|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

dsavarese0812(at)bellsout

Guest

|

Posted: Wed Jun 25, 2014 11:38 am Post subject: Pressure Problem Posted: Wed Jun 25, 2014 11:38 am Post subject: Pressure Problem |

|

|

Because you have completely depressurized the actuators with the selector in neutral. During normal operation, the air pressure on the UP side of the actuator acts like a "cushion" because when you put the gear selector to the DOWN position (the air pressure is pushing the gear down), the UP side of the actuator is depressurizing. That is what you hear coming out of the gear selector. With no pressure on the UP side, there is nothing to hold it back and thus the gear slams down.

| Quote: | A. Dennis Savarese

334-285-6263

334-546-8182 (mobile)

www.yak-52.com

Skype - Yakguy1 |

On 6/25/2014 11:54 AM, Ernest Martinez wrote:

[quote] Why then does the gear slam down if the selector is left in neutral?

Ernie

On Wed, Jun 25, 2014 at 12:48 PM, doug sapp <dougsappllc(at)gmail.com (dougsappllc(at)gmail.com)> wrote:

[quote] Mark, Great post and explanation of how the system works, much better than I could have done myself. 100% spot on.

Doug

On Wed, Jun 25, 2014 at 9:10 AM, Bitterlich, Mark G CIV NAVAIR, WD <mark.bitterlich(at)navy.mil (mark.bitterlich(at)navy.mil)> wrote:

[quote] --> Yak-List message posted by: "Bitterlich, Mark G CIV NAVAIR, WD" <mark.bitterlich(at)navy.mil (mark.bitterlich(at)navy.mil)>

Actually Keith, the gear selector in the YAK is something you really need to know in detail. When I first got my 50, I noticed that the gear handle "had a leak". I removed it from the aircraft, took it all apart, and there was not a darn thing wrong with it. This was about 14 years ago.

I reverse engineered every single air-line in that darn thing and finally figured it out, which it today pretty much common knowledge.

You're right about the port but it is important to know that the air you hear venting is coming from the OPPOSITE SIDE of the actuators that you are trying to pressurize. In other words, picture this: If you have an actuator and push on it in one direction, the internal plunger is going to push air OUT the other side! And that air has to go SOMEPLACE and that "someplace" is out the vent you are talking about.

So when you put the gear handle DOWN, air goes in and forces the actuators to move. The air on the OPPOSITE side of that piston is then pushed out of the actuator, up through the air lines, to the gear actuator and out the vent.

An important things to realize about this.

The actuators are internally sealed (in the YAK-50) with rubber Chevron Seals. These can fail, meaning they will leak. This is of course a very bad thing and needs to be corrected immediately. How do you know it is happening? Because when the gear goes down (or up) and the handle is left in that position, air pressure is constantly fed to the piston in the actuator. If the internal seals leak, the air will come out the opposite side of the actuator, go up the air-lines to the gear actuator handle and HISS out of the vent port constantly. This can leak you to believe you have a bad gear actuator selector when in fact you have a serious problem in your gear actuator(s)!

So bottom line, if you hear air hissing out of the gear actuator lever in the cockpit, do not immediately assume there is a leak in the gear selector, instead check to see if it is coming out of the VENT in which case, suspect a leaking gear actuator seal.

Mark

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

dsavarese0812(at)bellsout

Guest

|

Posted: Wed Jun 25, 2014 11:40 am Post subject: Pressure Problem Posted: Wed Jun 25, 2014 11:40 am Post subject: Pressure Problem |

|

|

OUTSTANDING! You're are definitely the answer to everyone's prayers on this!

| Quote: | A. Dennis Savarese

334-285-6263

334-546-8182 (mobile)

www.yak-52.com

Skype - Yakguy1 |

On 6/25/2014 2:02 PM, doug sapp wrote:

[quote] Dennis and all, About the air line fittings for the flap and gear valves:

I recently received a shipment which contained 90 degree, 45 degree, and straight pipe to flare fittings for this application. We also now carry the air line splicer fittings (double male).

Doug

On Wed, Jun 25, 2014 at 6:36 AM, A. Dennis Savarese <dsavarese0812(at)bellsouth.net (dsavarese0812(at)bellsouth.net)> wrote:

| Quote: | Yes, they are the same and 100% interchangeable. If you intend to R&R a gear or flap selector, (the flap selectors and front gear selector are the same), be very careful removing the fittings because they are quite scarce. You can easily gall the pipe threads trying to remove the old ones if you don't heat them up sufficiently before removing them.

Dennis

From: keithmckinley <cetopfed(at)gmail.com (cetopfed(at)gmail.com)>

To: yak-list(at)matronics.com (yak-list(at)matronics.com)

Sent: Wednesday, June 25, 2014 8:29 AM

Subject: Re: Pressure Problem

--> Yak-List message posted by: "keithmckinley" <cetopfed(at)gmail.com (cetopfed(at)gmail.com)>

The gear and flap selector valve has a small port that will vent air when the selector is moved from one position to the other. I've had one of these selector valves leak so bad through this port I could not build full pressure.

If you have started playing with the ones in the rear cockpit you may start there.

Mine was a CJ and I believe the selectors are the same in a Yak

--------

Keith McKinley

700HS

X26 Sebastian, FL

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=425avigator?Yak-List" "http://forums.matronics.com/" target="_blank">http://forums.matronics.cosp; -nics.com/contribution" target="_blank">http://www.matronics.com/contribut===============

|

[b]

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

Ernie

Joined: 11 Jan 2006

Posts: 513

|

Posted: Wed Jun 25, 2014 11:50 am Post subject: Pressure Problem Posted: Wed Jun 25, 2014 11:50 am Post subject: Pressure Problem |

|

|

This is why I posed the question.

Marks excellent explanation states that the vent is open when the gear is in the up, or down position in order to allow the "Opposite" side to vent. When in neutral, the vent is closed. So that logic dictates that the in the up position, the down side is being vented, so there is no back pressure to cushion the actuator.

Ernie

On Wed, Jun 25, 2014 at 3:38 PM, A. Dennis Savarese <dsavarese0812(at)bellsouth.net (dsavarese0812(at)bellsouth.net)> wrote:

[quote] Because you have completely depressurized the actuators with the selector in neutral. During normal operation, the air pressure on the UP side of the actuator acts like a "cushion" because when you put the gear selector to the DOWN position (the air pressure is pushing the gear down), the UP side of the actuator is depressurizing. That is what you hear coming out of the gear selector. With no pressure on the UP side, there is nothing to hold it back and thus the gear slams down.

| Quote: | A. Dennis Savarese

[url=tel:334-285-6263]334-285-6263[/url]

[url=tel:334-546-8182]334-546-8182[/url] (mobile)

www.yak-52.com

Skype - Yakguy1 |

On 6/25/2014 11:54 AM, Ernest Martinez wrote:

[quote] Why then does the gear slam down if the selector is left in neutral?

Ernie

On Wed, Jun 25, 2014 at 12:48 PM, doug sapp <dougsappllc(at)gmail.com (dougsappllc(at)gmail.com)> wrote:

[quote] Mark, Great post and explanation of how the system works, much better than I could have done myself. Â 100% spot on.

Doug

On Wed, Jun 25, 2014 at 9:10 AM, Bitterlich, Mark G CIV NAVAIR, WD <mark.bitterlich(at)navy.mil (mark.bitterlich(at)navy.mil)> wrote:

[quote] --> Yak-List message posted by: "Bitterlich, Mark G CIV NAVAIR, WD" <mark.bitterlich(at)navy.mil (mark.bitterlich(at)navy.mil)>

Actually Keith, the gear selector in the YAK is something you really need to know in detail. Â When I first got my 50, I noticed that the gear handle "had a leak". Â I removed it from the aircraft, took it all apart, and there was not a darn thing wrong with it. Â This was about 14 years ago.

I reverse engineered every single air-line in that darn thing and finally figured it out, which it today pretty much common knowledge.

You're right about the port but it is important to know that the air you hear venting is coming from the OPPOSITE SIDE of the actuators that you are trying to pressurize. Â In other words, picture this: Â If you have an actuator and push on it in one direction, the internal plunger is going to push air OUT the other side! Â And that air has to go SOMEPLACE and that "someplace" is out the vent you are talking about.

So when you put the gear handle DOWN, air goes in and forces the actuators to move. Â The air on the OPPOSITE side of that piston is then pushed out of the actuator, up through the air lines, to the gear actuator and out the vent.

An important things to realize about this.

The actuators are internally sealed (in the YAK-50) with rubber Chevron Seals. Â These can fail, meaning they will leak. Â This is of course a very bad thing and needs to be corrected immediately. Â How do you know it is happening? Â Because when the gear goes down (or up) and the handle is left in that position, air pressure is constantly fed to the piston in the actuator. Â If the internal seals leak, the air will come out the opposite side of the actuator, go up the air-lines to the gear actuator handle and HISS out of the vent port constantly. Â This can leak you to believe you have a bad gear actuator selector when in fact you have a serious problem in your gear actuator(s)!

So bottom line, if you hear air hissing out of the gear actuator lever in the cockpit, do not immediately assume there is a leak in the gear selector, instead check to see if it is coming out of the VENT in which case, suspect a leaking gear actuator seal.

Mark

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

mark.bitterlich(at)navy.m

Guest

|

Posted: Wed Jun 25, 2014 1:13 pm Post subject: Pressure Problem Posted: Wed Jun 25, 2014 1:13 pm Post subject: Pressure Problem |

|

|

Thanks for the compliment Ernie.

Let me add a tad more to the landing gear handle issue to be just a little more clear.

When the gear handle is in the middle, NO AIR PRESSURE AT ALL is fed to EITHER side of the landing gear actuators. They are totally isolated from the rest of the pneumatic system.

However, the vent is NOT closed in the middle. The vent is in fact open, and there should then be no high pressure on either side of the actuators.

This then carries us to how this knowledge might be used in an emergency.

In the YAK-52, the emergency air bottle is not pressurized from the engine compressor. By the way, on the YAK-50 it is! In any case, with the YAK-52, the emergency bottle is a one shot deal.

Moving on..... If for some reason you had a massive actuator leak and could not get the gear down, and you used the emergency bottle and still had an issue, if you then left the gear handle in the middle, the engine air compressor would then re-pressurize the MAIN bottle to 50 ATM (about 735 PSI) and you could then once AGAIN put the gear handle to the DOWN position, you would have no "back pressure" buffer and thus you would have another chance to get the gear down. This cycle could be repeated several times. This tidbit is not contained in any of the emergency operating procedures for either the YAK-50 or 52, but it is factual and something to store away and hopefully never have to use.

Mark

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

flying(at)jeffhove.com

Guest

|

Posted: Wed Jun 25, 2014 8:10 pm Post subject: Pressure Problem Posted: Wed Jun 25, 2014 8:10 pm Post subject: Pressure Problem |

|

|

Great description Mark.

Now for bonus points (I have not seen this mentioned before and

everyone should know this):

What happens if on the ground (gear down, engine off) you hear

hissing from the rear gear selector then, suspecting a leaky valve, you

wiggle it and find that lifting the rear selector just barely out of

it's down detent but still "down" stops the hissing? Problem solved!

Then to start repairs, you evacuate the air system (by dropping the

flaps and pumping the brake, or opening a fitting).

The result is (scroll down after you've thought this through a bit) ...

Gear collapse!

Even though the gear selector is still basically "down" and the safety

slide still in place, internally the valve has blocked the vent allowing

the gear-up-side pressure to release. The leaky cylinder seal allowed

the gear-up side of the cylinders to slowly achieve equal pressure but

that trapped air does not release as quickly as the gear-down pressure

releases when you evacuate the system. Once the gear-down pressure is

reduced, the gear-up side wins the fight.

We've all seen these type of aircraft sit just fine on their gear with

depleted air tanks. The ball-lock mechanisms in the actuators lock the

gear down without needing pressure. But a bit of residual pressure

trapped on the wrong side can be disastrous.

I hope this helps others avoid that fate.

Jeff Hove

Reluctant witness

On 6/25/2014 11:10 AM, Bitterlich, Mark G CIV NAVAIR, WD wrote:

[quote]

Actually Keith, the gear selector in the YAK is something you really need to know in detail. When I first got my 50, I noticed that the gear handle "had a leak". I removed it from the aircraft, took it all apart, and there was not a darn thing wrong with it. This was about 14 years ago.

I reverse engineered every single air-line in that darn thing and finally figured it out, which it today pretty much common knowledge.

You're right about the port but it is important to know that the air you hear venting is coming from the OPPOSITE SIDE of the actuators that you are trying to pressurize. In other words, picture this: If you have an actuator and push on it in one direction, the internal plunger is going to push air OUT the other side! And that air has to go SOMEPLACE and that "someplace" is out the vent you are talking about.

So when you put the gear handle DOWN, air goes in and forces the actuators to move. The air on the OPPOSITE side of that piston is then pushed out of the actuator, up through the air lines, to the gear actuator and out the vent.

An important things to realize about this.

The actuators are internally sealed (in the YAK-50) with rubber Chevron Seals. These can fail, meaning they will leak. This is of course a very bad thing and needs to be corrected immediately. How do you know it is happening? Because when the gear goes down (or up) and the handle is left in that position, air pressure is constantly fed to the piston in the actuator. If the internal seals leak, the air will come out the opposite side of the actuator, go up the air-lines to the gear actuator handle and HISS out of the vent port constantly. This can leak you to believe you have a bad gear actuator selector when in fact you have a serious problem in your gear actuator(s)!

So bottom line, if you hear air hissing out of the gear actuator lever in the cockpit, do not immediately assume there is a leak in the gear selector, instead check to see if it is coming out of the VENT in which case, suspect a leaking gear actuator seal.

Mark

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

dsavarese0812(at)bellsout

Guest

|

Posted: Thu Jun 26, 2014 4:46 am Post subject: Pressure Problem Posted: Thu Jun 26, 2014 4:46 am Post subject: Pressure Problem |

|

|

However, with the main air off and the gear selector in neutral, don't forget to depressurize the system by squeezing the brake handle until no "swoosh" is heard, which releases the emergency air pressure on the actuator shuttle valves. If you don't do this and you try to go back to the main air system and cycle the gear, the gear will lock into position up or down because the emergency air pressure is holding the gear down.

Dennis

| Quote: | A. Dennis Savarese

334-285-6263

334-546-8182 (mobile)

www.yak-52.com

Skype - Yakguy1 |

On 6/25/2014 4:13 PM, Bitterlich, Mark G CIV NAVAIR, WD wrote:

[quote] [quote]--> Yak-List message posted by: "Bitterlich, Mark G CIV NAVAIR, WD" <mark.bitterlich(at)navy.mil> (mark.bitterlich(at)navy.mil) Thanks for the compliment Ernie. Let me add a tad more to the landing gear handle issue to be just a little more clear. When the gear handle is in the middle, NO AIR PRESSURE AT ALL is fed to EITHER side of the landing gear actuators. They are totally isolated from the rest of the pneumatic system. However, the vent is NOT closed in the middle. The vent is in fact open, and there should then be no high pressure on either side of the actuators. This then carries us to how this knowledge might be used in an emergency. In the YAK-52, the emergency air bottle is not pressurized from the engine compressor. By the way, on the YAK-50 it is! In any case, with the YAK-52, the emergency bottle is a one shot deal. Moving on..... If for some reason you had a massive actuator leak and could not get the gear down, and you used the emergency bottle and still had an issue, if you then left the gear handle in the middle, the engine air compressor would then re-pressurize the MAIN bottle to 50 ATM (about 735 PSI) and you could then once AGAIN put the gear handle to the DOWN position, you would have no "back pressure" buffer and thus you would have another chance to get the gear down. This cycle could be repeated several times. This tidbit is not contained in any of the emergency operating procedures for either the YAK-50 or 52, but it is factual and something to store away and hopefully never have to use. Mark --

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

dsavarese0812(at)bellsout

Guest

|

Posted: Thu Jun 26, 2014 4:55 am Post subject: Pressure Problem Posted: Thu Jun 26, 2014 4:55 am Post subject: Pressure Problem |

|

|

I should have said will NOT lock into position. Sorry.

| Quote: | A. Dennis Savarese

334-285-6263

334-546-8182 (mobile)

www.yak-52.com

Skype - Yakguy1 |

On 6/26/2014 7:46 AM, A. Dennis Savarese wrote:

[quote] However, with the main air off and the gear selector in neutral, don't forget to depressurize the system by squeezing the brake handle until no "swoosh" is heard, which releases the emergency air pressure on the actuator shuttle valves. If you don't do this and you try to go back to the main air system and cycle the gear, the gear will lock into position up or down because the emergency air pressure is holding the gear down.

Dennis

| Quote: | A. Dennis Savarese

334-285-6263

334-546-8182 (mobile)

www.yak-52.com

Skype - Yakguy1 |

On 6/25/2014 4:13 PM, Bitterlich, Mark G CIV NAVAIR, WD wrote:

[quote] [quote]--> Yak-List message posted by: "Bitterlich, Mark G CIV NAVAIR, WD" <mark.bitterlich(at)navy.mil> (mark.bitterlich(at)navy.mil) Thanks for the compliment Ernie. Let me add a tad more to the landing gear handle issue to be just a little more clear. When the gear handle is in the middle, NO AIR PRESSURE AT ALL is fed to EITHER side of the landing gear actuators. They are totally isolated from the rest of the pneumatic system. However, the vent is NOT closed in the middle. The vent is in fact open, and there should then be no high pressure on either side of the actuators. This then carries us to how this knowledge might be used in an emergency. In the YAK-52, the emergency air bottle is not pressurized from the engine compressor. By the way, on the YAK-50 it is! In any case, with the YAK-52, the emergency bottle is a one shot deal. Moving on..... If for some reason you had a massive actuator leak and could not get the gear down, and you used the emergency bottle and still had an issue, if you then left the gear handle in the middle, the engine air compressor would then re-pressurize the MAIN bottle to 50 ATM (about 735 PSI) and you could then once AGAIN put the gear handle to the DOWN position, you would have no "back pressure" buffer and thus you would have another chance to get the gear down. This cycle could be repeated several times. This tidbit is not contained in any of the emergency operating procedures for either the YAK-50 or 52, but it is factual and something to store away and hopefully never have to use. Mark --

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

keithmckinley

Joined: 11 Aug 2008

Posts: 434

|

Posted: Thu Jun 26, 2014 5:38 am Post subject: Re: Pressure Problem Posted: Thu Jun 26, 2014 5:38 am Post subject: Re: Pressure Problem |

|

|

Another thing I found when I was having issues was that the air was leaking out of the front selector valve but it was due to a bad rear valve......

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

Bill1200

Joined: 19 Oct 2008

Posts: 111

Location: medford oregon

|

Posted: Thu Jun 26, 2014 6:02 am Post subject: Re: Pressure Problem Posted: Thu Jun 26, 2014 6:02 am Post subject: Re: Pressure Problem |

|

|

UPDATE:

Nose wheel actuator is the problem.

Tested per instructions here. Plane on jacks, gear up, didn't need U/S detector, fairly big air leak from top of nose wheel actuator.

Sent for seal kit from M14P

Until repair, plan on flying with gear handle in neutral. Understand, to put it back in gear up position before gear down prior to landing.

Thanks to all again.

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

mark.bitterlich(at)navy.m

Guest

|

Posted: Thu Jun 26, 2014 6:18 am Post subject: Pressure Problem Posted: Thu Jun 26, 2014 6:18 am Post subject: Pressure Problem |

|

|

Well darn, that most definitely sucks!

In the "For what it is worth" category, I do not own a YAK-52 (can't fit), and am not up to speed on all the complexities of the dual pneumatic controls in that thing. See Dennis for expert explanations. The Yak-50 has no flaps, and mine has no air brakes (been converted to Cleveland wheels with standard hydraulic toe brakes), so comments from me regarding 52's are not based on experience but instead "converted knowledge" learned from my 50 ... which once in a while has bit me in the tail because there are some real differences. An example is the locking ball system in the 52's gear actuators as compared to an external locking wedge system in the 50's down and lock design. Based on what you just said here.... I think I like mine better.  Whew... glad no one was hurt. Whew... glad no one was hurt.

Mark

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

keithmckinley

Joined: 11 Aug 2008

Posts: 434

|

Posted: Thu Jun 26, 2014 12:40 pm Post subject: Re: Pressure Problem Posted: Thu Jun 26, 2014 12:40 pm Post subject: Re: Pressure Problem |

|

|

A lot of times we have these long maintenance threads but the original poster never shares the results. Thanks for posting the results of your troubleshooting!

Keith

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

PaulW

Joined: 14 May 2013

Posts: 25

|

Posted: Sun Jul 06, 2014 9:37 pm Post subject: Re: Pressure Problem Posted: Sun Jul 06, 2014 9:37 pm Post subject: Re: Pressure Problem |

|

|

Hi

I see mention of the compressor building pressure a bit while taxing?

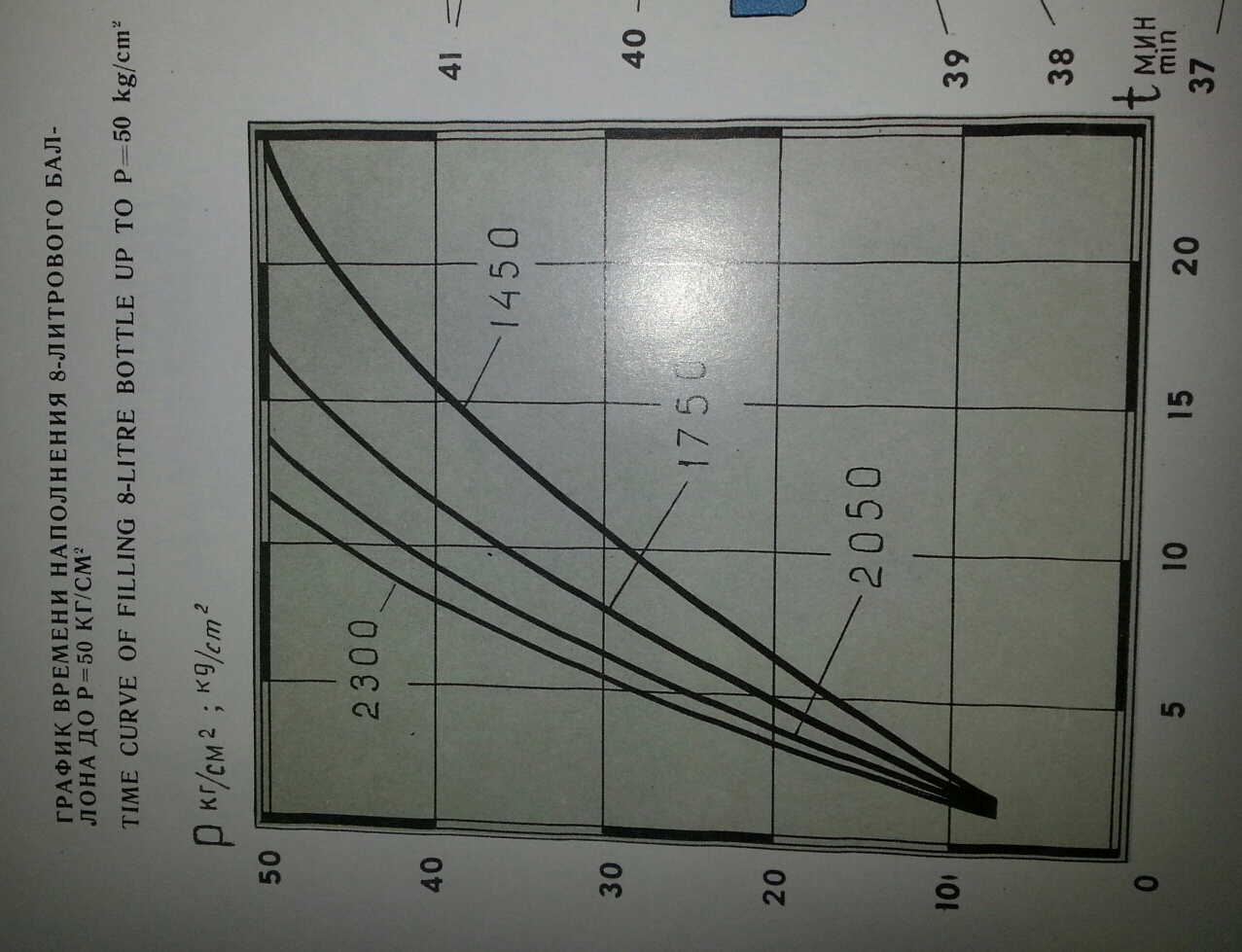

I also saw in the manual that the charge rate is approx 8litres in 30 minutes at 60%.

At what percentage do the compressor start charging and will it charge faster if the RPM is higher?

We have a problem where the compressor don't seem to charge but I don't know if it will only visibly charge enough while in the air or also on the ground. ie. 50% for how many minutes, etc?

There is no audible hissing sounds with gear down.

Paul

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

Rob Rowe

Joined: 10 Jan 2006

Posts: 124

Location: Berkshire, UK

|

Posted: Mon Jul 07, 2014 8:00 pm Post subject: Re: Pressure Problem Posted: Mon Jul 07, 2014 8:00 pm Post subject: Re: Pressure Problem |

|

|

Paul,

The attached graph image is from the AK50 schematic poster that may be of some help to you.

Note :

- the graph is to fill an 8 litre bottle, on a YAK-52 the main bottle is 11 litres

- the RPM quoted "may" be related to the compressor speed, which is 0.9 engine speed (I think)

If you've no obvious leak then it's worth a quick check of the compressor outlet non-return valve. If this is leaking then the charge performance gets reduced and as the compressor cools post shutdown air trapped in the pipes & "snot pot" downstream of the pressure regulator valve gets bled back into the engine crank case and out the breather vent.

Easy way to find out is to check whether the "snot" valve loses back pressure soon after shutting down. Also try putting a rubber glove over the breather vent just after shutdown, if it starts to inflate then that's where your air has gone!

Now this may not be your problem, but at least it's an easy way to eliminate one candidate.

Hope this helps.

Brgds, Rob R

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

| Description: |

|

| Filesize: |

371.59 KB |

| Viewed: |

14121 Time(s) |

|

|

|

| Back to top |

|

|

PaulW

Joined: 14 May 2013

Posts: 25

|

Posted: Mon Jul 07, 2014 11:33 pm Post subject: Re: Pressure Problem Posted: Mon Jul 07, 2014 11:33 pm Post subject: Re: Pressure Problem |

|

|

Thanks Rob! Will investigate coming weekend.

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

dsavarese0812(at)bellsout

Guest

|

Posted: Tue Jul 08, 2014 3:38 am Post subject: Pressure Problem Posted: Tue Jul 08, 2014 3:38 am Post subject: Pressure Problem |

|

|

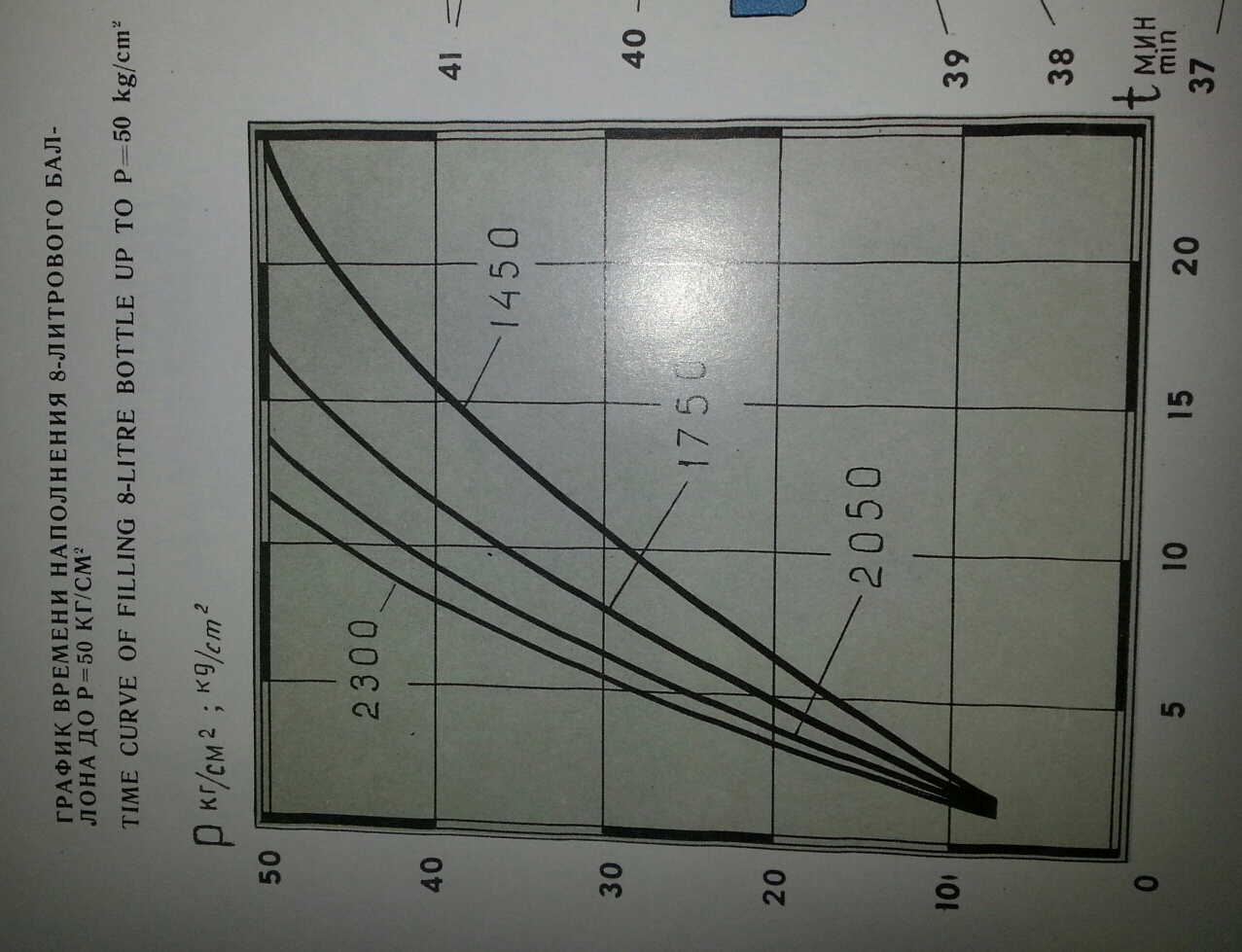

Most folks either never or very rarely remove the output check valve on the compressor to disassemble and clean it. The little "piston" gets so carboned up that it is stuck closed. It is suppose to open and close with each output stroke of the compressor.

It might be a good idea to remove it, disassemble it, clean it and reinstall with new crush washers. The attached photo is not the best. But it does show the compressor output check valve disassembled. The "piston" is next to the little spring on the left. The spring fits inside the piston and the piston inside the assembly just to the left of it. The end of the unit (left side) fits inside the compressor. The end of the little "piston" is about the size of a pencil eraser.

Dennis

From: Rob Rowe <yak-list(at)robrowe.plus.com>

To: yak-list(at)matronics.com

Sent: Monday, July 7, 2014 11:00 PM

Subject: Re: Pressure Problem

--> Yak-List message posted by: "Rob Rowe" <yak-list(at)robrowe.plus.com (yak-list(at)robrowe.plus.com)>

Paul,

The attached graph image is from the AK50 schematic poster that may be of some help to you.

Note :

- the graph is to fill an 8 litre bottle, on a YAK-52 the main bottle is 11 litres

- the RPM quoted "may" be related to the compressor speed, which is 0.9 engine speed (I think)

If you've no obvious leak then it's worth a quick check of the compressor outlet non-return valve. If this is leaking then the charge performance gets reduced and as the compressor cools post shutdown air trapped in the pipes & "snot pot" downstream of the pressure regulator valve gets bled back into the engine crank case and out the breather vent.

Easy way to find out is to check whether the "snot" valve loses back pressure soon after shutting down. Also try putting a rubber glove over the breather vent just after shutdown, if it starts to inflate then that's where your air has gone!

Now this may not be your problem, but at least it's an easy way to eliminate one candidate.

Hope this helps.

Brgds, Rob R

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=426270#426270

Attachments:

http://forums.matronics.com//files/ak50_compressor_performance_139.jpg

| Quote: | http://fo= - List Contribution Web Site &nbs="http://www.matronics.com/contribution" target="_blank">http://www.mat=====================

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

| Description: |

|

| Filesize: |

38.15 KB |

| Viewed: |

14108 Time(s) |

|

|

|

| Back to top |

|

|

k7wx

Joined: 24 May 2010

Posts: 117

|

Posted: Tue Jul 15, 2014 11:04 am Post subject: Pressure Problem Posted: Tue Jul 15, 2014 11:04 am Post subject: Pressure Problem |

|

|

Mark,

Wanted to thank you for the insights below. Had several episodes of an intermittent in-flight gear up problem associated with loud hissing from the forward cockpit gear actuator selector. Long story short, the problem ended up being a main gear actuator seal. Ended up eventually replacing all three gear actuators. Problem solved. Great explanation that helped me figure this one out.

The tired old joke is that we fly these airplanes to see what needs to be fixed next.

Warren Hill

N464TW

Mesa, AZ

On Jun 25, 2014, at 9:10 AM, Bitterlich, Mark G CIV NAVAIR, WD <mark.bitterlich(at)navy.mil> wrote:

[quote]

Actually Keith, the gear selector in the YAK is something you really need to know in detail. When I first got my 50, I noticed that the gear handle "had a leak". I removed it from the aircraft, took it all apart, and there was not a darn thing wrong with it. This was about 14 years ago.

I reverse engineered every single air-line in that darn thing and finally figured it out, which it today pretty much common knowledge.

You're right about the port but it is important to know that the air you hear venting is coming from the OPPOSITE SIDE of the actuators that you are trying to pressurize. In other words, picture this: If you have an actuator and push on it in one direction, the internal plunger is going to push air OUT the other side! And that air has to go SOMEPLACE and that "someplace" is out the vent you are talking about.

So when you put the gear handle DOWN, air goes in and forces the actuators to move. The air on the OPPOSITE side of that piston is then pushed out of the actuator, up through the air lines, to the gear actuator and out the vent.

An important things to realize about this.

The actuators are internally sealed (in the YAK-50) with rubber Chevron Seals. These can fail, meaning they will leak. This is of course a very bad thing and needs to be corrected immediately. How do you know it is happening? Because when the gear goes down (or up) and the handle is left in that position, air pressure is constantly fed to the piston in the actuator. If the internal seals leak, the air will come out the opposite side of the actuator, go up the air-lines to the gear actuator handle and HISS out of the vent port constantly. This can leak you to believe you have a bad gear actuator selector when in fact you have a serious problem in your gear actuator(s)!

So bottom line, if you hear air hissing out of the gear actuator lever in the cockpit, do not immediately assume there is a leak in the gear selector, instead check to see if it is coming out of the VENT in which case, suspect a leaking gear actuator seal.

Mark

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

mark.bitterlich(at)navy.m

Guest

|

Posted: Wed Jul 16, 2014 7:03 am Post subject: Pressure Problem Posted: Wed Jul 16, 2014 7:03 am Post subject: Pressure Problem |

|

|

Hi Warren, thanks for the feedback, and I am glad that you were able to use the knowledge to good advantage! That said, sorry you had to replace all three gear actuators! Holy Cow! On the other hand, you are probably a lot safer now than you were before... and I am not talking "safety for the sake of safety" I am talking about having a landing accident!

Like your "old joke". I'll use that one!

Take care and I hope it's quite a while before anything else decides it needs to be fixed!

Mark

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

k7wx

Joined: 24 May 2010

Posts: 117

|

Posted: Wed Jul 16, 2014 7:59 am Post subject: Pressure Problem Posted: Wed Jul 16, 2014 7:59 am Post subject: Pressure Problem |

|

|

Mark,

Thanks. My A&P guy was able to identify the failed main gear actuator, but recommended that we also replace the others as they were looking quite rough. Now that its done Im glad we made this extra effort as the gear swing is a thing of beauty. The plan is to rebuild the old ones and keep them on the shelf for the other members of our group. We now have six CJs on the field and five of us are in the same very large hanger, with lots of spare parts. To paraphrase

it sometimes takes a community to own a CJ.

All the best,

Warren

On Jul 16, 2014, at 8:02 AM, Bitterlich, Mark G CIV NAVAIR, WD <mark.bitterlich(at)navy.mil> wrote:

[quote]

Hi Warren, thanks for the feedback, and I am glad that you were able to use the knowledge to good advantage! That said, sorry you had to replace all three gear actuators! Holy Cow! On the other hand, you are probably a lot safer now than you were before... and I am not talking "safety for the sake of safety" I am talking about having a landing accident!

Like your "old joke". I'll use that one!

Take care and I hope it's quite a while before anything else decides it needs to be fixed!

Mark

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|