|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

steve.freeman(at)syntaxds

Guest

|

Posted: Mon Dec 23, 2013 9:53 pm Post subject: Question to list Posted: Mon Dec 23, 2013 9:53 pm Post subject: Question to list |

|

|

Hi List,

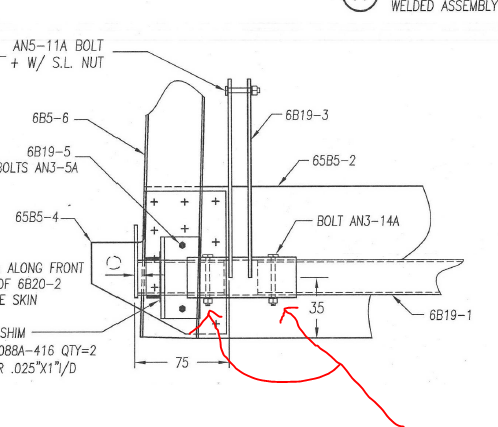

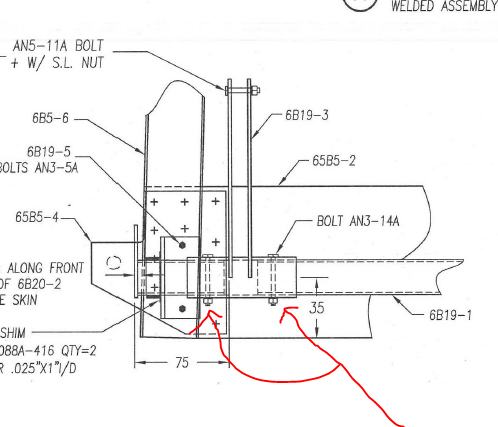

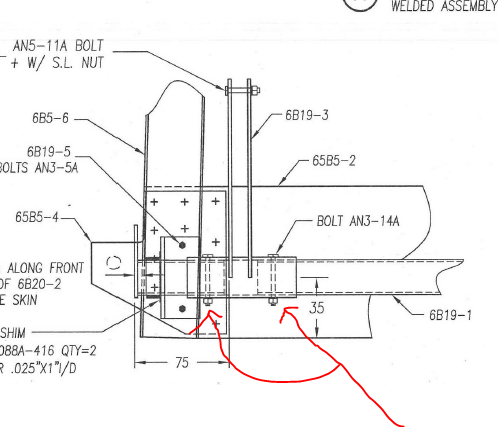

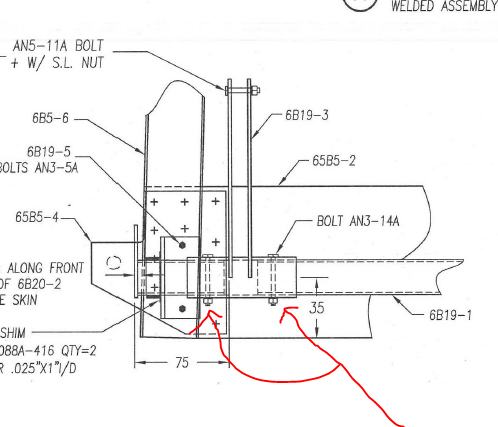

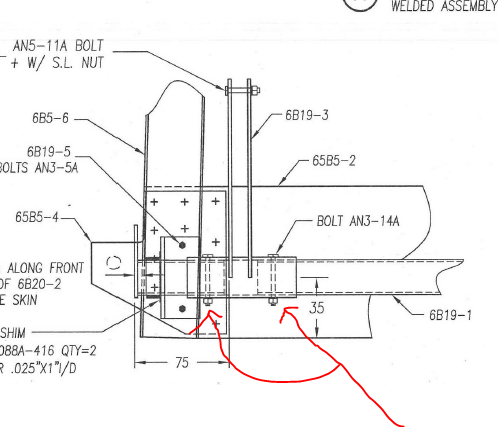

I am getting ready to install my flaps. I have been dreading this because it is one of those things that I fear is really easy to screw up and I am wondering if any of you can offer any advice for how you drilled the torque tube after getting everything lined up where it belongs.

I believe I can figure out how to get the flap in to the right position and secured. But what I am scared of is actually drilling the Torque Tubes and the Flap Control Arm that fits over the Torque Tubes.

Any advice for how any of you did this would be really appreciated.

How did you drill for this location???

[img]cid:image001.png(at)01CF0031.A3F0D2A0[/img]

From: owner-zenith-list-server(at)matronics.com [mailto:owner-zenith-list-server(at)matronics.com] On Behalf Of Carlos Sa

Sent: Thursday, December 19, 2013 6:42 PM

To: zenith-list(at)matronics.com

Subject: today's work

Finished installation of the Hendricks (canopy) latch

More pics here: http://www.zenith.aero/profile/CarlosSa

Carlos

CH601-HD, plans

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

| Description: |

|

| Filesize: |

83.15 KB |

| Viewed: |

6379 Time(s) |

|

|

|

| Back to top |

|

|

jaybannist(at)cs.com

Guest

|

Posted: Tue Dec 24, 2013 6:46 am Post subject: Question to list Posted: Tue Dec 24, 2013 6:46 am Post subject: Question to list |

|

|

Hey Steve, You have a right to be concerned. This one can be booger.

I messed mine up, big time. I thought I had everything lined up and drilled for those bolts. But when I got everything hooked up and tried it out, it was obviously wrong. I had to re-set everything and drill new holes. I had the old style actuator with the microswitches. They somehow limited the flap travel called for and no adjustment of the switches would work. I actually had to design (a real geometry problem) and fabricate an offset extension to the control arm to make everything work right.

My only suggestion would be to leave drilling for those bolts to the very last. Wait until you have everything hooked up and can test the action. Then drill through only the first part of the tube with a #40 drill and cleco (A3). Check the action. If it is OK, drill the tubes all the way. If not, you can re-adjust and do it again. Access for drilling and installing the bolts and nuts is a bitch, so think it through before proceeding.

Good luck -- Jay

[quote][b]

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

ding(at)tbscc.com

Guest

|

Posted: Tue Dec 24, 2013 8:19 am Post subject: Question to list Posted: Tue Dec 24, 2013 8:19 am Post subject: Question to list |

|

|

Steve,

I have the older style flap motor, and also had geometry issues to achieve as much travel as possible. I ended up with 24 degrees, and I'm glad I have all that. It's been very useful with my short field. To achieve this, I had to cut a clearance slot in crossmember 65B5-2 in your picture. My initial positioning was done by drilling 1/8 inch holes in the back side, and using A4 rivits, left side only. This allows testing without much committment. I felt that Clecos would allow too much movement to trust. The right side needs only to match the left, and can be done secondarily. Achieving that little bit of flap twist pressure against the up stop is critical, and the down position is just a matter of getting all you can geometrically. Final drilling for bolts is best done last, by removing the assembly and re-riviting on the bench. I drilled mine vertically as in your picture to get best access to the bolts.

Also, if things don't end up just perfect, as mine didn't, the nylon plate in the end of the flap can be slightly repositioned or replaced as a way to final adjust without the issues of adjusting at the torque tube inside.

Lynn Dingfelder

601XLb 160 hours

Corry, PA

[quote] ---

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

| Description: |

|

| Filesize: |

83.15 KB |

| Viewed: |

6373 Time(s) |

|

|

|

| Back to top |

|

|

paulrod36(at)msn.com

Guest

|

Posted: Tue Dec 24, 2013 11:02 am Post subject: Question to list Posted: Tue Dec 24, 2013 11:02 am Post subject: Question to list |

|

|

<?xml:namespace prefix="v" /><?xml:namespace prefix="o" /><![endif]--> Hi Steve-- I did the whole thing somewhat differently. but it seems to work. For openers, I bought a 12V linear motor from Surplus Parts, for about $70 or so. It had a 4 inch throw, and a 110 pound push, with internal micro switches. Just for grins, I mounted the flaps with clecos, and figured out where I wanted the mtor to be. I mounted it behind the seat top crosspiece, and put the transverse (torque) tube in, along with the flap actuator arms, pins in the holes, etc, everything except the drive arm. I then worked out with a protractor, compass, straight edges and Sharpies, on the table, what it would take for a 4-inch throw to rotate the flaps 40 degrees. Once I figured that out, I fabricated the drive arm to the proper length, (allowing for the pivot point to be at the center of the pipe's interior diameter)and reassembled everything in its proper place. Then, using MASKING TAPE to hold everything together, I checked that full extension would drive the left flap very close to 40 degrees. (Don't make perfect the enemy of good.. As Chris says, it's a garden tractor, not a Space Shuttle) Once happy with the drive, I rolled the right flap down to match the left, and then, after putting match marks on the masking tape, separated the torque tube from the arms with a razor blade. That gave me the distance to overlap the torque tube, and lined up how the arms would be oriented. Then I drilled the arms in place over the tube for an an-3 bolt. Last thing was to repeat the process on the drive arm. Actually, once you have made the proper index marks, you can take it all apart, and drill with a drill press on the bench.

Paul R

[quote] ---

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

| Description: |

|

| Filesize: |

83.15 KB |

| Viewed: |

6371 Time(s) |

|

|

|

| Back to top |

|

|

DaveG601XL

Joined: 27 Oct 2006

Posts: 351

Location: Cincinnati, Oh

|

Posted: Mon Jan 06, 2014 1:51 pm Post subject: Re: Question to list Posted: Mon Jan 06, 2014 1:51 pm Post subject: Re: Question to list |

|

|

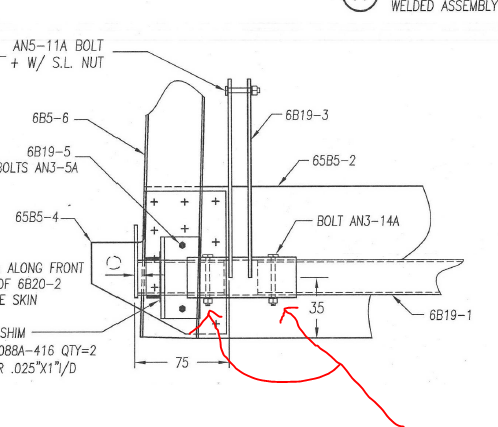

I 2nd Paul's comment on using tape to secure the torque tubes and control arm together. Prior to wing fitting, I taped them together just so I could get all the fuselage portion of the flap control system assembled and actuating. Just a little tape will hold the pieces together quite well. I waited until after the wings were fitted and flaps cleco'd in place to make the final positioning and drilling.

Good luck,

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

| Description: |

|

| Filesize: |

232.34 KB |

| Viewed: |

6308 Time(s) |

|

_________________

David Gallagher

Cincinnati, OH area |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|