|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

teamgrumman(at)yahoo.com

Guest

|

Posted: Thu Oct 31, 2013 8:12 pm Post subject: MT Props Posted: Thu Oct 31, 2013 8:12 pm Post subject: MT Props |

|

|

I was going to post this on GG but realized I can't post pics.

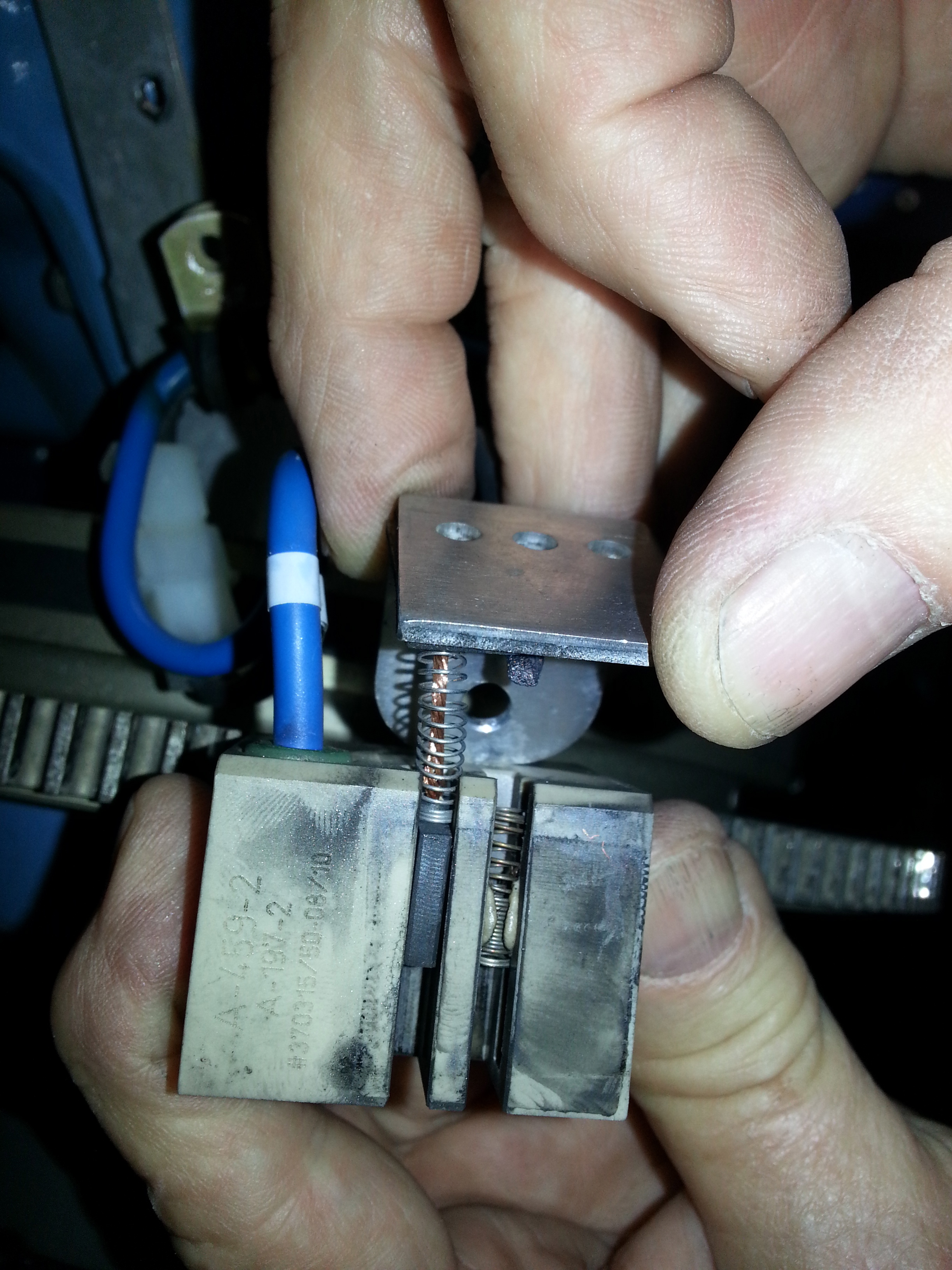

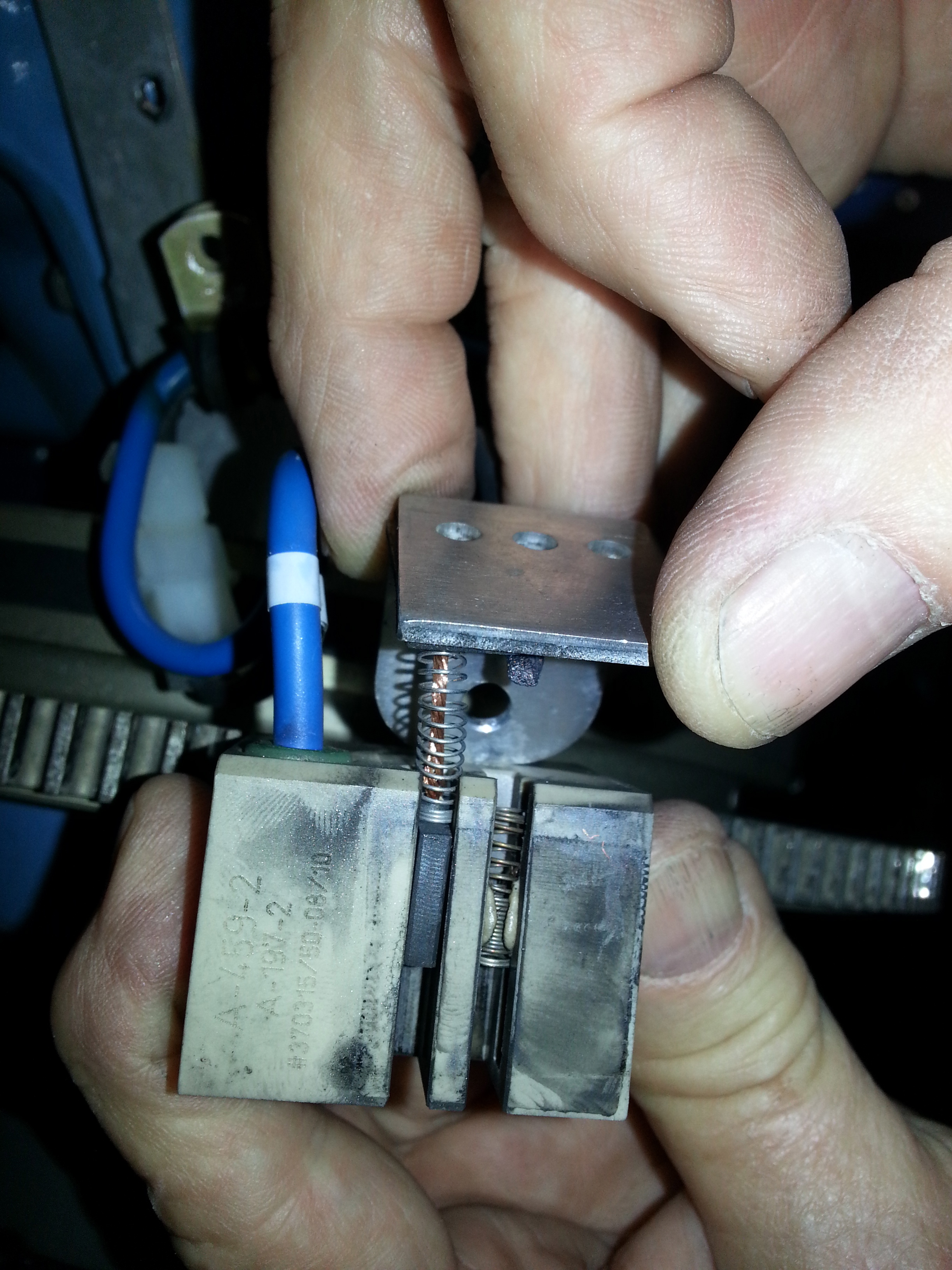

This is the second brush block installed on this plane. The first one failed in less than 100 hours. This one failed in less than 90 hours.

It isn't a well designed piece of hardware.

Gary

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

| Description: |

|

| Filesize: |

2.04 MB |

| Viewed: |

3270 Time(s) |

|

|

|

| Back to top |

|

|

n26390(at)AOL.COM

Guest

|

Posted: Thu Oct 31, 2013 8:46 pm Post subject: MT Props Posted: Thu Oct 31, 2013 8:46 pm Post subject: MT Props |

|

|

Gary: So what is that goo on the right spring that's still in the unit?

Roger Rucker

AA5A '78 HWO

--

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

aa5_driver(at)yahoo.com

Guest

|

Posted: Thu Oct 31, 2013 8:55 pm Post subject: MT Props Posted: Thu Oct 31, 2013 8:55 pm Post subject: MT Props |

|

|

I've not heard of this issue from others, have you?

Kevin

On Oct 31, 2013, at 11:11 PM, Gary L Vogt <teamgrumman(at)yahoo.com (teamgrumman(at)yahoo.com)> wrote:

[quote]I was going to post this on GG but realized I can't post pics.

This is the second brush block installed on this plane. The first one failed in less than 100 hours. This one failed in less than 90 hours.

It isn't a well designed piece of hardware.

Gary

<20131031_180437.jpg>

[b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Fri Nov 01, 2013 12:50 am Post subject: MT Props Posted: Fri Nov 01, 2013 12:50 am Post subject: MT Props |

|

|

Melted Block, Roger.

MT chose the wrong material for the the insulation block. AND they did not use a large enough brush system. One brush failed, guessing here, probably by the copper braid loosing connection. This caused a high resistance and a higher current through that brushes spring which, is not copper - ergo still higher resistance , which caused the spring to heat up and melted the plastic.

*Barry*

*“Chop’d Liver”*

NJ has taken the next step. They are identifying cars with bad drivers. You will notice some cars with a large red "R" on them. That is to identify the drivers as "R"estricted. Restricted is just a polite way of saying Bad Drivers. Be cautious around them.

On Fri, Nov 1, 2013 at 12:46 AM, <n26390(at)aol.com (n26390(at)aol.com)> wrote:

[quote] Gary: So what is that goo on the right spring that's still in the unit?

Roger Rucker

AA5A '78 HWO

--

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

aa5_driver(at)yahoo.com

Guest

|

Posted: Fri Nov 01, 2013 3:05 am Post subject: MT Props Posted: Fri Nov 01, 2013 3:05 am Post subject: MT Props |

|

|

Barry,

You may have shed some light on the issue. Not knowing what year the tiger is, is it possible that the part is the wrong part number? Could that be the part for a 24 volt system and it is failing with double the amps at 12 volts? I don't recall this failure being discussed previously by any of those with the mt. Also wondering if there could be a ground issue (bad ground) in the circuit somewhere causing resistance which is causing a heat build up in this part?

Kevin

On Nov 1, 2013, at 3:49 AM, FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)> wrote:

[quote]Melted Block, Roger.

MT chose the wrong material for the the insulation block. AND they did not use a large enough brush system. One brush failed, guessing here, probably by the copper braid loosing connection. This caused a high resistance and a higher current through that brushes spring which, is not copper - ergo still higher resistance , which caused the spring to heat up and melted the plastic.

*Barry*

*“Chop’d Liver”*

NJ has taken the next step. They are identifying cars with bad drivers. You will notice some cars with a large red "R" on them. That is to identify the drivers as "R"estricted. Restricted is just a polite way of saying Bad Drivers. Be cautious around them.

On Fri, Nov 1, 2013 at 12:46 AM, <n26390(at)aol.com (n26390(at)aol.com)> wrote:

[quote] Gary: So what is that goo on the right spring that's still in the unit?

Roger Rucker

AA5A '78 HWO

--

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Fri Nov 01, 2013 6:00 am Post subject: MT Props Posted: Fri Nov 01, 2013 6:00 am Post subject: MT Props |

|

|

Kevin:

Is this your plane?

I do not have enough pictures and I wish I could check the hardness of the material (Durometer) but yes, there are lots more questions that could come up:

Question: Is this a dual brush system? Meaning two (2) brushes for each side of the connection. In a dual brush system the a single brush is usually chosen to handle 100% of the current Plus a safety margin of 50% more. In this case the individual size of the brush is too small. But therein lies the rub (Hamlet). You would go to a dual brush system because of space and/or cost of a large brush. They did not have the space for a Large one brush system.

There is also the idea of redundancy - If one brush should fail you would want to still have control over the prop.

Ever notice in Motor Designs [look at a good quality electric drill] the Brush Runs Inside a METAL sleeve or Bakelite (not feasible in aircraft due to its brittleness) . This sleeve offers a lower coefficient of friction [Nylon and machined plastics; even Teflon have a very high coefficient of friction] for the sliding brush, an alternate current path, as well as cooling [heatsink] for the brushes. MT lost sight of the requirements.

Getting back to your question Kevin:

Yes, a bad ground or any bad connection in the MT system could cause high current.

To answer a question before asked: Shouldn't the CARBON of the brush help lower the coefficient of friction? YES, to some extent but the friction will wear away the carbon as well.

But, your synopsis of a 24 Volt system Vs a 12 Volt System is incorrect, you just have things reversed. If you INCREASE the Voltage (Double in this case) you DECREASE the Current (It would draw 1/2 the current in this case).

Power (Watts) = I x E

Lets say the system draws 200 Watts

200 Watts / 12 Volts = 16.66 Amps

Now you up the voltage...

200 Watts / 24 Volts = 8.33 Amps

I just had an appfinity - What if you installed an AMMETER in the circuit. You should be able to monitor the condition of the brushes. As the brushes deteriorate the current would go up. Set a Delta for how much is acceptable and of course if a brush totally fails the current would jump.

Gary - Being there is such a short life cycle [MTBF], this sure sounds like AD material and a phone call to MT is in order.

*Barry*

*“Chop’d Liver”*

NJ has taken the next step. They are identifying cars with bad drivers. You will notice some cars with a large red "R" on them. That is to identify the drivers as "R"estricted. Restricted is just a polite way of saying Bad Drivers. Be cautious around them.

On Fri, Nov 1, 2013 at 7:04 AM, Airport Bum <aa5_driver(at)yahoo.com (aa5_driver(at)yahoo.com)> wrote:

[quote] Barry,

You may have shed some light on the issue. Not knowing what year the tiger is, is it possible that the part is the wrong part number? Could that be the part for a 24 volt system and it is failing with double the amps at 12 volts? I don't recall this failure being discussed previously by any of those with the mt. Also wondering if there could be a ground issue (bad ground) in the circuit somewhere causing resistance which is causing a heat build up in this part?

Kevin

On Nov 1, 2013, at 3:49 AM, FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)> wrote:

[quote] Melted Block, Roger.

MT chose the wrong material for the the insulation block. AND they did not use a large enough brush system. One brush failed, guessing here, probably by the copper braid loosing connection. This caused a high resistance and a higher current through that brushes spring which, is not copper - ergo still higher resistance , which caused the spring to heat up and melted the plastic.

*Barry*

*“Chop’d Liver”*

NJ has taken the next step. They are identifying cars with bad drivers. You will notice some cars with a large red "R" on them. That is to identify the drivers as "R"estricted. Restricted is just a polite way of saying Bad Drivers. Be cautious around them.

On Fri, Nov 1, 2013 at 12:46 AM, <n26390(at)aol.com (n26390(at)aol.com)> wrote:

[quote] Gary: So what is that goo on the right spring that's still in the unit?

Roger Rucker

AA5A '78 HWO

--

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

aa5_driver(at)yahoo.com

Guest

|

Posted: Fri Nov 01, 2013 7:14 am Post subject: MT Props Posted: Fri Nov 01, 2013 7:14 am Post subject: MT Props |

|

|

Barry,

I think you mis read my post. I stated...

"Not knowing what year the tiger is, is it possible that the part is the wrong part number? Could that be the part for a 24 volt system and it is failing with double the amps at 12 volts?"

And you replied...

"But, your synopsis of a 24 Volt system Vs a 12 Volt System is incorrect, you just have things reversed. If you INCREASE the Voltage (Double in this case) you DECREASE the Current (It would draw 1/2 the current in this case). Power (Watts) = I x E

Lets say the system draws 200 Watts | Quote: | 200 Watts / 12 Volts = 16.66 Amps

Now you up the voltage...

200 Watts / 24 Volts = 8.33 Amps"

|

Yes, I know that 24 volts requires half the amps of 12 volts, or inversely, 12 volts takes twice the amps as 24 volts. That is why I asked if it was a 24 volt part being used in a 12 volt system that was causing the failure.

No it's not my plane, but the prop interests me. I'd like to see the mount for the brushes as well as the harness. I'm wondering how much of this is factory parts vs how much is supplied/made by the installer?

Any other ideas? Are any other mt users experiencing this issue?

Kevin

On Nov 1, 2013, at 9:00 AM, FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)> wrote:

[quote]Kevin:

Is this your plane?

I do not have enough pictures and I wish I could check the hardness of the material (Durometer) but yes, there are lots more questions that could come up:

Question: Is this a dual brush system? Meaning two (2) brushes for each side of the connection. In a dual brush system the a single brush is usually chosen to handle 100% of the current Plus a safety margin of 50% more. In this case the individual size of the brush is too small. But therein lies the rub (Hamlet). You would go to a dual brush system because of space and/or cost of a large brush. They did not have the space for a Large one brush system.

There is also the idea of redundancy - If one brush should fail you would want to still have control over the prop.

Ever notice in Motor Designs [look at a good quality electric drill] the Brush Runs Inside a METAL sleeve or Bakelite (not feasible in aircraft due to its brittleness) . This sleeve offers a lower coefficient of friction [Nylon and machined plastics; even Teflon have a very high coefficient of friction] for the sliding brush, an alternate current path, as well as cooling [heatsink] for the brushes. MT lost sight of the requirements.

Getting back to your question Kevin:

Yes, a bad ground or any bad connection in the MT system could cause high current.

To answer a question before asked: Shouldn't the CARBON of the brush help lower the coefficient of friction? YES, to some extent but the friction will wear away the carbon as well.

But, your synopsis of a 24 Volt system Vs a 12 Volt System is incorrect, you just have things reversed. If you INCREASE the Voltage (Double in this case) you DECREASE the Current (It would draw 1/2 the current in this case).

Power (Watts) = I x E

Lets say the system draws 200 Watts

200 Watts / 12 Volts = 16.66 Amps

Now you up the voltage...

200 Watts / 24 Volts = 8.33 Amps

I just had an appfinity - What if you installed an AMMETER in the circuit. You should be able to monitor the condition of the brushes. As the brushes deteriorate the current would go up. Set a Delta for how much is acceptable and of course if a brush totally fails the current would jump.

Gary - Being there is such a short life cycle [MTBF], this sure sounds like AD material and a phone call to MT is in order.

*Barry*

*“Chop’d Liver”*

NJ has taken the next step. They are identifying cars with bad drivers. You will notice some cars with a large red "R" on them. That is to identify the drivers as "R"estricted. Restricted is just a polite way of saying Bad Drivers. Be cautious around them.

On Fri, Nov 1, 2013 at 7:04 AM, Airport Bum <aa5_driver(at)yahoo.com (aa5_driver(at)yahoo.com)> wrote:

[quote] Barry,

You may have shed some light on the issue. Not knowing what year the tiger is, is it possible that the part is the wrong part number? Could that be the part for a 24 volt system and it is failing with double the amps at 12 volts? I don't recall this failure being discussed previously by any of those with the mt. Also wondering if there could be a ground issue (bad ground) in the circuit somewhere causing resistance which is causing a heat build up in this part?

Kevin

On Nov 1, 2013, at 3:49 AM, FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)> wrote:

[quote] Melted Block, Roger.

MT chose the wrong material for the the insulation block. AND they did not use a large enough brush system. One brush failed, guessing here, probably by the copper braid loosing connection. This caused a high resistance and a higher current through that brushes spring which, is not copper - ergo still higher resistance , which caused the spring to heat up and melted the plastic.

*Barry*

*“Chop’d Liver”*

NJ has taken the next step. They are identifying cars with bad drivers. You will notice some cars with a large red "R" on them. That is to identify the drivers as "R"estricted. Restricted is just a polite way of saying Bad Drivers. Be cautious around them.

On Fri, Nov 1, 2013 at 12:46 AM, <n26390(at)aol.com (n26390(at)aol.com)> wrote:

[quote] Gary: So what is that goo on the right spring that's still in the unit?

Roger Rucker

AA5A '78 HWO

--

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Fri Nov 01, 2013 7:29 am Post subject: MT Props Posted: Fri Nov 01, 2013 7:29 am Post subject: MT Props |

|

|

Kevin:

Yes, I did misread your point. Looking back at it I doubt that there would

be two different parts for this operation. If the 12 V part was designed

properly handling the higher voltage and lower current for a 24 V part

would be easy. The 12 V system would be the worse case scenario, so 24 V

would be easy. In addition, nobody wants to carry double the inventory if

not needed.

Home made parts for this operation - I doubt it. You can read part numbers

on this brush block. We can't see elsewhere in the system though, Gary

will have to comment on that.

AND - I doubt if Gary would allow homemade parts.

*Barry*

*“Chop’d Liver”*

NJ has taken the next step. They are identifying cars with bad drivers.

You will notice some cars with a large red "R" on them. That is to

identify the drivers as "R"estricted. Restricted is just a polite way of

saying Bad Drivers. Be cautious around them.

On Fri, Nov 1, 2013 at 11:13 AM, Airport Bum <aa5_driver(at)yahoo.com> wrote:

[quote] Barry,

I think you mis read my post. I stated...

"Not knowing what year the tiger is, is it possible that the part is the

wrong part number? Could that be the part for a 24 volt system and it is

failing with double the amps at 12 volts?"

And you replied...

"But, your synopsis of a 24 Volt system Vs a 12 Volt System is incorrect,

you just have things reversed. If you INCREASE the Voltage (Double in this

case) you DECREASE the Current (It would draw 1/2 the current in this

case). Power (Watts) = I x E

Lets say the system draws 200 Watts

200 Watts / 12 Volts = 16.66 Amps

Now you up the voltage...

200 Watts / 24 Volts = 8.33 Amps"

Yes, I know that 24 volts requires half the amps of 12 volts, or

inversely, 12 volts takes twice the amps as 24 volts. That is why I asked

if it was a 24 volt part being used in a 12 volt system that was causing

the failure.

No it's not my plane, but the prop interests me. I'd like to see the

mount for the brushes as well as the harness. I'm wondering how much of

this is factory parts vs how much is supplied/made by the installer?

Any other ideas? Are any other mt users experiencing this issue?

Kevin

On Nov 1, 2013, at 9:00 AM, FLYaDIVE <flyadive(at)gmail.com> wrote:

Kevin:

Is this your plane?

I do not have enough pictures and I wish I could check the hardness of the

material (Durometer) but yes, there are lots more questions that could come

up:

Question: Is this a dual brush system? Meaning two (2) brushes for each

side of the connection. In a dual brush system the a single brush is

usually chosen to handle 100% of the current Plus a safety margin of 50%

more. In this case the individual size of the brush is too small. But

therein lies the rub (Hamlet). You would go to a dual brush system because

of space and/or cost of a large brush. They did not have the space for a

Large one brush system.

There is also the idea of redundancy - If one brush should fail you would

want to still have control over the prop.

Ever notice in Motor Designs [look at a good quality electric drill] the

Brush Runs Inside a METAL sleeve or Bakelite (not feasible in aircraft due

to its brittleness) . This sleeve offers a lower coefficient of friction

[Nylon and machined plastics; even Teflon have a very high coefficient of

friction] for the sliding brush, an alternate current path, as well as

cooling [heatsink] for the brushes. MT lost sight of the requirements.

Getting back to your question Kevin:

Yes, a bad ground or any bad connection in the MT system could cause high

current.

To answer a question before asked: Shouldn't the CARBON of the brush help

lower the coefficient of friction? YES, to some extent but the friction

will wear away the carbon as well.

But, your synopsis of a 24 Volt system Vs a 12 Volt System is incorrect,

you just have things reversed. If you INCREASE the Voltage (Double in this

case) you DECREASE the Current (It would draw 1/2 the current in this

case).

Power (Watts) = I x E

Lets say the system draws 200 Watts

200 Watts / 12 Volts = 16.66 Amps

Now you up the voltage...

200 Watts / 24 Volts = 8.33 Amps

I just had an appfinity - What if you installed an AMMETER in the circuit

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

aa5_driver(at)yahoo.com

Guest

|

Posted: Fri Nov 01, 2013 7:53 am Post subject: MT Props Posted: Fri Nov 01, 2013 7:53 am Post subject: MT Props |

|

|

I'm not claiming anyone used home made parts, just trying to determine how much of the system is factory complete and, where, if any place can installer error be injected. We're all human and make mistakes, heck I made one once..... . .

I'd like to think your right about there being only one part, but still feel the need to ask. I've not seen any install material from mt, so I don't know what they supply and what is required of the installer to complete the install. There is some issue here, and apparently the cause is not readily ascertainable to Gary or the rest of us at this point. I'd be curious to know what kind of resistance the circuit has. Without photos, documentation, or first hand knowledge, one has to ask questions to gain understanding.

Gary makes homemade parts all the time, and they are usually pretty good parts.

I'd still like to know if others are having this issue? What, if any, variables exist from this install to others that may not have the same issue.

Kevin

On Nov 1, 2013, at 10:28 AM, FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)> wrote:

[quote]Kevin:

Yes, I did misread your point. Looking back at it I doubt that there would be two different parts for this operation. If the 12 V part was designed properly handling the higher voltage and lower current for a 24 V part would be easy. The 12 V system would be the worse case scenario, so 24 V would be easy. In addition, nobody wants to carry double the inventory if not needed.

Home made parts for this operation - I doubt it. You can read part numbers on this brush block. We can't see elsewhere in the system though, Gary will have to comment on that.

AND - I doubt if Gary would allow homemade parts.

*Barry*

*“Chop’d Liver”*

NJ has taken the next step. They are identifying cars with bad drivers. You will notice some cars with a large red "R" on them. That is to identify the drivers as "R"estricted. Restricted is just a polite way of saying Bad Drivers. Be cautious around them.

On Fri, Nov 1, 2013 at 11:13 AM, Airport Bum <aa5_driver(at)yahoo.com (aa5_driver(at)yahoo.com)> wrote:

[quote]

Barry,

I think you mis read my post. I stated...

"Not knowing what year the tiger is, is it possible that the part is the wrong part number? Could that be the part for a 24 volt system and it is failing with double the amps at 12 volts?"

And you replied...

"But, your synopsis of a 24 Volt system Vs a 12 Volt System is incorrect, you just have things reversed. If you INCREASE the Voltage (Double in this case) you DECREASE the Current (It would draw 1/2 the current in this case). Power (Watts) = I x E

Lets say the system draws 200 Watts | Quote: | 200 Watts / 12 Volts = 16.66 Amps

Now you up the voltage...

200 Watts / 24 Volts = 8.33 Amps"

|

Yes, I know that 24 volts requires half the amps of 12 volts, or inversely, 12 volts takes twice the amps as 24 volts. That is why I asked if it was a 24 volt part being used in a 12 volt system that was causing the failure.

No it's not my plane, but the prop interests me. I'd like to see the mount for the brushes as well as the harness. I'm wondering how much of this is factory parts vs how much is supplied/made by the installer?

Any other ideas? Are any other mt users experiencing this issue?

Kevin

On Nov 1, 2013, at 9:00 AM, FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)> wrote:

[quote]Kevin:

Is this your plane?

I do not have enough pictures and I wish I could check the hardness of the material (Durometer) but yes, there are lots more questions that could come up:

Question: Is this a dual brush system? Meaning two (2) brushes for each side of the connection. In a dual brush system the a single brush is usually chosen to handle 100% of the current Plus a safety margin of 50% more. In this case the individual size of the brush is too small. But therein lies the rub (Hamlet). You would go to a dual brush system because of space and/or cost of a large brush. They did not have the space for a Large one brush system.

There is also the idea of redundancy - If one brush should fail you would want to still have control over the prop.

Ever notice in Motor Designs [look at a good quality electric drill] the Brush Runs Inside a METAL sleeve or Bakelite (not feasible in aircraft due to its brittleness) . This sleeve offers a lower coefficient of friction [Nylon and machined plastics; even Teflon have a very high coefficient of friction] for the sliding brush, an alternate current path, as well as cooling [heatsink] for the brushes. MT lost sight of the requirements.

Getting back to your question Kevin:

Yes, a bad ground or any bad connection in the MT system could cause high current.

To answer a question before asked: Shouldn't the CARBON of the brush help lower the coefficient of friction? YES, to some extent but the friction will wear away the carbon as well.

But, your synopsis of a 24 Volt system Vs a 12 Volt System is incorrect, you just have things reversed. If you INCREASE the Voltage (Double in this case) you DECREASE the Current (It would draw 1/2 the current in this case).

Power (Watts) = I x E

Lets say the system draws 200 Watts

200 Watts / 12 Volts = 16.66 Amps

Now you up the voltage...

200 Watts / 24 Volts = 8.33 Amps

I just had an appfinity - What if you installed an AMMETER in the circuit. You should be able to monitor the condition of the brushes. As the brushes deteriorate the current would go up. Set a Delta for how much is acceptable and of course if a brush totally fails the current would jump.

Gary - Being there is such a short life cycle [MTBF], this sure sounds like AD material and a phone call to MT is in order.

*Barry*

*“Chop’d Liver”*

NJ has taken the next step. They are identifying cars with bad drivers. You will notice some cars with a large red "R" on them. That is to identify the drivers as "R"estricted. Restricted is just a polite way of saying Bad Drivers. Be cautious around them.

On Fri, Nov 1, 2013 at 7:04 AM, Airport Bum <aa5_driver(at)yahoo.com (aa5_driver(at)yahoo.com)> wrote:

[quote] Barry,

You may have shed some light on the issue. Not knowing what year the tiger is, is it possible that the part is the wrong part number? Could that be the part for a 24 volt system and it is failing with double the amps at 12 volts? I don't recall this failure being discussed previously by any of those with the mt. Also wondering if there could be a ground issue (bad ground) in the circuit somewhere causing resistance which is causing a heat build up in this part?

Kevin

On Nov 1, 2013, at 3:49 AM, FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)> wrote:

[quote] Melted Block, Roger.

MT chose the wrong material for the the insulation block. AND they did not use a large enough brush system. One brush failed, guessing here, probably by the copper braid loosing connection. This caused a high resistance and a higher current through that brushes spring which, is not copper - ergo still higher resistance , which caused the spring to heat up and melted the plastic.

*Barry*

*“Chop’d Liver”*

NJ has taken the next step. They are identifying cars with bad drivers. You will notice some cars with a large red "R" on them. That is to identify the drivers as "R"estricted. Restricted is just a polite way of saying Bad Drivers. Be cautious around them.

On Fri, Nov 1, 2013 at 12:46 AM, <n26390(at)aol.com (n26390(at)aol.com)> wrote:

[quote] Gary: So what is that goo on the right spring that's still in the unit?

Roger Rucker

AA5A '78 HWO

--

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

teamgrumman(at)yahoo.com

Guest

|

Posted: Fri Nov 01, 2013 4:26 pm Post subject: MT Props Posted: Fri Nov 01, 2013 4:26 pm Post subject: MT Props |

|

|

It melted

On Thursday, October 31, 2013 9:51 PM, "n26390(at)AOL.COM" <n26390(at)AOL.COM> wrote:

Gary: So what is that goo on the right spring that's still in the unit?

Roger Rucker AA5A '78 HWO

--

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|