|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

LarryRosen

Joined: 16 Jan 2006

Posts: 415

Location: Medford, NJ

|

Posted: Mon Mar 23, 2015 6:37 pm Post subject: Rear Heat SCAT Tube Routing Posted: Mon Mar 23, 2015 6:37 pm Post subject: Rear Heat SCAT Tube Routing |

|

|

After a very long break, I have started working on building my RV10

again. I am working on fixing some of the things I don't like about how

that came out. One is how the rear heat scat tube is routed around my

fuel valve and over the wing spar.

I have two possible solutions.

One is to reduce to a 1 or 1-1/2" tube. Those that fly in the cold

north, do you think you would still get enough heat to the back

passengers with a 1" tube?

The second is to construct a fiberglass duct to route around the problem

areas. Is the hot air from the heater valve hot enough to cause

problems with a duct constructed of glass and west epoxy?

Larry

RV10 #40356

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Larry Rosen

#40356

N205EN (reserved)

<http> |

|

| Back to top |

|

|

rv10flyer(at)live.com

Guest

|

Posted: Mon Mar 23, 2015 7:10 pm Post subject: Rear Heat SCAT Tube Routing Posted: Mon Mar 23, 2015 7:10 pm Post subject: Rear Heat SCAT Tube Routing |

|

|

Larry

The heat is plenty hot that when we use it it has been about 1-10th of open, so smaller tubing would work fine

I have a Fiberglass plenum over my engine and there is no issue, so I can not imagine it would be an issue. I used Aeropoxy slow cure and that is rated for hotter temps, sure west marine has a higher temp resin as well.

Best of success

Sent from my iPad

| Quote: | On Mar 23, 2015, at 7:40 PM, Larry Rosen <n205en(at)gmail.com> wrote:

After a very long break, I have started working on building my RV10 again. I am working on fixing some of the things I don't like about how that came out. One is how the rear heat scat tube is routed around my fuel valve and over the wing spar.

I have two possible solutions.

One is to reduce to a 1 or 1-1/2" tube. Those that fly in the cold north, do you think you would still get enough heat to the back passengers with a 1" tube?

The second is to construct a fiberglass duct to route around the problem areas. Is the hot air from the heater valve hot enough to cause problems with a duct constructed of glass and west epoxy?

Larry

RV10 #40356

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

johngoodman

Joined: 18 Sep 2006

Posts: 530

Location: GA

|

Posted: Tue Mar 24, 2015 4:11 am Post subject: Re: Rear Heat SCAT Tube Routing Posted: Tue Mar 24, 2015 4:11 am Post subject: Re: Rear Heat SCAT Tube Routing |

|

|

Larry,

I used a 1.75 inch scat tube from Aircraft Spruce - it works fine.

John

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

#40572 Phase One complete in 2011 |

|

| Back to top |

|

|

carl.froehlich(at)verizon

Guest

|

Posted: Tue Mar 24, 2015 6:27 am Post subject: Rear Heat SCAT Tube Routing Posted: Tue Mar 24, 2015 6:27 am Post subject: Rear Heat SCAT Tube Routing |

|

|

Larry,

I used a 1.5" hose from the fire wall to the rear connector, with homebrew

reducers at each end to make the transition between 2" and 1.5". I did this

as it made routing the hose much easier.

Assuming you are doing the stock Vetterman exhaust there is an amazing

amount of heat available for the cabin. Considering this, I installed a

3/4" diameter restrictor in the rear baffle heat muff hose connectors to

reduce the amount of air going to the heat muff. As I would never use that

much heat, I figured that the other 90% of flying where the heat is off I'd

rather have that air cooling the engine instead of bypassing it. Now on the

coldest days I have the rear heat half open and the front heat cracked open

or shut.

One other point - I view the per plans cabin heat valve location as

problematic. On the hottest day you have hot air off the heat muffs being

directed back at the engine - right at the mechanical fuel pump. My fix for

this was to install a piece of Koolmat between the firewall cabin heat boxes

(holes cut out for the box air exit) such that the mat extends over the top

of the boxes and then down over the front of the boxes. The result is when

the cabin heat valves are shut, the dumped hot air is directed down toward

the bottom of the cowl, and the conductive heat from the boxes to the

firewall is reduced. This is the Koolmat product:

http://www.aircraftspruce.com/catalog/appages/koolmat.php?clickkey=261602

I'm happy with how it all worked out.

Carl

--

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

LarryRosen

Joined: 16 Jan 2006

Posts: 415

Location: Medford, NJ

|

Posted: Tue Mar 24, 2015 10:36 am Post subject: Rear Heat SCAT Tube Routing Posted: Tue Mar 24, 2015 10:36 am Post subject: Rear Heat SCAT Tube Routing |

|

|

| Quote: |

I used a 1.5" hose from the fire wall to the rear connector, with homebrew

reducers at each end to make the transition between 2" and 1.5". I did this

as it made routing the hose much easier.

It sounds like 1" tubing would provide more than enough heat.

|

I may homebrew or just use these reducers from planeinovations

<http://www.planeinnovations.com/scat-adapters.html> It will depend if I

want to spend time or money.

| Quote: | One other point - I view the per plans cabin heat valve location as

problematic. On the hottest day you have hot air off the heat muffs being

directed back at the engine - right at the mechanical fuel pump. My fix for

this was to install a piece of Koolmat between the firewall cabin heat boxes

(holes cut out for the box air exit) such that the mat extends over the top

of the boxes and then down over the front of the boxes. The result is when

the cabin heat valves are shut, the dumped hot air is directed down toward

the bottom of the cowl, and the conductive heat from the boxes to the

firewall is reduced. This is the Koolmat product:

http://www.aircraftspruce.com/catalog/appages/koolmat.php?clickkey=261602

I am having a hard time visualizing what you installed. Are you using

|

the koolmat to direct the hot air down instead of towards the engine.

In this case the koolmat is working as a plenum and not insulating the fwf.

Larry

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Larry Rosen

#40356

N205EN (reserved)

<http> |

|

| Back to top |

|

|

Bob Turner

Joined: 03 Jan 2009

Posts: 885

Location: Castro Valley, CA

|

Posted: Tue Mar 24, 2015 11:10 am Post subject: Re: Rear Heat SCAT Tube Routing Posted: Tue Mar 24, 2015 11:10 am Post subject: Re: Rear Heat SCAT Tube Routing |

|

|

I visualize this as the cool mat being in an inverted U shape. One side against the firewall for insulation; the other hanging down a few inches from the firewall to direct the hot air down.

I did half this: put silicon baffle material under the box to insulate it from the firewall.

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Bob Turner

RV-10 QB |

|

| Back to top |

|

|

carl.froehlich(at)verizon

Guest

|

Posted: Tue Mar 24, 2015 11:54 am Post subject: Rear Heat SCAT Tube Routing Posted: Tue Mar 24, 2015 11:54 am Post subject: Rear Heat SCAT Tube Routing |

|

|

Larry,

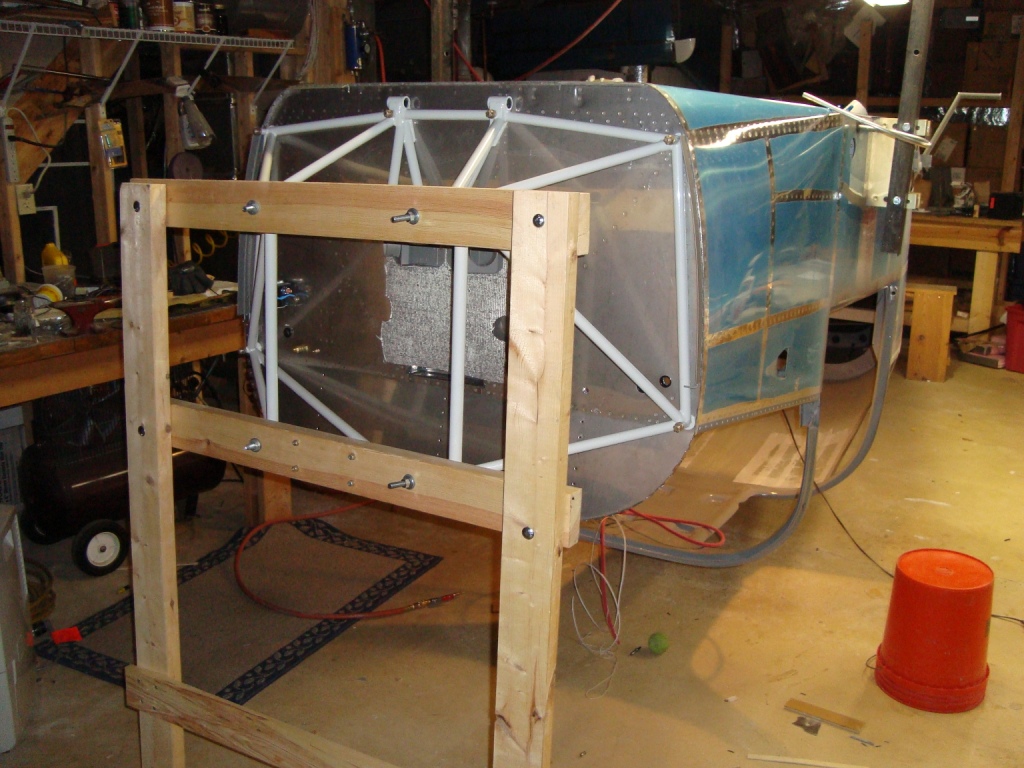

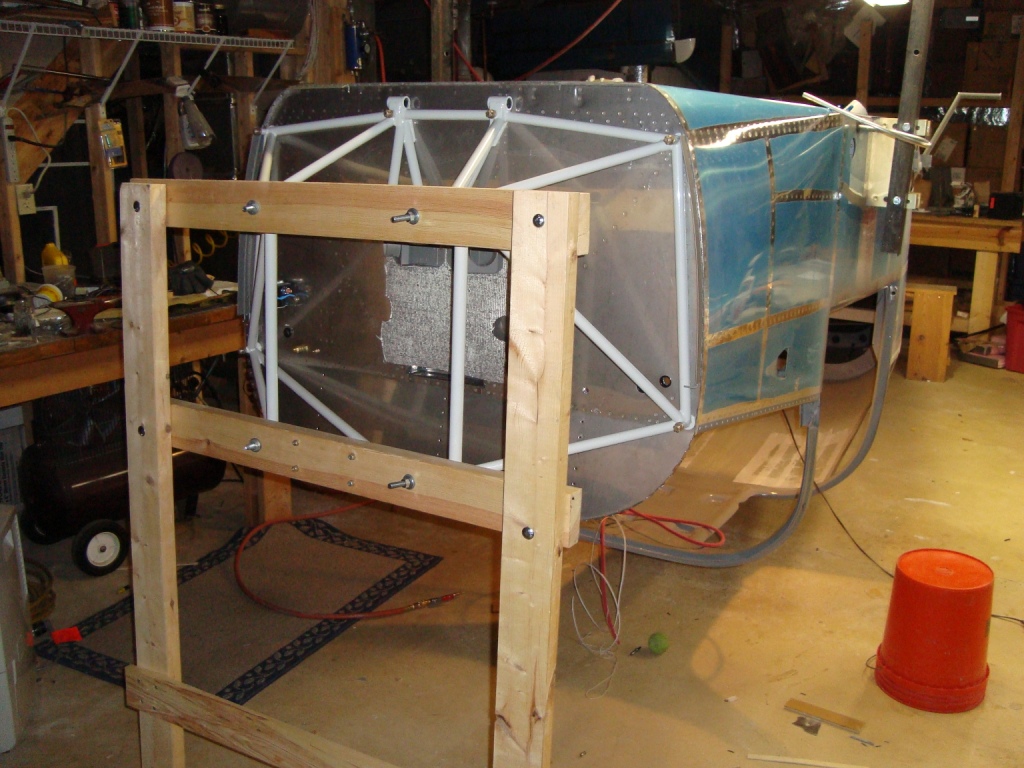

I looked for a photo but only found one when the fuselage was upside down

(attached). So if you can visualize, the flap that is hanging down would

hang over the top of the boxes and scat hoses when upright. You can see the

round notches cut to lay over the scat hoses. The result is the dumped hot

air from the cabin heat boxes is directed down toward the cowl exhaust area.

Carl

--

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

318.26 KB |

| Viewed: |

16590 Time(s) |

|

|

|

| Back to top |

|

|

Deems Davis

Joined: 09 Jan 2006

Posts: 925

|

Posted: Tue Mar 24, 2015 12:20 pm Post subject: Rear Heat SCAT Tube Routing Posted: Tue Mar 24, 2015 12:20 pm Post subject: Rear Heat SCAT Tube Routing |

|

|

http://deemsrv10.com/album/Final%20Assembly/slides/DSC06932.html

On Tue, Mar 24, 2015 at 12:50 PM, Carl Froehlich <carl.froehlich(at)verizon.net (carl.froehlich(at)verizon.net)> wrote:

[quote]Larry,

I looked for a photo but only found one when the fuselage was upside down

(attached). So if you can visualize, the flap that is hanging down would

hang over the top of the boxes and scat hoses when upright. You can see the

round notches cut to lay over the scat hoses. The result is the dumped hot

air from the cabin heat boxes is directed down toward the cowl exhaust area.

Carl

--

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

Deems Davis

Joined: 09 Jan 2006

Posts: 925

|

Posted: Tue Mar 24, 2015 12:21 pm Post subject: Rear Heat SCAT Tube Routing Posted: Tue Mar 24, 2015 12:21 pm Post subject: Rear Heat SCAT Tube Routing |

|

|

http://deemsrv10.com/album/Final%20Assembly/slides/DSC07074.html

click forward for a few more pics

On Tue, Mar 24, 2015 at 11:33 AM, Larry Rosen <n205en(at)gmail.com (n205en(at)gmail.com)> wrote:

[quote]--> RV10-List message posted by: Larry Rosen <n205en(at)gmail.com (n205en(at)gmail.com)>

| Quote: |

I used a 1.5" hose from the fire wall to the rear connector, with homebrew

reducers at each end to make the transition between 2" and 1.5". I did this

as it made routing the hose much easier.

|

It sounds like 1" tubing would provide more than enough heat.

I may homebrew or just use these reducers from planeinovations <http://www.planeinnovations.com/scat-adapters.html> It will depend if I want to spend time or money.

| Quote: | One other point - I view the per plans cabin heat valve location as

problematic. On the hottest day you have hot air off the heat muffs being

directed back at the engine - right at the mechanical fuel pump. My fix for

this was to install a piece of Koolmat between the firewall cabin heat boxes

(holes cut out for the box air exit) such that the mat extends over the top

of the boxes and then down over the front of the boxes. The result is when

the cabin heat valves are shut, the dumped hot air is directed down toward

the bottom of the cowl, and the conductive heat from the boxes to the

firewall is reduced. This is the Koolmat product:

http://www.aircraftspruce.com/catalog/appages/koolmat.php?clickkey=261602

|

I am having a hard time visualizing what you installed. Are you using the koolmat to direct the hot air down instead of towards the engine. In this case the koolmat is working as a plenum and not insulating the fwf.

Larry

====================================

-List" target="_blank">http://www.matronics.com/Navigator?RV10-List

====================================

FORUMS -

_blank">http://forums.matronics.com

====================================

b Site -

-Matt Dralle, List Admin.

target="_blank">http://www.matronics.com/contribution

====================================

[b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

LarryRosen

Joined: 16 Jan 2006

Posts: 415

Location: Medford, NJ

|

Posted: Tue Mar 24, 2015 1:40 pm Post subject: Rear Heat SCAT Tube Routing Posted: Tue Mar 24, 2015 1:40 pm Post subject: Rear Heat SCAT Tube Routing |

|

|

Deems,

1" Scat tubing?

I take it, no issues with the fiberglass in the heater line.

Larry

On 3/24/2015 4:18 PM, Deems Davis wrote:

[quote] http://deemsrv10.com/album/Final%20Assembly/slides/DSC07074.html

click forward for a few more pics

On Tue, Mar 24, 2015 at 11:33 AM, Larry Rosen <n205en(at)gmail.com (n205en(at)gmail.com)> wrote:

| Quote: | --> RV10-List message posted by: Larry Rosen <n205en(at)gmail.com (n205en(at)gmail.com)>

| Quote: |

I used a 1.5" hose from the fire wall to the rear connector, with homebrew

reducers at each end to make the transition between 2" and 1.5". I did this

as it made routing the hose much easier.

|

It sounds like 1" tubing would provide more than enough heat.

I may homebrew or just use these reducers from planeinovations <http://www.planeinnovations.com/scat-adapters.html> It will depend if I want to spend time or money.

| Quote: | One other point - I view the per plans cabin heat valve location as

problematic. On the hottest day you have hot air off the heat muffs being

directed back at the engine - right at the mechanical fuel pump. My fix for

this was to install a piece of Koolmat between the firewall cabin heat boxes

(holes cut out for the box air exit) such that the mat extends over the top

of the boxes and then down over the front of the boxes. The result is when

the cabin heat valves are shut, the dumped hot air is directed down toward

the bottom of the cowl, and the conductive heat from the boxes to the

firewall is reduced. This is the Koolmat product:

http://www.aircraftspruce.com/catalog/appages/koolmat.php?clickkey=261602

|

I am having a hard time visualizing what you installed. Are you using the koolmat to direct the hot air down instead of towards the engine. In this case the koolmat is working as a plenum and not insulating the fwf.

Larry

====================================

-List" target="_blank">http://www.matronics.com/Navigator?RV10-List

====================================

FORUMS -

_blank">http://forums.matronics.com

====================================

b Site -

-Matt Dralle, List Admin.

target="_blank">http://www.matronics.com/contribution

====================================

|

[b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Larry Rosen

#40356

N205EN (reserved)

<http> |

|

| Back to top |

|

|

carl.froehlich(at)verizon

Guest

|

Posted: Tue Mar 24, 2015 1:56 pm Post subject: Rear Heat SCAT Tube Routing Posted: Tue Mar 24, 2015 1:56 pm Post subject: Rear Heat SCAT Tube Routing |

|

|

My first 2â-1.5â scat reducer was made of fiberglass. The first time I turned on the rear heat it did off gas. I replaced it with one made of aluminum.

Carl

From: owner-rv10-list-server(at)matronics.com [mailto:owner-rv10-list-server(at)matronics.com] On Behalf Of Larry Rosen

Sent: Tuesday, March 24, 2015 5:37 PM

To: rv10-list(at)matronics.com

Subject: Re: Rear Heat SCAT Tube Routing

Deems,

1" Scat tubing?

I take it, no issues with the fiberglass in the heater line.

Larry

On 3/24/2015 4:18 PM, Deems Davis wrote:

| Quote: |

http://deemsrv10.com/album/Final%20Assembly/slides/DSC07074.html

click forward for a few more pics

On Tue, Mar 24, 2015 at 11:33 AM, Larry Rosen <n205en(at)gmail.com (n205en(at)gmail.com)> wrote:

--> RV10-List message posted by: Larry Rosen <n205en(at)gmail.com (n205en(at)gmail.com)>

I used a 1.5" hose from the fire wall to the rear connector, with homebrew

reducers at each end to make the transition between 2" and 1.5". I did this

as it made routing the hose much easier.

It sounds like 1" tubing would provide more than enough heat.

I may homebrew or just use these reducers from planeinovations <http://www.planeinnovations.com/scat-adapters.html> It will depend if I want to spend time or money.

One other point - I view the per plans cabin heat valve location as

problematic. On the hottest day you have hot air off the heat muffs being

directed back at the engine - right at the mechanical fuel pump. My fix for

this was to install a piece of Koolmat between the firewall cabin heat boxes

(holes cut out for the box air exit) such that the mat extends over the top

of the boxes and then down over the front of the boxes. The result is when

the cabin heat valves are shut, the dumped hot air is directed down toward

the bottom of the cowl, and the conductive heat from the boxes to the

firewall is reduced. This is the Koolmat product:

http://www.aircraftspruce.com/catalog/appages/koolmat.php?clickkey=261602

I am having a hard time visualizing what you installed. Are you using the koolmat to direct the hot air down instead of towards the engine. In this case the koolmat is working as a plenum and not insulating the fwf.

Larry

====================================

-List" target="_blank">http://www.matronics.com/Navigator?RV10-List

====================================

FORUMS -

_blank">http://forums.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

target="_blank">http://www.matronics.com/contribution

====================================

|

<    - MATRONICS WEB FORUMS via the Web   --> http://forums.matronics.com[/url]        - List Contribution Web generous                        -Matt http://www.matronics.com/c=[/b] [/quote]

[quote][b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

Deems Davis

Joined: 09 Jan 2006

Posts: 925

|

Posted: Tue Mar 24, 2015 2:29 pm Post subject: Rear Heat SCAT Tube Routing Posted: Tue Mar 24, 2015 2:29 pm Post subject: Rear Heat SCAT Tube Routing |

|

|

The 1" was something I had lying around the hangar. No issues with the fiberglass and the heat.I made the reducers by carving some styrofoam and wraping it with duct/mylar tape and then glassing over it.

On Tue, Mar 24, 2015 at 2:37 PM, Larry Rosen <n205en(at)gmail.com (n205en(at)gmail.com)> wrote:

[quote] Deems,

1" Scat tubing?

I take it, no issues with the fiberglass in the heater line.

Larry

On 3/24/2015 4:18 PM, Deems Davis wrote:

| Quote: | http://deemsrv10.com/album/Final%20Assembly/slides/DSC07074.html

click forward for a few more pics

On Tue, Mar 24, 2015 at 11:33 AM, Larry Rosen <n205en(at)gmail.com (n205en(at)gmail.com)> wrote:

| Quote: | --> RV10-List message posted by: Larry Rosen <n205en(at)gmail.com (n205en(at)gmail.com)>

| Quote: |

I used a 1.5" hose from the fire wall to the rear connector, with homebrew

reducers at each end to make the transition between 2" and 1.5". I did this

as it made routing the hose much easier.

|

It sounds like 1" tubing would provide more than enough heat.

I may homebrew or just use these reducers from planeinovations <http://www.planeinnovations.com/scat-adapters.html> It will depend if I want to spend time or money.

| Quote: | One other point - I view the per plans cabin heat valve location as

problematic. On the hottest day you have hot air off the heat muffs being

directed back at the engine - right at the mechanical fuel pump. My fix for

this was to install a piece of Koolmat between the firewall cabin heat boxes

(holes cut out for the box air exit) such that the mat extends over the top

of the boxes and then down over the front of the boxes. The result is when

the cabin heat valves are shut, the dumped hot air is directed down toward

the bottom of the cowl, and the conductive heat from the boxes to the

firewall is reduced. This is the Koolmat product:

http://www.aircraftspruce.com/catalog/appages/koolmat.php?clickkey=261602

|

I am having a hard time visualizing what you installed. Are you using the koolmat to direct the hot air down instead of towards the engine. In this case the koolmat is working as a plenum and not insulating the fwf.

Larry

====================================

-List" target="_blank">http://www.matronics.com/Navigator?RV10-List

====================================

FORUMS -

_blank">http://forums.matronics.com

====================================

b Site -

-Matt Dralle, List Admin.

target="_blank">http://www.matronics.com/contribution

====================================

|

get="_blank">http://www.matronics.com/Navigator?RV10-List

tp://forums.matronics.com

_blank">http://www.matronics.com/contribution

|

[b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

AirMike

Joined: 27 Feb 2007

Posts: 514

Location: Nevada

|

Posted: Tue Mar 24, 2015 4:01 pm Post subject: Rear Heat SCAT Tube Routing - other issues Posted: Tue Mar 24, 2015 4:01 pm Post subject: Rear Heat SCAT Tube Routing - other issues |

|

|

I just followed the standard plans and crushed the large scat tube to fit the space. After 5 years no problems with chafe or perforation. It is ugly, but it works. Deems' installation is obviously 1st class, but a bit of extra work.

I would say two far more important issues are : 1) the cheap aluminum air distribution boxes on the firewall supplied by Vans. I suggest using only the excellent (after market) fire resistant stainless steel steel boxes. Could save your life. 2) Also, if I were building again, I would improvise easier access to the fuel system (in the tunnel) - pump and filter - for easy servicing. Servicing the fuel filter is a real pain. Top and side access portals would facilitate servicing.

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

See you OSH '18

Q/B - sold. |

|

| Back to top |

|

|

dmaib@me.com

Joined: 25 Apr 2006

Posts: 455

Location: New Smyrna Beach, Florida

|

Posted: Tue Mar 24, 2015 5:32 pm Post subject: Re: Rear Heat SCAT Tube Routing - other issues Posted: Tue Mar 24, 2015 5:32 pm Post subject: Re: Rear Heat SCAT Tube Routing - other issues |

|

|

| AirMike wrote: | I just followed the standard plans and crushed the large scat tube to fit the space. After 5 years no problems with chafe or perforation. It is ugly, but it works. Deems' installation is obviously 1st class, but a bit of extra work.

I would say two far more important issues are : 1) the cheap aluminum air distribution boxes on the firewall supplied by Vans. I suggest using only the excellent (after market) fire resistant stainless steel steel boxes. Could save your life. 2) Also, if I were building again, I would improvise easier access to the fuel system (in the tunnel) - pump and filter - for easy servicing. Servicing the fuel filter is a real pain. Top and side access portals would facilitate servicing. |

I did the same thing with the large scat and it works fine. Coming up on 7 years with no issues, but as Mike says, it is ugly. However, I am the only one that looks at it! ^_^

I agree with Mike's comments about the aluminum heat distribution box and tunnel access. I even thought about making a belly access panel, ala Piper, but that would introduce some other engineering issues I imagine. You will thank yourself later on if you make access to the fuel filter as easy as possible.

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

David Maib

RV-10 #40559

New Smyrna Beach, FL |

|

| Back to top |

|

|

kearney

Joined: 20 Sep 2008

Posts: 563

|

Posted: Wed Mar 25, 2015 5:10 am Post subject: Re: Rear Heat SCAT Tube Routing - other issues:Fuel Filter Posted: Wed Mar 25, 2015 5:10 am Post subject: Re: Rear Heat SCAT Tube Routing - other issues:Fuel Filter |

|

|

Hi

Agree with David's comment on the fuel filters. One of the "legacy" items from my earlier filters install was placement of fuel filters in the wing roots. I was able to install two Earl's Performance filters - one in each wing root. They are user serviceable and easily accessed simply by removing the wing root cover panel. Now I don't have to contort myself to get at them as I would if they were in the tunnel.

Regular cleaning, especially when first flying, is a must. There can be a lot of accumulated crud when building.

I also installed an access panel on the pilot's side wall of the tunnel for easy access to the aux fuel pump.

Cheer

Les

| easily(at)me.com wrote: | | AirMike wrote: | I just followed the standard plans and crushed the large scat tube to fit the space. After 5 years no problems with chafe or perforation. It is ugly, but it works. Deems' installation is obviously 1st class, but a bit of extra work.

I would say two far more important issues are : 1) the cheap aluminum air distribution boxes on the firewall supplied by Vans. I suggest using only the excellent (after market) fire resistant stainless steel steel boxes. Could save your life. 2) Also, if I were building again, I would improvise easier access to the fuel system (in the tunnel) - pump and filter - for easy servicing. Servicing the fuel filter is a real pain. Top and side access portals would facilitate servicing. |

I did the same thing with the large scat and it works fine. Coming up on 7 years with no issues, but as Mike says, it is ugly. However, I am the only one that looks at it! ^_^

I agree with Mike's comments about the aluminum heat distribution box and tunnel access. I even thought about making a belly access panel, ala Piper, but that would introduce some other engineering issues I imagine. You will thank yourself later on if you make access to the fuel filter as easy as possible. |

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

rv10free2fly(at)yahoo.com

Guest

|

Posted: Wed Mar 25, 2015 12:15 pm Post subject: Rear Heat SCAT Tube Routing Posted: Wed Mar 25, 2015 12:15 pm Post subject: Rear Heat SCAT Tube Routing |

|

|

Any pictures of the wing root filter installations please Les?

Warm regards

Patrick

| Quote: | On 25 Mar 2015, at 23:40, kearney <kearney(at)shaw.ca> wrote:

Hi

Agree with David's comment on the fuel filters. One of the "legacy" items from my earlier filters install was placement of fuel filters in the wing roots. I was able to install two Earl's Performance filters - one in each wing root. They are user serviceable and easily accessed simply by removing the wing root cover panel. Now I don't have to contort myself to get at them as I would if they were in the tunnel.

Regular cleaning, especially when first flying, is a must. There can be a lot of accumulated crud when building.

I also installed an access panel on the pilot's side wall of the tunnel for easy access to the aux fuel pump.

Cheer

Les

easily(at)me.com wrote:

>

> AirMike wrote:

>> I just followed the standard plans and crushed the large scat tube to fit the space. After 5 years no problems with chafe or perforation. It is ugly, but it works. Deems' installation is obviously 1st class, but a bit of extra work.

>>

>> I would say two far more important issues are : 1) the cheap aluminum air distribution boxes on the firewall supplied by Vans. I suggest using only the excellent (after market) fire resistant stainless steel steel boxes. Could save your life. 2) Also, if I were building again, I would improvise easier access to the fuel system (in the tunnel) - pump and filter - for easy servicing. Servicing the fuel filter is a real pain. Top and side access portals would facilitate servicing.

>

>

> I did the same thing with the large scat and it works fine. Coming up on 7 years with no issues, but as Mike says, it is ugly. However, I am the only one that looks at it! ^_^

> I agree with Mike's comments about the aluminum heat distribution box and tunnel access. I even thought about making a belly access panel, ala Piper, but that would introduce some other engineering issues I imagine. You will thank yourself later on if you make access to the fuel filter as easy as possible.

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=439860#439860

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

LarryRosen

Joined: 16 Jan 2006

Posts: 415

Location: Medford, NJ

|

Posted: Tue Mar 31, 2015 12:43 pm Post subject: Rear Heat SCAT Tube Routing Posted: Tue Mar 31, 2015 12:43 pm Post subject: Rear Heat SCAT Tube Routing |

|

|

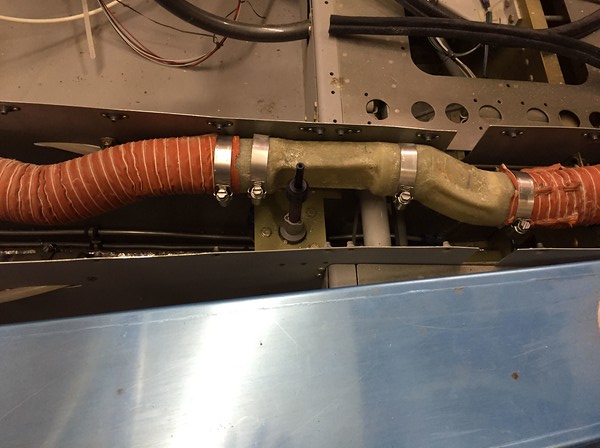

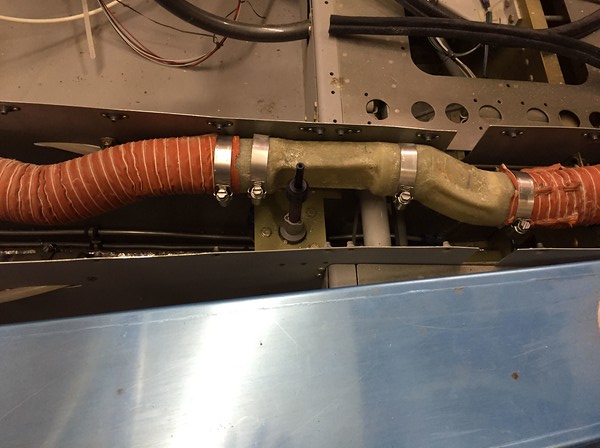

Attached is a photo of my SCAT tube solution. I made a fiberglass tube

to go around the Andair fuel valve stem. The tube is held in place by 2

pipe clamps that are riveted to the tunnel.

Larry

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

64.25 KB |

| Viewed: |

16463 Time(s) |

|

_________________

Larry Rosen

#40356

N205EN (reserved)

<http> |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|