|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

rickofudall

Joined: 19 Sep 2009

Posts: 1392

Location: Udall, KS, USA

|

Posted: Sun Jul 07, 2013 11:41 am Post subject: I Love Left handed drill bits Posted: Sun Jul 07, 2013 11:41 am Post subject: I Love Left handed drill bits |

|

|

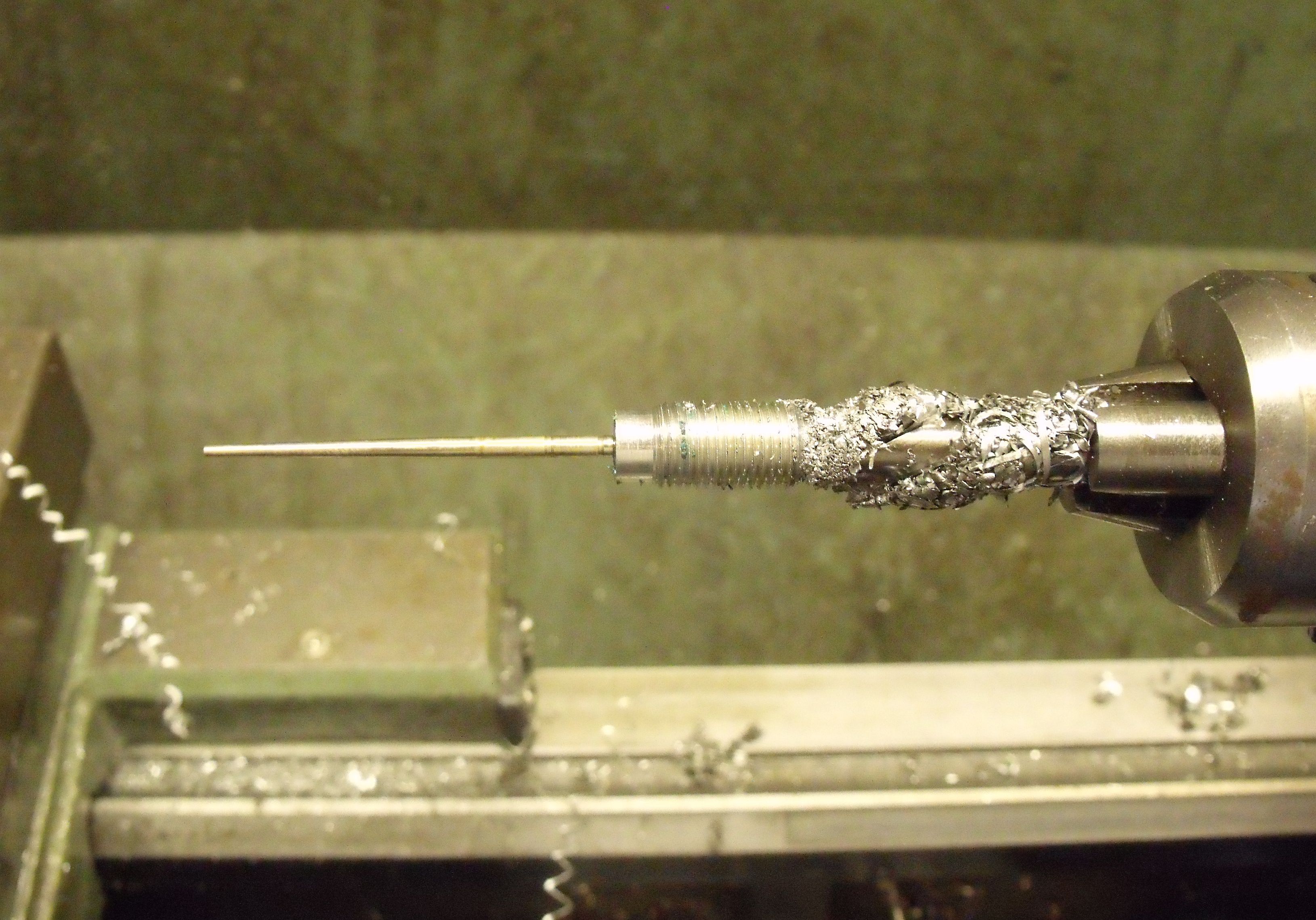

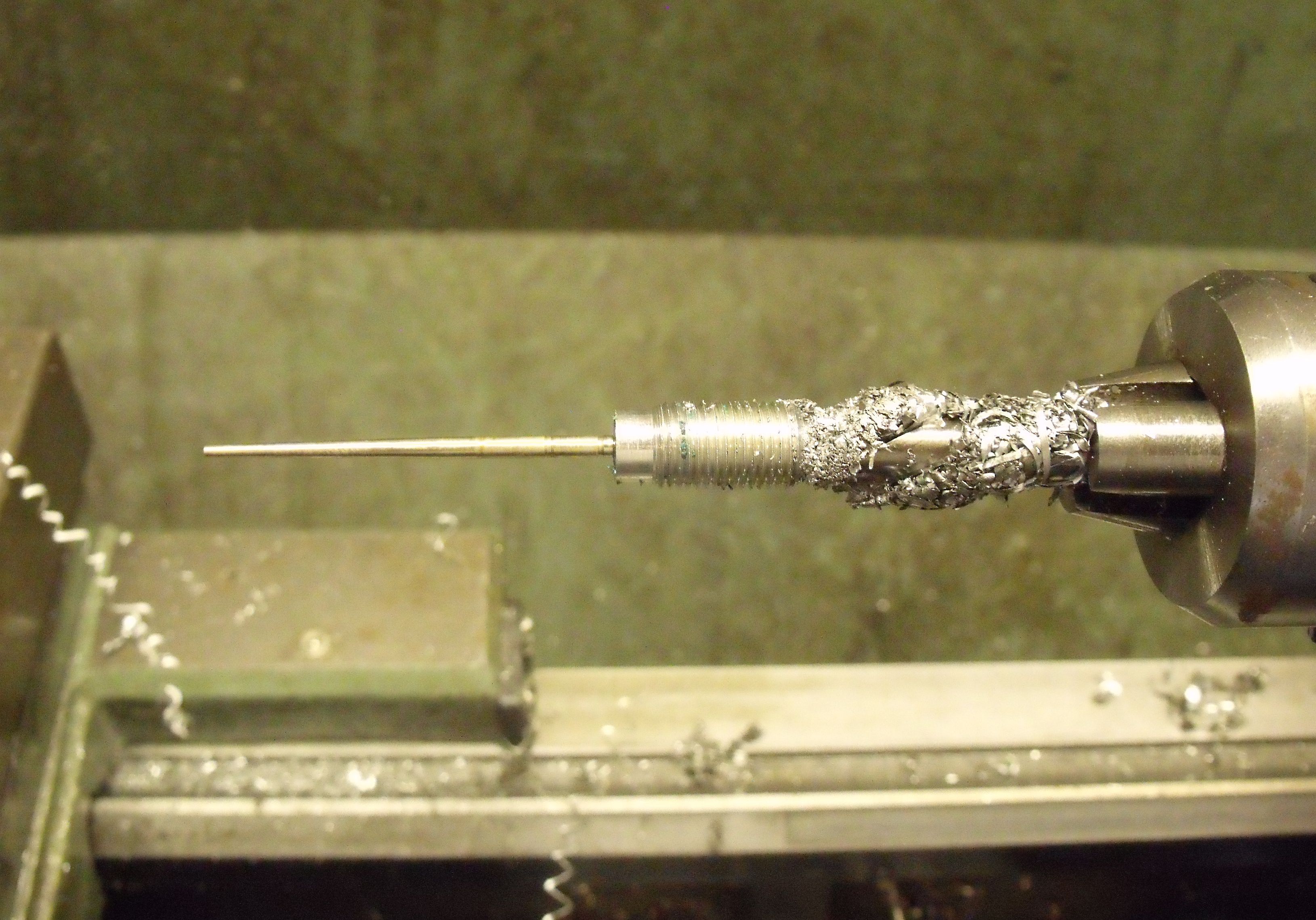

Let's face it, there are ham handed people in this world who should not be allowed near fine machinery. The fellow who logged that he "cleaned" the carbs on the 912 belonging to my customer is one. He put the fixation screw holding the jet needle in so tight that the screw driver slot just stripped off its ears when I tried to get it out. Soaked it with PB Blaster for 36 hours and no luck. Chucked the piston in my lathe, touched the top of the screw with a center drill and chucked up a left handed drill bit. Took longer to set up than it did for the drill to pull the screw out. As you can see by the picture the needle is quite literally jammed into the bottom of the screw. The carb piston, thankfully, is completely pristeen. Did I mention that I love left handed drill bits?

Rick Girard

--

Zulu Delta

Mk IIIC

Thanks, Homer GBYM

It isn't necessary to have relatives in Kansas City in order to be unhappy.

- Groucho Marx

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

| Description: |

|

| Filesize: |

948.59 KB |

| Viewed: |

9162 Time(s) |

|

_________________

The smallest miracle right in front of you is enough to make you happy.... |

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Sun Jul 07, 2013 1:21 pm Post subject: I Love Left handed drill bits Posted: Sun Jul 07, 2013 1:21 pm Post subject: I Love Left handed drill bits |

|

|

"THE REASON WHY PILOTS THINK THEY ARE MECHANICS IS BECAUSE THEY CAN BUY TOOLS AT HOME DEPOT."

Barry

On Sun, Jul 7, 2013 at 3:41 PM, Richard Girard <aslsa.rng(at)gmail.com (aslsa.rng(at)gmail.com)> wrote:

[quote]Let's face it, there are ham handed people in this world who should not be allowed near fine machinery. The fellow who logged that he "cleaned" the carbs on the 912 belonging to my customer is one. He put the fixation screw holding the jet needle in so tight that the screw driver slot just stripped off its ears when I tried to get it out. Soaked it with PB Blaster for 36 hours and no luck. Chucked the piston in my lathe, touched the top of the screw with a center drill and chucked up a left handed drill bit. Took longer to set up than it did for the drill to pull the screw out. As you can see by the picture the needle is quite literally jammed into the bottom of the screw. The carb piston, thankfully, is completely pristeen. Did I mention that I love left handed drill bits?

Rick Girard

--

Zulu Delta

Mk IIIC

Thanks, Homer GBYM

It isn't necessary to have relatives in Kansas City in order to be unhappy.

- Groucho Marx

[b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

Roger Lee

Joined: 10 Jan 2006

Posts: 1464

Location: Tucson, Az.

|

Posted: Sun Jul 07, 2013 7:08 pm Post subject: Re: I Love Left handed drill bits Posted: Sun Jul 07, 2013 7:08 pm Post subject: Re: I Love Left handed drill bits |

|

|

Hi Rick,

It wasn't the mechanics fault. These fixation screws have Loctite on them from Bing and they can strip out if not heated. Once in a while I find one I can remove without over torquing it, but most times I heat them with a heat gun or small butane torch. Once heated they come right out.

What were you saying on the other post about Rotax engines, problems and owners?

It usually isn't the engine that has the issues, but not having the proper training to maintain them or maintaining them on schedule. They are not Continental's or Lycoming's and treating them as such will only cost owners and mechanics grief and money.

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

Roger Lee

Tucson, Az.

Rotax Instructor & Rotax IRC

Light Sport Repairman

Home 520-574-1080 TRY HOME FIRST

Cell 520-349-7056 |

|

| Back to top |

|

|

Thom Riddle

Joined: 10 Jan 2006

Posts: 1597

Location: Buffalo, NY, USA (9G0)

|

Posted: Mon Jul 08, 2013 4:19 am Post subject: Re: I Love Left handed drill bits Posted: Mon Jul 08, 2013 4:19 am Post subject: Re: I Love Left handed drill bits |

|

|

Anyone who thinks that this connection needs thread locker clearly does not understand that aluminum has a very high coefficient of friction. In use, there is no external torque that would tend to loosen this connection. Applying thread locker to this connection is unnecessary and a very bad idea.

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

Thom Riddle

Buffalo, NY (9G0)

Don't worry about old age... it doesn't last very long.

- Anonymous |

|

| Back to top |

|

|

Roger Lee

Joined: 10 Jan 2006

Posts: 1464

Location: Tucson, Az.

|

Posted: Mon Jul 08, 2013 1:23 pm Post subject: Re: I Love Left handed drill bits Posted: Mon Jul 08, 2013 1:23 pm Post subject: Re: I Love Left handed drill bits |

|

|

Hi Thom,

I comes with a dry blue Loctite from Bing. Either from the factory or if ordered separately.

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

Roger Lee

Tucson, Az.

Rotax Instructor & Rotax IRC

Light Sport Repairman

Home 520-574-1080 TRY HOME FIRST

Cell 520-349-7056 |

|

| Back to top |

|

|

rickofudall

Joined: 19 Sep 2009

Posts: 1392

Location: Udall, KS, USA

|

Posted: Tue Jul 09, 2013 6:47 am Post subject: I Love Left handed drill bits Posted: Tue Jul 09, 2013 6:47 am Post subject: I Love Left handed drill bits |

|

|

Thom, As Roger noted the Locktite comes applied to the fixation screw in dry form. Also, the use of Locktite 221 is specified for this part in the 912 Illustrated Parts Catalog.

Rick Girard

On Mon, Jul 8, 2013 at 7:19 AM, Thom Riddle <riddletr(at)gmail.com (riddletr(at)gmail.com)> wrote:

| Quote: | --> RotaxEngines-List message posted by: "Thom Riddle" <riddletr(at)gmail.com (riddletr(at)gmail.com)>

Anyone who thinks that this connection needs thread locker clearly does not understand that aluminum has a very high coefficient of friction. In use, there is no external torque that would tend to loosen this connection. Applying thread locker to this connection is unnecessary and a very bad idea.

--------

Thom Riddle

Buffalo, NY (9G0)

Don't worry about old age... it doesn't last very long.

- Anonymous

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=404178#404178

===========

-List" target="_blank">http://www.matronics.com/Navigator?RotaxEngines-List

===========

http://forums.matronics.com

===========

le, List Admin.

="_blank">http://www.matronics.com/contribution

===========

|

--

Zulu Delta

Mk IIIC

Thanks, Homer GBYM

It isn't necessary to have relatives in Kansas City in order to be unhappy.

- Groucho Marx

[quote][b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

The smallest miracle right in front of you is enough to make you happy.... |

|

| Back to top |

|

|

Thom Riddle

Joined: 10 Jan 2006

Posts: 1597

Location: Buffalo, NY, USA (9G0)

|

Posted: Wed Jul 10, 2013 4:05 am Post subject: Re: I Love Left handed drill bits Posted: Wed Jul 10, 2013 4:05 am Post subject: Re: I Love Left handed drill bits |

|

|

I am aware that Rotax puts the blue loctite on that screw. I am also aware that they have changed their minds on many other things as their customer base's experience increased over the years. As experience grew they have redesigned or changed specs on many things over the years. One original design element in particular that caused all kinds of grief which they eventually changed was the internal Torx type fitting on the gearbox magnetic oil fitting.

My experience with aluminum threads, where no in-use external torque is applied in the loosening direction, is that no thread locker is needed due to the high coefficient of friction. Perhaps Rotax will one day realize that loctite is not needed on this carb part. Until then, use it if you want.

I remove it from the carbs I disassemble and do not apply new loctite when re-installing. In fact upon reinstallation I torque it only with thumb and one finger because even without loctite it very easy to over torque this part and make the left-handed drills or easy-outs a required part of future disassembly. Been there once and that was enough.

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

Thom Riddle

Buffalo, NY (9G0)

Don't worry about old age... it doesn't last very long.

- Anonymous |

|

| Back to top |

|

|

Roger Lee

Joined: 10 Jan 2006

Posts: 1464

Location: Tucson, Az.

|

Posted: Wed Jul 10, 2013 8:26 am Post subject: Re: I Love Left handed drill bits Posted: Wed Jul 10, 2013 8:26 am Post subject: Re: I Love Left handed drill bits |

|

|

Hi Thom,

The reason Loctite is applied here is that these are two different metals and this area gets significant vibration and any loosening would cause a needle change in the jet and possibly a aircraft incident before it was found. I'm sure they have had their reasons over the last 22 years to apply this. It's a better safe than sorry application. Too much Loctite here can be a problem getting it out later. Just the tiniest drop is needed. If it still has some of the old Loctite on the screw it will work just fine. Heating it is no big deal either for removal. Like I said, I take a small butane torch and heat it for a few seconds and they all come right out.

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

Roger Lee

Tucson, Az.

Rotax Instructor & Rotax IRC

Light Sport Repairman

Home 520-574-1080 TRY HOME FIRST

Cell 520-349-7056 |

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Wed Jul 10, 2013 9:34 am Post subject: I Love Left handed drill bits Posted: Wed Jul 10, 2013 9:34 am Post subject: I Love Left handed drill bits |

|

|

Gaggle:

From a Test Engineer viewpoint; Thom is quite accurate with aluminum threads not requiring a liquid locking agent. There are a few questions that would have to be asked though:

1 - What type of aluminum is the part made from?

2 - What temper is it brought to?

3 - Was the tempering done before or after the threads were cut?

4 - Were the threads cut or rolled?

5 - What type of thread is being used?

6 - What material is the part being threaded into?

And then a repeat of all the questions above about the mating threaded part:7 - What type of aluminum is the part made from?

8 - What temper is it brought to?

9 - Was the tempering done before or after the threads were cut?

10 - Were the threads cut or molded <-- Since this is a internal thread.

11 - What type of thread is being used? <-- This should be the same as the mating part - BUT - Sometimes one company makes part A and another makes part B and little things like percentage of thread is different.

Now if both parts are aluminum and ESPECIALLY if they are not ANODIZED, There is a very high possibility of galling and/or fretting.

Some methods of prevention are:

Shoulder Seat - To limit force/torque on threads - This is something Roatx really should consider. Maybe in the next generation of engineering changes.

Lock washer - I guess none was used in this situation.

Nylon Stop Plug

Teflon Tape - Not for this situation. Untrained users.

Teflon Paste - HMmmmm much better idea - But 99.9987% of the users tend to OVER APPLY it and cause catastrophic problems.

Liquid Locking Compound - Well this would be BLUE Loctite but there is a problem with this -- They advertize a holding strength of 8.5 Nm (~6.2 Ft/Lbs). Well this is WAY too much holding force for such a small thread and material. So, again I hope Rotax makes some changes. AND when Loctite did this testing and came up with the 8.5 Nm, they did NOT test it on aluminum threads. Holding force is VERY argumentative. They TRY to be scientific but in the long run it is a shot in the twilight.

Last point: It truly is a good idea to use SOMETHING on the threads. Not really needed too much for holding but for thread protection. If aluminum threads are not protected they will gall/frett and LOCK-UP! From an FAA standpoint they and you need some reassurance that the thing will not vibrate free in flight AND should be easy to remove for inspection/repair/replacement. Just think there are companies that have made entire fortunes on just doing that - Loctite!

Barry

On Wed, Jul 10, 2013 at 8:05 AM, Thom Riddle <riddletr(at)gmail.com (riddletr(at)gmail.com)> wrote:

[quote]--> RotaxEngines-List message posted by: "Thom Riddle" <riddletr(at)gmail.com (riddletr(at)gmail.com)>

I am aware that Rotax puts the blue loctite on that screw. I am also aware that they have changed their minds on many other things as their customer base's experience increased over the years. As experience grew they have redesigned or changed specs on many things over the years. One original design element in particular that caused all kinds of grief which they eventually changed was the internal Torx type fitting on the gearbox magnetic oil fitting.

My experience with aluminum threads, where no in-use external torque is applied in the loosening direction, is that no thread locker is needed due to the high coefficient of friction. Perhaps Rotax will one day realize that loctite is not needed on this carb part. Until then, use it if you want.

I remove it from the carbs I disassemble and do not apply new loctite when re-installing. In fact upon reinstallation I torque it only with thumb and one finger because even without loctite it very easy to over torque this part and make the left-handed drills or easy-outs a required part of future disassembly. Been there once and that was enough.

--------

Thom Riddle

Buffalo, NY (9G0)

Don't worry about old age... it doesn't last very long.

- Anonymous

[b]

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

|

|

| Back to top |

|

|

Roger Lee

Joined: 10 Jan 2006

Posts: 1464

Location: Tucson, Az.

|

Posted: Wed Jul 10, 2013 1:54 pm Post subject: Re: I Love Left handed drill bits Posted: Wed Jul 10, 2013 1:54 pm Post subject: Re: I Love Left handed drill bits |

|

|

I may agree about aluminum, but from the Bing and Rotax guys it's a liability issue. Adding a little heat as far as they are concerned is no big deal for peace of mind.

Should be peace of mind for you now too.

| | - The Matronics RotaxEngines-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RotaxEngines-List |

|

_________________

Roger Lee

Tucson, Az.

Rotax Instructor & Rotax IRC

Light Sport Repairman

Home 520-574-1080 TRY HOME FIRST

Cell 520-349-7056 |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|