|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

rkharr

Joined: 10 Jan 2006

Posts: 12

Location: Columbia, SC

|

Posted: Fri Jan 31, 2014 11:53 am Post subject: Essential Bus question Posted: Fri Jan 31, 2014 11:53 am Post subject: Essential Bus question |

|

|

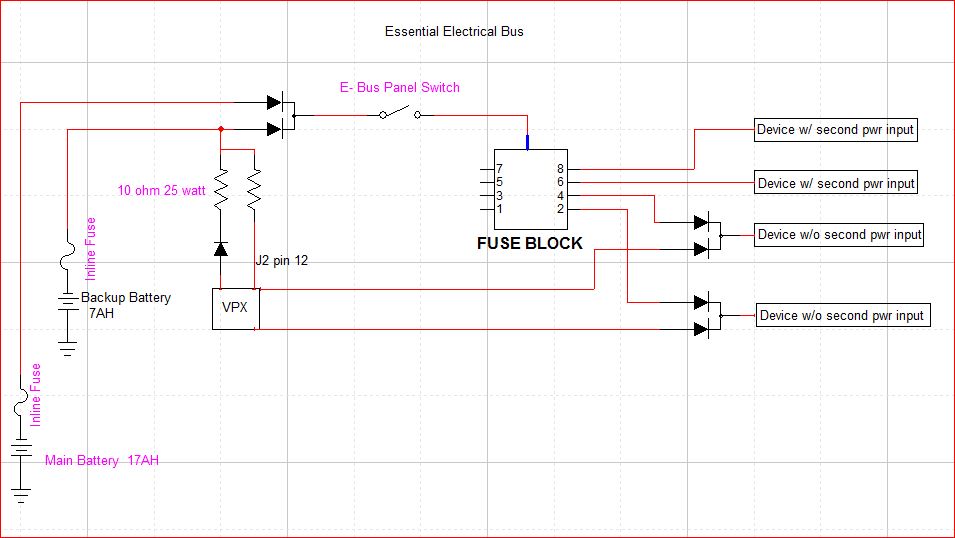

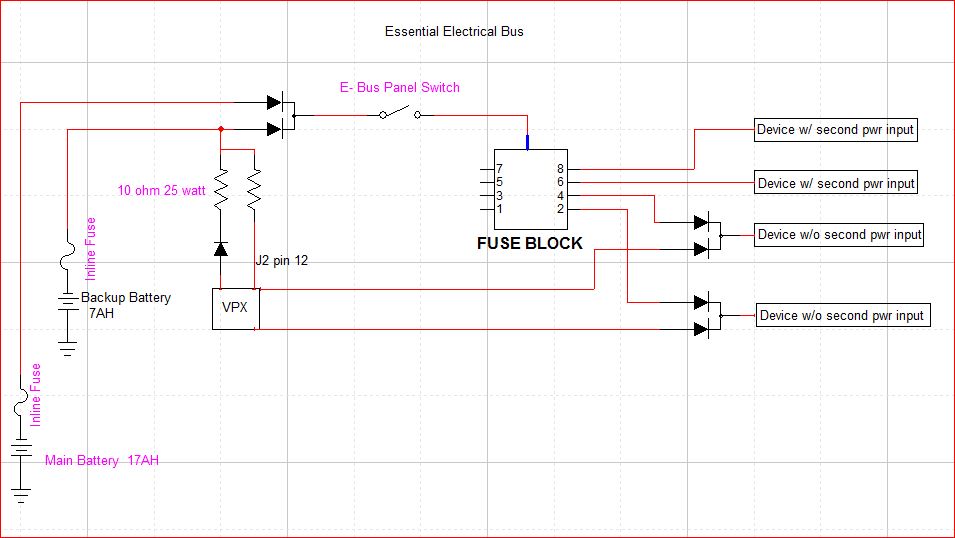

My RV-6 has been flying 12 years now with an electrical system based on the Z diagrams. Now I am assisting my wife complete her RV-7 electrical system. She has chosen to use the VPX Pro unit and wants to incorporate a "backup" source of power for clearances, engine start, and "endurance" (if the VPX box were to quit).

The circuit that we are considering uses a bridge diode that would allow the main battery to supplement the "backup" battery for increased endurance. Since I have not seen this variation before, there must be a "gotcha" that I haven't found. Attached is a picture of the basic circuit. Any suggestions and/or comments would be appreciated.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

72.25 KB |

| Viewed: |

12132 Time(s) |

|

_________________

Ken

RV-6

South Carolina |

|

| Back to top |

|

|

Kellym

Joined: 10 Jan 2006

Posts: 1705

Location: Sun Lakes AZ

|

Posted: Fri Jan 31, 2014 6:27 pm Post subject: Essential Bus question Posted: Fri Jan 31, 2014 6:27 pm Post subject: Essential Bus question |

|

|

My first question would be why add the complexity of a second electrical

system, when virtually all situations can be handled by either backup

battery for EFIS, ship's battery or just plain old magnetos.

On 1/31/2014 12:53 PM, rkharr wrote:

| Quote: |

My RV-6 has been flying 12 years now with an electrical system based on the Z diagrams. Now I am assisting my wife complete her RV-7 electrical system. She has chosen to use the VPX Pro unit and wants to incorporate a "backup" source of power for clearances, engine start, and "endurance" (if the VPX box were to quit).

The circuit that we are considering uses a bridge diode that would allow the main battery to supplement the "backup" battery for increased endurance. Since I have not seen this variation before, there must be a "gotcha" that I haven't found. Attached is a picture of the basic circuit. Any suggestions and/or comments would be appreciated.

--------

Ken

RV-6

South Carolina

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=417953#417953

Attachments:

http://forums.matronics.com//files/essential_bus_237.jpg

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor # 5286

KCHD |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Feb 02, 2014 8:13 am Post subject: Essential Bus question Posted: Sun Feb 02, 2014 8:13 am Post subject: Essential Bus question |

|

|

At 08:25 PM 1/31/2014, you wrote:

My first question would be why add the complexity of a second

electrical system, when virtually all situations . . .

Define "all situations" . . . the term is non-

quantified/qualified. When we're designing a

TC aircraft, EVERY situation needs to be articulated

in the design documents along with the plan-B, C, . . .

or Z that mitigates that situation. Then we have

to go TEST every one of those plans to demonstrate

compliance with design goals.

. . . can be handled by either backup battery for EFIS, ship's

battery or just plain old magnetos.

For OBAM aircraft it's a function of design goals built upon

the pilot's skills, maintenance protocols, airplane capabilities

and anticipated missions. Obviously, the manner in which

one might outfit a Kitfox can depart greatly from the

way you would craft an LAIV-P. At the same time, the

builder of an RV-6 in the Pacific NW (Lots of clouds

all the time) who travels a lot might have a more

sophisticated system than another builder who intends

to use is LAIV only in day VMC but wants the

speed, ability to hop the occasional mountain range

and air conditioning.

This litany of potential "situations" offers

a brief peek into the value of having design

goals synchronized to the end-use.

Production aircraft tend to have cookie-cutter

approaches to system architecture . . . because

the designers can only hypothesize greatest risk

situations for the targeted customer then address

those hypotheses within the framework of the

impediments to creativity imposed by the FARS.

We on the List have a clean sheet of paper

for the beginning of every project. The Z-figures

are intended to offer a sort of "Cliff's Notes"

on architectures that span the spectrum of

possibilities. Some builders have put Z-14

into their 2 place RV's at no small penalty

for cost and weight . . . but find comfort

in not having to go through the very non-

trivial exercise of optimizing their decision.

There ARE LAIV-P aircraft flying with one

battery, one alternator, and backup batteries

sprinkled over the panel and perhaps some

more in the flight bag.

Its unlikely that either builder has tested

available failure response plans against his/her

perceptions of capability in the Plan-B

hardware.

Given the decreasing failure rates of modern

electro-whizzies, it's unlikely that either

of the pilots in the last two examples will

have a 'dark-n-stormy night' story to write

up for Flying Magazine.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Feb 02, 2014 8:42 am Post subject: Essential Bus question Posted: Sun Feb 02, 2014 8:42 am Post subject: Essential Bus question |

|

|

At 01:53 PM 1/31/2014, you wrote:

| Quote: |

My RV-6 has been flying 12 years now with an electrical system based

on the Z diagrams. Now I am assisting my wife complete her RV-7

electrical system. She has chosen to use the VPX Pro unit and wants

to incorporate a "backup" source of power for clearances, engine

start, and "endurance" (if the VPX box were to quit).

|

Okay, you're plagued with the same litany of concerns

that arise from lack of confidence in your present

'vision' for how this system should evolve.

| Quote: |

The circuit that we are considering uses a bridge diode that would

allow the main battery to supplement the "backup" battery for

increased endurance. Since I have not seen this variation before,

there must be a "gotcha" that I haven't found. Attached is a

picture of the basic circuit. Any suggestions and/or comments would

be appreciated.

|

Read through the posting I made a few minutes ago

and then consider a list of design goals that are

based on . . .

(1) How will this airplane be used? Do you

anticipate long legs of travel at night over

unfriendly terrain?

(2) Are you anticipating more than a tiny

percentage of approaches to landing to be

in IMC?

(3) Do you plan to carry the ultimate in

backup reliability in your flight bag?

http://tinyurl.com/d5mrjgh

This is the stuff I recommend for folks like

me who only rent airplanes . . . but if

it were my airplane, those items would still

be with me. In fact, I've not turned on a

VOR or ADF in 15 years . . . nor have I used

a panel mounted GPS . . . but that's another

story.

(4) Are your skill sets going to be honed

to the levels necessary for low risk

implementation of the hardware you plan to install?

It's entirely possible to have an airplane

decked out to the window-sills with goodies

only to have A pilot become the weak link

in the chain.

http://tinyurl.com/kb2zr8m

I've flown with pilots who were quite proud

of all those dials, switches and knobs on

the panel who never flew more IFR than to

keep their ticket current. The greatest

risk for bending their airplane was not

rooted failure of hardware.

Keep in mind that 2x the hardware is 2x

the probability of failure. Got some more

batteries scattered around the airplane

. . . guess what . . . now you're running

a clinic for batteries upon which you believe

you're building a 'dependable' system.

Commodity items like batteries are like house plants.

Just because you have two of them does not mitigate

the need for knowledgeable preventative

maintenance but it DOES double the maintenance

$time$.

So before we spend a lot of time refining

the work-arounds for hypothesized failures,

let's look at the big picture and size the

solutions to realistic risks having the

greatest probability of presentation.

Then you're ready to sift solutions for those

having the lowest cost of ownership, weight

penalties on the aircraft and taxation of

your skill sets.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

tim2542(at)sbcglobal.net

Guest

|

Posted: Sun Feb 02, 2014 9:32 am Post subject: Essential Bus question Posted: Sun Feb 02, 2014 9:32 am Post subject: Essential Bus question |

|

|

I would just add a simple Brown out 7ah Alarm battery/Aux bus charged thru a Schottky diode and maybe a resistor is very simple & cheap to do. A lot of equipment now comes with multiple diode isolated power inputs making it easy.

This allows flight plan entry and clearance requests before start up without draining the main battery, keeps the GPS/NAV/COM and EFIS from rebooting when cranking the engine, and provides maybe 20-30 minutes of extra time to get back on the ground.

Weight/cost is about $35 and 5 lbs. cheaper than a factory backup, which only powers one item.

Tim

| Quote: | On Feb 2, 2014, at 8:39 AM, "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com> wrote:

At 01:53 PM 1/31/2014, you wrote:

>

>

> My RV-6 has been flying 12 years now with an electrical system based on the Z diagrams. Now I am assisting my wife complete her RV-7 electrical system. She has chosen to use the VPX Pro unit and wants to incorporate a "backup" source of power for clearances, engine start, and "endurance" (if the VPX box were to quit).

Okay, you're plagued with the same litany of concerns

that arise from lack of confidence in your present

'vision' for how this system should evolve.

>

> The circuit that we are considering uses a bridge diode that would allow the main battery to supplement the "backup" battery for increased endurance. Since I have not seen this variation before, there must be a "gotcha" that I haven't found. Attached is a picture of the basic circuit. Any suggestions and/or comments would be appreciated.

Read through the posting I made a few minutes ago

and then consider a list of design goals that are

based on . . .

(1) How will this airplane be used? Do you

anticipate long legs of travel at night over

unfriendly terrain?

(2) Are you anticipating more than a tiny

percentage of approaches to landing to be

in IMC?

(3) Do you plan to carry the ultimate in

backup reliability in your flight bag?

http://tinyurl.com/d5mrjgh

This is the stuff I recommend for folks like

me who only rent airplanes . . . but if

it were my airplane, those items would still

be with me. In fact, I've not turned on a

VOR or ADF in 15 years . . . nor have I used

a panel mounted GPS . . . but that's another

story.

(4) Are your skill sets going to be honed

to the levels necessary for low risk

implementation of the hardware you plan to install?

It's entirely possible to have an airplane

decked out to the window-sills with goodies

only to have A pilot become the weak link

in the chain.

http://tinyurl.com/kb2zr8m

I've flown with pilots who were quite proud

of all those dials, switches and knobs on

the panel who never flew more IFR than to

keep their ticket current. The greatest

risk for bending their airplane was not

rooted failure of hardware.

Keep in mind that 2x the hardware is 2x

the probability of failure. Got some more

batteries scattered around the airplane

. . . guess what . . . now you're running

a clinic for batteries upon which you believe

you're building a 'dependable' system.

Commodity items like batteries are like house plants.

Just because you have two of them does not mitigate

the need for knowledgeable preventative

maintenance but it DOES double the maintenance

$time$.

So before we spend a lot of time refining

the work-arounds for hypothesized failures,

let's look at the big picture and size the

solutions to realistic risks having the

greatest probability of presentation.

Then you're ready to sift solutions for those

having the lowest cost of ownership, weight

penalties on the aircraft and taxation of

your skill sets.

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Feb 02, 2014 10:47 am Post subject: Essential Bus question Posted: Sun Feb 02, 2014 10:47 am Post subject: Essential Bus question |

|

|

At 11:31 AM 2/2/2014, you wrote:

| Quote: |

I would just add a simple Brown out 7ah Alarm battery/Aux bus

charged thru a Schottky diode and maybe a resistor is very simple &

cheap to do. A lot of equipment now comes with multiple diode

isolated power inputs making it easy.

This allows flight plan entry and clearance requests before start up

without draining the main battery, keeps the GPS/NAV/COM and EFIS

from rebooting when cranking the engine, and provides maybe 20-30

minutes of extra time to get back on the ground.

Weight/cost is about $35 and 5 lbs. cheaper than a factory backup,

which only powers one item.

Tim

|

Good data points. Let us consider the premises

underlying the evolution of Figure Z-07

http://tinyurl.com/my9u3ud

this shows a two battery/single alternator system

for an electrically dependent engine. This

exercise in 'electron gazing' grew out of Fred's

project already fitted with a EXP-Bus. I could

see a way to accommodate Fred's initial design

goals for two batteries with a simple mod to

the EXP-Bus . . . but I could see an alternative

to Z-19 evolving from the deliberations . . .

hence Z-07.

Off in the distance, I think I see a single-battery

variant of this architecture but that's possible

only after we get real energy requirements data

. . . and further refine the operating philosophy

for the system. Tim's words raise useful questions

that go directly to deliberations for sizing risks

in a single-battery design.

Where is it written or demonstrated that having

the ship's processors 'reboot' is a bad thing?

Under what operating scenarios is it useful/necessary

minimize the time between the glass being awake

and reaching the end of the runway just prior

to engine run-up?

I recall some stories about the Blue-Mountain

systems (hard drives?) taking perhaps 90

seconds to wake up . . . but when was the

last time you were ready to check mags less

than, say 3-4 minutes after engine startup?

I've reviewed as many of the airports I've

visited that I can remember. I cannot recall

any departure where engine run-up was accomplished

for before the oil was warmed up a bit and I

had taxied from parking to the run-up stand,

certainly 4 minutes, sometimes 10. I think

it took 15 minutes to get out of KCI once.

. . . the check list belongs to YOU . . . you

can adjust sequences of events to fit hardware.

Let us consider "draining the main battery"

for the purposes of gathering the ATIS data

and getting a clearance delivery. Suppose the

e-bus runs 5A and the exercise takes 3 minutes.

12v x 5a x 60s x 3m = 10,800 watt-seconds.

Cranking the engine 12v x 200a x 10s = 24,000

watt-seconds. What does the battery hold?

12v x 5a x 60s x 120m = 432,000 watt-seconds.

Okay, you used up 34,800 watt-seconds before

the engine was lit for 35K/432K or 8 percent

of the battery's capacity. If you're targeting

80% of new capacity for banishing your battery

to kiddie-car duty, then the last flight

will tax the battery to 10% of available

capacity.

The above analysis is a first order estimate

and does not take into account vagaries of

temperature and internal impedances of the

battery but it's in the right church if not

in the right pew.

Whats is the return on investment for 5 more

pounds of battery and two batteries to maintain

instead of one?

The value of this . . . or even more detailed

analysis presumes that you KNOW what the

drains are and what the battery's capabilities

are after accounting for aforementioned

vagaries AND targeted end of life decisions.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jluckey(at)pacbell.net

Guest

|

Posted: Sun Feb 02, 2014 2:34 pm Post subject: Essential Bus question Posted: Sun Feb 02, 2014 2:34 pm Post subject: Essential Bus question |

|

|

my comments in larger font...

-Jeff

From: "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com>

To: aeroelectric-list(at)matronics.com

Sent: Sunday, February 2, 2014 10:47 AM

Subject: Re: Essential Bus question

--> AeroElectric-List message posted by: "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)>

At 11:31 AM 2/2/2014, you wrote:

| Quote: | --> AeroElectric-List message posted by: Tim Andres <tim2542(at)sbcglobal.net (tim2542(at)sbcglobal.net)>

I would just add a simple Brown out 7ah Alarm battery/Aux bus charged thru a Schottky diode and maybe a resistor is very simple & cheap to do. A lot of equipment now comes with multiple diode isolated power inputs making it easy.

This allows flight plan entry and clearance requests before start up without draining the main battery, keeps the GPS/NAV/COM and EFIS from rebooting when cranking the engine, and provides maybe 20-30 minutes of extra time to get back on the ground.

Weight/cost is about $35 and 5 lbs. cheaper than a factory backup, which only powers one item.

Tim

|

Good data points. Let us consider the premises

underlying the evolution of Figure Z-07

http://tinyurl.com/my9u3ud

this shows a two battery/single alternator system

for an electrically dependent engine. This

exercise in 'electron gazing' grew out of Fred's

project already fitted with a EXP-Bus. I could

see a way to accommodate Fred's initial design

goals for two batteries with a simple mod to

the EXP-Bus . . . but I could see an alternative

to Z-19 evolving from the deliberations . . .

hence Z-07.

Off in the distance, I think I see a single-battery

variant of this architecture but that's possible

only after we get real energy requirements data

. . . and further refine the operating philosophy

for the system. Tim's words raise useful questions

that go directly to deliberations for sizing risks

in a single-battery design.

Where is it written or demonstrated that having

the ship's processors 'reboot' is a bad thing?

OK, let me write it here:

Watching the Garmin 430 in my Cherokee re-boot after engine start is very inconvenient. Is it catastrophic? No. Are there work-arounds? Certainly. It's just a pain in the (at)ss. In an experimental w/ all glass, it would be even more annoying.

Now that I'm designing the electrical system for my RV-7A, I'm certainly want a design where that does not happen. This is one of the reasons people like us build our own airplanes - we get to engineer-out those little annoyances that we just have to put up with in certified airplanes.

Under what operating scenarios is it useful/necessary

minimize the time between the glass being awake

and reaching the end of the runway just prior

to engine run-up?

I recall some stories about the Blue-Mountain

systems (hard drives?) taking perhaps 90

seconds to wake up . . . but when was the

last time you were ready to check mags less

than, say 3-4 minutes after engine startup?

I've reviewed as many of the airports I've

visited that I can remember. I cannot recall

any departure where engine run-up was accomplished

for before the oil was warmed up a bit and I

had taxied from parking to the run-up stand,

certainly 4 minutes, sometimes 10. I think

it took 15 minutes to get out of KCI once.

All true but, there are also thousands of quiet little airports where you can depart as quickly as you want to

. . . the check list belongs to YOU . . . you

can adjust sequences of events to fit hardware.

Let us consider "draining the main battery"

for the purposes of gathering the ATIS data

and getting a clearance delivery. Suppose the

e-bus runs 5A and the exercise takes 3 minutes.

12v x 5a x 60s x 3m = 10,800 watt-seconds.

Cranking the engine 12v x 200a x 10s = 24,000

watt-seconds. What does the battery hold?

12v x 5a x 60s x 120m = 432,000 watt-seconds.

Okay, you used up 34,800 watt-seconds before

the engine was lit for 35K/432K or 8 percent

of the battery's capacity. If you're targeting

80% of new capacity for banishing your battery

to kiddie-car duty, then the last flight

will tax the battery to 10% of available

capacity.

The above analysis is a first order estimate

and does not take into account vagaries of

temperature and internal impedances of the

battery but it's in the right church if not

in the right pew.

Whats is the return on investment for 5 more

pounds of battery and two batteries to maintain

instead of one?

The value of this . . . or even more detailed

analysis presumes that you KNOW what the

drains are and what the battery's capabilities

are after accounting for aforementioned

vagaries AND targe> http://foru - List Contribution Web Site -

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Feb 02, 2014 3:39 pm Post subject: Essential Bus question Posted: Sun Feb 02, 2014 3:39 pm Post subject: Essential Bus question |

|

|

OK, let me write it here:

Watching the Garmin 430 in my Cherokee re-boot after engine start is

very inconvenient.

Stop-watch that for me some time. I'd really

like to have a number on this widely discussed

but never quantified driver of design goals.

Is it catastrophic? No. Are there work-arounds? Certainly. It's

just a pain in the (at)ss.

In an experimental w/all glass, it would be even more annoying.

Now that I'm designing the electrical system for my RV-7A, I'm

certainly want a design

where that does not happen. This is one of the reasons people like

us build our own

airplanes - we get to engineer-out those little annoyances that we just have to

put up with in certified airplanes.

Then by all means do so. It's your airplane and your

design goals. The question wasn't whether or not you

wanted to do a particular thing, it was an invitation

explore why you wanted to do it . . . hopefully for reasons

firmly of your own choosing and not 'just because'

hangar lore and legacy traditions dictated it.

Brownout batteries have been discussed her on the list often

for several years an even illustrated one approach

in Z-10/8

http://tinyurl.com/7ro5yuc

All true but, there are also thousands of quiet little airports where you can

depart as quickly as you want to

Yup . . . there are. If a significant percentage

of your departures are so expeditious that

boot time on the glass becomes an impediment,

then you have an element of fact that drives

a different design goal.

I'm trying head off any notions that just because

one is considering a glass cockpit that a brownout

battery is recommended . . . it comes with a price in

weight and costs of ownership that may add little

or no value.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

tim2542(at)sbcglobal.net

Guest

|

Posted: Sun Feb 02, 2014 4:14 pm Post subject: Essential Bus question Posted: Sun Feb 02, 2014 4:14 pm Post subject: Essential Bus question |

|

|

Not to argue your points Bob, and I agree simple is often better, but I would just add that I don't want to wait 20 seconds for the screens to reboot after engine start as my engine data is there also and I want see oil pressure etc right away.

And I much prefer to enter a lengthy flight plan with the prop off as my attention will be focused inside the plane, I'll admit on occasion I've looked up from the panel and discovered the plane moving. My flight plan will then be lost when I then crank the engine, unless I save it to memory, which I won't unless I'm using it again.

And sometimes I take off with a hot engine, I'd rather not sit with the already hot engine running in the summer heat while I enter several waypoints in the Garmin.

To me it's worth the 5lbs for the convenience, and the cost is easily overcome in fuel not burned.

The beauty of EAB, built what you want, then live with your decisions.

Tim

| Quote: | On Feb 2, 2014, at 10:47 AM, "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com> wrote:

At 11:31 AM 2/2/2014, you wrote:

>

>

> I would just add a simple Brown out 7ah Alarm battery/Aux bus charged thru a Schottky diode and maybe a resistor is very simple & cheap to do. A lot of equipment now comes with multiple diode isolated power inputs making it easy.

> This allows flight plan entry and clearance requests before start up without draining the main battery, keeps the GPS/NAV/COM and EFIS from rebooting when cranking the engine, and provides maybe 20-30 minutes of extra time to get back on the ground.

> Weight/cost is about $35 and 5 lbs. cheaper than a factory backup, which only powers one item.

>

> Tim

Good data points. Let us consider the premises

underlying the evolution of Figure Z-07

http://tinyurl.com/my9u3ud

this shows a two battery/single alternator system

for an electrically dependent engine. This

exercise in 'electron gazing' grew out of Fred's

project already fitted with a EXP-Bus. I could

see a way to accommodate Fred's initial design

goals for two batteries with a simple mod to

the EXP-Bus . . . but I could see an alternative

to Z-19 evolving from the deliberations . . .

hence Z-07.

Off in the distance, I think I see a single-battery

variant of this architecture but that's possible

only after we get real energy requirements data

. . . and further refine the operating philosophy

for the system. Tim's words raise useful questions

that go directly to deliberations for sizing risks

in a single-battery design.

Where is it written or demonstrated that having

the ship's processors 'reboot' is a bad thing?

Under what operating scenarios is it useful/necessary

minimize the time between the glass being awake

and reaching the end of the runway just prior

to engine run-up?

I recall some stories about the Blue-Mountain

systems (hard drives?) taking perhaps 90

seconds to wake up . . . but when was the

last time you were ready to check mags less

than, say 3-4 minutes after engine startup?

I've reviewed as many of the airports I've

visited that I can remember. I cannot recall

any departure where engine run-up was accomplished

for before the oil was warmed up a bit and I

had taxied from parking to the run-up stand,

certainly 4 minutes, sometimes 10. I think

it took 15 minutes to get out of KCI once.

. . . the check list belongs to YOU . . . you

can adjust sequences of events to fit hardware.

Let us consider "draining the main battery"

for the purposes of gathering the ATIS data

and getting a clearance delivery. Suppose the

e-bus runs 5A and the exercise takes 3 minutes.

12v x 5a x 60s x 3m = 10,800 watt-seconds.

Cranking the engine 12v x 200a x 10s = 24,000

watt-seconds. What does the battery hold?

12v x 5a x 60s x 120m = 432,000 watt-seconds.

Okay, you used up 34,800 watt-seconds before

the engine was lit for 35K/432K or 8 percent

of the battery's capacity. If you're targeting

80% of new capacity for banishing your battery

to kiddie-car duty, then the last flight

will tax the battery to 10% of available

capacity.

The above analysis is a first order estimate

and does not take into account vagaries of

temperature and internal impedances of the

battery but it's in the right church if not

in the right pew.

Whats is the return on investment for 5 more

pounds of battery and two batteries to maintain

instead of one?

The value of this . . . or even more detailed

analysis presumes that you KNOW what the

drains are and what the battery's capabilities

are after accounting for aforementioned

vagaries AND targeted end of life decisions.

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Kellym

Joined: 10 Jan 2006

Posts: 1705

Location: Sun Lakes AZ

|

Posted: Sun Feb 02, 2014 4:14 pm Post subject: Essential Bus question Posted: Sun Feb 02, 2014 4:14 pm Post subject: Essential Bus question |

|

|

Virtually all glass have their own light weight backup batteries so do

not have startup brown out issues unless no backup battery is installed.

I see very little value in being able to turn on GPS prior to start.

While one needs engine instrumentation prior to and during start, one

does not need avionics on.

Of course newer avionics that allow faster input of flight plans than

the 430 help, if that is the reason for turning on 430 before start.

On 2/2/2014 4:39 PM, Robert L. Nuckolls, III wrote:

| Quote: |

Brownout batteries have been discussed her on the list often

for several years an even illustrated one approach

in Z-10/8

http://tinyurl.com/7ro5yuc

All true but, there are also thousands of quiet little airports where

you can

depart as quickly as you want to

Yup . . . there are. If a significant percentage

of your departures are so expeditious that

boot time on the glass becomes an impediment,

then you have an element of fact that drives

a different design goal.

I'm trying head off any notions that just because

one is considering a glass cockpit that a brownout

battery is recommended . . . it comes with a price in

weight and costs of ownership that may add little

or no value.

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor # 5286

KCHD |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Feb 02, 2014 5:11 pm Post subject: Essential Bus question Posted: Sun Feb 02, 2014 5:11 pm Post subject: Essential Bus question |

|

|

At 06:14 PM 2/2/2014, you wrote:

| Quote: |

Not to argue your points Bob, and I agree simple is often better,

but I would just add that I don't want to wait 20 seconds for the

screens to reboot after engine start as my engine data is there also

and I want see oil pressure etc right away.

|

Yeah . . . that's an old saw that has been around

since the Curtis Jenny . . . when sheared oil pump

shafts were relatively common . . . along with a

host of other ills associated with vintage engines.

I've never encountered a pilot who's oil pump died

at startup. I've flown lots of airplanes in cold

weather that didn't show any pressure for 30-45

seconds after start.

| Quote: | And I much prefer to enter a lengthy flight plan with the prop off

as my attention will be focused inside the plane, I'll admit on

occasion I've looked up from the panel and discovered the plane

moving. My flight plan will then be lost when I then crank the

engine, unless I save it to memory, which I won't unless I'm using it again.

|

| Quote: | And sometimes I take off with a hot engine, I'd rather not sit with

the already hot engine running in the summer heat while I enter

several waypoints in the Garmin.

|

You mean its stored waypoints go away during

reboot?

| Quote: |

To me it's worth the 5lbs for the convenience, and the cost is

easily overcome in fuel not burned.

The beauty of EAB, built what you want, then live with your decisions.

|

Absolutely. But why 5#? What did Eric decide about

his brown-out eliminator? Perhaps we still need

to refine the electronic bus-booster idea . . . it

weights a few ounces and has no periodic maintenance

requirements. Of course, a battery used only for

brownout protection can be run until it dies . . .

as long as the pilot doesn't included it in his/her

calculations for battery only endurance.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

rickofudall

Joined: 19 Sep 2009

Posts: 1392

Location: Udall, KS, USA

|

Posted: Mon Feb 03, 2014 5:28 am Post subject: Essential Bus question Posted: Mon Feb 03, 2014 5:28 am Post subject: Essential Bus question |

|

|

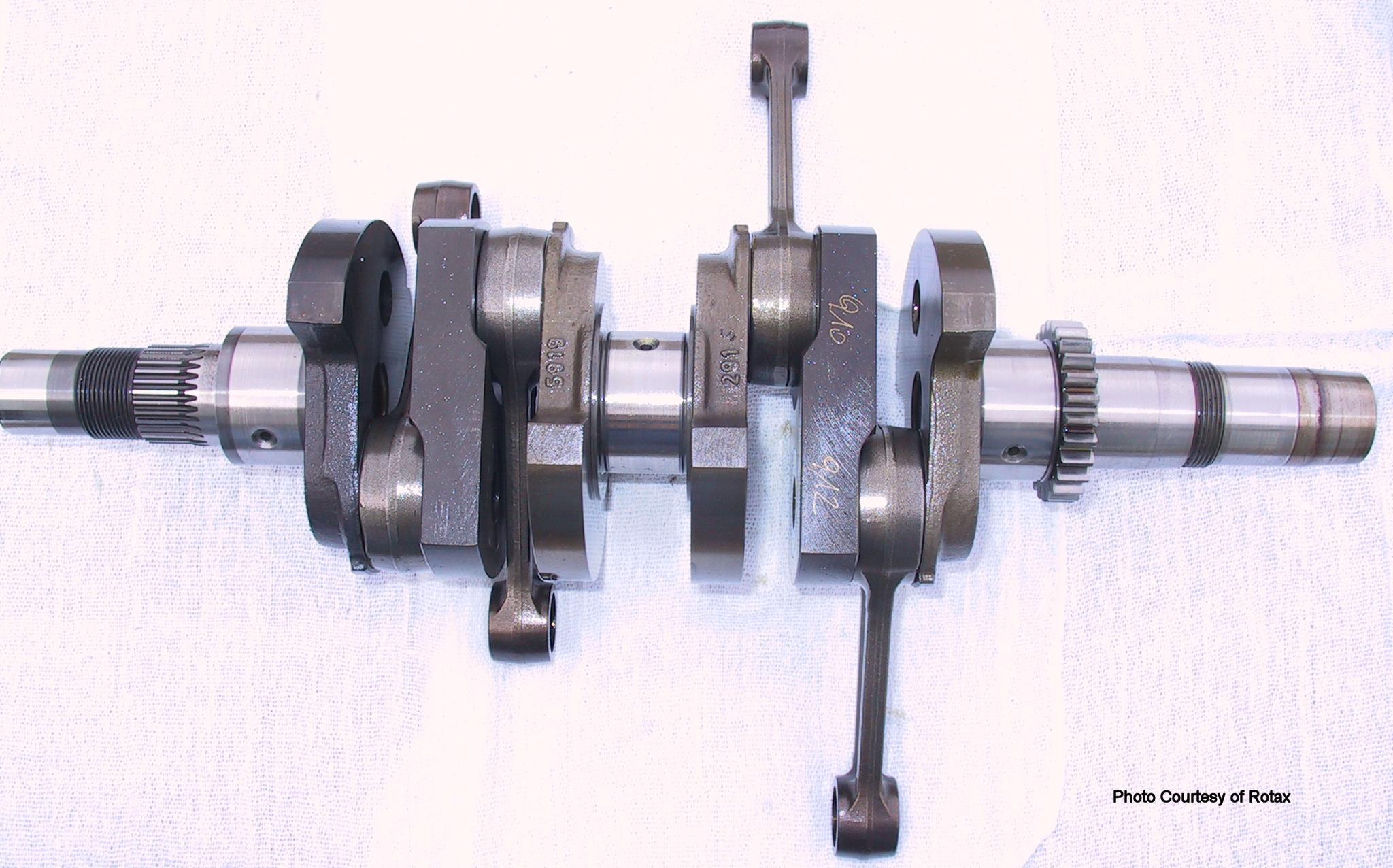

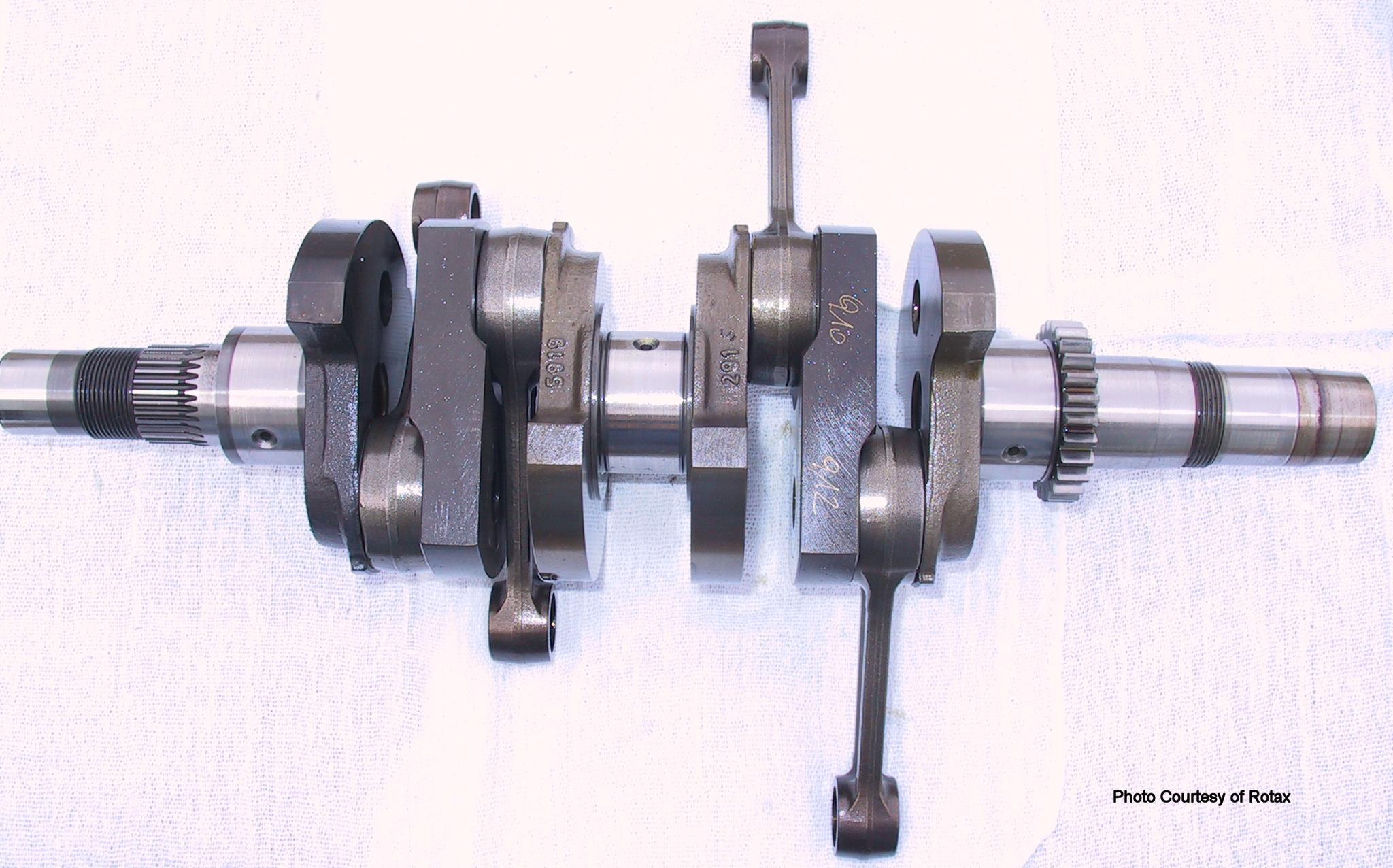

Bob, There is more than inconvenience to not having engine instruments if you fly with a Rotax. Unlike the LyConosaurs, these engines are so tight, the wear limit on a piston is only .0015" and a standard new fit is .0000" to .0009", that to lose oil pressure is catastrophic within seconds. The example that I saw in school was an engine that the owner had hooked the oil hoses up backward. On first start up the engine ran for less than 10 seconds before it threw a rod and blew a big hole in the engine case.

Rick Girard

On Sun, Feb 2, 2014 at 7:10 PM, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | --> AeroElectric-List message posted by: "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)>

At 06:14 PM 2/2/2014, you wrote:

| Quote: | --> AeroElectric-List message posted by: Tim Andres <tim2542(at)sbcglobal.net (tim2542(at)sbcglobal.net)>

Not to argue your points Bob, and I agree simple is often better, but I would just add that I don't want to wait 20 seconds for the screens to reboot after engine start as my engine data is there also and I want see oil pressure etc right away.

|

Yeah . . . that's an old saw that has been around

since the Curtis Jenny . . . when sheared oil pump

shafts were relatively common . . . along with a

host of other ills associated with vintage engines.

I've never encountered a pilot who's oil pump died

at startup. I've flown lots of airplanes in cold

weather that didn't show any pressure for 30-45

seconds after start.

| Quote: | And I much prefer to enter a lengthy flight plan with the prop off as my attention will be focused inside the plane, I'll admit on occasion I've looked up from the panel and discovered the plane moving. My flight plan will then be lost when I then crank the engine, unless I save it to memory, which I won't unless I'm using it again.

And sometimes I take off with a hot engine, I'd rather not sit with the already hot engine running in the summer heat while I enter several waypoints in the Garmin.

|

You mean its stored waypoints go away during

reboot?

| Quote: |

To me it's worth the 5lbs for the convenience, and the cost is easily overcome in fuel not burned.

The beauty of EAB, built what you want, then live with your decisions.

|

Absolutely. But why 5#? What did Eric decide about

his brown-out eliminator? Perhaps we still need

to refine the electronic bus-booster idea . . . it

weights a few ounces and has no periodic maintenance

requirements. Of course, a battery used only for

brownout protection can be run until it dies . . .

as long as the pilot doesn't included it in his/her

calculations for battery only endurance.

Bob . . .

====================================

-List" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

====================================

http://forums.matronics.com

====================================

le, List Admin.

="_blank">http://www.matronics.com/contribution

====================================

|

--

Zulu Delta

Mk IIIC

Thanks, Homer GBYM

It isn't necessary to have relatives in Kansas City in order to be unhappy.

- Groucho Marx

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

The smallest miracle right in front of you is enough to make you happy.... |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Feb 03, 2014 10:51 am Post subject: Essential Bus question Posted: Mon Feb 03, 2014 10:51 am Post subject: Essential Bus question |

|

|

At 07:27 AM 2/3/2014, you wrote:

| Quote: | Bob, There is more than inconvenience to not having engine

instruments if you fly with a Rotax. Unlike the LyConosaurs, these

engines are so tight, the wear limit on a piston is only .0015" and

a standard new fit is .0000" to .0009", that to lose oil pressure is

catastrophic within seconds. The example that I saw in school was an

engine that the owner had hooked the oil hoses up backward. On first

start up the engine ran for less than 10 seconds before it threw a

rod and blew a big hole in the engine case.

|

Back in the day, the oil pressure gage was the same

device on grandpa's Ferguson tractor . . . a pressure

gage plumbed to the engine with a small diameter

tube.

In cold weather, the 50W oil would turn to road

tar in the tubing and delay accurate readings of

the gage by many seconds.

If I had an engine so critically vulnerable to

low oil pressure, then I'd add a pressure switch

as close as practical to the engine plumbed in

with any transducer intended to drive electronics.

10 seconds to destruct because the oil pressure

was absent on THAT start? Broke a rod because the

piston fits got tight? I'm skeptical. Pistons

seizing up progressively in the bores will

load up the engine until it stalls.

I worked a Rotax 912 accident that the owner tried to

blame on an electrical issue with ignition. I proved

the ignition system to be intact . . . but in the

accident narrative, the owner had taxied around for

30+ minutes 'getting the feel of the airplane' before

he decided to take off. On climb out the engine

slowly lost power . . . as if somebody was closing

the throttle. He descended into the trees, destroyed

the airplane and received a back injury. I told my

client attorney that they should do a teardown

of the engine and inspect cylinders for signs of

seizing due to overheat. Whether engine seizes

due to poor oil, air or water flow, the behavior is

the same.

I'll bet that engine had been in trouble for some

time and only decided to give up the ghost on that start-

event. It probably would have shelled out pretty

soon whether it had oil pressure or not.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

rickofudall

Joined: 19 Sep 2009

Posts: 1392

Location: Udall, KS, USA

|

Posted: Mon Feb 03, 2014 12:58 pm Post subject: Essential Bus question Posted: Mon Feb 03, 2014 12:58 pm Post subject: Essential Bus question |

|

|

Bob, As one Rotax mechanic I know put it quite succinctly, "The worst enemy of the Rotax 912 is their owners". As for the blown up engine I saw, the school I attended was taught by the owner of the Rotax North American distributorship. I cannot fathom why he would make up such a story. If the owner had followed the manual, prelubed the engine, and then burped the oil system (the 912 has a dry sump oiling system that has no scavenge pump but instead relies upon blow by to pressurize the crankcase and push the oil out) he'd never have had a problem.

Rick

do not archive

On Mon, Feb 3, 2014 at 12:50 PM, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | --> AeroElectric-List message posted by: "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)>

At 07:27 AM 2/3/2014, you wrote:

| Quote: | Bob, There is more than inconvenience to not having engine instruments if you fly with a Rotax. Unlike the LyConosaurs, these engines are so tight, the wear limit on a piston is only .0015" and a standard new fit is .0000" to .0009", that to lose oil pressure is catastrophic within seconds. The example that I saw in school was an engine that the owner had hooked the oil hoses up backward. On first start up the engine ran for less than 10 seconds before it threw a rod and blew a big hole in the engine case.

|

Back in the day, the oil pressure gage was the same

device on grandpa's Ferguson tractor . . . a pressure

gage plumbed to the engine with a small diameter

tube.

In cold weather, the 50W oil would turn to road

tar in the tubing and delay accurate readings of

the gage by many seconds.

If I had an engine so critically vulnerable to

low oil pressure, then I'd add a pressure switch

as close as practical to the engine plumbed in

with any transducer intended to drive electronics.

10 seconds to destruct because the oil pressure

was absent on THAT start? Broke a rod because the

piston fits got tight? I'm skeptical. Pistons

seizing up progressively in the bores will

load up the engine until it stalls.

I worked a Rotax 912 accident that the owner tried to

blame on an electrical issue with ignition. I proved

the ignition system to be intact . . . but in the

accident narrative, the owner had taxied around for

30+ minutes 'getting the feel of the airplane' before

he decided to take off. On climb out the engine

slowly lost power . . . as if somebody was closing

the throttle. He descended into the trees, destroyed

the airplane and received a back injury. I told my

client attorney that they should do a teardown

of the engine and inspect cylinders for signs of

seizing due to overheat. Whether engine seizes

due to poor oil, air or water flow, the behavior is

the same.

I'll bet that engine had been in trouble for some

time and only decided to give up the ghost on that start-

event. It probably would have shelled out pretty

soon whether it had oil pressure or not.

Bob . . .

====================================

-List" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

====================================

http://forums.matronics.com

====================================

le, List Admin.

="_blank">http://www.matronics.com/contribution

====================================

|

--

Zulu Delta

Mk IIIC

Thanks, Homer GBYM

It isn't necessary to have relatives in Kansas City in order to be unhappy.

- Groucho Marx

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

The smallest miracle right in front of you is enough to make you happy.... |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Feb 03, 2014 5:26 pm Post subject: Essential Bus question Posted: Mon Feb 03, 2014 5:26 pm Post subject: Essential Bus question |

|

|

At 02:57 PM 2/3/2014, you wrote:

| Quote: | Bob, As one Rotax mechanic I know put it quite succinctly, "The

worst enemy of the Rotax 912 is their owners".

As for the blown up engine I saw, the school I attended was taught

by the owner of the Rotax North American distributorship. I cannot

fathom why he would make up such a story. If the owner had followed

the manual, prelubed the engine, and then burped the oil system (the

912 has a dry sump oiling system that has no scavenge pump but

instead relies upon blow by to pressurize the crankcase and push the

oil out) he'd never have had a problem.

|

But a broken rod in 10 seconds? Rod failures

tend to be the byproduct of hammering of the

end cap after the bearing is worn . . . a process

that takes hours. To break the rod with the

torque offered by a seized bearing that

lacked lubrication for 10 seconds doesn't

fit with the physics. You cited tight fits

for the pistons and segued to a broken

rod.

To be sure, we don't have the benefit of

failure analysis on the subject engine

but using what appears to be capitalization

of outlier event to re-enforce a perfectly

reasonable caution to be certain of engine

lubrication smells of "teaching by

sensationalism." This sort of teaching is core

to many the useless if not expensive

ol' mechanic's tales that plague our

community.

I'm not calling him a liar . . . but I am

skeptical based on the cause/effect cited.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

rickofudall

Joined: 19 Sep 2009

Posts: 1392

Location: Udall, KS, USA

|

Posted: Mon Feb 03, 2014 6:24 pm Post subject: Essential Bus question Posted: Mon Feb 03, 2014 6:24 pm Post subject: Essential Bus question |

|

|

Bob, You also have to take into account that unlike the LyCo's, the Rotax has a five piece crank that is pressed together with nothing but the pressure of the fit to keep it together and aligned. I would imagine the trail of tears would include a piston seizure that causes the crank to come out of alignment which not only destroys a bearing or two, but gives the various crank sections a chance to beat upon each other. The reason for the multipiece crank is so that it can be made shorter by reducing the clearance between the side of the rod, see picture. With so little clearance between the rod and the adjacent crank web the twisted, misaligned crank now has a chance to really start beating on the rods, the piston skirts, and any pieces that have come loose. Of course the Rotax engineers have reduced clearances between the rotating assembly and the case halves to shave off more weight and by now the bearings are not only being twisted out of their seats but the case webs are being hammered, too. Well, that's about all I can conjecture about the cause and effect trail, but you get the idea. Rotax engines are just a different animal.

Rick

do not archive

On Mon, Feb 3, 2014 at 7:25 PM, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | --> AeroElectric-List message posted by: "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)>

At 02:57 PM 2/3/2014, you wrote:

| Quote: | Bob, As one Rotax mechanic I know put it quite succinctly, "The worst enemy of the Rotax 912 is their owners".

As for the blown up engine I saw, the school I attended was taught by the owner of the Rotax North American distributorship. I cannot fathom why he would make up such a story. If the owner had followed the manual, prelubed the engine, and then burped the oil system (the 912 has a dry sump oiling system that has no scavenge pump but instead relies upon blow by to pressurize the crankcase and push the oil out) he'd never have had a problem.

|

But a broken rod in 10 seconds? Rod failures

tend to be the byproduct of hammering of the

end cap after the bearing is worn . . . a process

that takes hours. To break the rod with the

torque offered by a seized bearing that

lacked lubrication for 10 seconds doesn't

fit with the physics. You cited tight fits

for the pistons and segued to a broken

rod.

To be sure, we don't have the benefit of

failure analysis on the subject engine

but using what appears to be capitalization

of outlier event to re-enforce a perfectly

reasonable caution to be certain of engine

lubrication smells of "teaching by

sensationalism." This sort of teaching is core

to many the useless if not expensive

ol' mechanic's tales that plague our

community.

I'm not calling him a liar . . . but I am

skeptical based on the cause/effect cited.

Bob . . .

====================================

-List" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

====================================

http://forums.matronics.com

====================================

le, List Admin.

="_blank">http://www.matronics.com/contribution

====================================

|

--

Zulu Delta

Mk IIIC

Thanks, Homer GBYM

It isn't necessary to have relatives in Kansas City in order to be unhappy.

- Groucho Marx

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

309.38 KB |

| Viewed: |

12053 Time(s) |

|

_________________

The smallest miracle right in front of you is enough to make you happy.... |

|

| Back to top |

|

|

tim2542(at)sbcglobal.net

Guest

|

Posted: Mon Feb 03, 2014 7:08 pm Post subject: Essential Bus question Posted: Mon Feb 03, 2014 7:08 pm Post subject: Essential Bus question |

|

|

I think the multi piece crank is needed when they use one piece rods with roller bearings. Still hard to imagine a 10 sec failure. An oil change now becomes a major event in the life of your engine!

Tim

[quote] On Feb 3, 2014, at 6:23 PM, Richard Girard <aslsa.rng(at)gmail.com> wrote:

Bob, You also have to take into account that unlike the LyCo's, the Rotax has a five piece crank that is pressed together with nothing but the pressure of the fit to keep it together and aligned. I would imagine the trail of tears would include a piston seizure that causes the crank to come out of alignment which not only destroys a bearing or two, but gives the various crank sections a chance to beat upon each other. The reason for the multipiece crank is so that it can be made shorter by reducing the clearance between the side of the rod, see picture. With so little clearance between the rod and the adjacent crank web the twisted, misaligned crank now has a chance to really start beating on the rods, the piston skirts, and any pieces that have come loose. Of course the Rotax engineers have reduced clearances between the rotating assembly and the case halves to shave off more weight and by now the bearings are not only being twisted out of their seats but the case webs are being hammered, too.

Well, that's about all I can conjecture about the cause and effect trail, but you get the idea. Rotax engines are just a different animal.

Rick

do not archive

> On Mon, Feb 3, 2014 at 7:25 PM, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com> wrote:

>

>

> At 02:57 PM 2/3/2014, you wrote:

>> Bob, As one Rotax mechanic I know put it quite succinctly, "The worst enemy of the Rotax 912 is their owners".

>> As for the blown up engine I saw, the school I attended was taught by the owner of the Rotax North American distributorship. I cannot fathom why he would make up such a story. If the owner had followed the manual, prelubed the engine, and then burped the oil system (the 912 has a dry sump oiling system that has no scavenge pump but instead relies upon blow by to pressurize the crankcase and push the oil out) he'd never have had a problem.

>

> But a broken rod in 10 seconds? Rod failures

> tend to be the byproduct of hammering of the

> end cap after the bearing is worn . . . a process

> that takes hours. To break the rod with the

> torque offered by a seized bearing that

> lacked lubrication for 10 seconds doesn't

> fit with the physics. You cited tight fits

> for the pistons and segued to a broken

> rod.

>

> To be sure, we don't have the benefit of

> failure analysis on the subject engine

> but using what appears to be capitalization

> of outlier event to re-enforce a perfectly

> reasonable caution to be certain of engine

> lubrication smells of "teaching by

> sensationalism." This sort of teaching is core

> to many the useless if not expensive

> ol' mechanic's tales that plague our

> community.

>

> I'm not calling him a liar . . . but I am

> skeptical based on the cause/effect cited.

>

>

>

> Bob . . .

>

> =========================>> -List" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

> =========================>> http://forums.matronics.com

> =========================>> le, List Admin.

> ="_blank">http://www.matronics.com/contribution

> =========================>

--

Zulu Delta

Mk IIIC

Thanks, Homer GBYM

It isn't necessary to have relatives in Kansas City in order to be unhappy

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

mrspudandcompany(at)veriz

Guest

|

Posted: Tue Feb 04, 2014 5:33 am Post subject: Essential Bus question Posted: Tue Feb 04, 2014 5:33 am Post subject: Essential Bus question |

|

|

You also have to take into account that unlike the LyCo's, the Rotax has a five piece crank that is pressed together with nothing but the pressure of the fit to keep it together and aligned. I would imagine the trail of tears would include a piston seizure that causes the crank to come out of alignment which not only destroys a bearing or two, but gives the various crank sections a chance to beat upon each other. The reason for the multipiece crank is so that it can be made shorter by reducing the clearance between the side of the rod, see picture. With so little clearance between the rod and the adjacent crank web the twisted, misaligned crank now has a chance to really start beating on the rods, the piston skirts, and any pieces that have come loose. Of course the Rotax engineers have reduced clearances between the rotating assembly and the case halves to shave off more weight and by now the bearings are not only being twisted out of their seats but the case webs are being hammered, too.

| Quote: | | Quote: | | Quote: | I find this scenerio to be highly unlikely! If this were the case, then I would wager that there would be cases of this type of failure during normal operation, due to the stress and vibration created during high power running.

Roger

|

|

|

I am using the Free version of SPAMfighter.SPAMfighter has removed 1850 of my spam emails to date.Do you have a slow PC? Try a free scan! [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Eric M. Jones

Joined: 10 Jan 2006

Posts: 565

Location: Massachusetts

|

Posted: Wed Feb 05, 2014 12:48 pm Post subject: Re: Rotax Crank was Essential Bus question Posted: Wed Feb 05, 2014 12:48 pm Post subject: Re: Rotax Crank was Essential Bus question |

|

|

| Quote: | You also have to take into account that unlike the LyCo's, the Rotax has a five piece crank that is pressed together with nothing but the pressure of the fit to keep it together and aligned. I would imagine the trail of tears would include a piston seizure that causes the crank to come out of alignment which not only destroys a bearing or two, but gives the various crank sections a chance to beat upon each other. The reason for the multipiece crank is so that it can be made shorter by reducing the clearance between the side of the rod, see picture. With so little clearance between the rod and the adjacent crank web the twisted, misaligned crank now has a chance to really start beating on the rods, the piston skirts, and any pieces that have come loose. Of course the Rotax engineers have reduced clearances between the rotating assembly and the case halves to shave off more weight and by now the bearings are not only being twisted out of their seats but the case webs are being hammered, too.

I find this scenerio to be highly unlikely! If this were the case, then I would wager that there would be cases of this type of failure during

normal operation, due to the stress and vibration created during high power running. Roger |

Let me venture way outside my pay-grade and offer an opinion that the Rotax multipiece crank is in no way an inferior design, and in fact offers lots of advantages:

1) Cost

2) The connecting rods need no end bearing caps, thus they are stronger and lighter.

3) Exceptional resistance to failure from torsional vibration.

4) The ability to use different metals for the various parts.

5) Shorter crank.

6) The ability to use roller bearings. (I have no idea if they actually should or do).

As long as the rod and main bearings are good, the idea that the crank can come apart is simply a distraction. Porsche 4-cam racing engines used a similar design, although they keyed theirs. But Still... Your Mileage May Vary.

Off Topic... Do not Archive

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Eric M. Jones

www.PerihelionDesign.com

113 Brentwood Drive

Southbridge, MA 01550

(508) 764-2072

emjones(at)charter.net |

|

| Back to top |

|

|

Mauledriver(at)nc.rr.com

Guest

|

Posted: Fri Feb 07, 2014 2:31 pm Post subject: Essential Bus question Posted: Fri Feb 07, 2014 2:31 pm Post subject: Essential Bus question |

|

|

Sorry about adding to this rather old discussion but I've been away for

awhile.

I finished my RV10 in 2011 which means that I designed my electrical

system and panel around 2008 for a 2009-2010 build.

I have 3 GRT HX EFISs - 2 aimed at the pilot, 1 at the passenger. They

supply synthetic vision, moving map, weather, traffic and a complete

suite of engine stats. No light weight backup batteries can be

configured at the factory with these systems. These screens have no

integral on/off switch. I chose not to add any switches or operable

CBs. They come on with the master and will usually reboot when my IO540

cold starts with a single, fresh PC 680 battery.

The GPS WAAS smarts for this system are supplied by a G430W.

I am a serious traveler with this machine and practically all flight are

on IFR plans. My normal routine for all flights is to file my plan

using Foreflight on an iPad. Whenever at an airport with clearance

delivery, or when departing into IMC conditions, I obtain my clearance

on the ground, before engine start, and enter it into my iPad and then

into my G430. Many times in congested areas, this entry is followed by

no small amount of study. As my aging mind continues to fog over, I'm

finding that the study time grows.

Here's the challenge on G430 based panels; it loses any entered flight

plan when powered off. An engine start that reboots my GRTs, reboots my

G430.

An acute challenge on 430 based panels when used for flights around the

Wash DC area or for flights along Florida's Atlantic coast is that the

G430 does not know what a Victor airway is. These are flights I make

regularly and clearances in these areas typically still include Victor

airways. So in the routine described above, entry into the iPad

generates the necessary waypoints to any Victor airways. Accurate entry

of these waypoints into the G430 is important and there's no way I want

to redo the work.

As Bob would put it, this is the 'kitchen sink' I choose to fly with. I

think it's fantastic and works very very well for me. It's now a well

grooved swing. The inability of some (e.g. Bob, not necessarily you

Kelly but I did choose to respond to your post) to 'get' this

requirement for this pilot, seems to me is just an inability to see past

old school experience or perhaps your current pleasure flying routines.

I have a Z-14 with 2 batts, 2 alts, and 2 buses and I REALLY like it. I

bring up the 'kitchen sink' on one battery, get my clearances, enter

them into my systems, study my departure plan when doing complicated

airspace or low IMC departures and then bring up the 2nd battery bus,

cross link them and start my engine. Everything stays up. Before

takeoff I've learned, per Bob, to de-link the buses and off I go.

Per Bob, I've eliminated any semblance of an avionics bus, extra

switches or CBs. After a few operational adjustments and refinements

(Thanks Bob!), the 'overkill' of a Z-14 has given me exactly what I

think I need.

I need my avionics on before start and I have a big kitchen sink that

takes care of the dishes just like I want them done. So can we please

stop dismissing this approach to equipping and traveling in our very

fine OBAM aircraft within the user fee free ATC system we have? Some

of us do it every day because that's the way we choose to roll.

PS: I've been out of the loop island hopping the Bahamas. Recommend it

highly. What an adjustment flying VFR from place to place! However, I

still used the same procedures because that's what standard procedures

are for.

Bill "It's pretty darn good in the Bahamas" Watson

N215TG

On 2/2/2014 7:14 PM, Kelly McMullen wrote:

| Quote: |

<kellym(at)aviating.com>

Virtually all glass have their own light weight backup batteries so do

not have startup brown out issues unless no backup battery is installed.

I see very little value in being able to turn on GPS prior to start.

While one needs engine instrumentation prior to and during start, one

does not need avionics on.

Of course newer avionics that allow faster input of flight plans than

the 430 help, if that is the reason for turning on 430 before start.

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|