|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

jluckey(at)pacbell.net

Guest

|

Posted: Tue Nov 05, 2013 4:55 pm Post subject: Bussing W58 Series Breakers Posted: Tue Nov 05, 2013 4:55 pm Post subject: Bussing W58 Series Breakers |

|

|

Does anyone have a picture showing a row of W58 series (reset-only) circuit breakers w/ .250 quick connect terminals and how the feed side was bussed?

I can see using several quick connect terminals jumpered together but i'm curious about other more elegant solutions.

TIA

-Jeff

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

rene(at)felker.com

Guest

|

Posted: Tue Nov 05, 2013 5:17 pm Post subject: Bussing W58 Series Breakers Posted: Tue Nov 05, 2013 5:17 pm Post subject: Bussing W58 Series Breakers |

|

|

No pictures…but copper bus bar across the terminals.

Rene' Felker

N423CF

801-721-6080

From: owner-aeroelectric-list-server(at)matronics.com [mailto:owner-aeroelectric-list-server(at)matronics.com] On Behalf Of Jeff Luckey

Sent: Tuesday, November 05, 2013 7:54 PM

To: aeroelectric-list(at)matronics.com

Subject: Bussing W58 Series Breakers

Does anyone have a picture showing a row of W58 series (reset-only) circuit breakers w/ .250 quick connect terminals and how the feed side was bussed?

I can see using several quick connect terminals jumpered together but i'm curious about other more elegant solutions.

TIA

-Jeff

0123456789012345678

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue Nov 05, 2013 8:53 pm Post subject: Bussing W58 Series Breakers Posted: Tue Nov 05, 2013 8:53 pm Post subject: Bussing W58 Series Breakers |

|

|

At 06:53 PM 11/5/2013, you wrote:

| Quote: | Does anyone have a picture showing a row of W58 series (reset-only) circuit breakers w/ .250 quick connect terminals and how the feed side was bussed?

I can see using several quick connect terminals jumpered together but i'm curious about other more elegant solutions.

|

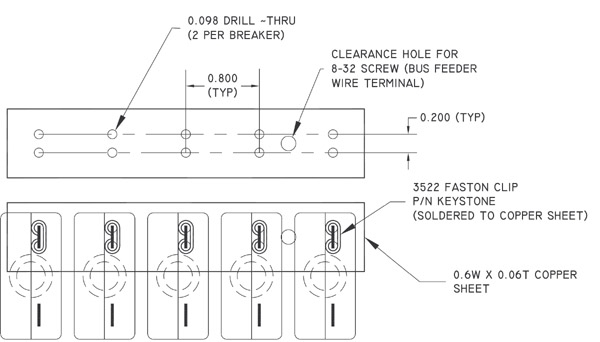

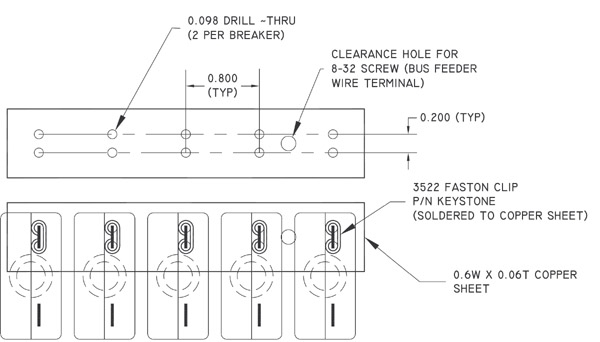

Keystone electronics makes a .250 wide

faston socket for use on etched circuit

boards. A bus-board could be fabricated

to accept a row of these clips spaced at

what ever matches your breaker layout.

[img]cid:7.1.0.9.0.20131105224658.01f16878(at)aeroelectric.com.0[/img]

This would make a very low parts count

bus-bar for fast-on tabbed breakers.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

27.83 KB |

| Viewed: |

10474 Time(s) |

|

|

|

| Back to top |

|

|

uuccio(at)gmail.com

Guest

|

Posted: Tue Nov 05, 2013 9:46 pm Post subject: Bussing W58 Series Breakers Posted: Tue Nov 05, 2013 9:46 pm Post subject: Bussing W58 Series Breakers |

|

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jluckey(at)pacbell.net

Guest

|

Posted: Wed Nov 06, 2013 11:50 am Post subject: Bussing W58 Series Breakers Posted: Wed Nov 06, 2013 11:50 am Post subject: Bussing W58 Series Breakers |

|

|

Now, why didn't I think of that???

I may have a few of those clips left over from a previous project. Don't even need a circuit board, I could simply solder them to a brass strip to form a buss.

Thx Bob,

-Jeff

From: "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com>

To: aeroelectric-list(at)matronics.com

Sent: Tuesday, November 5, 2013 8:53 PM

Subject: Re: Bussing W58 Series Breakers

At 06:53 PM 11/5/2013, you wrote:

| Quote: | Does anyone have a picture showing a row of W58 series (reset-only) circuit breakers w/ .250 quick connect terminals and how the feed side was bussed?

I can see using several quick connect terminals jumpered together but i'm curious about other more elegant solutions.

|

Keystone electronics makes a .250 wide

faston socket for use on etched circuit

boards. A bus-board could be fabricated

to accept a row of these clips spaced at

what ever matches your breaker layout.

[img]cid:1.1028564332(at)web184904.mail.gq1.yahoo.com[/img]

This would make a very low parts count

bus-bar for fast-on tabbed breakers.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

27.83 KB |

| Viewed: |

10467 Time(s) |

|

|

|

| Back to top |

|

|

uuccio(at)gmail.com

Guest

|

Posted: Wed Nov 06, 2013 12:10 pm Post subject: Bussing W58 Series Breakers Posted: Wed Nov 06, 2013 12:10 pm Post subject: Bussing W58 Series Breakers |

|

|

I think I’d like to give that a go too when I upgrade my current wiring… Can a circuit board carry enough current though? The copper layers don’t look very thick. On the other hand, the brass strips that are found in home electrical stores seem a bit oversized to the task.

Now, why didn't I think of that???

I may have a few of those clips left over from a previous project. Don't even need a circuit board, I could simply solder them to a brass strip to form a buss.

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

mrspudandcompany(at)veriz

Guest

|

Posted: Wed Nov 06, 2013 12:44 pm Post subject: Bussing W58 Series Breakers Posted: Wed Nov 06, 2013 12:44 pm Post subject: Bussing W58 Series Breakers |

|

|

| Quote: |

Can a circuit board carry enough current though? The copper layers donít look very thick. On the other hand, the brass strips that are found in home electrical stores seem a bit oversized to the task.

| Quote: | Something I have found that works great is soft copper tubing.† You can purchase by the foot at your local hardware store. Take a 1/4" diameter piece and flatten gently with a hammer and it makes a great bus bar. If you want to attach it to the CB's with screws you can drill holes and screw it on or solder if you prefer. a similar method makes a nice forrest of tabs for grounding.

Roger

|

|

I am using the Free version of SPAMfighter.SPAMfighter has removed 1371 of my spam emails to date.Do you have a slow PC? Try a free scan! [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Nov 06, 2013 3:58 pm Post subject: Bussing W58 Series Breakers Posted: Wed Nov 06, 2013 3:58 pm Post subject: Bussing W58 Series Breakers |

|

|

At 06:53 PM 11/5/2013, you wrote:

Does anyone have a picture showing a row of W58 series (reset-only) circuit breakers w/ .250 quick connect terminals and how the feed side was bussed?

I can see using several quick connect terminals jumpered together but i'm curious about other more elegant solutions.

Keystone electronics makes a .250 wide

FastOn socket for use on etched circuit

boards. A bus-board could be fabricated

to accept a row of these clips spaced at

what ever matches your breaker layout.

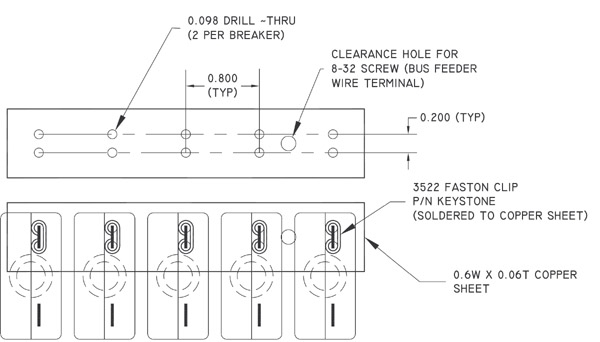

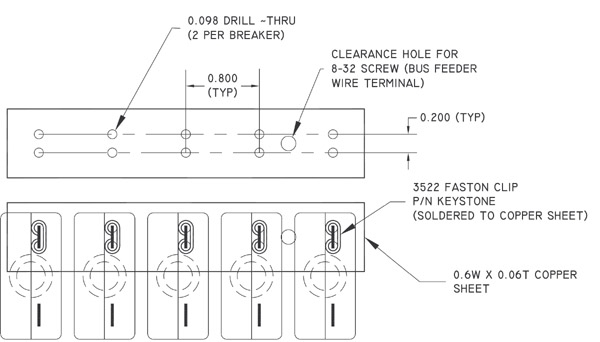

If you're really handy with sheet metal and

getting rows of holes accurately located, you

could fabricate from scratch . . .

[img]cid:.0[/img]

Suggest you not try to bus more than 5 breakers

at once. The finished bus-bar needs to press-on/

pry-off of n-terminals all at once. Unless

I could locate the holes on a digitally indicated

milling machine, I'd probably go the etched

circuit board route. $60 will get you 3 boards

5 breakers long that can be sheared into 3

bus bars each. Enough material with precisely

located holes to neatly tie 45 breakers together

in groups of up to 5.

Have you bought the breakers? They are available

in screw terminal versions . . .

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

65.46 KB |

| Viewed: |

10463 Time(s) |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Nov 06, 2013 5:30 pm Post subject: Bussing W58 Series Breakers Posted: Wed Nov 06, 2013 5:30 pm Post subject: Bussing W58 Series Breakers |

|

|

At 02:09 PM 11/6/2013, you wrote:

| Quote: | I think Iíd like to give that a go too when I

upgrade my current wiringÖ Can a circuit board

carry enough current though? The copper layers

donít look very thick. On the other hand, the

brass strips that are found in home electrical

stores seem a bit oversized to the task.

|

Yes, the number of breakers that can be fed

from one piece of double sided board won't

overheat it. You also connect the feeder

wire as close as practical to the center

so that copper clad is only 'feeding'

two breakers.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Nov 06, 2013 5:32 pm Post subject: Bussing W58 Series Breakers Posted: Wed Nov 06, 2013 5:32 pm Post subject: Bussing W58 Series Breakers |

|

|

At 01:49 PM 11/6/2013, you wrote:

| Quote: | Now, why didn't I think of that???

I may have a few of those clips left over from a previous project.

Don't even need a circuit board, I could simply solder them to a

brass strip to form a buss.

|

yes. you need to fixture them to be

VERY well aligned before soldering.

Normal to the buss surface and no

twisting of the breaker terminal.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jluckey(at)pacbell.net

Guest

|

Posted: Wed Nov 06, 2013 6:30 pm Post subject: Bussing W58 Series Breakers Posted: Wed Nov 06, 2013 6:30 pm Post subject: Bussing W58 Series Breakers |

|

|

The nice thing about using 3 or 4 insulated quick connect terminals

like this:

jumped together is that it makes the buss well insulated. There would be no exposed B+ or metal bar. (For the purposes of this discussion lets call this a "jumper buss")

With a buss bar like the one shown below we lose that insulation -- also could be difficult to work with for several reasons: difficult to pry on and off, easily bend brass bar or break circuit board, etc.

What are the problems, issues, cons of a "jumper buss"?

-Jeff

From: "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com>

To: aeroelectric-list(at)matronics.com

Sent: Wednesday, November 6, 2013 2:07 PM

Subject: Re: Bussing W58 Series Breakers

At 06:53 PM 11/5/2013, you wrote:

Does anyone have a picture showing a row of W58 series (reset-only) circuit breakers w/ .250 quick connect terminals and how the feed side was bussed?

I can see using several quick connect terminals jumpered together but i'm curious about other more elegant solutions.

Keystone electronics makes a .250 wide

FastOn socket for use on etched circuit

boards. A bus-board could be fabricated

to accept a row of these clips spaced at

what ever matches your breaker layout.

If you're really handy with sheet metal and

getting rows of holes accurately located, you

could fabricate from scratch . . .

[img]cid:1.1031637242(at)web184906.mail.gq1.yahoo.com[/img]

Suggest you not try to bus more than 5 breakers

at once. The finished bus-bar needs to press-on/

pry-off of n-terminals all at once. Unless

I could locate the holes on a digitally indicated

milling machine, I'd probably go the etched

† circuit board route. $60 will get you 3 boards

5 breakers long that can be sheared into 3

bus bars each. Enough material with precisely

located holes to neatly tie 45 breakers together

in groups of up to 5.

Have you bought the breakers? They are available

in screw terminal versions . . .

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

65.46 KB |

| Viewed: |

10460 Time(s) |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Nov 06, 2013 7:07 pm Post subject: Bussing W58 Series Breakers Posted: Wed Nov 06, 2013 7:07 pm Post subject: Bussing W58 Series Breakers |

|

|

At 08:29 PM 11/6/2013, you wrote:

| Quote: | The nice thing about using 3 or 4 insulated quick connect terminals

like this:

jumped together is that it makes the buss well insulated. There would be no exposed B+ or metal bar. (For the purposes of this discussion lets call this a "jumper buss")

With a buss bar like the one shown below we lose that insulation -- also could be difficult to work with for several reasons: difficult to pry on and off, easily bend brass bar or break circuit board, etc.

What are the problems, issues, cons of a "jumper buss"? |

Technically not a 'buss' due to the

daisy chain of serial connections . . .

but lots of those breakers have

been wired that way. Probably not

high risk . . . but what's wrong

with a nice fuse-block?

Bob . . . [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jay(at)horriblehyde.com

Guest

|

Posted: Thu Nov 07, 2013 2:28 am Post subject: Bussing W58 Series Breakers Posted: Thu Nov 07, 2013 2:28 am Post subject: Bussing W58 Series Breakers |

|

|

I do the same, however, the copper tube (I use the stuff that is used as

water pipes in houses) is hard drawn and slightly brittle. To get around

that I use a small blowtorch to heat it up until it glows red hot and then

let it cool in air. That anneals it and makes it softer and more resistant

to cracking and easier to form- like when you flatten it.

Jay

From: owner-aeroelectric-list-server(at)matronics.com

[mailto:owner-aeroelectric-list-server(at)matronics.com] On Behalf Of R. curtis

Sent: 06 November 2013 10:43 PM

To: aeroelectric-list(at)matronics.com

Subject: Re: Bussing W58 Series Breakers

Can a circuit board carry enough current though? The copper layers don't

look very thick. On the other hand, the brass strips that are found in

home electrical stores seem a bit oversized to the task.

Something I have found that works great is soft copper tubing. You can

purchase by the foot at your local hardware store. Take a 1/4" diameter

piece and flatten gently with a hammer and it makes a great bus bar. If you

want to attach it to the CB's with screws you can drill holes and screw it

on or solder if you prefer. a similar method makes a nice forrest of tabs

for grounding.

Roger

_____

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

bob.verwey(at)gmail.com

Guest

|

Posted: Thu Nov 07, 2013 2:39 am Post subject: Bussing W58 Series Breakers Posted: Thu Nov 07, 2013 2:39 am Post subject: Bussing W58 Series Breakers |

|

|

C'mon guys, you can buy copper strip cut to size, and save yourself a lot of hassle. Plus it looks better!

Best...

Bob Verwey

IO 470 †A35 †ZU-DLW

On 7 November 2013 12:27, Jay Hyde <jay(at)horriblehyde.com (jay(at)horriblehyde.com)> wrote:

[quote]

I do the same, however, the copper tube (I use the stuff that is used as water pipes in houses) is hard drawn and slightly brittle.† To get around that I use a small blowtorch to heat it up until it glows red hot and then let it cool in air.† That anneals it and makes it softer and more resistant to cracking and easier to form- like when you flatten it.

†

Jay

†

†

From: owner-aeroelectric-list-server(at)matronics.com (owner-aeroelectric-list-server(at)matronics.com) [mailto:owner-aeroelectric-list-server(at)matronics.com (owner-aeroelectric-list-server(at)matronics.com)] On Behalf Of R. curtis

Sent: 06 November 2013 10:43 PM

To: aeroelectric-list(at)matronics.com (aeroelectric-list(at)matronics.com)

Subject: Re: Bussing W58 Series Breakers

†

†

| Quote: |

†

†Can a circuit board carry enough current though? The copper layers donít look very thick. ††On the other hand, the brass strips that are found in home electrical stores seem a bit oversized to the task.

† | Quote: |

Something I have found that works great is soft copper tubing.† You can purchase by the foot at your local hardware store.† Take a 1/4" diameter piece and flatten gently with a hammer and it makes a great bus bar.† If you want to attach it to the CB's with screws you can drill holes and screw it on or solder if you prefer.† a similar method makes a nice forrest of tabs for grounding.

†

Roger

|

|

†

I am using the Free version of SPAMfighter.

SPAMfighter href="http://www.spamfighter.com/SLOW-PCfighter?cid=sigen">slow PC? Try a free scan! 012 34 5 67 8901234 5678 9

0

[b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Nov 07, 2013 6:37 am Post subject: Bussing W58 Series Breakers Posted: Thu Nov 07, 2013 6:37 am Post subject: Bussing W58 Series Breakers |

|

|

At 04:38 AM 11/7/2013, you wrote:

| Quote: | C'mon guys, you can buy copper strip cut to size, and save yourself a lot of hassle. Plus it looks better!

|

I'll second that but with foundations in physics. Review

the articles on our website that cite the term "gas tight"

http://tinyurl.com/mjjl9dt

I'll remind Listers that connectivity-magic happens

when two conductors are held together with such force

and rigidity across compliant surfaces that (1) ingress

of moisture laden air and (2) relative motion between

conductors is prevented.

This design goal is the reason why round-wires and

terminals become decidedly un-round under the crush

of a crimped joint -OR- encapsulated in a cocoon of

metal in the soldered joint.

The most problematic joints in a wiring system are

installer-fabricated with poor regard for process.

Threaded fasteners are particularly needful of

attention to details of flatness, force and

rigidity.

This is why the fuse-blocks dropped onto B&C's

counter at OSH turned out to be a kind of

installer's dream for relief of worries about

knowledge and skill sets. First, the metal to

metal joints were minimized. All but the threaded

stud on the end of the assembly are manufactured

for integrity and service life. If the builder

can get a nice flat flag on an AMP terminal

cinched down on a 10-32 stud, probabilities for

very low risk and cost of ownership are good.

The circuit breakers under discussion are

suited to service in appliances and/or systems

were design goals call for protection of a single

feeder. But lining a bunch of them up on a panel

with some notion of bussing their supply terminals

is a mis-application of original design goals.

The technical definition of a buss is a conductive

structure ideally comprised of one piece of

metal from which numerous taps supply power to

various loads in the system with an architecture

that prevents any single failure from propagating

beyond the single feeder. Here's a collection

of pictures for a 'buss and breaker' structure

removed from a legacy Piper airplane . . .

http://tinyurl.com/lmbcm66

http://tinyurl.com/lucl439

http://tinyurl.com/myhmoew

The OBAM aviation builder-sphere is replete

with arguments against religious observation

of legacy design goals, "Well, the guy next

to me in the hanger has been flying this

(you fill in the blank) for years and hasn't

had a bit of trouble."

Given that our art is beginning its second

century of real-life application, there are

constellations of lessons-learned derived

from a distillation of proven recipes for

success re-enforced by understanding of the

physics upon which they're built.

Nobody stands over us with a rule book under

one arm and a citation book under the other . . .

but there ARE folks who we pay to worry that

would be glad to assume that role in our

craft. That event will mark the time when

innovation and exploration of new ideas will

slow to a crawl . . . if not halt completely.

We would do well to expand our understanding of

the arts and science while propagating it to

the greatest number of interested individuals.

There will always be those who don't find

value in this endeavor . . . most will survive

with little more than an elevated cost of

ownership and laundry soap for the underwear.

But a few will become candidates for trial in the Court

of Dark-n-Stormy Nights where the narrator

was not on board the airplane.

The short response is, "buy already mill-flat

materials from which to craft buss bars and

fat-terminal jumpers". It is the exceedingly

rare OBAM aviation shop that can take a round

piece of metal and achieve such flatness.

See: http://tinyurl.com/khymmf3

http://tinyurl.com/leunhah

Bob . . . [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

bbradburry(at)bellsouth.n

Guest

|

Posted: Thu Nov 07, 2013 7:08 am Post subject: Bussing W58 Series Breakers Posted: Thu Nov 07, 2013 7:08 am Post subject: Bussing W58 Series Breakers |

|

|

There seems to be a typo on this ebay site. I don’t think that one cubic inch of copper weighs 4 pounds! ??

http://www.ebay.com/itm/48-oz-1-16-Flat-Copper-Sheet-Plate-4-x-4-/271192124476?pt=LH_DefaultDomain_0&hash=item3f244f6c3c

Bill

From: owner-aeroelectric-list-server(at)matronics.com [mailto:owner-aeroelectric-list-server(at)matronics.com] On Behalf Of Robert L. Nuckolls, III

Sent: Thursday, November 07, 2013 9:36 AM

To: aeroelectric-list(at)matronics.com

Subject: Re: AeroElectric-List: Bussing W58 Series Breakers

At 04:38 AM 11/7/2013, you wrote:

C'mon guys, you can buy copper strip cut to size, and save yourself a lot of hassle. Plus it looks better!

I'll second that but with foundations in physics. Review

the articles on our website that cite the term "gas tight"

http://tinyurl.com/mjjl9dt

I'll remind Listers that connectivity-magic happens

when two conductors are held together with such force

and rigidity across compliant surfaces that (1) ingress

of moisture laden air and (2) relative motion between

conductors is prevented.

This design goal is the reason why round-wires and

terminals become decidedly un-round under the crush

of a crimped joint -OR- encapsulated in a cocoon of

metal in the soldered joint.

The most problematic joints in a wiring system are

installer-fabricated with poor regard for process.

Threaded fasteners are particularly needful of

attention to details of flatness, force and

rigidity.

This is why the fuse-blocks dropped onto B&C's

counter at OSH turned out to be a kind of

installer's dream for relief of worries about

knowledge and skill sets. First, the metal to

metal joints were minimized. All but the threaded

stud on the end of the assembly are manufactured

for integrity and service life. If the builder

can get a nice flat flag on an AMP terminal

cinched down on a 10-32 stud, probabilities for

very low risk and cost of ownership are good.

The circuit breakers under discussion are

suited to service in appliances and/or systems

were design goals call for protection of a single

feeder. But lining a bunch of them up on a panel

with some notion of bussing their supply terminals

is a mis-application of original design goals.

The technical definition of a buss is a conductive

structure ideally comprised of one piece of

metal from which numerous taps supply power to

various loads in the system with an architecture

that prevents any single failure from propagating

beyond the single feeder. Here's a collection

of pictures for a 'buss and breaker' structure

removed from a legacy Piper airplane . . .

http://tinyurl.com/lmbcm66

http://tinyurl.com/lucl439

http://tinyurl.com/myhmoew

The OBAM aviation builder-sphere is replete

with arguments against religious observation

of legacy design goals, "Well, the guy next

to me in the hanger has been flying this

(you fill in the blank) for years and hasn't

had a bit of trouble."

Given that our art is beginning its second

century of real-life application, there are

constellations of lessons-learned derived

from a distillation of proven recipes for

success re-enforced by understanding of the

physics upon which they're built.

Nobody stands over us with a rule book under

one arm and a citation book under the other . . .

but there ARE folks who we pay to worry that

would be glad to assume that role in our

craft. That event will mark the time when

innovation and exploration of new ideas will

slow to a crawl . . . if not halt completely.

We would do well to expand our understanding of

the arts and science while propagating it to

the greatest number of interested individuals.

There will always be those who don't find

value in this endeavor . . . most will survive

with little more than an elevated cost of

ownership and laundry soap for the underwear.

But a few will become candidates for trial in the Court

of Dark-n-Stormy Nights where the narrator

was not on board the airplane.

The short response is, "buy already mill-flat

materials from which to craft buss bars and

fat-terminal jumpers". It is the exceedingly

rare OBAM aviation shop that can take a round

piece of metal and achieve such flatness.

See: http://tinyurl.com/khymmf3

http://tinyurl.com/leunhah

Bob . . . 012345678901234567890

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

wtmills

Joined: 05 Feb 2007

Posts: 32

|

Posted: Thu Nov 07, 2013 9:05 am Post subject: Bussing W58 Series Breakers Posted: Thu Nov 07, 2013 9:05 am Post subject: Bussing W58 Series Breakers |

|

|

I disagree with letting it "cool in air"†unless the alloys of copper water-pipe and spark-plug gaskets differ significantly which I doubt.

As a fledgling A&P in 1973 we were taught to heat copper spark-plug gaskets to "cherry red" and quench immediately in water.

I admit having no experience with allowing the gaskets to cool in air.†

Here's an EAA demo:

http://www.eaavideo.org/video.aspx?v=57437956001

Respectfully -

Bill

SF bay area

†

[quote] On 7 November 2013 12:27, you†

wrote:

| Quote: |

I do the same, however, the copper tube (I use the stuff that is used as water pipes in houses) is hard drawn and slightly brittle.† To get around that I use a small blowtorch to heat it up until it glows red hot and then let it cool in air.† That anneals it and makes it softer and more resistant to cracking and easier to form- like when you flatten it.

|

[b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Nov 07, 2013 9:33 am Post subject: Bussing W58 Series Breakers Posted: Thu Nov 07, 2013 9:33 am Post subject: Bussing W58 Series Breakers |

|

|

At 09:08 AM 11/7/2013, you wrote:

That's an unfortunate citation. In the time

before etched circuit boards, copper was rated/sold

by gage and/or thickness times some dimension

that described area. Then came copper clad ecb

materials where somebody thought it was a good

idea to speak to the thickness of copper not in

terms of thickness but in some new convention

like 'ounces per square foot'.

It's a close cousin to logic that speaks of 'circular

mil area' of a wire. A 10AWG solid wire is 102 mils

in diameter with a real cross section of

3.14 x (.051)^2 = 0.00816 square inches. 10AWG

said to have a CMA of 102^2 or 10,400 'circular

mils'. It's 'handier' to rate current density in

a wire in Amps per CMA . . . it's a discipline

specific vernacular for folks who work with wires

a lot . . . but it bugs a physicist.

The ounces per square foot are easier to measure/verify

than the actual thickness of the copper where

1 ounce per square foot is 1.344 mils.

Copper has a density of 5.168 oz/cu-in. So a

sheet of copper 1" square and ".001344" thick

will have weight of 5.168 x 0.001344 = .006945

oz/sq-in x 144 = 1.000 oz/sq foot.

Getting back to the eBay ad, we have .062"

thick for 0.323 oz/sq-in x 144 = 46.5

oz/sq-ft. Hence the citation for "48 oz"

copper . . . a description that would be

meaningless to guys who do copper gutters

and flashing . . . or buss bars in airplanes.

Bob . . . [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

mrspudandcompany(at)veriz

Guest

|

Posted: Thu Nov 07, 2013 10:33 am Post subject: Bussing W58 Series Breakers Posted: Thu Nov 07, 2013 10:33 am Post subject: Bussing W58 Series Breakers |

|

|

| Quote: | I disagree with letting it "cool in air" unless the alloys of copper water-pipe and spark-plug gaskets differ significantly which I doubt.

| Quote: | Air cooling of the cherry red hot copper will anneal it, however it will anneal to a softer state if you quench the copper in water.

Roger

|

|

I am using the Free version of SPAMfighter.SPAMfighter has removed 1378 of my spam emails to date.Do you have a slow PC? Try a free scan! [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

wtmills

Joined: 05 Feb 2007

Posts: 32

|

Posted: Thu Nov 07, 2013 10:45 am Post subject: Bussing W58 Series Breakers Posted: Thu Nov 07, 2013 10:45 am Post subject: Bussing W58 Series Breakers |

|

|

Thank you for this clarification.

Bill

Do not archive

Sent via the Samsung Galaxy Note¬ģ II, an AT&T 4G LTE smartphone

-------- Original message --------

From: "R. curtis" <mrspudandcompany(at)verizon.net>

Date: 11/07/2013 10:32 AM (GMT-08:00)

To: aeroelectric-list(at)matronics.com

Subject: Re: AeroElectric-List: Bussing W58 Series Breakers

I disagree with letting it "cool in air" unless the alloys of copper water-pipe and spark-plug gaskets differ significantly which I doubt.

Air cooling of the cherry red hot copper will anneal it, however it will anneal to a softer state if you quench the copper in water.

Roger

I am using the Free version of SPAMfighter.

SPAMfighter has removed 1378 of my spam emails to date.

Do you have a slow PC? Try a free scan!

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|