|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Jun 19, 2013 5:34 pm Post subject: 63/37 "Body Solder" Posted: Wed Jun 19, 2013 5:34 pm Post subject: 63/37 "Body Solder" |

|

|

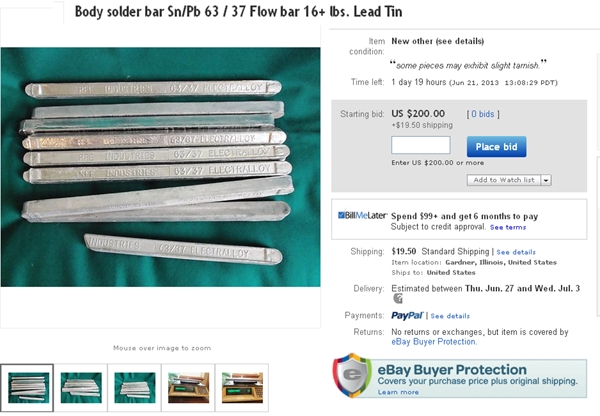

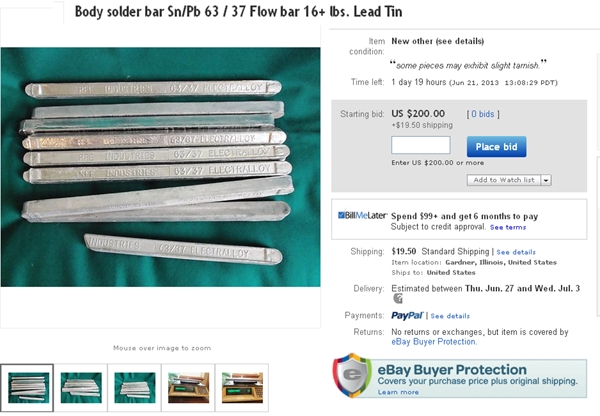

Found this interesting offer on eBay . . .

[img]cid:.0[/img]

The product offered is indeed supplied in cast bars

just like those used in body shops but if anyone would

purchased this item with the notion of doing body work,

they would be exceedingly disappointed.

Body solder alloys have a large 'plastic' range between

solid and liquid. I suspect an alloy like 40/60 would

be useful to a body shop. 63/37 has no plastic range.

About the time the user thought the solder was ready

to mold into the desired shape, it would melt and simply

fall on the floor.

This solder is, in fact, intended to charge the well

of liquid solder that is pumped over a 'wave' for soldering

electronics.

We got our first wave soldering machine at Electro-Mech

about 1978. We would take a week's production of board

stuffing and solder them in about an hour. Sounds neat . . .

but . . .

We had to build racks to hold many hundreds of boards

in a ready-to-solder state. The board then needed to

be cleaned of the flux oil that was used to protect the

surface of the wave. The machine became sort of a bottle

neck for production where large quantities of un soldered

and cleaned/soldered boards accumulated on both sides.

It was not conducive to the way we did business. We had

several dozen products of many sizes most of which were

on boards too small to solder individually

on the machine . . . so another problem presented when

we were obliged to lay out multiple boards on a sheet,

stuff, solder, clean and then cut them apart. In aviation,

you have few customers that want hundreds of parts in

a single delivery. More likely a hundred parts is a

two or three year supply that gets delivered 6 pieces

a month! So effective use of the wave solder machine

caused us to invest a lot of $time$ into finished goods

inventory that might not move for months. The machine

took 6+ hours to set up and a couple of hours to clean

up after a run while one hour of time actually soldering

product was several weeks worth of product flow.

Don't remember what we spent for the machine but I do

remember seeing it sit back in a storage area for years

after our 'experiment' in labor reduction. There were

several hundred pounds of 63/37 bar solder in crates

stored beside it. Who ever made the decision to buy

would have served the company well by going to see how

folks used the machine and figuring out if it was a

real 'fit' for us.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

150.78 KB |

| Viewed: |

2054 Time(s) |

|

|

|

| Back to top |

|

|

uuccio(at)gmail.com

Guest

|

Posted: Wed Jun 19, 2013 8:33 pm Post subject: 63/37 "Body Solder" Posted: Wed Jun 19, 2013 8:33 pm Post subject: 63/37 "Body Solder" |

|

|

Sort of like buying a Ferrari to drive on a gravel road...

Very interesting insight Bob.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

rparigoris

Joined: 24 Nov 2009

Posts: 792

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|