|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

jeff(at)westcottpress.com

Guest

|

Posted: Sat Sep 21, 2013 2:21 pm Post subject: Outboard Tension Rod Posted: Sat Sep 21, 2013 2:21 pm Post subject: Outboard Tension Rod |

|

|

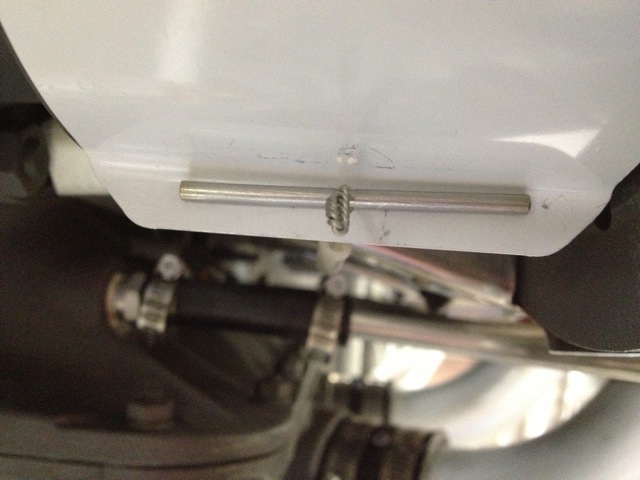

When I make the outboard tension rods to the plan specs, I get the gap you see in the attached picture between the curved portion of the fwd left air ramp and the cooling fins. Is this correct, or should a make a new tension rod to reduce the gap?

Also, I don't feel much resistance as I tighten the MS21042-06 lock nut on the 6-32 threaded end of the tension rod. Is this peculiar to me or have others found this? Any suggestions to keep this from backing off in flight?

Jeff Carpenter

40304

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

270.75 KB |

| Viewed: |

7715 Time(s) |

|

|

|

| Back to top |

|

|

Tim Olson

Joined: 25 Jan 2007

Posts: 2879

|

Posted: Sat Sep 21, 2013 2:55 pm Post subject: Outboard Tension Rod Posted: Sat Sep 21, 2013 2:55 pm Post subject: Outboard Tension Rod |

|

|

Regarding the baffle rods, definitely do something else in addition to

the plans for them instead of just washers. It took 900+ hours, but

finally the stress was too great and the washer cracked through the

metal on those bent tabs of the baffle ramps. To fix the other one,

I got some 1/8" thick angle steel (remember one side of aluminum angle

has a rounded lip?), and cut it into 2 strips instead of being angle.

So I had 1/2" approx by 1.5 or 2" length. The rounded lip fit nicely

into the bend in that baffle, and I drilled a hole thru where the

baffle hole was. That way the entire piece of aluminum 1/8" backing

is pushing on that baffle ear, evening out the stress a bit.

Mine haven't backed off in flight, but they were snug.

Tim

On 9/21/2013 5:18 PM, Jeff Carpenter wrote:

| Quote: | When I make the outboard tension rods to the plan specs, I get the gap you see in the attached picture between the curved portion of the fwd left air ramp and the cooling fins. Is this correct, or should a make a new tension rod to reduce the gap?

Also, I don't feel much resistance as I tighten the MS21042-06 lock nut on the 6-32 threaded end of the tension rod. Is this peculiar to me or have others found this? Any suggestions to keep this from backing off in flight?

Jeff Carpenter

40304

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

jesse(at)saintaviation.co

Guest

|

Posted: Sat Sep 21, 2013 3:00 pm Post subject: Outboard Tension Rod Posted: Sat Sep 21, 2013 3:00 pm Post subject: Outboard Tension Rod |

|

|

There should be tension due to the nut being a lock but. It is possible that you have cut e threads on the rod too small.

In a perfect world, you would want it tighter against the cylinders, but I doubt you will see any measurable difference in cooling. I personally have started using .041" safety wire with a sleeve over it, which has proven to work well. I would make a mental note and see if that cylinder runs hot and then maybe make a new rod. The nut tension would be much more important to me. You could score the threads behind the nut to keep it from backing off, but make sure you have good threads.

Do not archive

Sent from my iPad

On Sep 21, 2013, at 6:18 PM, Jeff Carpenter <jeff(at)westcottpress.com> wrote:

| Quote: | When I make the outboard tension rods to the plan specs, I get the gap you see in the attached picture between the curved portion of the fwd left air ramp and the cooling fins. Is this correct, or should a make a new tension rod to reduce the gap?

Also, I don't feel much resistance as I tighten the MS21042-06 lock nut on the 6-32 threaded end of the tension rod. Is this peculiar to me or have others found this? Any suggestions to keep this from backing off in flight?

Jeff Carpenter

40304

<photo.jpeg>

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

cooprv7(at)yahoo.com

Guest

|

Posted: Sat Sep 21, 2013 3:02 pm Post subject: Outboard Tension Rod Posted: Sat Sep 21, 2013 3:02 pm Post subject: Outboard Tension Rod |

|

|

Jeff,

I would recommend you do close the gap to make the most use of the cooling fins on the cylinder. I struggled with the rods as well and on the right side never could get a good fit and also not interfere with anything. In the end I just used a long piece of safety wire and it has worked great for over 600 hours and 7 years. Probably not so clean and I'm sure I just caused great disgust in someone, but whatever method you choose the baffle should fit tight. I vaguely remember the locknut not having as much tension as well, may just be due to the small size of the rod but I can't be certain.

Looks like you are getting close, have fun.

Marcus

On Sep 21, 2013, at 6:18 PM, Jeff Carpenter <jeff(at)westcottpress.com> wrote:

When I make the outboard tension rods to the plan specs, I get the gap you see in the attached picture between the curved portion of the fwd left air ramp and the cooling fins. Is this correct, or should a make a new tension rod to reduce the gap?

Also, I don't feel much resistance as I tighten the MS21042-06 lock nut on the 6-32 threaded end of the tension rod. Is this peculiar to me or have others found this? Any suggestions to keep this from backing off in flight?

Jeff Carpenter

40304

do not archive

<photo.jpeg>

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

rv10free2fly(at)yahoo.com

Guest

|

Posted: Sat Sep 21, 2013 3:11 pm Post subject: Outboard Tension Rod Posted: Sat Sep 21, 2013 3:11 pm Post subject: Outboard Tension Rod |

|

|

Do you have photos on your website of this baffle securing modification please Tim, as I'm up to this section.

Warm regards

Patrick Pulis

Adelaide, South Australia

On 22/09/2013, at 8:23, Tim Olson <Tim(at)MyRV10.com> wrote:

| Quote: |

Regarding the baffle rods, definitely do something else in addition to

the plans for them instead of just washers. It took 900+ hours, but

finally the stress was too great and the washer cracked through the

metal on those bent tabs of the baffle ramps. To fix the other one,

I got some 1/8" thick angle steel (remember one side of aluminum angle

has a rounded lip?), and cut it into 2 strips instead of being angle.

So I had 1/2" approx by 1.5 or 2" length. The rounded lip fit nicely

into the bend in that baffle, and I drilled a hole thru where the

baffle hole was. That way the entire piece of aluminum 1/8" backing

is pushing on that baffle ear, evening out the stress a bit.

Mine haven't backed off in flight, but they were snug.

Tim

On 9/21/2013 5:18 PM, Jeff Carpenter wrote:

> When I make the outboard tension rods to the plan specs, I get the gap you see in the attached picture between the curved portion of the fwd left air ramp and the cooling fins. Is this correct, or should a make a new tension rod to reduce the gap?

>

> Also, I don't feel much resistance as I tighten the MS21042-06 lock nut on the 6-32 threaded end of the tension rod. Is this peculiar to me or have others found this? Any suggestions to keep this from backing off in flight?

>

> Jeff Carpenter

> 40304

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

flying-nut(at)cfl.rr.com

Guest

|

Posted: Sat Sep 21, 2013 3:23 pm Post subject: Outboard Tension Rod Posted: Sat Sep 21, 2013 3:23 pm Post subject: Outboard Tension Rod |

|

|

I'm not there yet so take this with a grain of salt: (maybe not salt

... bad for the heart)

Seeing the replies using safety wire ..... I'll use the supplied rod to

go horizontally on the lip with the safety wire looped over the rod. An

anti-chafe tube over the safety wire should clean things up a bit.

Thanks for triggering a few brain cells!

Linn

On 9/21/2013 6:53 PM, Tim Olson wrote:

| Quote: |

Regarding the baffle rods, definitely do something else in addition to

the plans for them instead of just washers. It took 900+ hours, but

finally the stress was too great and the washer cracked through the

metal on those bent tabs of the baffle ramps. To fix the other one,

I got some 1/8" thick angle steel (remember one side of aluminum angle

has a rounded lip?), and cut it into 2 strips instead of being angle.

So I had 1/2" approx by 1.5 or 2" length. The rounded lip fit nicely

into the bend in that baffle, and I drilled a hole thru where the

baffle hole was. That way the entire piece of aluminum 1/8" backing

is pushing on that baffle ear, evening out the stress a bit.

Mine haven't backed off in flight, but they were snug.

Tim

On 9/21/2013 5:18 PM, Jeff Carpenter wrote:

> When I make the outboard tension rods to the plan specs, I get the

> gap you see in the attached picture between the curved portion of the

> fwd left air ramp and the cooling fins. Is this correct, or should a

> make a new tension rod to reduce the gap?

>

> Also, I don't feel much resistance as I tighten the MS21042-06 lock

> nut on the 6-32 threaded end of the tension rod. Is this peculiar to

> me or have others found this? Any suggestions to keep this from

> backing off in flight?

>

> Jeff Carpenter

> 40304

>

-----

No virus found in this message.

Checked by AVG - www.avg.com

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

Tim Olson

Joined: 25 Jan 2007

Posts: 2879

|

Posted: Sat Sep 21, 2013 3:23 pm Post subject: Outboard Tension Rod Posted: Sat Sep 21, 2013 3:23 pm Post subject: Outboard Tension Rod |

|

|

I don't, sorry. It was something I found on a quick oil change opening

and I didn't shoot pictures...just fixed it asap.

Tim

On 9/21/2013 6:11 PM, Patrick Pulis wrote:

| Quote: |

Do you have photos on your website of this baffle securing modification please Tim, as I'm up to this section.

Warm regards

Patrick Pulis

Adelaide, South Australia

On 22/09/2013, at 8:23, Tim Olson <Tim(at)MyRV10.com> wrote:

>

>

> Regarding the baffle rods, definitely do something else in addition to

> the plans for them instead of just washers. It took 900+ hours, but

> finally the stress was too great and the washer cracked through the

> metal on those bent tabs of the baffle ramps. To fix the other one,

> I got some 1/8" thick angle steel (remember one side of aluminum angle

> has a rounded lip?), and cut it into 2 strips instead of being angle.

> So I had 1/2" approx by 1.5 or 2" length. The rounded lip fit nicely

> into the bend in that baffle, and I drilled a hole thru where the

> baffle hole was. That way the entire piece of aluminum 1/8" backing

> is pushing on that baffle ear, evening out the stress a bit.

>

> Mine haven't backed off in flight, but they were snug.

> Tim

>

> On 9/21/2013 5:18 PM, Jeff Carpenter wrote:

>> When I make the outboard tension rods to the plan specs, I get the gap you see in the attached picture between the curved portion of the fwd left air ramp and the cooling fins. Is this correct, or should a make a new tension rod to reduce the gap?

>>

>> Also, I don't feel much resistance as I tighten the MS21042-06 lock nut on the 6-32 threaded end of the tension rod. Is this peculiar to me or have others found this? Any suggestions to keep this from backing off in flight?

>>

>> Jeff Carpenter

>> 40304

>

>

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

Kelly McMullen

Joined: 16 Apr 2008

Posts: 1188

Location: Sun Lakes AZ

|

Posted: Sat Sep 21, 2013 3:39 pm Post subject: Outboard Tension Rod Posted: Sat Sep 21, 2013 3:39 pm Post subject: Outboard Tension Rod |

|

|

Y'all are doing it the hard way. I admit to making rods per plans, but will replace any that don't fit right with 6X32 all thread rod available at your favorite FAA/PMA dept of Lowes, Home Depot, etc.

The supplied rods are a real pain to run through a die to make the threads, especially due to small size.

The all thread has it done for you and you just cut to length, where it isn't critical because you can adjust nuts to fit.

You can then get 4 flat nuts for each rod, put one on each end inside the baffle, install rod and put one on each outside, with washers as desired. Then tighten the inner and outer nut against each other. I've done this and seen it done on certified planes with good results. You can enhance by placing sleeve of heat shrink over the rod to prevent any abrasion with rocker drainback tubes, as well as bending for clearance. If it makes you feel better you can use the self locking nuts on the outside. I do not like those tiny self locking nuts.

Kelly

On Sat, Sep 21, 2013 at 7:22 PM, Linn Walters <flying-nut(at)cfl.rr.com (flying-nut(at)cfl.rr.com)> wrote:

| Quote: | --> RV10-List message posted by: Linn Walters <flying-nut(at)cfl.rr.com (flying-nut(at)cfl.rr.com)>

I'm not there yet so take this with a grain of salt: (maybe not salt .... bad for the heart)

Seeing the replies using safety wire ..... I'll use the supplied rod to go horizontally on the lip with the safety wire looped over the rod. An anti-chafe tube over the safety wire should clean things up a bit. Thanks for triggering a few brain cells!

Linn

On 9/21/2013 6:53 PM, Tim Olson wrote:

| Quote: | --> RV10-List message posted by: Tim Olson <Tim(at)myrv10.com (Tim(at)myrv10.com)>

Regarding the baffle rods, definitely do something else in addition to

the plans for them instead of just washers. It took 900+ hours, but

finally the stress was too great and the washer cracked through the

metal on those bent tabs of the baffle ramps. To fix the other one,

I got some 1/8" thick angle steel (remember one side of aluminum angle

has a rounded lip?), and cut it into 2 strips instead of being angle.

So I had 1/2" approx by 1.5 or 2" length. The rounded lip fit nicely

into the bend in that baffle, and I drilled a hole thru where the

baffle hole was. That way the entire piece of aluminum 1/8" backing

is pushing on that baffle ear, evening out the stress a bit.

Mine haven't backed off in flight, but they were snug.

Tim

On 9/21/2013 5:18 PM, Jeff Carpenter wrote:

| Quote: | When I make the outboard tension rods to the plan specs, I get the gap you see in the attached picture between the curved portion of the fwd left air ramp and the cooling fins. Is this correct, or should a make a new tension rod to reduce the gap?

Also, I don't feel much resistance as I tighten the MS21042-06 lock nut on the 6-32 threaded end of the tension rod. Is this peculiar to me or have others found this? Any suggestions to keep this from backing off in flight?

Jeff Carpenter

40304

|

-----

No virus found in this message.

Checked by AVG - www.avg.com

|

====================================

arget="_blank">http://www.matronics.com/Navigator?RV10-List

====================================

http://forums.matronics.com

====================================

le, List Admin.

="_blank">http://www.matronics.com/contribution

====================================

|

--

- sent from the microchip implanted in my forearm

[quote][b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor

KCHD |

|

| Back to top |

|

|

Kelly McMullen

Joined: 16 Apr 2008

Posts: 1188

Location: Sun Lakes AZ

|

Posted: Sat Sep 21, 2013 3:47 pm Post subject: Outboard Tension Rod Posted: Sat Sep 21, 2013 3:47 pm Post subject: Outboard Tension Rod |

|

|

While your sleeve may protect the baffling, in general I would advise against safety wire for this application, as I have seen it on many aircraft and it eventually cuts right through the baffling, leaving a broken hole.

Many production aircraft came with a pair of springs that hooked into the hole in the baffle, with a washer underneath to protect the aluminum, and then the other end of springs hooked together in middle, under center cylinder(or between cylinders on 4 cyl engine). I haven't found anything easier to install, nor more durable than the all thread rod.

On Sat, Sep 21, 2013 at 6:58 PM, Jesse Saint <jesse(at)saintaviation.com (jesse(at)saintaviation.com)> wrote:

| Quote: | --> RV10-List message posted by: Jesse Saint <jesse(at)saintaviation.com (jesse(at)saintaviation.com)>

There should be tension due to the nut being a lock but. It is possible that you have cut e threads on the rod too small.

In a perfect world, you would want it tighter against the cylinders, but I doubt you will see any measurable difference in cooling. I personally have started using .041" safety wire with a sleeve over it, which has proven to work well. I would make a mental note and see if that cylinder runs hot and then maybe make a new rod. The nut tension would be much more important to me. You could score the threads behind the nut to keep it from backing off, but make sure you have good threads.

Do not archive

Sent from my iPad

On Sep 21, 2013, at 6:18 PM, Jeff Carpenter <jeff(at)westcottpress.com (jeff(at)westcottpress.com)> wrote:

> When I make the outboard tension rods to the plan specs, I get the gap you see in the attached picture between the curved portion of the fwd left air ramp and the cooling fins. Is this correct, or should a make a new tension rod to reduce the gap?

>

> Also, I don't feel much resistance as I tighten the MS21042-06 lock nut on the 6-32 threaded end of the tension rod. Is this peculiar to me or have others found this? Any suggestions to keep this from backing off in flight?

>

> Jeff Carpenter

> 40304

>

===========

arget="_blank">http://www.matronics.com/Navigator?RV10-List

===========

http://forums.matronics.com

===========

le, List Admin.

="_blank">http://www.matronics.com/contribution

===========

|

--

- sent from the microchip implanted in my forearm

[quote][b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor

KCHD |

|

| Back to top |

|

|

pilotdds(at)aol.com

Guest

|

Posted: Sat Sep 21, 2013 5:47 pm Post subject: Outboard Tension Rod Posted: Sat Sep 21, 2013 5:47 pm Post subject: Outboard Tension Rod |

|

|

For whatever its worth on my kit the rod vans suppled was to small in diameter to achieve a true 6-32 .I wound up using all thread -The bends provid tension when the nuts are tightened.

--

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

jeff(at)westcottpress.com

Guest

|

Posted: Sun Sep 22, 2013 11:10 am Post subject: Outboard Tension Rod Posted: Sun Sep 22, 2013 11:10 am Post subject: Outboard Tension Rod |

|

|

Okay... here's what I've come up with... a shortened tension rod and a custom washer made from j-channel. I don't think it's possible to get the gap any better. I'm still not happy with the lock nut resistance. I've got that question in to Vans.. and not happy that the nut isn't sitting flat, but that's been determined by Vans putting the hole too close to the bend.

On Sep 21, 2013, at 3:18 PM, Jeff Carpenter wrote:

| Quote: | When I make the outboard tension rods to the plan specs, I get the gap you see in the attached picture between the curved portion of the fwd left air ramp and the cooling fins. Is this correct, or should a make a new tension rod to reduce the gap?

Also, I don't feel much resistance as I tighten the MS21042-06 lock nut on the 6-32 threaded end of the tension rod. Is this peculiar to me or have others found this? Any suggestions to keep this from backing off in flight?

Jeff Carpenter

40304

<photo.jpeg>

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

295.92 KB |

| Viewed: |

7679 Time(s) |

|

|

|

| Back to top |

|

|

flying-nut(at)cfl.rr.com

Guest

|

Posted: Sun Sep 22, 2013 2:51 pm Post subject: Outboard Tension Rod Posted: Sun Sep 22, 2013 2:51 pm Post subject: Outboard Tension Rod |

|

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

jeff(at)westcottpress.com

Guest

|

Posted: Mon Sep 23, 2013 4:01 pm Post subject: Outboard Tension Rod Posted: Mon Sep 23, 2013 4:01 pm Post subject: Outboard Tension Rod |

|

|

.. just to report on the feedback from Joe at Vans:

He said that the curved portion of the air ramps should be pulled in as close to the fins as possible, but suggested a bead of red RTV near the flange to keep them from actually touching. If they touch, the fins will eventually wear through the baffle.

He offered that safety wire could be used instead of the rods, but that some kind of steel around the flange of the baffle would be necessary to keep the wire from cutting through the baffle at the hole.

Two nuts or loctite is what I need to use as the lock nuts don't seem to be "locking"

On Sep 21, 2013, at 3:18 PM, Jeff Carpenter wrote:

| Quote: | When I make the outboard tension rods to the plan specs, I get the gap you see in the attached picture between the curved portion of the fwd left air ramp and the cooling fins. Is this correct, or should a make a new tension rod to reduce the gap?

Also, I don't feel much resistance as I tighten the MS21042-06 lock nut on the 6-32 threaded end of the tension rod. Is this peculiar to me or have others found this? Any suggestions to keep this from backing off in flight?

Jeff Carpenter

40304

<photo.jpeg>

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

john(at)trollingers.com

Guest

|

Posted: Wed Sep 25, 2013 2:43 am Post subject: Outboard Tension Rod Posted: Wed Sep 25, 2013 2:43 am Post subject: Outboard Tension Rod |

|

|

What is the purpose of the tension rods, is it to pull the baffling close to the cylinders, or is it to hold the baffling in place as air moves around the engine.

I ask because I made the rods per the plans and they do not seem to pull the baffling close to the cylinders at all and I am not sure if they are to long, or if that is the expected behavior.

thanks,

John

40923

On Mon, Sep 23, 2013 at 8:00 PM, Jeff Carpenter <jeff(at)westcottpress.com (jeff(at)westcottpress.com)> wrote:

[quote]--> RV10-List message posted by: Jeff Carpenter <jeff(at)westcottpress.com (jeff(at)westcottpress.com)>

.. just to report on the feedback from Joe at Vans:

He said that the curved portion of the air ramps should be pulled in as close to the fins as possible, but suggested a bead of red RTV near the flange to keep them from actually touching. If they touch, the fins will eventually wear through the baffle.

He offered that safety wire could be used instead of the rods, but that some kind of steel around the flange of the baffle would be necessary to keep the wire from cutting through the baffle at the hole.

Two nuts or loctite is what I need to use as the lock nuts don't seem to be "locking"

On Sep 21, 2013, at 3:18 PM, Jeff Carpenter wrote:

> When I make the outboard tension rods to the plan specs, I get the gap you see in the attached picture between the curved portion of the fwd left air ramp and the cooling fins. Is this correct, or should a make a new tension rod to reduce the gap?

>

> Also, I don't feel much resistance as I tighten the MS21042-06 lock nut on the 6-32 threaded end of the tension rod. Is this peculiar to me or have others found this? Any suggestions to keep this from backing off in flight?

>

> Jeff Carpenter

> 40304

>

===========

arget="_blank">http://www.matronics.com/Navigator?RV10-List

===========

http://forums.matronics.com

===========

le, List Admin.

="_blank">http://www.matronics.com/contribution

===========

[b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

Kelly McMullen

Joined: 16 Apr 2008

Posts: 1188

Location: Sun Lakes AZ

|

Posted: Wed Sep 25, 2013 3:10 am Post subject: Outboard Tension Rod Posted: Wed Sep 25, 2013 3:10 am Post subject: Outboard Tension Rod |

|

|

They are supposed to do both. You need to get most of the air to exit where the openings are, centered on each cylinder. Think what will happen with the baffles with no rods and 200 mph air flowing past them. You want an even gap, about 1/8" between cylinders and the baffle, which should not be wider at the bottom.

Makes me wonder if some of the folks reporting high CHTs have baffles pulled snug like they should be.

On Wed, Sep 25, 2013 at 6:42 AM, John Trollinger <john(at)trollingers.com (john(at)trollingers.com)> wrote:

[quote]What is the purpose of the tension rods, is it to pull the baffling close to the cylinders, or is it to hold the baffling in place as air moves around the engine.

I ask because I made the rods per the plans and they do not seem to pull the baffling close to the cylinders at all and I am not sure if they are to long, or if that is the expected behavior.

thanks,

John

40923

On Mon, Sep 23, 2013 at 8:00 PM, Jeff Carpenter <jeff(at)westcottpress.com (jeff(at)westcottpress.com)> wrote:

| Quote: | --> RV10-List message posted by: Jeff Carpenter <jeff(at)westcottpress.com (jeff(at)westcottpress.com)>

.. just to report on the feedback from Joe at Vans:

He said that the curved portion of the air ramps should be pulled in as close to the fins as possible, but suggested a bead of red RTV near the flange to keep them from actually touching. If they touch, the fins will eventually wear through the baffle.

He offered that safety wire could be used instead of the rods, but that some kind of steel around the flange of the baffle would be necessary to keep the wire from cutting through the baffle at the hole.

Two nuts or loctite is what I need to use as the lock nuts don't seem to be "locking"

|

[b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor

KCHD |

|

| Back to top |

|

|

rv10flyer(at)live.com

Guest

|

Posted: Wed Sep 25, 2013 6:11 am Post subject: Outboard Tension Rod Posted: Wed Sep 25, 2013 6:11 am Post subject: Outboard Tension Rod |

|

|

Let me tell you from experience, (Eci cylinders) you want to assure there is no where for the air to go than through the cylinders. I recall the tension rods were an issue for me as well. I have RTV on both sides (inside and outside of baffles), but I also have a good fit with front and back tight enough that it will hold solid and not work itself loose.

From: John Trollinger (john(at)trollingers.com)

Sent: Wednesday, September 25, 2013 3:42 AM

To: rv10-list(at)matronics.com (rv10-list(at)matronics.com)

Subject: Re: Outboard Tension Rod

What is the purpose of the tension rods, is it to pull the baffling close to the cylinders, or is it to hold the baffling in place as air moves around the engine.

I ask because I made the rods per the plans and they do not seem to pull the baffling close to the cylinders at all and I am not sure if they are to long, or if that is the expected behavior.

thanks,

John

40923

On Mon, Sep 23, 2013 at 8:00 PM, Jeff Carpenter <jeff(at)westcottpress.com (jeff(at)westcottpress.com)> wrote:

| Quote: | --> RV10-List message posted by: Jeff Carpenter <jeff(at)westcottpress.com (jeff(at)westcottpress.com)>

... just to report on the feedback from Joe at Vans:

He said that the curved portion of the air ramps should be pulled in as close to the fins as possible, but suggested a bead of red RTV near the flange to keep them from actually touching. If they touch, the fins will eventually wear through the baffle.

He offered that safety wire could be used instead of the rods, but that some kind of steel around the flange of the baffle would be necessary to keep the wire from cutting through the baffle at the hole.

Two nuts or loctite is what I need to use as the lock nuts don't seem to be "locking"

On Sep 21, 2013, at 3:18 PM, Jeff Carpenter wrote:

| Quote: | When I make the outboard tension rods to the plan specs, I get the gap you see in the attached picture between the curved portion of the fwd left air ramp and the cooling fins. Is this correct, or should a make a new tension rod to reduce the gap?

Also, I don't feel much resistance as I tighten the MS21042-06 lock nut on the 6-32 threaded end of the tension rod. Is this peculiar to me or have others found this? Any suggestions to keep this from backing off in flight?

Jeff Carpenter

40304

|

===========

arget="_blank">http://www.matronics.com/Navigator?RV10-List

===========

http://forums.matronics.com

===========

le, List Admin.

="_blank">http://www.matronics.com/contribution

===========

|

[quote]

href="http://www.matronics.com/Navigator?RV10-List">http://www.matronics.com/Navigator?RV10-List

href="http://forums.matronics.com">http://forums.matronics.com

href="http://www.matronics.com/contribution">http://www.matronics.com/c

[b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

jeff(at)westcottpress.com

Guest

|

Posted: Mon Sep 30, 2013 4:11 pm Post subject: Outboard Tension Rod Posted: Mon Sep 30, 2013 4:11 pm Post subject: Outboard Tension Rod |

|

|

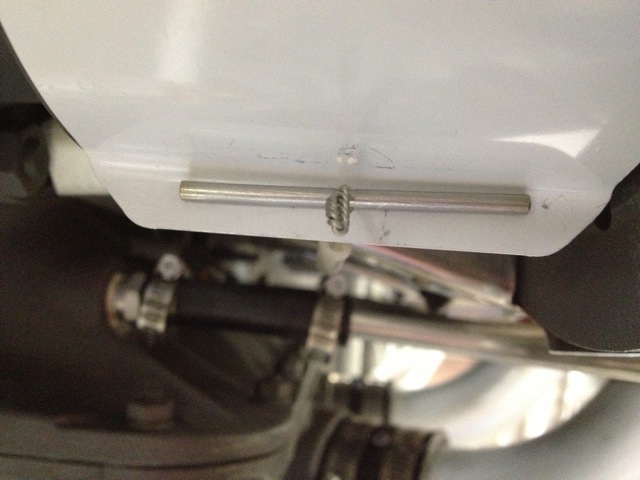

Okay... so here's what I finally wound up with. I feel like this will wear well. Time will tell.

Had I started with this approach I'd probably be finishing up the exhaust system by now... oh well.

Jeff Carpenter

40304

On Sep 21, 2013, at 3:18 PM, Jeff Carpenter wrote:

| Quote: | When I make the outboard tension rods to the plan specs, I get the gap you see in the attached picture between the curved portion of the fwd left air ramp and the cooling fins. Is this correct, or should a make a new tension rod to reduce the gap?

Also, I don't feel much resistance as I tighten the MS21042-06 lock nut on the 6-32 threaded end of the tension rod. Is this peculiar to me or have others found this? Any suggestions to keep this from backing off in flight?

Jeff Carpenter

40304

<photo.jpeg>

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

72.68 KB |

| Viewed: |

7555 Time(s) |

|

| Description: |

|

| Filesize: |

70.57 KB |

| Viewed: |

7555 Time(s) |

|

| Description: |

|

| Filesize: |

77.67 KB |

| Viewed: |

7555 Time(s) |

|

|

|

| Back to top |

|

|

larkrv10(at)gmail.com

Guest

|

Posted: Mon Sep 30, 2013 6:24 pm Post subject: Outboard Tension Rod Posted: Mon Sep 30, 2013 6:24 pm Post subject: Outboard Tension Rod |

|

|

Nice Jeff, is that aluminum rod or stainless?

Rick

#40956

Southampton, Ont

On Mon, Sep 30, 2013 at 8:03 PM, Jeff Carpenter <jeff(at)westcottpress.com (jeff(at)westcottpress.com)> wrote:

[quote]Okay... so here's what I finally wound up with. I feel like this will wear well. Time will tell.

Had I started with this approach I'd probably be finishing up the exhaust system by now... oh well.

Jeff Carpenter

40304

On Sep 21, 2013, at 3:18 PM, Jeff Carpenter wrote:

> When I make the outboard tension rods to the plan specs, I get the gap you see in the attached picture between the curved portion of the fwd left air ramp and the cooling fins. Is this correct, or should a make a new tension rod to reduce the gap?

>

> Also, I don't feel much resistance as I tighten the MS21042-06 lock nut on the 6-32 threaded end of the tension rod. Is this peculiar to me or have others found this? Any suggestions to keep this from backing off in flight?

>

> Jeff Carpenter

> 40304

>

> <photo.jpeg>

[b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

jeff(at)westcottpress.com

Guest

|

Posted: Mon Sep 30, 2013 7:18 pm Post subject: Outboard Tension Rod Posted: Mon Sep 30, 2013 7:18 pm Post subject: Outboard Tension Rod |

|

|

That's the stainless rod that was furnished to make the tension rods with. You can see in one of the pictures that I ground a "dog bone" style groove in the center of the rods for the wire to nest in. That should keep the rods from working their way out.

On Sep 30, 2013, at 7:24 PM, Rick Lark wrote:

[quote]Nice Jeff, is that aluminum rod or stainless?

Rick

#40956

Southampton, Ont

On Mon, Sep 30, 2013 at 8:03 PM, Jeff Carpenter <jeff(at)westcottpress.com (jeff(at)westcottpress.com)> wrote:

| Quote: | Okay... so here's what I finally wound up with. I feel like this will wear well. Time will tell.

Had I started with this approach I'd probably be finishing up the exhaust system by now... oh well.

Jeff Carpenter

40304

On Sep 21, 2013, at 3:18 PM, Jeff Carpenter wrote:

> When I make the outboard tension rods to the plan specs, I get the gap you see in the attached picture between the curved portion of the fwd left air ramp and the cooling fins. Is this correct, or should a make a new tension rod to reduce the gap?

>

> Also, I don't feel much resistance as I tighten the MS21042-06 lock nut on the 6-32 threaded end of the tension rod. Is this peculiar to me or have others found this? Any suggestions to keep this from backing off in flight?

>

> Jeff Carpenter

> 40304

>

> <photo.jpeg>

|

[b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|