|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

wlannon(at)shaw.ca

Guest

|

Posted: Thu Aug 15, 2013 8:13 am Post subject: Hydraulic Lock Prevention Posted: Thu Aug 15, 2013 8:13 am Post subject: Hydraulic Lock Prevention |

|

|

Gentlemen;

Would greatly appreciate your comments on this subject.

Both the Huosai and M14P (and probably the whole Ivchenko series) are notoriously bad in this area.

I have not been too keen on oil shut-off valves in the past but now am convinced it is necessary. Any suggestions on valve and systems to purchase?

Is an auxiliary oil scavenge pump a necessity? Or will a standard post-flight scavenge run suffice given that oil from the tank will be closed off?

Thanks;

Walt

[quote][b]

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

dabear

Joined: 21 Jan 2011

Posts: 92

Location: Warrenton, VA

|

Posted: Thu Aug 15, 2013 8:50 am Post subject: Hydraulic Lock Prevention Posted: Thu Aug 15, 2013 8:50 am Post subject: Hydraulic Lock Prevention |

|

|

I’ve used the system from Kevin Kimball for about 6 years. Yes, you need the shut off valve and the scavenge pump both. Even running up at 1800 rpm for a while doesn’t get all the oil out. I’ve NEVER had a lock since the system has been installed (over 700 hours). I’ve had some oil in the exhaust/drain (very small amount). But never close enough to cause a problem

Bear

From: owner-yak-list-server(at)matronics.com [mailto:owner-yak-list-server(at)matronics.com] On Behalf Of Walter Lannon

Sent: Thursday, August 15, 2013 12:11 PM

To: yak-list(at)matronics.com

Subject: Hydraulic Lock Prevention

Gentlemen;

Would greatly appreciate your comments on this subject.

Both the Huosai and M14P (and probably the whole Ivchenko series) are notoriously bad in this area.

I have not been too keen on oil shut-off valves in the past but now am convinced it is necessary. Any suggestions on valve and systems to purchase?

Is an auxiliary oil scavenge pump a necessity? Or will a standard post-flight scavenge run suffice given that oil from the tank will be closed off?

Thanks;

Walt

| Quote: | | http://www.matronics.com/Navigator?Yak-List |

01234567

[quote][b]

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

LawnDart

Joined: 05 Jun 2006

Posts: 64

|

Posted: Thu Aug 15, 2013 10:50 am Post subject: Re: Hydraulic Lock Prevention Posted: Thu Aug 15, 2013 10:50 am Post subject: Re: Hydraulic Lock Prevention |

|

|

I started years ago with no "add-on" system. I always do a quick post-flight scavenge run and I added an intake drain system several years back. Although this has reduced the number of locks to almost zero, they still happen occasionally (usually if the plane sits a while).

I am convinced to reduce the odds further, I must do something about the sump filling (oil past the pump valve, etc.). I have a hose with fittings that I can connect to the sump drain (M14P) and open the valve and allow the oil to collect in a jug (all done with hand through the cowl flaps). I am working on replacing the stock sump valve with one that will be easier to actuate and have a semi-permanent line run to a convenient location low on the firewall for future. I am currently not interested in a shut-off valve or and electronic scavenge system. We'll see how it goes.

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

JOE HOWSE

Joined: 10 Jan 2006

Posts: 140

Location: DUNCAN BC CANADA

|

Posted: Thu Aug 15, 2013 6:14 pm Post subject: Hydraulic Lock Prevention Posted: Thu Aug 15, 2013 6:14 pm Post subject: Hydraulic Lock Prevention |

|

|

Hi Walt

My 2 cents worth

We decided against the electric shut off attached to the oil tank as I know of several cases of the tank cracking with the weight of the valve

and associated plumbing.

I believe some owners have installed a mechanical gate valve and bowden cable with safety micro switch. Looks like best fix to me.

We have a drain manifold installed with a drain valve when parked plus cans hanginging under the ex pipes.

Carl Hayes engineered a better gravity check valve in the oil pump, we had him modify one for us but have not changed it yet.

Only had one hyd. lock so far before attempting to start! I believe the cause was oil from the master rod with crank throw in the lowest

position allowing oil to fill one of the bottom pistons then past the rings into the cylinder, removed a spark plug to drain, rare, but I am sure that is what happened, I was afraid to turn the prop without removing the spark plug.

One owner I spoke to when parking long term, removes a top plug to make sure the master rod is a the top.

I think Craig Payne has installed a window in the case for visibly checking rod pos.(I think one of the older engines with centrifuge port)

How did you make out with your leaking prop

Good to see you but too but you did not make Vandehoof

Joe

[quote]

[b]

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

_________________

J.C. HOWSE |

|

| Back to top |

|

|

byronmfox(at)gmail.com

Guest

|

Posted: Thu Aug 15, 2013 9:51 pm Post subject: Hydraulic Lock Prevention Posted: Thu Aug 15, 2013 9:51 pm Post subject: Hydraulic Lock Prevention |

|

|

I'm previously one of those with an electric valve that ultimately failed and also cracked the oil tank because the valve hanging beneath the tank was insufficiently supported. Now have a mechanical ball valve mounted to the port firewall. When the valve is open, it's red handle closes a micro switch wired to the start switch. I must open the valve with my dumb hand before getting into the cockpit. Should my dumb hand forget, the engine won't start and a red light on the panel advises me of the dumb hand's error. It's worked flawlessly since Vladimir installed it three years ago.

Blitz Fox415-307-2405

On Aug 15, 2013, at 7:09 PM, "Joe Howse" <joeh(at)shaw.ca (joeh(at)shaw.ca)> wrote:

[quote]

Hi Walt

My 2 cents worth

We decided against the electric shut off attached to the oil tank as I know of several cases of the tank cracking with the weight of the valve

and associated plumbing.

I believe some owners have installed a mechanical gate valve and bowden cable with safety micro switch. Looks like best fix to me.

We have a drain manifold installed with a drain valve when parked plus cans hanginging under the ex pipes.

Carl Hayes engineered a better gravity check valve in the oil pump, we had him modify one for us but have not changed it yet.

Only had one hyd. lock so far before attempting to start! I believe the cause was oil from the master rod with crank throw in the lowest

position allowing oil to fill one of the bottom pistons then past the rings into the cylinder, removed a spark plug to drain, rare, but I am sure that is what happened, I was afraid to turn the prop without removing the spark plug.

One owner I spoke to when parking long term, removes a top plug to make sure the master rod is a the top.

I think Craig Payne has installed a window in the case for visibly checking rod pos.(I think one of the older engines with centrifuge port)

How did you make out with your leaking prop

Good to see you but too but you did not make Vandehoof

Joe

[b]

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

cpayne(at)joimail.com

Guest

|

Posted: Fri Aug 16, 2013 2:17 am Post subject: Hydraulic Lock Prevention Posted: Fri Aug 16, 2013 2:17 am Post subject: Hydraulic Lock Prevention |

|

|

Walt,

Do not believe there is a solution to "prevent" hydro lock, only various techniques to mitigate. My "window" fits the M-14P Series II engines and allows the operator to position the prop with all of the lower cylinder pistons near BDC by putting #1 at TDC. It helps but does not fix the issue.

Pilots must still follow POH procedures and always pull through. I also use the helicopter oil tank shut off with a 1/4" plate welded on the bottom of the tank to prevent cracking. While some folks are sensitive to the sight of blood; I get weak in the knees and tremble at the sight of oil on the hanger floor:)

Craig Payne

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

cjpilot710(at)aol.com

Guest

|

Posted: Fri Aug 16, 2013 3:49 am Post subject: Hydraulic Lock Prevention Posted: Fri Aug 16, 2013 3:49 am Post subject: Hydraulic Lock Prevention |

|

|

I have both systems on my airplane. I put on Payne's simply because I like cheap, simple, effective ideas (also I happen to like his wife  ). I re-enforced the bottom of my oil tank after it cracked, sometime after I installed Bill Blackwell's system. Except for the crack, the system has worked flawlessly for over 1700 hours. I STILL pull my prop though before start. BTW at the foundation, on the B-24 I fly, we pull the props through on the PW 1830s before the first start of the day. The 1830s and the 1820s on the B-17 have never had a lock in the 13 years I've been flying them. We fly them each day, and pull them though each day. The ramp under the 1830s are dry however under the B-17, the R1820 leaves its calling card. (I'm little surprised the EPA isn't chasseing our ass around) ). I re-enforced the bottom of my oil tank after it cracked, sometime after I installed Bill Blackwell's system. Except for the crack, the system has worked flawlessly for over 1700 hours. I STILL pull my prop though before start. BTW at the foundation, on the B-24 I fly, we pull the props through on the PW 1830s before the first start of the day. The 1830s and the 1820s on the B-17 have never had a lock in the 13 years I've been flying them. We fly them each day, and pull them though each day. The ramp under the 1830s are dry however under the B-17, the R1820 leaves its calling card. (I'm little surprised the EPA isn't chasseing our ass around)

Jim "Pappy" Goolsby

In a message dated 8/16/2013 6:17:17 A.M. Eastern Daylight Time, cpayne(at)joimail.com writes:

| Quote: | --> Yak-List message posted by: Cpayne <cpayne(at)joimail.com>

Walt,

Do not believe there is a solution to "prevent" hydro lock, only various techniques to mitigate. My "window" fits the M-14P Series II engines and allows the operator to position the prop with all of the lower cylinder pistons near BDC by putting #1 at TDC. It helps but does not fix the issue.

Pilots must still follow POH procedures and always pull through. I also use the helicopter oil tank shut off with a 1/4" plate welded on the bottom of the tank to prevent cracking. While some folks are sensitive to the sight of blood; I get weak in the knees and tremble at the sight of oil on the hanger floor:)

Craig ies ay - MATRONICS WEB FORUMS - List Contribution Web Site p;

|

[quote][b]

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

viperdoc(at)mindspring.co

Guest

|

Posted: Fri Aug 16, 2013 6:12 am Post subject: Hydraulic Lock Prevention Posted: Fri Aug 16, 2013 6:12 am Post subject: Hydraulic Lock Prevention |

|

|

Yep, the Air Force does get a little touchy about their ramps getting marked by the YAKs and CJs. At the last MXF airshow I took her to one of the ramp rats was awfully concerned about the oil Miss Mollie was dripping on the ramp after I opened the intake drain. He really liked my quote " don't worry, I'm just winding up the hamsters" as I pulled blades to depart especially when she hit about blade four and puked on his clean ramp.

At the Gathering of Eagles my YAK and a B-26 were the only round motors there. Then of course there was the P-51. Again the ramp rats were all touchy about the oil dripping from the stacks..especially from the 26! Now that bugger can soil a nice pretty sealed ramp over in the fuel cell area with their light brown epoxy painted ramps. The poor airman that was watching the those round motors puke on his ramp was quit concerned to say the least.

I just told him not to worry, " they are just marking their territory". Of course he was looking at me like I was a fossil!

Too funny,

Doc

Sent from my iPad

On Aug 16, 2013, at 6:45 AM, cjpilot710(at)aol.com (cjpilot710(at)aol.com) wrote:

[quote] I have both systems on my airplane. I put on Payne's simply because I like cheap, simple, effective ideas (also I happen to like his wife  ). I re-enforced the bottom of my oil tank after it cracked, sometime after I installed Bill Blackwell's system. Except for the crack, the system has worked flawlessly for over 1700 hours. I STILL pull my prop though before start. BTW at the foundation, on the B-24 I fly, we pull the props through on the PW 1830s before the first start of the day. The 1830s and the 1820s on the B-17 have never had a lock in the 13 years I've been flying them. We fly them each day, and pull them though each day. The ramp under the 1830s are dry however under the B-17, the R1820 leaves its calling card. (I'm little surprised the EPA isn't chasseing our ass around) ). I re-enforced the bottom of my oil tank after it cracked, sometime after I installed Bill Blackwell's system. Except for the crack, the system has worked flawlessly for over 1700 hours. I STILL pull my prop though before start. BTW at the foundation, on the B-24 I fly, we pull the props through on the PW 1830s before the first start of the day. The 1830s and the 1820s on the B-17 have never had a lock in the 13 years I've been flying them. We fly them each day, and pull them though each day. The ramp under the 1830s are dry however under the B-17, the R1820 leaves its calling card. (I'm little surprised the EPA isn't chasseing our ass around)

Jim "Pappy" Goolsby

In a message dated 8/16/2013 6:17:17 A.M. Eastern Daylight Time, cpayne(at)joimail.com (cpayne(at)joimail.com) writes:

| Quote: | --> Yak-List message posted by: Cpayne <cpayne(at)joimail.com (cpayne(at)joimail.com)>

Walt,

Do not believe there is a solution to "prevent" hydro lock, only various techniques to mitigate. My "window" fits the M-14P Series II engines and allows the operator to position the prop with all of the lower cylinder pistons near BDC by putting #1 at TDC. It helps but does not fix the issue.

Pilots must still follow POH procedures and always pull through. I also use the helicopter oil tank shut off with a 1/4" plate welded on the bottom of the tank to prevent cracking. While some folks are sensitive to the sight of blood; I get weak in the knees and tremble at the sight of oil on the hanger floor:)

Craig ies ay - MATRONICS WEB FORUMS - List Contribution Web Site p;

|

| Quote: |

===================================

//www.matronics.com/Navigator?Yak-List

===================================

cs.com

===================================

matronics.com/contribution

===================================

|

[b]

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

wlannon(at)shaw.ca

Guest

|

Posted: Fri Aug 16, 2013 9:31 am Post subject: Hydraulic Lock Prevention Posted: Fri Aug 16, 2013 9:31 am Post subject: Hydraulic Lock Prevention |

|

|

Many thanks to all for the response to my questions on this subject. You provided a wealth of very good information that will help guide my decision.

I have often considered the Russian approach to this problem with the Pratt & Whitney method. I do not understand how the Russian method can actually work.

This appears to be a very small, spring loaded valve inside the oil pump drive shaft. Since it is a gear type pump I would expect oil from the tank to find it’s way through the pump regardless of the valve.

Pratt & Whitney use a relatively large, lightly spring loaded, poppet style valve external to the pump on the pressure side. It is readily removable for inspection with the oil-in screen and is very reliable.

Not to say it cannot leak at some time, and there has been hydraulic lock damage. But it is a very rare occurrence. In more than 40 years of maintaining and operating the R1340 (& R985) I have never seen one!

Thanks again;

Walt

[quote][b]

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

cjpilot710(at)aol.com

Guest

|

Posted: Fri Aug 16, 2013 12:22 pm Post subject: Hydraulic Lock Prevention Posted: Fri Aug 16, 2013 12:22 pm Post subject: Hydraulic Lock Prevention |

|

|

Sort of like getting a squadron sticker stuck, no?

Pappy

In a message dated 8/16/2013 1:13:05 P.M. Eastern Daylight Time, viperdoc(at)mindspring.com writes:

| Quote: | Yep, the Air Force does get a little touchy about their ramps getting marked by the YAKs and CJs. At the last MXF airshow I took her to one of the ramp rats was awfully concerned about the oil Miss Mollie was dripping on the ramp after I opened the intake drain. He really liked my quote " don't worry, I'm just winding up the hamsters" as I pulled blades to depart especially when she hit about blade four and puked on his clean ramp.

At the Gathering of Eagles my YAK and a B-26 were the only round motors there. Then of course there was the P-51. Again the ramp rats were all touchy about the oil dripping from the stacks...especially from the 26! Now that bugger can soil a nice pretty sealed ramp over in the fuel cell area with their light brown epoxy painted ramps. The poor airman that was watching the those round motors puke on his ramp was quit concerned to say the least.

I just told him not to worry, " they are just marking their territory". Of course he was looking at me like I was a fossil!

Too funny,

Doc

Sent from my iPad

On Aug 16, 2013, at 6:45 AM, cjpilot710(at)aol.com (cjpilot710(at)aol.com) wrote:

| Quote: | I have both systems on my airplane. I put on Payne's simply because I like cheap, simple, effective ideas (also I happen to like his wife  ). I re-enforced the bottom of my oil tank after it cracked, sometime after I installed Bill Blackwell's system. Except for the crack, the system has worked flawlessly for over 1700 hours. I STILL pull my prop though before start. BTW at the foundation, on the B-24 I fly, we pull the props through on the PW 1830s before the first start of the day. The 1830s and the 1820s on the B-17 have never had a lock in the 13 years I've been flying them. We fly them each day, and pull them though each day. The ramp under the 1830s are dry however under the B-17, the R1820 leaves its calling card. (I'm little surprised the EPA isn't chasseing our ass around) ). I re-enforced the bottom of my oil tank after it cracked, sometime after I installed Bill Blackwell's system. Except for the crack, the system has worked flawlessly for over 1700 hours. I STILL pull my prop though before start. BTW at the foundation, on the B-24 I fly, we pull the props through on the PW 1830s before the first start of the day. The 1830s and the 1820s on the B-17 have never had a lock in the 13 years I've been flying them. We fly them each day, and pull them though each day. The ramp under the 1830s are dry however under the B-17, the R1820 leaves its calling card. (I'm little surprised the EPA isn't chasseing our ass around)

Jim "Pappy" Goolsby

In a message dated 8/16/2013 6:17:17 A.M. Eastern Daylight Time, cpayne(at)joimail.com (cpayne(at)joimail.com) writes:

| Quote: | --> Yak-List message posted by: Cpayne <cpayne(at)joimail.com (cpayne(at)joimail.com)>

Walt,

Do not believe there is a solution to "prevent" hydro lock, only various techniques to mitigate. My "window" fits the M-14P Series II engines and allows the operator to position the prop with all of the lower cylinder pistons near BDC by putting #1 at TDC. It helps but does not fix the issue.

Pilots must still follow POH procedures and always pull through. I also use the helicopter oil tank shut off with a 1/4" plate welded on the bottom of the tank to prevent cracking. While some folks are sensitive to the sight of blood; I get weak in the knees and tremble at the sight of oil on the hanger floor:)

Craig ies ay - MATRONICS WEB FORUMS - List Contribution Web Site p;

|

| Quote: |

==========

//www.matronics.com/Navigator?Yak-List

==========

cs.com

==========

matronics.com/contribution

==========

|

="http://www.matronics.com/Navigator?Yak-List">http://www.matronics.com/Navigator?Yak-List

s.matronics.com/">http://forums.matronics.com

p://www.matronics.com/contribution">http://www.matronics.com/contribution

|

|

[quote][b]

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

viperdoc(at)mindspring.co

Guest

|

Posted: Fri Aug 16, 2013 9:04 pm Post subject: Hydraulic Lock Prevention Posted: Fri Aug 16, 2013 9:04 pm Post subject: Hydraulic Lock Prevention |

|

|

Yeah! ;^))

Doc

Sent from my iPad

On Aug 16, 2013, at 3:20 PM, cjpilot710(at)aol.com (cjpilot710(at)aol.com) wrote:

[quote] Sort of like getting a squadron sticker stuck, no?

Pappy

In a message dated 8/16/2013 1:13:05 P.M. Eastern Daylight Time, viperdoc(at)mindspring.com (viperdoc(at)mindspring.com) writes:

| Quote: | Yep, the Air Force does get a little touchy about their ramps getting marked by the YAKs and CJs. At the last MXF airshow I took her to one of the ramp rats was awfully concerned about the oil Miss Mollie was dripping on the ramp after I opened the intake drain. He really liked my quote " don't worry, I'm just winding up the hamsters" as I pulled blades to depart especially when she hit about blade four and puked on his clean ramp.

At the Gathering of Eagles my YAK and a B-26 were the only round motors there. Then of course there was the P-51. Again the ramp rats were all touchy about the oil dripping from the stacks...especially from the 26! Now that bugger can soil a nice pretty sealed ramp over in the fuel cell area with their light brown epoxy painted ramps. The poor airman that was watching the those round motors puke on his ramp was quit concerned to say the least.

I just told him not to worry, " they are just marking their territory". Of course he was looking at me like I was a fossil!

Too funny,

Doc

Sent from my iPad

On Aug 16, 2013, at 6:45 AM, cjpilot710(at)aol.com (cjpilot710(at)aol.com) wrote:

| Quote: | I have both systems on my airplane. I put on Payne's simply because I like cheap, simple, effective ideas (also I happen to like his wife  ). I re-enforced the bottom of my oil tank after it cracked, sometime after I installed Bill Blackwell's system. Except for the crack, the system has worked flawlessly for over 1700 hours. I STILL pull my prop though before start. BTW at the foundation, on the B-24 I fly, we pull the props through on the PW 1830s before the first start of the day. The 1830s and the 1820s on the B-17 have never had a lock in the 13 years I've been flying them. We fly them each day, and pull them though each day. The ramp under the 1830s are dry however under the B-17, the R1820 leaves its calling card. (I'm little surprised the EPA isn't chasseing our ass around) ). I re-enforced the bottom of my oil tank after it cracked, sometime after I installed Bill Blackwell's system. Except for the crack, the system has worked flawlessly for over 1700 hours. I STILL pull my prop though before start. BTW at the foundation, on the B-24 I fly, we pull the props through on the PW 1830s before the first start of the day. The 1830s and the 1820s on the B-17 have never had a lock in the 13 years I've been flying them. We fly them each day, and pull them though each day. The ramp under the 1830s are dry however under the B-17, the R1820 leaves its calling card. (I'm little surprised the EPA isn't chasseing our ass around)

Jim "Pappy" Goolsby

In a message dated 8/16/2013 6:17:17 A.M. Eastern Daylight Time, cpayne(at)joimail.com (cpayne(at)joimail.com) writes:

| Quote: | --> Yak-List message posted by: Cpayne <cpayne(at)joimail.com (cpayne(at)joimail.com)>

Walt,

Do not believe there is a solution to "prevent" hydro lock, only various techniques to mitigate. My "window" fits the M-14P Series II engines and allows the operator to position the prop with all of the lower cylinder pistons near BDC by putting #1 at TDC. It helps but does not fix the issue.

Pilots must still follow POH procedures and always pull through. I also use the helicopter oil tank shut off with a 1/4" plate welded on the bottom of the tank to prevent cracking. While some folks are sensitive to the sight of blood; I get weak in the knees and tremble at the sight of oil on the hanger floor:)

Craig ies ay - MATRONICS WEB FORUMS - List Contribution Web Site p;

|

="http://www.matronics.com/Navigator?Yak-List">http://www.matronics.com/Navigator?Yak-List

s.matronics.com/">http://forums.matronics.com

p://www.matronics.com/contribution">http://www.matronics.com/contribution

|

|

[b]

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

barryhancock

Joined: 09 Oct 2008

Posts: 285

|

Posted: Fri Aug 23, 2013 7:23 am Post subject: Re: Hydraulic Lock Prevention Posted: Fri Aug 23, 2013 7:23 am Post subject: Re: Hydraulic Lock Prevention |

|

|

Walt,

On the two CJ's I've owned I have installed the electric shutoff valve. Tank cracking is a problem and we solved it by welding gussets to the bottom of the tank (not the big square plate welded to the bottom of some which WILL eventually crack at the corners due to the stress).

On our restoration projects we installed the Kimball valve, which also works very well. It's a bit less complicated to install and does the job. The things I don't like about it are that it creates an extra push/pull lever in the cockpit (v. using an existing switch in the panel) and because it is mechanical it requires a pretty forceful pull to the open position (this turns opens the start electrical circuit). But, it does do the job well aside from these more minor hassles.

We do have a tank that is welded up with the gussets and ready to go if anyone is looking to install an electric shut off valve.

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

_________________

Barry Hancock

Worldwide Warbirds, Inc.

www.worldwidewarbirds.com |

|

| Back to top |

|

|

wlannon(at)shaw.ca

Guest

|

Posted: Fri Aug 23, 2013 8:46 am Post subject: Hydraulic Lock Prevention Posted: Fri Aug 23, 2013 8:46 am Post subject: Hydraulic Lock Prevention |

|

|

Thanks Barry;

I will be using the Kimball valve as well and am planning manual operation.

However I will make final decisions on the installation after I receive the

valve.

Cheers;

Walt

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

rmhou(at)yahoo.com

Guest

|

Posted: Fri Aug 23, 2013 10:43 am Post subject: Hydraulic Lock Prevention Posted: Fri Aug 23, 2013 10:43 am Post subject: Hydraulic Lock Prevention |

|

|

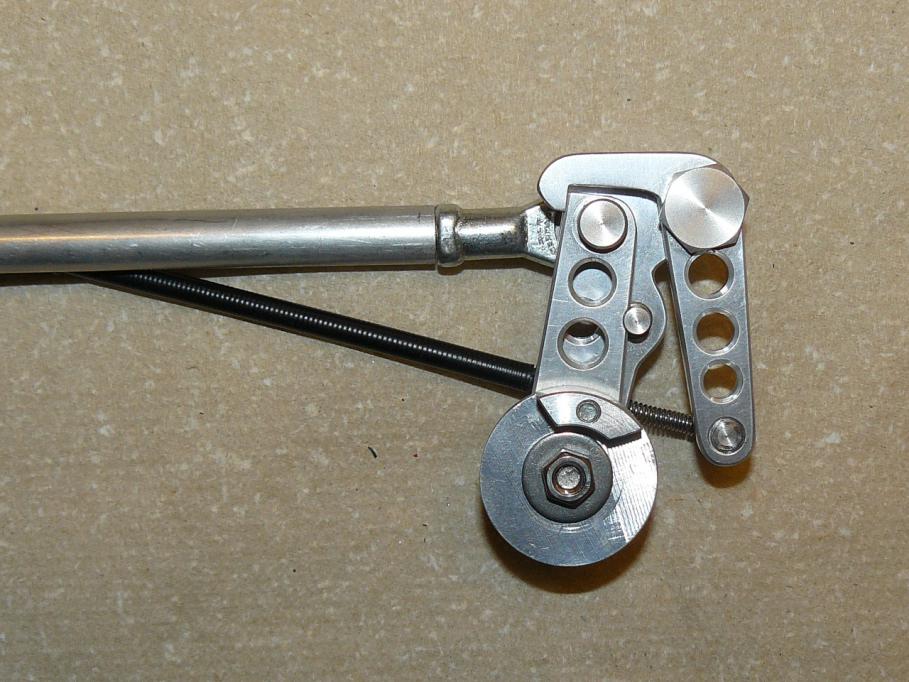

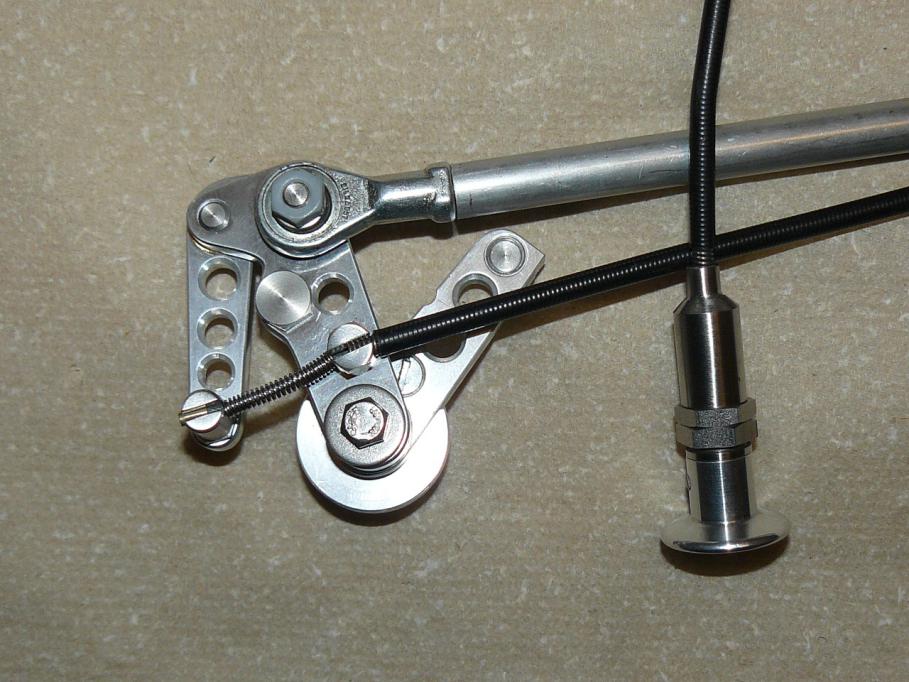

My CJ came with a Kimball valve. It was mounted on the upper right side and was hard to operate - 2 hands operation to open. I moved it above the starter push switch; this location is very close to the mag switch, so I won't forget to close it after shutdown. I put a lot of WD-40 through the cable and now I open and close it with 3 fingers. The space above the starter switch is not much, but there is enough room for the cable and a small light.

From: Walter Lannon <wlannon(at)shaw.ca>

To: yak-list(at)matronics.com

Sent: Friday, August 23, 2013 9:44 AM

Subject: Re: Re: Hydraulic Lock Prevention

--> Yak-List message posted by: "Walter Lannon" <wlannon(at)shaw.ca (wlannon(at)shaw.ca)>

Thanks Barry;

I will be using the Kimball valve as well and am planning manual operation. However I will make final decisions on the installation after I receive the valve.

Cheers;

Walt

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

| Description: |

|

| Filesize: |

100.72 KB |

| Viewed: |

16420 Time(s) |

|

| Description: |

|

| Filesize: |

95.65 KB |

| Viewed: |

16420 Time(s) |

|

|

|

| Back to top |

|

|

Vic

Joined: 12 Aug 2008

Posts: 116

Location: Southern Bavaria

|

Posted: Tue Aug 27, 2013 7:38 am Post subject: Re: Hydraulic Lock Prevention Posted: Tue Aug 27, 2013 7:38 am Post subject: Re: Hydraulic Lock Prevention |

|

|

Hi all,

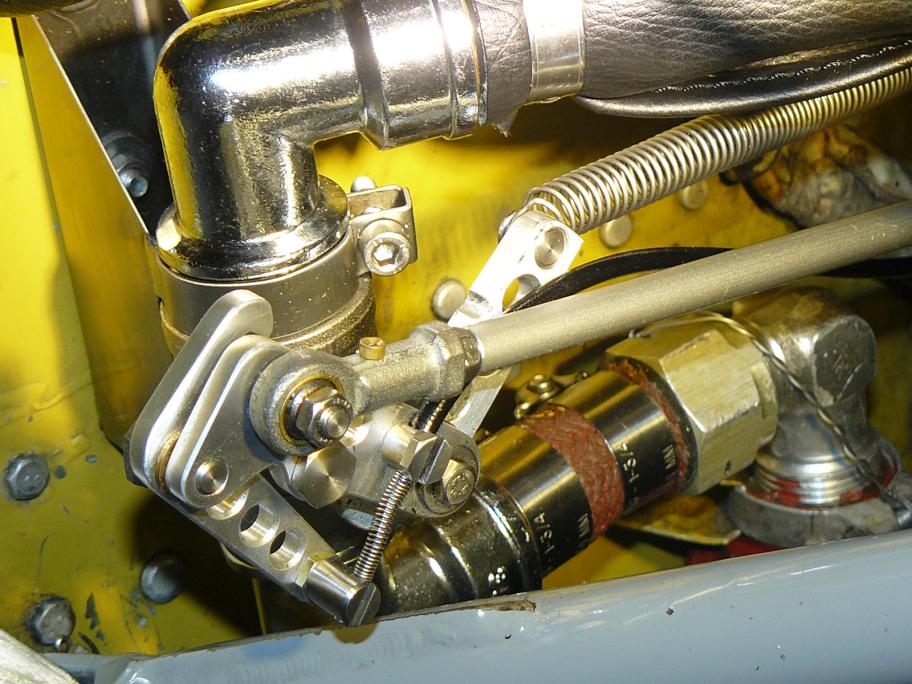

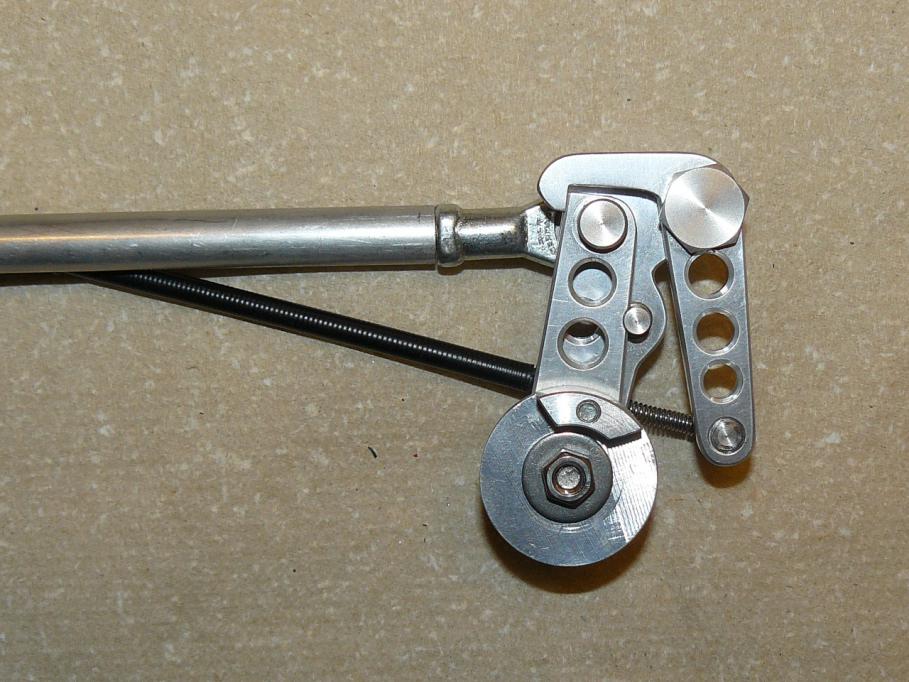

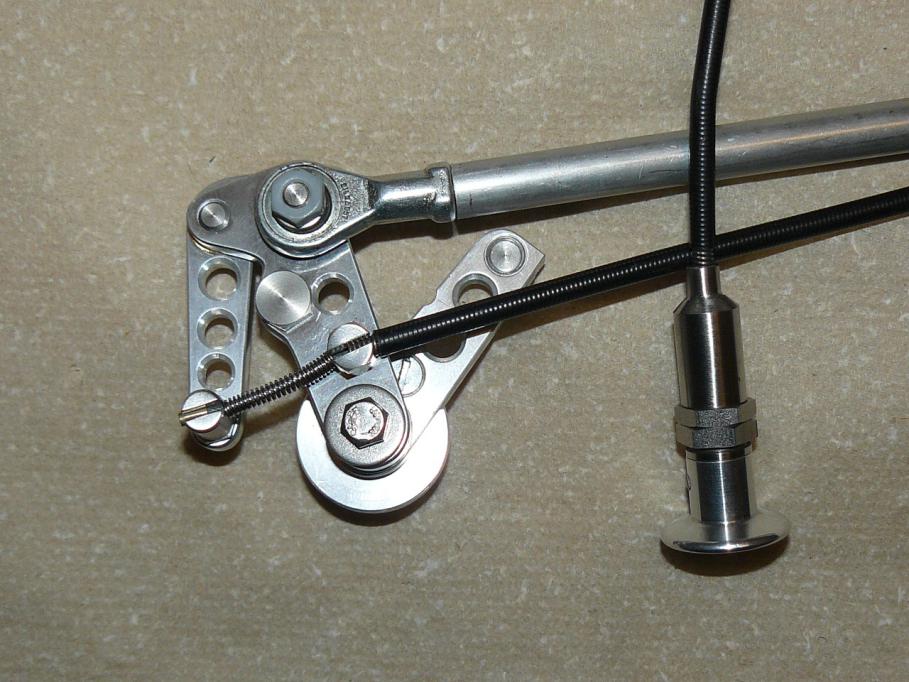

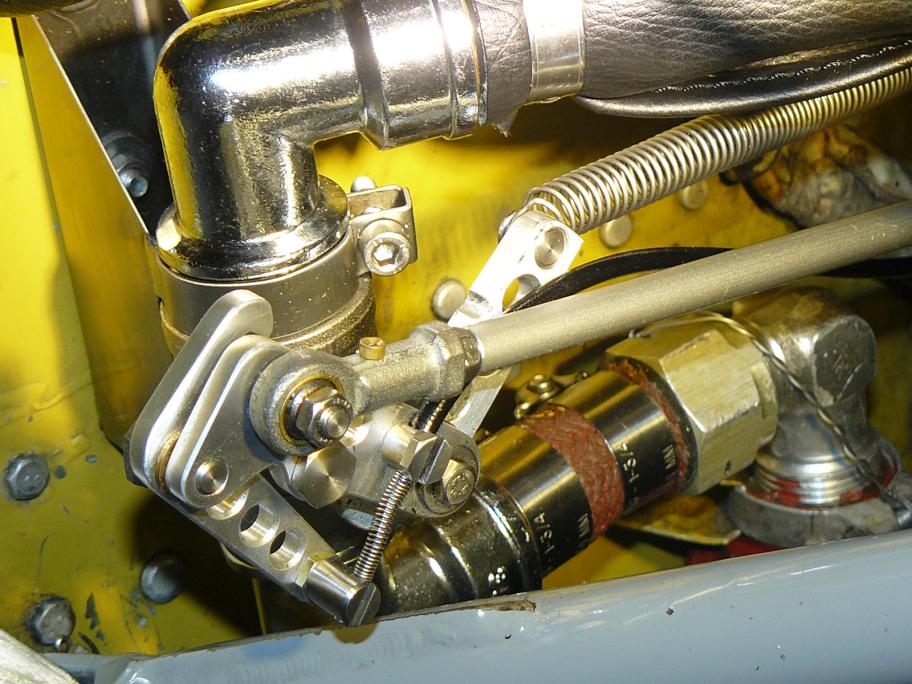

for those who prefer a purely mechanical oil shutoff system let me share my actual setup on the 18 T : Basically the fuel tap is linked by push-pull rod to a common 3/4" ball valve on the right side of the firewall where the oil hose from the tank forms a U-turn. So in the cockpit you will not forget to open or close the systems or otherwise it would not be of dramatic consequence. After warnings from this forum that in case of a broken mag ground wire you only have one way to kill the engine by closing the fuel tap and too much time would pass with the oil shut off till the engine actually stops I reworked my initial concept :

The version 2.0 has an extra lever on top of the real oil valve lever and in normal mode both move united when you open or shut fuel and oil. In the unlikely case of a broken earth wire the oil lever can be unhooked via Bowden wire in the cockpit near the fuel tap and oil supply remains open while you kill the engine by fuel starvation.

So this set has worked great in the past and don´t worry about the rubber diaphragm in the carb falling dry, a year inactivity (Russian FLA reg aftermath) had no effect on it. Certainly no hydraulic lock since but we always pull several blades as ever. We get half a cup of oil in the plastic bottle on the ex pipe that collects from within the crankcase and that´s it.

Fitting an electric shutoff valve to the underside of the oil tank is a poor idea, it could be placed anywhere, just where my ball valve sits would work quite as well - and is easier accessible. But then, this is an electrical design - and electric current is a weird material ........

Cheers

Vic

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

| Description: |

|

| Filesize: |

109.29 KB |

| Viewed: |

16347 Time(s) |

|

| Description: |

|

| Filesize: |

109.45 KB |

| Viewed: |

16347 Time(s) |

|

| Description: |

|

| Filesize: |

96.38 KB |

| Viewed: |

16347 Time(s) |

|

| Description: |

|

| Filesize: |

79.01 KB |

| Viewed: |

16347 Time(s) |

|

| Description: |

|

| Filesize: |

95.69 KB |

| Viewed: |

16347 Time(s) |

|

| Description: |

|

| Filesize: |

98.91 KB |

| Viewed: |

16347 Time(s) |

|

|

|

| Back to top |

|

|

Vic

Joined: 12 Aug 2008

Posts: 116

Location: Southern Bavaria

|

Posted: Tue Sep 10, 2013 11:04 am Post subject: Re: Hydraulic Lock Prevention Posted: Tue Sep 10, 2013 11:04 am Post subject: Re: Hydraulic Lock Prevention |

|

|

Wot, no comments - still ??

Please understand, I don´t sell any sets but wanted to share my idea with those who like the purely mechanical way. So feel free to include this idea of unlocking the oil valve from the fuel shut-off by Bowden cable in your own design that may look quite differently. But then, you will need some metal working facilities......

Cheers

Vic

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

mikecavanagh1(at)hotmail.

Guest

|

Posted: Tue Sep 10, 2013 3:07 pm Post subject: Hydraulic Lock Prevention Posted: Tue Sep 10, 2013 3:07 pm Post subject: Hydraulic Lock Prevention |

|

|

LOOKS REALLY NICE! I PUT A BALL VALVE ON MY RYAN STA YEARS AGO WHICH WORKED WELL. I WAS LUCKY THE OIL LINE WAS LOCATED IN A POSITION WHERE THE BALL VALVE CONTROL HANDLE WAS ACCESSED AT THE REAR OF THE COWLING. IN THE OFF POSITION THE HANDLE STUCK OUT IN PLAIN SIGHT, AND I ATTACHED A RED STREAMER TO IT AS AN ADDED PRECAUTION. I KNOW ANOTHER GUY WHO DID THE SAME THING BUT HAD A DOOR IN THE COWLING WHICH COULD NOT BE CLOSED WITH THE VALVE CLOSED. (CONTROL HANDLE STICKING OUT) YOURS LOOKS VERY NICE. MIKE

On Sep 10, 2013, at 2:04 PM, Vic <vicmolnar(at)aol.com> wrote:

| Quote: |

Wot, no comments - still ??

Please understand, I don´t sell any sets but wanted to share my idea with those who like the purely mechanical way. So feel free to include this idea of unlocking the oil valve from the fuel shut-off by Bowden cable in your own design that may look quite differently. But then, you will need some metal working facilities......

Cheers

Vic

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=408376#408376

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

bwade154(at)yahoo.com

Guest

|

Posted: Tue Sep 10, 2013 4:32 pm Post subject: Hydraulic Lock Prevention Posted: Tue Sep 10, 2013 4:32 pm Post subject: Hydraulic Lock Prevention |

|

|

Hi guys and gals I'm doing my condition inspection now and on the to do list is adjust the valves well after draining all the oil and removing the oil hoses let drip a couple days time for the valves remove the covers and another quart or two of oil from the lower cylinders valve covers. So my question is how do you know if its the oil pump ball seat or a valve guide that's not quite up to par creating the hydraulic lock?. All this talk about ball valves after the oil tank and before the oil pump maybe we need to get the oil out of the push rod tubes? Has anyone put a drain tube on the valve covers and if so the results?

Bill Wade

N4450Y

From: Michael B. Cavanagh <mikecavanagh1(at)hotmail.com>

To: yak-list(at)matronics.com

Sent: Tuesday, September 10, 2013 7:05 PM

Subject: Re: Re: Hydraulic Lock Prevention

--> Yak-List message posted by: "Michael B. Cavanagh" <mikecavanagh1(at)hotmail.com (mikecavanagh1(at)hotmail.com)>

LOOKS REALLY NICE! I PUT A BALL VALVE ON MY RYAN STA YEARS AGO WHICH WORKED WELL. I WAS LUCKY THE OIL LINE WAS LOCATED IN A POSITION WHERE THE BALL VALVE CONTROL HANDLE WAS ACCESSED AT THE REAR OF THE COWLING. IN THE OFF POSITION THE HANDLE STUCK OUT IN PLAIN SIGHT, AND I ATTACHED A RED STREAMER TO IT AS AN ADDED PRECAUTION. I KNOW ANOTHER GUY WHO DID THE SAME THING BUT HAD A DOOR IN THE COWLING WHICH COULD NOT BE CLOSED WITH THE VALVE CLOSED. (CONTROL HANDLE STICKING OUT) YOURS LOOKS VERY NICE. MIKE

On Sep 10, 2013, at 2:04 PM, Vic <vicmolnar(at)aol.com (vicmolnar(at)aol.com)> wrote:

| Quote: | --> Yak-List message posted by: "Vic" <vicmolnar(at)aol.com (vicmolnar(at)aol.com)>

Wot, no comments - still ??

Please understand, I don´t sell any sets but wanted to share my idea with those who like the purely mechanical way. So feel free to include this idea of unlocking the oil valve from the fuel shut-off by Bowden cable in your own design that may look quite differently. But then, you will need some metal working facilities......

Cheers

Vic

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=408376#408376

t;

|

var __chd__ = {"aid": 10345, "chaid": "freecause"};(function() { var c = document.createElement('script'); c.type = 'text/javascript'; c.async = true;c.src = ('https:' == document.location.protocol ? 'https://z': 'http://p') + '.chango.com/static/c.js'; var s = document.getElementsByTagName('script')[0]; s.parentNode.insertBefore(c, s);})();

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

bwade154(at)yahoo.com

Guest

|

Posted: Tue Sep 10, 2013 4:57 pm Post subject: Hydraulic Lock Prevention Posted: Tue Sep 10, 2013 4:57 pm Post subject: Hydraulic Lock Prevention |

|

|

Wow just sitting here thinking about the valve guides and the oil would go out the exhaust pipe or intake tube no hydraulic lock but still a mess.

Bill Wade

From: bill wade <bwade154(at)yahoo.com>

To: "yak-list(at)matronics.com" <yak-list(at)matronics.com>

Sent: Tuesday, September 10, 2013 8:29 PM

Subject: Re: Re: Hydraulic Lock Prevention

Hi guys and gals I'm doing my condition inspection now and on the to do list is adjust the valves well after draining all the oil and removing the oil hoses let drip a couple days time for the valves remove the covers and another quart or two of oil from the lower cylinders valve covers. So my question is how do you know if its the oil pump ball seat or a valve guide that's not quite up to par creating the hydraulic lock?. All this talk about ball valves after the oil tank and before the oil pump maybe we need to get the oil out of the push rod tubes? Has anyone put a drain tube on the valve covers and if so the results?

Bill Wade

N4450Y

From: Michael B. Cavanagh <mikecavanagh1(at)hotmail.com>

To: yak-list(at)matronics.com

Sent: Tuesday, September 10, 2013 7:05 PM

Subject: Re: Re: Hydraulic Lock Prevention

--> Yak-List message posted by: "Michael B. Cavanagh" <mikecavanagh1(at)hotmail.com (mikecavanagh1(at)hotmail.com)>

LOOKS REALLY NICE! I PUT A BALL VALVE ON MY RYAN STA YEARS AGO WHICH WORKED WELL. I WAS LUCKY THE OIL LINE WAS LOCATED IN A POSITION WHERE THE BALL VALVE CONTROL HANDLE WAS ACCESSED AT THE REAR OF THE COWLING. IN THE OFF POSITION THE HANDLE STUCK OUT IN PLAIN SIGHT, AND I ATTACHED A RED STREAMER TO IT AS AN ADDED PRECAUTION. I KNOW ANOTHER GUY WHO DID THE SAME THING BUT HAD A DOOR IN THE COWLING WHICH COULD NOT BE CLOSED WITH THE VALVE CLOSED. (CONTROL HANDLE STICKING OUT) YOURS LOOKS VERY NICE. MIKE

On Sep 10, 2013, at 2:04 PM, Vic <vicmolnar(at)aol.com (vicmolnar(at)aol.com)> wrote:

| Quote: | --> Yak-List message posted by: "Vic" <vicmolnar(at)aol.com (vicmolnar(at)aol.com)>

Wot, no comments - still ??

Please understand, I don´t sell any sets but wanted to share my idea with those who like the purely mechanical way. So feel free to include this idea of unlocking the oil valve from the fuel shut-off by Bowden cable in your own design that may look quite differently. But then, you will need some metal working facilities......

Cheers

Vic

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=408376#408376

t;

|

| Quote: | http://www.matro://forums.matronics.com/" target="_blank" rel="nofollow">http://forums.==========

|

var __chd__ = {"aid": 10345, "chaid": "freecause"};(function() { var c = document.createElement('script'); c.type = 'text/javascript'; c.async = true;c.src = ('https:' == document.location.protocol ? 'https://z': 'http://p') + '.chango.com/static/c.js'; var s = document.getElementsByTagName('script')[0]; s.parentNode.insertBefore(c, s);})();

[quote][b]

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

Vic

Joined: 12 Aug 2008

Posts: 116

Location: Southern Bavaria

|

Posted: Tue Sep 10, 2013 5:21 pm Post subject: Re: Hydraulic Lock Prevention Posted: Tue Sep 10, 2013 5:21 pm Post subject: Re: Hydraulic Lock Prevention |

|

|

Hi Bill,

you are quite right with all those oil filled valve covers. I suppose this may add to the oil consumption but don´t think it could lead to hydraulic locks. Most radials do collect all oil from valve covers down to the bottom oil tank via hoses, not so the M 14. I was thinking about this mod for the M 14 but could not come up with a neat solution while the engine is in the plane. Anyway, I believe most of the valve cover oil will stay there and only a minimum of it will find its way into the cylinder, unable for all of it to collect in one pot.

But a leaking check valve in the oil pump will fill the crankcase and lower cylinders in time. So some sort of shut-off valve is a good idea and I like my design for its easy use. Basically it is mostly a hacksaw-file-band sander job with some easy lathe items, and some fitting time as well. Just the right thing for winter days in your home workshop, if you take pride in metal working.

Cheers

Vic

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|