|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Oct 09, 2014 8:39 am Post subject: Should a tripped circuit breaker be reset in flight? Posted: Thu Oct 09, 2014 8:39 am Post subject: Should a tripped circuit breaker be reset in flight? |

|

|

At 10:07 2014-10-09, you wrote:

| Quote: |

There is an article in the October 2014 issue of Sport Aviation on

page 92 titled, "I'll Never Do That Again". The author experienced

an avionics failure while in IFR conditions. Other pilots in

similar emergency situations have crashed. This pilot was very

experienced. After briefly losing control, he was able to use

backup instruments and land. While safely on the ground, he noticed

a popped circuit breaker and reset it. It immediately tripped

again, accompanied by an unusual smell. The pilot wrote, "I will

never reset a breaker in the air. I did not have a fire, but I

clearly was cooking something while I was on the ramp. Flames on

the ground are a problem. Flames in the air are deadly."

Take away the resettable feature of circuit breakers and they

have no advantage (in most cases) over fuses, other than the cool

factor of the appearance of a neat row of breakers. Fuses cost

less, weigh less, and never fail to open when overloaded.

|

In the revenue generating class of aircraft

there can be maintenance conveniences for having

disconnect capabilities at the bus . . . I won't

pretend to know the big picture of what constitutes

an elegant solution for those folks.

Further, there is probably not much risk of fire

for having reset a breaker . . . even multiple times.

The pundits are fond of citing the Ricky Nelson

DC-3 crash on New Year's eve 1985 wherein it was

hypothesized that repeated attempts to get a

gas-fired cabin heater to stay on line were

unsuccessful and MAY have lead to the fire which

definitely started in the rear of the cabin. Forensics

failed to conclusively tag the heater.

It's REALLY hard to set anything on fire by repeatedly

reseting a breaker as long as the trip is protecting

a hard-faulted wire. The major risks for in-flight fire

are from failures within a piece of equipment and

SOFT faults to a wire. "SOFT" being defined as a

condition that dissipates a lot of energy over a period

of time but at current levels lower than the trip

value for the breaker. Cases in point: Swissair 111

and a C90 that experienced elevator disconnect

due to soft-fault arcing of the cable against a

wire that was breaker protected at 40A.

My own preference for not re-setting breakers has

more to do with builder competence in crafting

and pilot competence in carry out a Plan-B. These

are exercises in pre-incident planning that go

to making breaker resets or fuse replacements

irrelevant.

This isn't about fires, it's about avoiding that

deer-in-the-headlights look that overcomes too

many of our span-can driving brothers. Incidents

described in detail over decades of what I've called the

"Dark n Stormy Night" stories popular with the

journals . . . Sport Aviation not withstanding.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Oct 13, 2014 8:31 am Post subject: Should a tripped circuit breaker be reset in flight? Posted: Mon Oct 13, 2014 8:31 am Post subject: Should a tripped circuit breaker be reset in flight? |

|

|

There has been some remarkably good discussion on this subject and I want to add my two cents:

1) Breakers themselves fail or degrade. Abused breakers are difficult to detect. Resetting them after they

cool down may be possible. But diagnosis should be a ground-repair issue. Remember to Fly the Airplane.

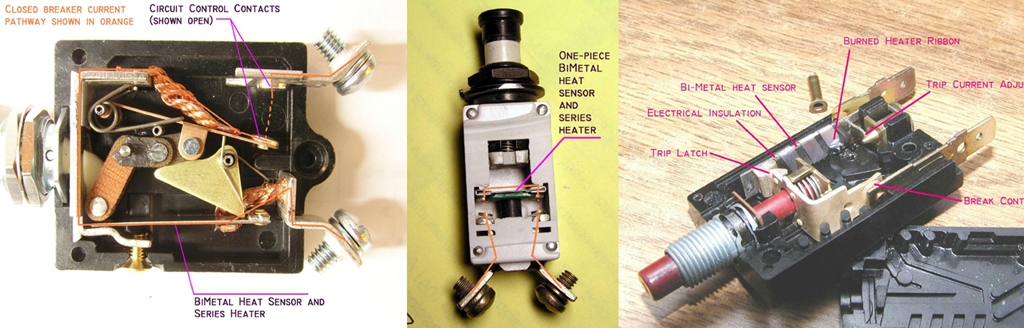

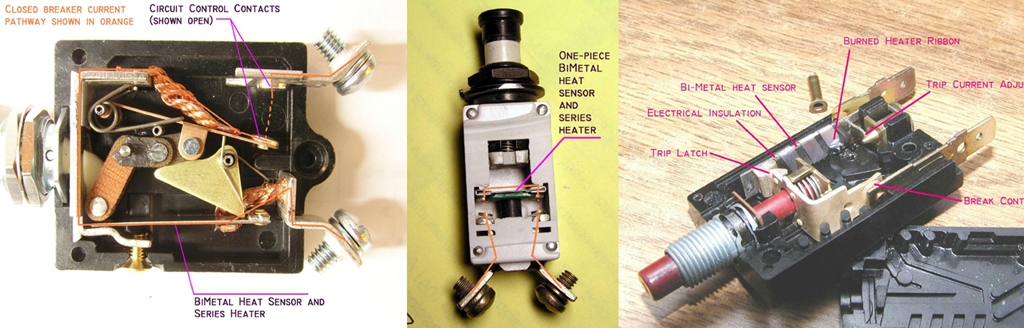

That's a pretty broad brush . . . SOME breakers are less robust than we might like for use in an extra-ordinarily abusive environment. Consider the inner monkey-motion and parts count of the switch-breaker (on left) and the commercial, off-the shelf appliance breaker on the right . . . with the military qualified device in the center that is RATED and TESTED for thousands of high-fault current trips without degradation of performance. I've never encountered a pre-mature failure in this style breaker when used solely as a circuit protective device and not a crew-operated power control.

[img]cid:.0[/img][/b]

2) The classic "breaker for every wire" seems old fashioned and indeed breakers sometimes

pop in commercial a/c and nobody notices. An LED warning on every breaker seems to be a great idea.

Three points to ponder here. Legacy design goals call limiting failure effects to one system only. It's generally not a good thing to have one failure take down multiple appliances. Hence, one protective device per feeder.

If a protective device operates then some system is off line as a result. If nobody notices, then that appliance is not being used. As soon as the crew expects that appliance to be available, the popped breaker will, no doubt, be noticed . . . whereupon Plan-B for that failure will be implemented.

Adding indicator lights to breaker/fuses only complicates the monkey-motion built into the device. It does not reduce risks to comfortable termination of flight. It might be a troubleshooting aid . . . but then . . . you already know that appliance is inop or you will know before next flight . . . it's on your preflight checklist . . . right?

3) Switch-Breaker combos save weight and panel space. These SBs have become much better,

smaller and cheaper than the early ones.

. . . but still MUCH more expensive than a fuse and they FORCE a modification of architecture to move a portion of the ship's bus structure onto the panel.

4) New approaches like solid state resettables certainly have their place.

But what is the return on investment? If you're not going to reset breakers or replace fuses in flight . . . what is the value of incorporating a 'more modern' approach to hardware that is more convenient to reset? 5) If you don't have to change a fuse during flight, a fuse works well. This

includes, wig-wags, entertainment systems, seat heaters, baggage compartment lights,

convenience lights, rear intercoms, and others.

Under what conditions would it EVER be necessary/useful/ prudent to replace a fuse in flight? Are there design goals to exercise that would eliminate any such condition?

6) Inherently Safe Buses are low-current or current-limited buses where no fuse is

required because a dead short will not generate enough power to ignite anything.

Worth considering in this low-current world of Cmos, Fet gates and LEDs.

Yes, feeders current limited at the bus can be considered intrinsically immune to damage as a consequence of a faulted wire. I've encountered perhaps a dozen such opportunities in my lifetime.

7) A design goal might be to eliminate the breaker panel by employing a variety

of other circuit protection methods. Are there some breakers that never pop? Why

have them?

Exactly. This question prompted an essay published in Sport Aviation 21 years ago: http://tinyurl.com/o9joztv The decision process for circuit protective philosophy has almost nothing to do with convenience or the performance issues unique to devices being considered. To be sure, devices like this http://tinyurl.com/oka6z2a may offer some unique opportunities for adding some appliance to an airplane but in general, a clean piece of paper design should strive for minimum risk, minimum cost, minimum complexity, minimum weight in that order of prominence.

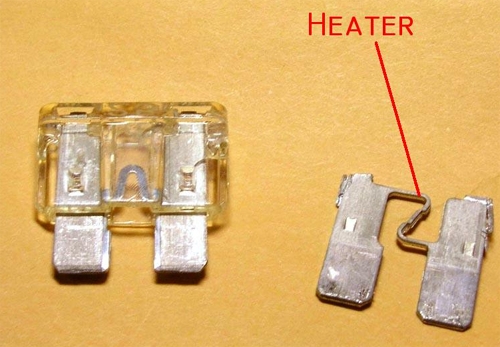

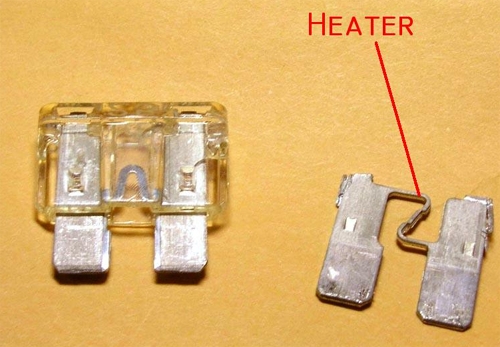

[img]cid:.1[/img][/b]

. . . at the present time, I'm unable to suggest a superior alternative to the rudimentary fuse for keeping all the smoke inside your wires . . .

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

306.9 KB |

| Viewed: |

6638 Time(s) |

|

| Description: |

|

| Filesize: |

138.55 KB |

| Viewed: |

6638 Time(s) |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue Oct 14, 2014 3:49 pm Post subject: Should a tripped circuit breaker be reset in flight? Posted: Tue Oct 14, 2014 3:49 pm Post subject: Should a tripped circuit breaker be reset in flight? |

|

|

| Quote: | The argument could be made that a popped breaker is easier to detect

than a blown fuse as Mike points out.

|

Given that there are 100x more ways a thing can

fail that DOESN'T pop a fuse, it seems that the

whole argument over the utility of visible notification

is moot. If it's important that piece of equipment

work before flight . . . then exercise the critter

in preflight. If not working, then indeed a

fuse MIGHT be open but it's more likely that it is not.

Visual inspection any circuit protective device

offers no assurance whatsoever of any system's

operational integrity.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

mmayfield

Joined: 09 Oct 2009

Posts: 40

Location: NSW Central Coast, Australia

|

Posted: Sun Oct 19, 2014 2:30 am Post subject: Re: Should a tripped circuit breaker be reset in flight? Posted: Sun Oct 19, 2014 2:30 am Post subject: Re: Should a tripped circuit breaker be reset in flight? |

|

|

| nuckolls.bob(at)aeroelect wrote: | | Visual inspection any circuit protective device offers no assurance whatsoever of any system's operational integrity.Bob . . . |

I recall at least one occasion in particular where the failure to visually detect a tripped circuit breaker before flight had no preflight consequences in a B767, but subsequently led to significant inflight consequences and an air safety incident report.

In fact it was taken so seriously by my (very large airline) company, that proper preflight inspection of circuit breakers was elevated to a major assessment item in annual flight reviews/check rides. I recall the pilot who failed to complete the CB check as required in the Ops Manual being quite distraught about the consequences.

Preflight exercising of each individual protected system is not necessarily practical or achievable, but in the case I mentioned, correct checking of CBs before getting airborne would've saved the subsequent tea and biscuits meeting with the Chief Pilot. Also, we had systems which required both preflight exercising, and a subsequent specific check that the system CBs had not tripped during the testing/exercising process, as it was possible for them to do so without any obvious symptoms until after takeoff. So it's a habit, and not an unhealthy one, which has been ingrained into my psyche.

("You're cordially invited to tea and biscuits with the Chief Pilot - cold tea, bring your own biscuits - you better make your explanation a good one.")

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Mike |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Oct 19, 2014 8:10 am Post subject: Should a tripped circuit breaker be reset in flight? Posted: Sun Oct 19, 2014 8:10 am Post subject: Should a tripped circuit breaker be reset in flight? |

|

|

At 05:30 2014-10-19, you wrote:

--> AeroElectric-List message posted by: "mmayfield" <mmayfield(at)ozemail.com.au>

nuckolls.bob(at)aeroelect wrote:

> Visual inspection any circuit protective device offers no assurance whatsoever of any system's operational integrity.Bob . . .

I recall at least one occasion in particular where the failure to visually detect a tripped circuit breaker before flight had no preflight consequences in a B767, but subsequently led to significant inflight consequences and an air safety incident report.

In fact it was taken so seriously by my (very large airline) company, that proper preflight inspection of circuit breakers was elevated to a major assessment item in annual flight reviews/check rides. I recall the pilot who failed to complete the CB check as required in the Ops Manual being quite distraught about the consequences.

Preflight exercising of each individual protected system is not necessarily practical or achievable, but in the case I mentioned, correct checking of CBs before getting airborne would've saved the subsequent tea and biscuits meeting with the Chief Pilot. Also, we had systems which required both preflight exercising, and a subsequent specific check that the system CBs had not tripped during the testing/exercising process, as it was possible for them to do so without any obvious symptoms until after takeoff. So it's a habit, and not an unhealthy one, which has been ingrained into my psyche.

We're talking about two VERY different kinds of airplanes.

At the same time, your narrative illustrates the fact that

heavy-iron pilots (indeed C-172 pilots too) are in a what-

you-see-is-what-you get situation with respect to system

architectures, consequences of inadequate FMEA by the

designers and/or hind-sight reactions to an 'in-flight

consequence' arising from failure to perform in the cockpit.

The idea that any system's integrity is assured by making

sure it's breaker is closed speaks to poor system design.

If it's a critical system with no pre-flight detectable

tell-tales, the folks getting worked over with the

wet-noodles and stern mentors should NOT be the

flight crews - but the folks on the drawing boards.

Overhauling crews for missing one critical breaker

condition on an acres-of-breakers panel is like

dinging a TSA agent for letting grandma get through

with an unchecked water-bottle. You don't effectively

address known, critical items in preflight with broad

brush checklist items like "Copilot's breaker panel - CHECK"

or "Old lady water bottle - CHECK."

You identify every critical breaker by name and give

each a separate check-list bullet:" "#2 Slats Warn

Breaker - CHECK IN". That way, perhaps two or three

critical breakers out of dozens will get the special

attention they need . . . because for reasons

unexplained, those systems have no active notification

for loss of integrity other that to see that they're

powered up. The idea that those same systems never exhibit

failures that do not open their breakers lacks

credibility.

("You're cordially invited to tea and biscuits with the Chief Pilot - cold tea, bring your own biscuits - you better make your explanation a good one.")

Your tag-line is illustrative of far to many

institutional knee-jerk/CYA responses to incidents

rooted in poor attention to physics and human-

factors. I have analyzed the narratives of many

"dark-n-stormy" night stories published in the aviation

journals.

Two examples:

http://tinyurl.com/lk9d9sm

http://tinyurl.com/mrsnutr

Here's a third one that was the lead-in story

to Chapter 17 in the AeroElectric Connection.

http://tinyurl.com/otzkjft

http://tinyurl.com/n8x8bsc

I cannot recall a single story that cited poor

behavior on the part of designers and procedures

writers . . . instead the thrust of EVERY

article was to increase pilot awareness

of the potential for experiencing the same

or similar design shortfall all over again.

The foundation for my assertions here on the

List is built on the fact that OUR airplanes are

not (or at least should not be) products of the

time, talents and resources of Boeing, Cessna,

Podunk Airlines, the FAA or any other institution

who's after-market response to a design shortfall

is too often limited to writing more paragraphs

into the POH or adding new features to the pilot

training syllabus.

The way you avoid becoming a passenger in the

left seat of your own airplane is SIMPLE . . .

not necessarily easy but quite SIMPLE. As you cut wires, crimp terminals, mount electro- whizzies to your airplane, be constantly analyzing the following:

How can this part fail?

How can/will I know that the part has failed?

Is its functionality critical to comfortable termination of flight (CTCTOF)?

Is the failure pre-flight detectable?

If CTCTOF = TRUE then what considerations are best applied to (1) actively annunciate failure and (2) provide a Plan-B should loss of that item become a reality? Scanning the circuit breaker panel or putting

LEDs on the fuses is a close cousin to the "TSA

approach" to air travel security. You must PROFILE

every component of your airplane to assess (1) its

CTCTOF factor and (2) DO SOMETHING that mitigates

the risk.

Bob . . . [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

mmayfield

Joined: 09 Oct 2009

Posts: 40

Location: NSW Central Coast, Australia

|

Posted: Mon Oct 20, 2014 2:39 am Post subject: Re: Should a tripped circuit breaker be reset in flight? Posted: Mon Oct 20, 2014 2:39 am Post subject: Re: Should a tripped circuit breaker be reset in flight? |

|

|

Well Bob, you need to write to Boeing about addressing those issues and their system design or poorly conceived procedures because they are direct from the Boeing FCOM. Best of luck with that!

The "tea and biscuits" metaphor was just that. Yes he was called to explain what happened but in this particular case I don't believe it was actually an inquisitorial meeting (notwithstanding that it can be). However there was a reminder issued that checking the breaker panels is a preflight requirement and it was a big deal.

Even in my small plane, the breakers are there. They should all be in for engine start. Just like every other switch position I check before engine start in a standard panel scan, the breakers are part of that scan.

As an interesting aside, the Airbus A330 has all its physical breakers down in the electronics compartment. Technically it's accessible, but not within arms reach. However Airbus needed a way of allowing pilots to pull and reset power to systems so they created an overhead panel with "breaker-like" switches - they do not function as circuit protection but look exactly like breakers, and physically pull and push in the same manner!

It is quite common on the Airbus to use these to reset a system, both on the ground and in the air.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Mike |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Oct 20, 2014 9:47 am Post subject: Should a tripped circuit breaker be reset in flight? Posted: Mon Oct 20, 2014 9:47 am Post subject: Should a tripped circuit breaker be reset in flight? |

|

|

At 05:39 2014-10-20, you wrote:

| Quote: | --> AeroElectric-List message posted by: "mmayfield" <mmayfield(at)ozemail.com.au>

Well Bob, you need to write to Boeing about addressing those issues and their system design or poorly conceived procedures because they are direct from the Boeing FCOM. Best of luck with that! |

You miss my point. I fully understand and empathize with

the good folks at Boeing. Their accomplishments are without

peer . . . something one may expect from people with

"the right stuff" . . .

http://tinyurl.com/n7zo6ms

On the other hand, history has given us millions of

examples of "Aww s*%t!" epiphanies suffered by

successful and capable designers in companies of all sizes

and technologies. Consider recalls in the automotive

industries and other consumer products. I've had

a few of those myself in a company of only 100

employees. To date, the worst case of stubbing my toe

only cost the boss about $25K and didn't make it

onto any airplanes before it was caught.

| Quote: | | The "tea and biscuits" metaphor was just that. Yes he was called to explain what happened but in this particular case I don't believe it was actually an inquisitorial meeting (notwithstanding that it can be). However there was a reminder issued that checking the breaker panels is a preflight requirement and it was a big deal.Even in my small plane, the breakers are there. They should all be in for engine start. Just like every other switch position I check before engine start in a standard panel scan, the breakers are part of that scan. |

My point was not to argue against the general

statement for checking breakers. To be sure, finding

a breaker open in pre-flight offers data worthy of

further consideration. This assumes that the breaker

powers a CFCTOF=0 system and is 'tied open' by maintenance.

The point I was promoting is based on an inarguable

fact that unlike the OPEN breaker, the CLOSED breaker guarantees

nothing. It follows then that FMEA conducted during design

and verification in flight test should go to giving

the crew ALL information necessary for pre-flight

verification of integrity for all systems with CFCTOF=1.

To be sure, few "Aw s$#t" epiphanies in Boeing class

aircraft are going to generate an AD (recall) ESPECIALLY

when a 'fix' can be implemented with some new words in the

AFM.

Fortunately, OUR airplanes do not suffer from the square-

law effects the gargantuan institutions. The potential for

an "Aw s#(at)t" moment goes up with the square of influential

individuals not directly tasked with the design and verification

of a device. The discovery of something needing a fix in

an RV will cost perhaps a 100 times fewer dollars than

fixing a similar shortfall on a C-172 and a factor of a

100,000 less than a B787.

| Quote: | | As an interesting aside, the Airbus A330 has all its physical breakers down in the electronics compartment. Technically it's accessible, but not within arms reach. However Airbus needed a way of allowing pilots to pull and reset power to systems so they created an overhead panel with "breaker-like" switches - they do not function as circuit protection but look exactly like breakers, and physically pull and push in the same manner! |

Yup, you may find that these are actually 1A breakers

that are crowbared open in response to signals from

a "remotely controlled circuit breaker" (RCCB). There's

a bunch of them on the Eclipse that are controlled via

touch-screen buttons. Here is one of dozens of such

devices . . .

http://tinyurl.com/mtjcsyb

| Quote: | | It is quite common on the Airbus to use these to reset a system, both on the ground and in the air. |

No argument . . . when it's well considered procedure that

arises from the guys at the drawing boards. These are precisely

the tools needed for competent operation.

My point was to decry a DEPENDANCE upon catching

an open breaker . . . in a panel full of breakers . . .

for a system with a CTCTOF=1 . . . a system that apparently

enjoyed NO OTHER means for pre-flight verification.

Breakers and fuses are for the protection of wires and

to prevent a fault from propagating across multiple systems.

The prudent designer (and OBAM aircraft builder) will strive

to fit EVERY system with CTCTOF=1 with

1) pre-flight verifiable integrity that goes beyond checking for a closed breaker -AND-

(2) plan-B for mitigating loss of that system whether or not the breaker is open.

Finally, as OBAM aircraft owners and operators, we're

encouraged and privileged to FIX any latent shortfalls

in design with something more than a band-aid to the

procedures in the AFM.

Bob . . . [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

fvalarm(at)rapidnet.net

Guest

|

Posted: Mon Oct 20, 2014 1:36 pm Post subject: Should a tripped circuit breaker be reset in flight? Posted: Mon Oct 20, 2014 1:36 pm Post subject: Should a tripped circuit breaker be reset in flight? |

|

|

What does... CFCTOF=0 mean?

Bevan

From: owner-aeroelectric-list-server(at)matronics.com [mailto:owner-aeroelectric-list-server(at)matronics.com] On Behalf Of Robert L. Nuckolls, III

Sent: Monday, October 20, 2014 10:46 AM

To: aeroelectric-list(at)matronics.com

Subject: Re: Re: Should a tripped circuit breaker be reset in flight?

At 05:39 2014-10-20, you wrote:

| Quote: | --> AeroElectric-List message posted by: "mmayfield" <mmayfield(at)ozemail.com.au>

Well Bob, you need to write to Boeing about addressing those issues and their system design or poorly conceived procedures because they are direct from the Boeing FCOM. Best of luck with that! |

You miss my point. I fully understand and empathize with

the good folks at Boeing. Their accomplishments are without

peer . . . something one may expect from people with

"the right stuff" . . .

http://tinyurl.com/n7zo6ms

On the other hand, history has given us millions of

examples of "Aww s*%t!" epiphanies suffered by

successful and capable designers in companies of all sizes

and technologies. Consider recalls in the automotive

industries and other consumer products. I've had

a few of those myself in a company of only 100

employees. To date, the worst case of stubbing my toe

only cost the boss about $25K and didn't make it

onto any airplanes before it was caught.

| Quote: | | The "tea and biscuits" metaphor was just that. Yes he was called to explain what happened but in this particular case I don't believe it was actually an inquisitorial meeting (notwithstanding that it can be). However there was a reminder issued that checking the breaker panels is a preflight requirement and it was a big deal.Even in my small plane, the breakers are there. They should all be in for engine start. Just like every other switch position I check before engine start in a standard panel scan, the breakers are part of that scan. |

My point was not to argue against the general

statement for checking breakers. To be sure, finding

a breaker open in pre-flight offers data worthy of

further consideration. This assumes that the breaker

powers a CFCTOF=0 system and is 'tied open' by maintenance.

The point I was promoting is based on an inarguable

fact that unlike the OPEN breaker, the CLOSED breaker guarantees

nothing. It follows then that FMEA conducted during design

and verification in flight test should go to giving

the crew ALL information necessary for pre-flight

verification of integrity for all systems with CFCTOF=1.

To be sure, few "Aw s$#t" epiphanies in Boeing class

aircraft are going to generate an AD (recall) ESPECIALLY

when a 'fix' can be implemented with some new words in the

AFM.

Fortunately, OUR airplanes do not suffer from the square-

law effects the gargantuan institutions. The potential for

an "Aw s#(at)t" moment goes up with the square of influential

individuals not directly tasked with the design and verification

of a device. The discovery of something needing a fix in

an RV will cost perhaps a 100 times fewer dollars than

fixing a similar shortfall on a C-172 and a factor of a

100,000 less than a B787.

| Quote: | | As an interesting aside, the Airbus A330 has all its physical breakers down in the electronics compartment. Technically it's accessible, but not within arms reach. However Airbus needed a way of allowing pilots to pull and reset power to systems so they created an overhead panel with "breaker-like" switches - they do not function as circuit protection but look exactly like breakers, and physically pull and push in the same manner! |

Yup, you may find that these are actually 1A breakers

that are crowbared open in response to signals from

a "remotely controlled circuit breaker" (RCCB). There's

a bunch of them on the Eclipse that are controlled via

touch-screen buttons. Here is one of dozens of such

devices . . .

http://tinyurl.com/mtjcsyb

| Quote: | | It is quite common on the Airbus to use these to reset a system, both on the ground and in the air. |

No argument . . . when it's well considered procedure that

arises from the guys at the drawing boards. These are precisely

the tools needed for competent operation.

My point was to decry a DEPENDANCE upon catching

an open breaker . . . in a panel full of breakers . . .

for a system with a CTCTOF=1 . . . a system that apparently

enjoyed NO OTHER means for pre-flight verification.

Breakers and fuses are for the protection of wires and

to prevent a fault from propagating across multiple systems.

The prudent designer (and OBAM aircraft builder) will strive

to fit EVERY system with CTCTOF=1 with

1) pre-flight verifiable integrity that goes beyond checking for a closed breaker -AND-

(2) plan-B for mitigating loss of that system whether or not the breaker is open.

Finally, as OBAM aircraft owners and operators, we're

encouraged and privileged to FIX any latent shortfalls

in design with something more than a band-aid to the

procedures in the AFM.

Bob . . . [quote]

href="http://www.matronics.com/Navigator?AeroElectric-List">http://www.matronics.com/Navigator?AeroElectric-List

href="http://forums.matronics.com">http://forums.matronics.com

href="http://www.matronics.com/contribution">http://www.matronics.com/c

[b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|