely scientific, but if one end stays near ambient and the other raises blisters, you will have localized the problem.

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Eric M. Jones

Joined: 10 Jan 2006

Posts: 565

Location: Massachusetts

|

Posted: Sat May 04, 2013 4:57 am Post subject: Re: How to test engine ground? Posted: Sat May 04, 2013 4:57 am Post subject: Re: How to test engine ground? |

|

|

Big conductors and low resistances are usually measured by the "voltage drop method at a specific current". But just feeling the ground strap to see if it gets hot is a great way to go.

Note: There are temperature indicating materials available from: http://www.omega.com which are easy to apply to e.g. high-current lugs. Color change=loose or failing connector.

BTW: More stuff to worry about in the middle of the night....bad things happen when ground currents pass through bearings. Sometimes the designer catches these things...sometimes they don't.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Eric M. Jones

www.PerihelionDesign.com

113 Brentwood Drive

Southbridge, MA 01550

(508) 764-2072

emjones(at)charter.net |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sat May 04, 2013 9:15 am Post subject: How to test engine ground? Posted: Sat May 04, 2013 9:15 am Post subject: How to test engine ground? |

|

|

At 07:57 AM 5/4/2013, you wrote:

| Quote: | --> AeroElectric-List message posted by: "Eric M. Jones" <emjones(at)charter.net>

Big conductors and low resistances are usually measured by the "voltage drop method at a specific current". But just feeling the ground strap to see if it gets hot is a great way to go. |

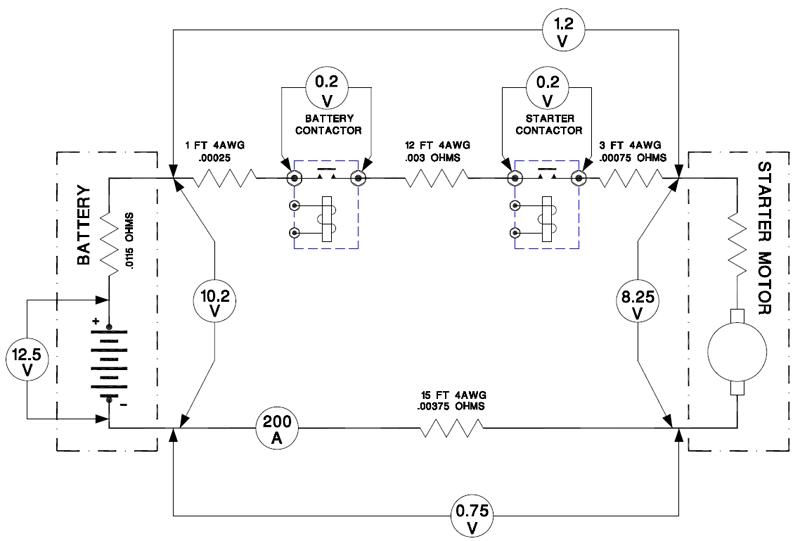

True. But placing the touchy-feely technique into context, I rather imagine

that any component that exhibits an extra-ordinary rise in temperature after

a few seconds under load is on the verge of driving over the cliff of

precipitous failure.

For example, I would think that dissipation local to the 'touch point'

must toss some goodly watts heat. Consider the 1' foot wire segment

between battery(+) and the contactor in the figure below. 0.00025

ohms x 200A = 50 millivolts of drop. 50mV x 200A is 10 watts. A 10

second 'cranking event' may produce detectable rise but would you

be able to tell if the rise were say TWICE the normal amount?

The 200 millivolt drops I hypothesized for each contactor is a total

for up to 6 metallic joints in the path that includes wire to terminal,

terminal to contact post, contact to armature, armature to contact,

contact post to terminal and terminal to wire. EACH of those joints

is very low in resistance but NOT zero. The drops in components and

joints can all add up to a significant total but no single joint

produces a predominantly obvious drop.

I think I once suggested that there's no such thing as a "12v starter".

I made that assertion based on a hypothetical not unlike that pictured

below.

[img]cid:.0[/img]

This figure illustrates the reasoning behind the notion for measuring

a battery's ability to deliver a current to a terminal voltage on

the order of 9 volts. We like to see numbers in the 400+ amps

range. This demonstrates that with a 200 amp load, voltage drop

within the battery will be about half thus leaving us with 1 to

1.5 volts of 'head room' to toss off in cranking circuit components

and still get 8-9 volts to the starter.

If one observes a change in cranking performance the prime suspect

will be the battery. It's either not fully charged or nearing end

of life. Look at the battery voltage under load first.

The starter is a second order suspect. Measure its terminal voltage

under load. If 'high', then for what ever reason, it's drawing

less than normal current (high internal resistance) and is probably

self destructing. If the voltage is low, then start looking at the

remainder of the cranking loop voltage drops. There's a lot of

opportunity for loop resistances to go up with the most likely

prospects being contactors. Any contactor who's voltage drop has

risen so much as to affect cranking performance will probably

be smelling bad but might not demonstrate a marked temperature

rise detectable by feeling the outside surface of the enclosure.

This narration is the foundation for the starter circuit analyzer.

An 8-channel, a/d complimented with data integration software

could take a 10 second look at a cranking event and instantly

highlight the probable culprit for poor starter performance.

The probability of identifying a 'warmer than usual' component

in a suite of components that warms up in normal situations

is somewhat problematic.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

109.79 KB |

| Viewed: |

11242 Time(s) |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sat May 04, 2013 9:38 am Post subject: How to test engine ground? Posted: Sat May 04, 2013 9:38 am Post subject: How to test engine ground? |

|

|

| Quote: |

BTW: More stuff to worry about in the middle of the night....bad

things happen when ground currents pass through bearings. Sometimes

the designer catches these things...sometimes they don't.

|

Yeah. Some years back we discovered root cause of

poor bearing life on starter-generators. It seems

that the steel shaft down through the center, while

thought to be in an area of "zero net flux" was

"excited" with microvolts of induced EMF shorted out

by micro-ohms of starter frame through the bearings

at each end. In retrospect, I'm not sure that the

frame of the starter-gen didn't see similar inducements.

A mysterious stress on bearing life went away with

incorporation of ceramic bearings or bearing

liners. Just because some stimulus is 'tiny' does

not necessarily negate its effects.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

edpav8r(at)yahoo.com

Guest

|

Posted: Sat May 04, 2013 9:57 am Post subject: How to test engine ground? Posted: Sat May 04, 2013 9:57 am Post subject: How to test engine ground? |

|

|

Is this bearing wear a result of microscopic arcing and pitting as the balls roll in their races, making and breaking electrical contact?

Eric

On May 4, 2013, at 1:36 PM, "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com> wrote:

| Quote: |

Yeah. Some years back we discovered root cause of poor bearing life on starter-generators. It seems that the steel shaft down through the center, while thought to be in an area of "zero net flux" was "excited" with microvolts of induced EMF shorted out by micro-ohms of starter frame through the bearings at each end. In retrospect, I'm not sure that the frame of the starter-gen didn't see similar inducements.

A mysterious stress on bearing life went away with incorporation of ceramic bearings or bearing liners. Just because some stimulus is 'tiny' does not necessarily negate its effects.

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sat May 04, 2013 11:19 am Post subject: How to test engine ground? Posted: Sat May 04, 2013 11:19 am Post subject: How to test engine ground? |

|

|

At 12:57 PM 5/4/2013, you wrote:

| Quote: |

Is this bearing wear a result of microscopic arcing and pitting as

the balls roll in their races, making and breaking electrical contact?

|

Yeah . . . sort of. I'm not so sure that 'arcing'

takes place so much as a kind of 'accelerated corrosion.'

We're talking VERY tiny voltages at SIGNIFICANT currents.

The area of contact between a spherical ball and

its races is small and the pressures are huge.

Hence the need for both harness and smoothness.

An ionizing current flow across the tiny 'joint'

cannot go unnoticed. Where the local magnetic fields

are large and fluctuating, there is a coupling of

energy between conductors. Making those conductors

massive produces a potential for significant currents

to flow at the tiniest of voltages. That once smooth

surface begins to chip away as the little electron-hammers

go to work on it.

Those shafts run at 7 to 10,000 rpm and pretty high

temperatures.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Eric M. Jones

Joined: 10 Jan 2006

Posts: 565

Location: Massachusetts

|

Posted: Sat May 04, 2013 11:34 am Post subject: Re: How to test engine ground? Posted: Sat May 04, 2013 11:34 am Post subject: Re: How to test engine ground? |

|

|

| Quote: | | Is this bearing wear a result of microscopic arcing and pitting as the balls roll in their races, making and breaking electrical contact? |

Maybe micro-welding more than corrosion. As I said...stuff to worry about in the middle of the night.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Eric M. Jones

www.PerihelionDesign.com

113 Brentwood Drive

Southbridge, MA 01550

(508) 764-2072

emjones(at)charter.net |

|

| Back to top |

|

|

henador_titzoff(at)yahoo.

Guest

|

Posted: Sat May 04, 2013 11:38 am Post subject: How to test engine ground? Posted: Sat May 04, 2013 11:38 am Post subject: How to test engine ground? |

|

|

Yes, Eric, it is due to making and breaking of metal surfaces as the bearings roll around. Here is a good article on this phenomenon:

http://www.ien.com/article/insulating-ball-bearings/7642

Keep in mind that grease and oil are not good conductors and therefore will introduce resistance within the bearing. As arcing occurs, it pits the metal surface areas as well as degrades the lubricants. From thereon, it's a snowball effect.

Henador Titzoff

From: Eric Page <edpav8r(at)yahoo.com>

To: "aeroelectric-list(at)matronics.com" <aeroelectric-list(at)matronics.com>

Sent: Saturday, May 4, 2013 1:57 PM

Subject: Re: AeroElectric-List: Re: How to test engine ground?

--> AeroElectric-List message posted by: Eric Page <edpav8r(at)yahoo.com (edpav8r(at)yahoo.com)>

Is this bearing wear a result of microscopic arcing and pitting as the balls roll in their races, making and breaking electrical contact?

Eric

On May 4, 2013, at 1:36 PM, "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: |

Yeah. Some years back we discovered root cause of poor bearing life on starter-generators. It seems that the steel shaft down through the center, while thought to be in an area of "zero net flux" was "excited" with microvolts of induced EMF shorted out by micro-ohms of starter frame through the bearings at each end. In retrospect, I'm not sure that the frame of the starter-gen didn't see similar inducements.

A mysterious stress on bearing life went away with incorporation of ceramic bearings or bearing liners. Just because some stimulus is 'tiny' does not necessarily negate its effects.

&nbroElectric-List" target="_blank">http://www.matronics.com/Navigator?AeroElectric-Lista href="http://forums.matronics.com/" target="_blank">http://forums.mat &nbs//www.matronics.com/contribution" target="_blank">http://www.matronics.co==================

|

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

versoelectric(at)gmail.co

Guest

|

Posted: Sat May 04, 2013 1:40 pm Post subject: How to test engine ground? Posted: Sat May 04, 2013 1:40 pm Post subject: How to test engine ground? |

|

|

Thank you Bob, Eric and Henador for the replies. Fascinating what goes on in the invisible world!

Eric

do not archive

On May 4, 2013, at 3:38 PM, Henador Titzoff <henador_titzoff(at)yahoo.com (henador_titzoff(at)yahoo.com)> wrote:

[quote]Yes, Eric, it is due to making and breaking of metal surfaces as the bearings roll around. Here is a good article on this phenomenon:

http://www.ien.com/article/insulating-ball-bearings/7642

Keep in mind that grease and oil are not good conductors and therefore will introduce resistance within the bearing. As arcing occurs, it pits the metal surface areas as well as degrades the lubricants. From thereon, it's a snowball effect.

Henador Titzoff

From: Eric Page <edpav8r(at)yahoo.com (edpav8r(at)yahoo.com)>

To: "aeroelectric-list(at)matronics.com (aeroelectric-list(at)matronics.com)" <aeroelectric-list(at)matronics.com (aeroelectric-list(at)matronics.com)>

Sent: Saturday, May 4, 2013 1:57 PM

Subject: Re: AeroElectric-List: Re: How to test engine ground?

--> AeroElectric-List message posted by: Eric Page <edpav8r(at)yahoo.com (edpav8r(at)yahoo.com)>

Is this bearing wear a result of microscopic arcing and pitting as the balls roll in their races, making and breaking electrical contact?

Eric

On May 4, 2013, at 1:36 PM, "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: |

Yeah. Some years back we discovered root cause of poor bearing life on starter-generators. It seems that the steel shaft down through the center, while thought to be in an area of "zero net flux" was "excited" with microvolts of induced EMF shorted out by micro-ohms of starter frame through the bearings at each end. In retrospect, I'm not sure that the frame of the starter-gen didn't see similar inducements.

A mysterious stress on bearing life went away with incorporation of ceramic bearings or bearing liners. Just because some stimulus is 'tiny' does not necessarily negate its effects.

&nbroElectric-List" target="_blank">http://www.matronics.com/Navigator?AeroElectric-Lista href="http://forums.matronics.com/" target="_blank">http://forums.mat &nbs//www.matronics.com/contribution" target="_blank">http://www.matronics.co==================

|

| Quote: |

===================================

st">http://www.matronics.com/Navigator?AeroElectric-List

===================================

cs.com

===================================

matronics.com/contribution

===================================

|

[b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|