|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

BobbyPaulk(at)comcast.net

Guest

|

Posted: Thu Mar 19, 2015 5:20 pm Post subject: Timing Posted: Thu Mar 19, 2015 5:20 pm Post subject: Timing |

|

|

List

I am need of help.

I had the flywheel and the back end of the engine removed to make repairs. The drives for both mags were removed and re-installed. ( I didn't need to do this but it was too late when I realized it. )

I purchased a degree wheel and found TDC of No. 1 by going about 30 degrees before and 30 degrees past ( measuring the piston down travel the same ) and splitting the difference to find the center of the dead spot. I lined up both rotor buttons with the timing marks on the side of the distributor support at 25 deg. BTC and made sure they were parallel. We did this about 12 to 15 times until we were satisfied it was correct. When the engine is at TDC on #1 the rotors are pointing to #1 on the distributor cap.

I used a Honda Coil on the right side and the Rotec E-Mag on the left.

The engine started but ran very, very rough and sounded like it was out of time. It also would not run with the choke off nor would it take the throttle. We used fresh 100 LL and took the bowl off the carb and made sure we had plenty of fuel flow with the elec. boost pump.

The engine would start easily but ran very rough and would not take the throttle even after warm up. Outside temp was 72 F. deg.

Going to either one mag made no difference in how the engine ran although you could hear a little drop in RPM.

Can anyone offer a solution. I sure do not want to remove the engine and flywheel and start over. Could I be a tooth off on the distributors??

The carb was removed from the rubber connector and left on the aircraft while the engine was removed and on a stand and not touched during this time ( all linkage remained in tact.

Bobby

Zodiac 601 XL "B"

Jabiru 3300 S/N 1141

Sensenich 64" x 51" Prop

Bing Carb 260 Main & 290 Needle Jet

Status - Flying 236 hrs.

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

UK Clive

Joined: 17 May 2013

Posts: 27

|

Posted: Fri Mar 20, 2015 3:10 am Post subject: Timing Posted: Fri Mar 20, 2015 3:10 am Post subject: Timing |

|

|

I had problems and adjusted the timing a few times, turned out to be the magnets so do the ‘pull test’ to make sure.

From your comments below and from what I remember.

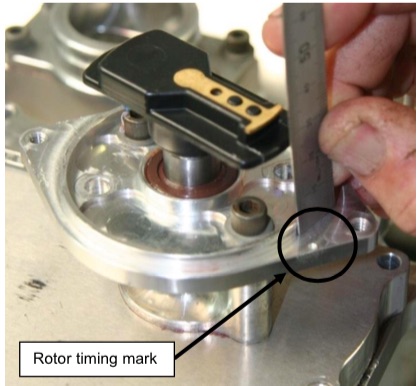

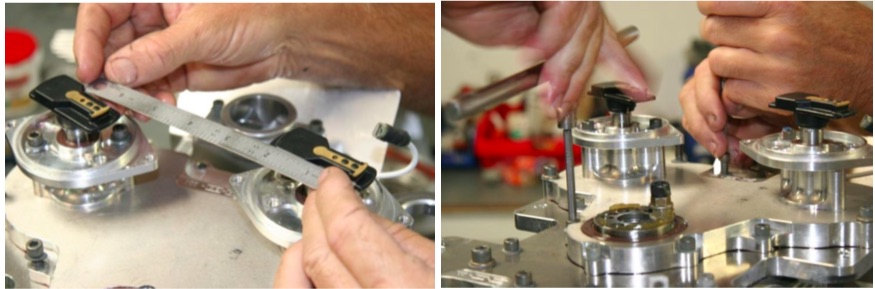

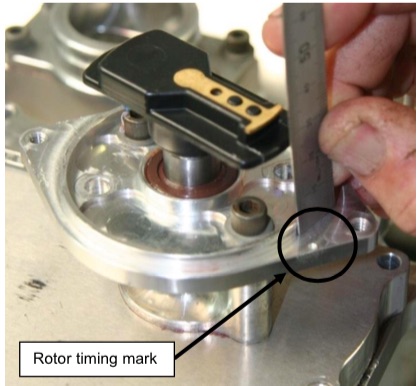

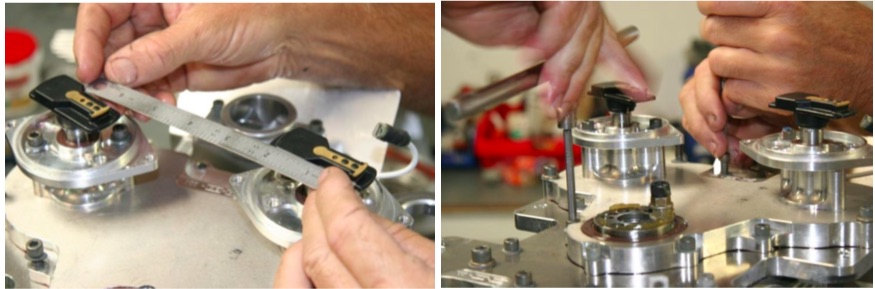

The rotors don’t look parallel to each other when they are in the correct position. See pictures.

You can see this without taking it all apart again look from left side of engine with dizzy caps out of the way.

With the engine at 25 deg BTC the rotor arms 'leading edge' of the metal bit must be in line with the timing marks.

See ruler against mark in the not very well taken picture.

Not the middle of the metal tab but the leading edge. right in the picture I think, might be left, move the engine to see which way the rotors move forward.

JEM explains it like this:

-

and provided the timing mark lines up with the tip of the cap it will work properly

I think I sussed out ‘tip of the cap’ meant leading edge of the metal bit.

Find TDC with screwdriver down the plug hole and then wind the engine back 25 degrees. That is 30mm measured on the prop hub circumference (hub is 140mm dia)

140 * 3.142, /360x25???

The gearing is such that one tooth will put it out enough to see so you know whether you have it right.

That’s what I recall and it was a few months ago so sorry if I got any of it wrong.

Of course if it’s nothing to do with the timing then good luck!

Regards, Clive

[img]cid:814E9DDC-73F5-4D17-BDF5-385A64444D45(at)Belkin[/img]

[img]cid:FF83C60F-2138-44C8-9ABE-B04BEED03641(at)Belkin[/img]

| Quote: | On 20 Mar 2015, at 01:19, BobbyPaulk(at)comcast.net (BobbyPaulk(at)comcast.net) wrote:

List

I am need of help.

I had the flywheel and the back end of the engine removed to make repairs. The drives for both mags were removed and re-installed. ( I didn't need to do this but it was too late when I realized it. )

I purchased a degree wheel and found TDC of No. 1 by going about 30 degrees before and 30 degrees past ( measuring the piston down travel the same ) and splitting the difference to find the center of the dead spot. I lined up both rotor buttons with the timing marks on the side of the distributor support at 25 deg. BTC and made sure they were parallel. We did this about 12 to 15 times until we were satisfied it was correct. When the engine is at TDC on #1 the rotors are pointing to #1 on the distributor cap.

I used a Honda Coil on the right side and the Rotec E-Mag on the left.

The engine started but ran very, very rough and sounded like it was out of time. It also would not run with the choke off nor would it take the throttle. We used fresh 100 LL and took the bowl off the carb and made sure we had plenty of fuel flow with the elec. boost pump.

The engine would start easily but ran very rough and would not take the throttle even after warm up. Outside temp was 72 F. deg.

Going to either one mag made no difference in how the engine ran although you could hear a little drop in RPM.

Can anyone offer a solution. I sure do not want to remove the engine and flywheel and start over. Could I be a tooth off on the distributors??

The carb was removed from the rubber connector and left on the aircraft while the engine was removed and on a stand and not touched during this time ( all linkage remained in tact.

Bobby

Zodiac 601 XL "B"Jabiru 3300 S/N 1141Sensenich 64" x 51" PropBing Carb 260 Main & 290 Needle JetStatus - Flying 236 hrs.

| Quote: |

href="http://www.matronics.com/Navigator?JabiruEngine-List" class="">http://www.matronics.com/Navigator?JabiruEngine-List

class="">http://forums.matronics.com

class="">http://www.matronics.com/contribution

|

|

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

| Description: |

|

| Filesize: |

53.6 KB |

| Viewed: |

12101 Time(s) |

|

| Description: |

|

| Filesize: |

81.18 KB |

| Viewed: |

12101 Time(s) |

|

|

|

| Back to top |

|

|

curts63

Joined: 04 Dec 2013

Posts: 30

Location: New Ringgold, PA

|

Posted: Fri Mar 20, 2015 3:17 am Post subject: Re: Timing Posted: Fri Mar 20, 2015 3:17 am Post subject: Re: Timing |

|

|

Not being an expert or even a beginner in Jabiru engines, my only question would be, are you on TDC for the compression stroke?

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

pete(at)usjabiru.com

Guest

|

Posted: Fri Mar 20, 2015 6:45 am Post subject: Timing Posted: Fri Mar 20, 2015 6:45 am Post subject: Timing |

|

|

Bobby,

<![if !supportLists]>1. <![endif]>Find TDC on the compression stroke.Â

<![if !supportLists]>2. <![endif]>Make a mark on one of the flywheel teeth and the gearcase cover.Â

<![if !supportLists]>3. <![endif]>Count seven teeth on the flywheel in the direction of rotation (clockwise) and make another mark on that tooth

<![if !supportLists]>4. <![endif]>Then turn the crankshaft (prop) counter clockwise (opposite of the direction of rotation) until the second mark lines up with the first reference mark on the gearcase.

<![if !supportLists]>5. <![endif]>Set the distributor shafts so that the rotor points to the timing mark on the distributor base.

You will most likely have to remove the flywheel anyway as you will have to lift the gearcase cover to change the distributor alighment. Lifting the cover will break the Loctite 515 seal so you will have to reapply the Loctite. If you remove the flywheel:

<![if !supportLists]>1. <![endif]>Line up the timing marks on the crank gear and cam gear.

<![if !supportLists]>2. <![endif]>Temporarily put the flywheel in place.

<![if !supportLists]>3. <![endif]>Turn the crankshaft backwards seven teeth

<![if !supportLists]>4. <![endif]>Remove the flywheel

<![if !supportLists]>5. <![endif]>Install the gearcase cover setting the distributor shafts so the rotor points to the timing mark as you install the cover

<![if !supportLists]>6. <![endif]>Reinstall flywheel

Hope this helps

Pete Krotje

Jabiru USA Sport Aircraft, LLC

931-680-2800

www.usjabiru.com

Office Hours:

Mon - Thur 9:00am to noon and 1:00pm to 4:00 pm Central Time

Friday 9:00 am to 1:00pm Central Time

From: owner-jabiruengine-list-server(at)matronics.com [mailto:owner-jabiruengine-list-server(at)matronics.com] On Behalf Of BobbyPaulk(at)comcast.net

Sent: Thursday, March 19, 2015 8:20 PM

To: Server, JabiruEngine-List Digest

Subject: Timing

List

I am need of help.

I had the flywheel and the back end of the engine removed to make repairs. The drives for both mags were removed and re-installed. ( I didn't need to do this but it was too late when I realized it. )

I purchased a degree wheel and found TDC of No. 1 by going about 30 degrees before and 30 degrees past ( measuring the piston down travel the same ) and splitting the difference to find the center of the dead spot. I lined up both rotor buttons with the timing marks on the side of the distributor support at 25 deg. BTC and made sure they were parallel. We did this about 12 to 15 times until we were satisfied it was correct. When the engine is at TDC on #1 the rotors are pointing to #1 on the distributor cap.

I used a Honda Coil on the right side and the Rotec E-Mag on the left.

The engine started but ran very, very rough and sounded like it was out of time. It also would not run with the choke off nor would it take the throttle. We used fresh 100 LL and took the bowl off the carb and made sure we had plenty of fuel flow with the elec. boost pump.

The engine would start easily but ran very rough and would not take the throttle even after warm up. Outside temp was 72 F. deg.

Going to either one mag made no difference in how the engine ran although you could hear a little drop in RPM.

Can anyone offer a solution. I sure do not want to remove the engine and flywheel and start over. Could I be a tooth off on the distributors??

The carb was removed from the rubber connector and left on the aircraft while the engine was removed and on a stand and not touched during this time ( all linkage remained in tact.

Bobby

Zodiac 601 XL "B"

Jabiru 3300 S/N 1141

Sensenich 64" x 51" Prop

Bing Carb 260 Main & 290 Needle Jet

Status - Flying 236 hrs.

| Quote: | | http://www.matronics.com/Navigator?JabiruEngine-List |

01234567

[quote][b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

UK Clive

Joined: 17 May 2013

Posts: 27

|

Posted: Fri Mar 20, 2015 10:22 am Post subject: Timing Posted: Fri Mar 20, 2015 10:22 am Post subject: Timing |

|

|

Pete, middle left or right side of rotor?, metal bit is about 10mm wide, what does ‘points' at mean ?

'so the rotor points to the timing mark'

ta, Clive

| Quote: | On 20 Mar 2015, at 14:44, Pete Krotje <pete(at)usjabiru.com (pete(at)usjabiru.com)> wrote:

<![endif]--> <![endif]-->Bobby,

1. Find TDC on the compression stroke.

2. Make a mark on one of the flywheel teeth and the gearcase cover.

3. Count seven teeth on the flywheel in the direction of rotation (clockwise) and make another mark on that tooth

4. Then turn the crankshaft (prop) counter clockwise (opposite of the direction of rotation) until the second mark lines up with the first reference mark on the gearcase.

5. Set the distributor shafts so that the rotor points to the timing mark on the distributor base.You will most likely have to remove the flywheel anyway as you will have to lift the gearcase cover to change the distributor alignment. Lifting the cover will break the Loctite 515 seal so you will have to reapply the Loctite. If you remove the flywheel:

1. Line up the timing marks on the crank gear and cam gear.

2. Temporarily put the flywheel in place.

3. Turn the crankshaft backwards seven teeth

4. Remove the flywheel

5. Install the gearcase cover setting the distributor shafts so the rotor points to the timing mark as you install the cover

6. Reinstall flywheelHope this helps

Pete Krotje

Jabiru USA Sport Aircraft, LLC

931-680-2800

www.usjabiru.com

Office Hours:

Mon - Thur 9:00am to noon and 1:00pm to 4:00 pm Central Time

Friday 9:00 am to 1:00pm Central Time

From: owner-jabiruengine-list-server(at)matronics.com (owner-jabiruengine-list-server(at)matronics.com) [mailto:owner-jabiruengine-list-server(at)matronics.com (owner-jabiruengine-list-server(at)matronics.com)] On Behalf Of BobbyPaulk(at)comcast.net (BobbyPaulk(at)comcast.net)Sent: Thursday, March 19, 2015 8:20 PMTo: Server, JabiruEngine-List DigestSubject: Timing

List

I am need of help.

I had the flywheel and the back end of the engine removed to make repairs. The drives for both mags were removed and re-installed. ( I didn't need to do this but it was too late when I realized it. )

I purchased a degree wheel and found TDC of No. 1 by going about 30 degrees before and 30 degrees past ( measuring the piston down travel the same ) and splitting the difference to find the center of the dead spot. I lined up both rotor buttons with the timing marks on the side of the distributor support at 25 deg. BTC and made sure they were parallel. We did this about 12 to 15 times until we were satisfied it was correct. When the engine is at TDC on #1 the rotors are pointing to #1 on the distributor cap.

I used a Honda Coil on the right side and the Rotec E-Mag on the left.

The engine started but ran very, very rough and sounded like it was out of time. It also would not run with the choke off nor would it take the throttle. We used fresh 100 LL and took the bowl off the carb and made sure we had plenty of fuel flow with the elec. boost pump.

The engine would start easily but ran very rough and would not take the throttle even after warm up. Outside temp was 72 F. deg.

Going to either one mag made no difference in how the engine ran although you could hear a little drop in RPM.

Can anyone offer a solution. I sure do not want to remove the engine and flywheel and start over. Could I be a tooth off on the distributors??

The carb was removed from the rubber connector and left on the aircraft while the engine was removed and on a stand and not touched during this time ( all linkage remained in tact.

Bobby

Zodiac 601 XL "B"Jabiru 3300 S/N 1141Sensenich 64" x 51" PropBing Carb 260 Main & 290 Needle JetStatus - Flying 236 hrs.

01234567

8

|

[quote][b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

pete(at)usjabiru.com

Guest

|

Posted: Fri Mar 20, 2015 11:08 am Post subject: Timing Posted: Fri Mar 20, 2015 11:08 am Post subject: Timing |

|

|

It does not matter.

From: owner-jabiruengine-list-server(at)matronics.com [mailto:owner-jabiruengine-list-server(at)matronics.com] On Behalf Of James Clive

Sent: Friday, March 20, 2015 1:22 PM

To: jabiruengine-list(at)matronics.com

Subject: Re: Timing

Pete, middle left or right side of rotor?, metal bit is about 10mm wide, what does ‘points' at mean ?

'so the rotor points to the timing mark'

ta, Clive

| Quote: |

On 20 Mar 2015, at 14:44, Pete Krotje <pete(at)usjabiru.com (pete(at)usjabiru.com)> wrote:

Bobby,

<![if !supportLists]>1. <![endif]>Find TDC on the compression stroke.

<![if !supportLists]>2. <![endif]>Make a mark on one of the flywheel teeth and the gearcase cover.

<![if !supportLists]>3. <![endif]>Count seven teeth on the flywheel in the direction of rotation (clockwise) and make another mark on that tooth

<![if !supportLists]>4. <![endif]>Then turn the crankshaft (prop) counter clockwise (opposite of the direction of rotation) until the second mark lines up with the first reference mark on the gearcase.

<![if !supportLists]>5. <![endif]>Set the distributor shafts so that the rotor points to the timing mark on the distributor base.

You will most likely have to remove the flywheel anyway as you will have to lift the gearcase cover to change the distributor alignment. Lifting the cover will break the Loctite 515 seal so you will have to reapply the Loctite. If you remove the flywheel:

<![if !supportLists]>1. <![endif]>Line up the timing marks on the crank gear and cam gear.

<![if !supportLists]>2. <![endif]>Temporarily put the flywheel in place.

<![if !supportLists]>3. <![endif]>Turn the crankshaft backwards seven teeth

<![if !supportLists]>4. <![endif]>Remove the flywheel

<![if !supportLists]>5. <![endif]>Install the gearcase cover setting the distributor shafts so the rotor points to the timing mark as you install the cover

<![if !supportLists]>6. <![endif]>Reinstall flywheel

Hope this helps

Pete Krotje

Jabiru USA Sport Aircraft, LLC

931-680-2800

www.usjabiru.com

Office Hours:

Mon - Thur 9:00am to noon and 1:00pm to 4:00 pm Central Time

Friday 9:00 am to 1:00pm Central Time

From: owner-jabiruengine-list-server(at)matronics.com (owner-jabiruengine-list-server(at)matronics.com) [mailto:owner-jabiruengine-list-server(at)matronics.com (owner-jabiruengine-list-server(at)matronics.com)] On Behalf Of BobbyPaulk(at)comcast.net (BobbyPaulk(at)comcast.net)

Sent: Thursday, March 19, 2015 8:20 PM

To: Server, JabiruEngine-List Digest

Subject: Timing

List

I am need of help.

I had the flywheel and the back end of the engine removed to make repairs. The drives for both mags were removed and re-installed. ( I didn't need to do this but it was too late when I realized it. )

I purchased a degree wheel and found TDC of No. 1 by going about 30 degrees before and 30 degrees past ( measuring the piston down travel the same ) and splitting the difference to find the center of the dead spot. I lined up both rotor buttons with the timing marks on the side of the distributor support at 25 deg. BTC and made sure they were parallel. We did this about 12 to 15 times until we were satisfied it was correct. When the engine is at TDC on #1 the rotors are pointing to #1 on the distributor cap.

I used a Honda Coil on the right side and the Rotec E-Mag on the left.

The engine started but ran very, very rough and sounded like it was out of time. It also would not run with the choke off nor would it take the throttle. We used fresh 100 LL and took the bowl off the carb and made sure we had plenty of fuel flow with the elec. boost pump.

The engine would start easily but ran very rough and would not take the throttle even after warm up. Outside temp was 72 F. deg.

Going to either one mag made no difference in how the engine ran although you could hear a little drop in RPM.

Can anyone offer a solution. I sure do not want to remove the engine and flywheel and start over. Could I be a tooth off on the distributors??

The carb was removed from the rubber connector and left on the aircraft while the engine was removed and on a stand and not touched during this time ( all linkage remained in tact.

Bobby

Zodiac 601 XL "B"

Jabiru 3300 S/N 1141

Sensenich 64" x 51" Prop

Bing Carb 260 Main & 290 Needle Jet

Status - Flying 236 hrs.

01

|

234567890123456789

[quote][b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

BobbyPaulk(at)comcast.net

Guest

|

Posted: Mon Mar 23, 2015 6:12 am Post subject: Timing Posted: Mon Mar 23, 2015 6:12 am Post subject: Timing |

|

|

Many thanks to Pete and Clive for the helpful info about timing the 3300.

I did the 7 tooth test as described by Pete and both rotors were in parallel with the trailing edge aligned with the timing marks on the distributor support.

So I do not believe I will have to re-do the timing.

I am buying new spark plugs and will do some more testing Tuesday if weather permits.

By The Way - When you go to purchase NGK D9EA spark plugs make sure thing have the threaded ferrule on top.

I found plenty of spark plugs but nobody had any NGK with the ferrules on top. I substituted Champion RA4HC's.

Hope they work.

Bobby

[quote][b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

UK Clive

Joined: 17 May 2013

Posts: 27

|

Posted: Mon Mar 23, 2015 6:39 am Post subject: Timing Posted: Mon Mar 23, 2015 6:39 am Post subject: Timing |

|

|

Hope you sort it swiftly, frustrating.

I will drop off one of my Dizzy caps and look at the timing marks and the rotor arm. I remember posing the question to myself but can’t remember what the answer was. I found the manual (Jem 001) unclear and the photo’s weren’t either.

I did have one apart a month or so ago so should have taken more notice. The accuracy of the timing is from the magnets passing the coils of course which I’m sure is why Pete said it doesn’t matter.

Remember though, the arms aren’t parallel with each other. They are almost but not truly parallel, recheck the picture in Jem-001. They are in the same position relative to each timing mark though.

NGK in the UK will send you free ferrules if you phone and ask. Or they always used to.

Cheers, Clive

| Quote: | On 23 Mar 2015, at 14:11, BobbyPaulk(at)comcast.net (BobbyPaulk(at)comcast.net) wrote:

Many thanks to Pete and Clive for the helpful info about timing the 3300.

I did the 7 tooth test as described by Pete and both rotors were in parallel with the trailing edge aligned with the timing marks on the distributor support.

So I do not believe I will have to re-do the timing.

I am buying new spark plugs and will do some more testing Tuesday if weather permits.

By The Way - When you go to purchase NGK D9EA spark plugs make sure thing have the threaded ferrule on top.

I found plenty of spark plugs but nobody had any NGK with the ferrules on top. I substituted Champion RA4HC's.

Hope they work.

Bobby

| Quote: |

href="http://www.matronics.com/Navigator?JabiruEngine-List" class="">http://www.matronics.com/Navigator?JabiruEngine-List

class="">http://forums.matronics.com

class="">http://www.matronics.com/contribution

|

|

[quote][b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

naftalih(at)hotmail.com

Guest

|

Posted: Mon Mar 23, 2015 11:40 am Post subject: Timing Posted: Mon Mar 23, 2015 11:40 am Post subject: Timing |

|

|

Bobby,By taking off the flywheel without pinning the gear, you might have lost the valve timing, not the ignition timing.

If this is the case, follow the instructions defined in the Overhaul Manual. It involves removing heads and the gear plate. And is very educative.

Have fun,

Naftali Horowitz.

Date: Mon, 23 Mar 2015 14:11:18 +0000

From: BobbyPaulk(at)comcast.net

To: jabiruengine-list(at)matronics.com

Subject: Timing

Many thanks to Pete and Clive for the helpful info about timing the 3300.

I did the 7 tooth test as described by Pete and both rotors were in parallel with the trailing edge aligned with the timing marks on the distributor support.

So I do not believe I will have to re-do the timing.

I am buying new spark plugs and will do some more testing Tuesday if weather permits.

By The Way - When you go to purchase NGK D9EA spark plugs make sure thing have the threaded ferrule on top.

I found plenty of spark plugs but nobody had any NGK with the ferrules on top. I substituted Champion RA4HC's.

Hope they work.

Bobby

[quote]

===========

-List" target="_blank">http://www.matronics.com/Navigator?JabiruEngine-List

===========

http://forums.matronics.com

===========

="_blank">http://www.matronics.com/contribution

===========

[b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

BobbyPaulk(at)comcast.net

Guest

|

Posted: Tue Mar 24, 2015 2:31 pm Post subject: Timing Posted: Tue Mar 24, 2015 2:31 pm Post subject: Timing |

|

|

List

Here is the latest in the timing drama on my 3300.

I installed new plugs and cranked the engine again. This time I was able to get it to run with the choke off.

I noticed that the EGT for #3, 4, & 5 was 800 to 900 degrees while #1, 2, & 6 were cold. After about a minute I got the RPM up to about 1100.

#6 came on line but #1 & 2 were still cold. With #6 on line I was able to coax the RPM up to about 1200 when #2 came in.

I determined then that I did not have a timing problem. When the throttle was brought back to 1100 #2 would quit cold again.

We grabbed a boroscope and started looking at the intake pipes and manifold. We found that the intake gasket on #1 had rotated on the outboard bolt about 30 degrees before it was tightened. That left a gap on both sides between the bolts of about 3/4" with part of the gasket in the pipe. That really messed up the manifold pressure and mixture.

After correcting this self induced problem the engine settled down to 750 RPM and was smooth as ever.

The Rotec E-Mag really makes a difference. It starts on the first blade when warm and not more than 2 or 3 when cold.

BTW - I modified my alternator to the Upgrade approved by Jabiru ( AVDALSR087-2 ) and I am getting 14.6 volts at 1300 RPM. Amp meter is always hunting but it got up to 4 amps so I think it will work better than original. I did not have to modify the Dynon tach display.

Bobby ( age 76 )

Zodiac 601 XL "B"

Jabiru 3300 S/N 1141

Sensenich 64" x 51" Prop

Bing Carb 260 Main & 290 Needle Jet

Status - Flying 236 hrs.

[quote][b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

bfy822q(at)mindspring.com

Guest

|

Posted: Tue Mar 24, 2015 6:53 pm Post subject: Timing Posted: Tue Mar 24, 2015 6:53 pm Post subject: Timing |

|

|

Congrats Bobby, I knew you could do it.

Victor-

-

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

UK Clive

Joined: 17 May 2013

Posts: 27

|

Posted: Wed Mar 25, 2015 12:05 am Post subject: Timing Posted: Wed Mar 25, 2015 12:05 am Post subject: Timing |

|

|

Always a process of elimination, well done for getting there. Always difficult to know where to start!Induction can always be quickly checked by hand propping with carby off and your hand blocking the air. You would hear the missing gasket in this case as the air is sucked in any leak.

So after a rebuild one to try before you put the carby on, or one to try if you suspect an induction leak.

Regards, Clive

| Quote: | On 24 Mar 2015, at 22:30, BobbyPaulk(at)comcast.net (BobbyPaulk(at)comcast.net) wrote:

List

Here is the latest in the timing drama on my 3300.

I installed new plugs and cranked the engine again. This time I was able to get it to run with the choke off.

I noticed that the EGT for #3, 4, & 5 was 800 to 900 degrees while #1, 2, & 6 were cold. After about a minute I got the RPM up to about 1100.

#6 came on line but #1 & 2 were still cold. With #6 on line I was able to coax the RPM up to about 1200 when #2 came in. I determined then that I did not have a timing problem. When the throttle was brought back to 1100 #2 would quit cold again.

We grabbed a boroscope and started looking at the intake pipes and manifold. We found that the intake gasket on #1 had rotated on the outboard bolt about 30 degrees before it was tightened. That left a gap on both sides between the bolts of about 3/4" with part of the gasket in the pipe. That really messed up the manifold pressure and mixture.

After correcting this self induced problem the engine settled down to 750 RPM and was smooth as ever.

The Rotec E-Mag really makes a difference. It starts on the first blade when warm and not more than 2 or 3 when cold.

BTW - I modified my alternator to the Upgrade approved by Jabiru ( AVDALSR087-2 ) and I am getting 14.6 volts at 1300 RPM. Amp meter is always hunting but it got up to 4 amps so I think it will work better than original. I did not have to modify the Dynon tach display.

Bobby ( age 76 )Zodiac 601 XL "B"Jabiru 3300 S/N 1141Sensenich 64" x 51" PropBing Carb 260 Main & 290 Needle JetStatus - Flying 236 hrs.

| Quote: |

href="http://www.matronics.com/Navigator?JabiruEngine-List" class="">http://www.matronics.com/Navigator?JabiruEngine-List

class="">http://forums.matronics.com

class="">http://www.matronics.com/contribution

|

|

[quote][b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|