|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

jpoint(at)wi.rr.com

Guest

|

Posted: Tue Mar 07, 2017 4:53 am Post subject: Z-17 battery/ alternator switch Posted: Tue Mar 07, 2017 4:53 am Post subject: Z-17 battery/ alternator switch |

|

|

All,

I'm building a simple day/ VFR airplane with Z-17 as the basis for my

electric system. I noticed that the battery/ alternator switch is a

two-throw switch wired as "Off-battery-alternator", presumably to be

able to start on battery power and bring the alternator online once the

engine is running. Other drawings (Z-13/8 for example) use a simple

single-throw switch to bring battery and alternator on together. I've

flown with a Z-13-type system in my RV-6 for 13 years so I have faith in it.

Why the different switch design in Z-17? Is there something about the

PM dynamo alternator that requires it to be off during engine start? Is

it because Z-17 doesn't use a master contactor? Would there be any harm

in starting with the PM alternator online?

Thanks

Jeff Point

Milwaukee WI

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

rene(at)felker.com

Guest

|

Posted: Tue Mar 07, 2017 5:11 am Post subject: Z-17 battery/ alternator switch Posted: Tue Mar 07, 2017 5:11 am Post subject: Z-17 battery/ alternator switch |

|

|

I always thought that the reason for split switches, etc, was so you could turn off the alternator without turning off the battery. I always start with the alternator on.......just my 2 cents.

--

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1927

Location: Riley TWP Michigan

|

Posted: Tue Mar 07, 2017 5:46 am Post subject: Re: Z-17 battery/ alternator switch Posted: Tue Mar 07, 2017 5:46 am Post subject: Re: Z-17 battery/ alternator switch |

|

|

| Quote: | | Would there be any harm in starting with the PM alternator online? |

No, in fact that is common practice and is recommended.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue Mar 07, 2017 8:48 am Post subject: Z-17 battery/ alternator switch Posted: Tue Mar 07, 2017 8:48 am Post subject: Z-17 battery/ alternator switch |

|

|

At 07:46 AM 3/7/2017, you wrote:

| Quote: | --> AeroElectric-List message posted by: "user9253" <fransew(at)gmail.com>

> Would there be any harm in starting with the PM alternator online? No, in fact that is common practice and is recommended. |

Actually, it's six-of-on, half-dozen-of-the-other.

A bit of history:

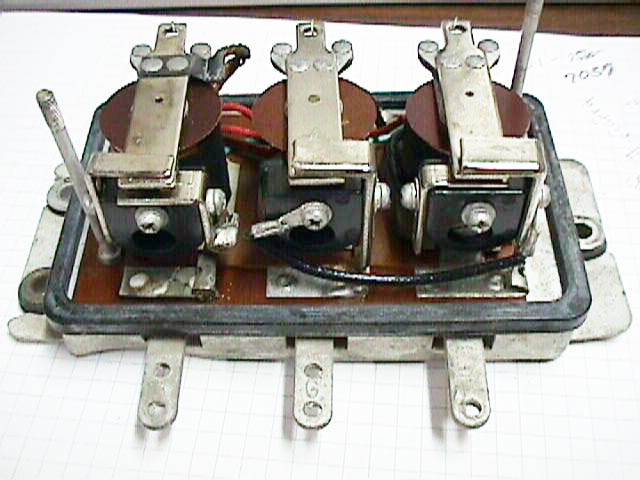

The first electrical systems to be installed on aircraft

used generators . . . just like the ones on cars, tractors

and trucks. These were simply shunt wound, DC MOTORS being

PUSHED with mechanical energy into the shaft such that they

became GENERATORS.

They required rather sophisticated regulators that not

only maintained the target bus voltage but limited

output current (to prevent commutator and armature

over-heat) and provided reverse current disconnect

so that a NON rotating generator did not revert to

it's roots as a motor and run the battery down after

the engine stopped. These electro-mechanical analogs

to modern electronics are exceedingly clever creations

of the era.

[img]cid:.0[/img]

Generators were self-exciting (meaning that they would come

on line with a simple input of mechanical energy (engine running)

and flipping the field supply switch to ON. Further, they

would run well without a battery on line.

Modern starter-generators on turbine aircraft retain traits

of their ancestors and they too run well without having a

battery on line.

Hence, aircraft with any form of generator will generally

have BOTH battery master and generator control switches.

Interestingly enough, the Beech Bonanza STILL has independent

BATTERY and ALTERNATOR switches . . . which is another

story.

When we started putting alternators on TC aircraft (mid 60s)

it was discovered that (1) the alternators did not self

excite at ramp idle rpm and (2) voltage regulation dynamics

were not as comfortable as the generators being replaced.

Cessna (and others) were 'upgrading' the panel styles to incorporate

rocker switches.

Cessna approached Carling to supply a split-rocker switch that

would (1) provide battery and alternator control in one device,

(2) allow battery only operations and (3) prevent alternator

only operations.

http://tinyurl.com/zbo3yg6

Nowadays, many if not most alternators will self excite at

less than cruise rpms . . . voltage regulation dynamics

are improved too . . . so it is less problematic to consider

alternator-only ops. Given the inherent reliability of

the artfully maintained battery, there is really no demontrable

value in planning to accommodate alternator only ops . . . but

it is not outside the realm of possibility . . . indeed, the

POH for Bonanzas (and I think Barons) speak to this option.

Now, how about the differences between the single-throw and

three-throw options depicted in the Z-figures?

EITHER approach is perfectly satisfactory. The single throw

switch prevents alternator-only ops while a PULLABLE circuit

breaker offers a means for breaking alternator field supply

for battery-only ops on the ground. The three throw switch

emulates the split-rocker switch functionality and design

goals adopted by the TC aircraft guys . . . a philosophy

that persists to this day.

MYTHBUSTING: In some circles it has been believed and taught

that turning an alternator ON/OFF while the engine is running

is a bad thing . . . puts lots of stresses on shafts, shear

couplings, gear trains, etc. etc. It has also been reputed

to induce radio zapping transients into the electrical system.

In a word . . . HOGWASH.

I've spent hundreds of hours evaluating alternator/battery/

airplane symbiosis in both in the lab and on airplanes. I've

conducted, witnessed and instrumented hundreds of switching

combinations of battery, alternators and system loads under

the full constellation of conditions.

There is no foundation in physics or practice for the admonition

to start the engine with the alternator switch ON. Leaving

it OFF does relive the battery of about 3A of parasitic load

during cranking . . . a trivial concern.

The short answer: Use which ever MASTER DC PWR switch

philosophy floats ur boat. Either will perform as advertised.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

142.7 KB |

| Viewed: |

9570 Time(s) |

|

|

|

| Back to top |

|

|

stuart(at)stuarthutchison

Guest

|

Posted: Tue Mar 07, 2017 3:03 pm Post subject: Z-17 battery/ alternator switch Posted: Tue Mar 07, 2017 3:03 pm Post subject: Z-17 battery/ alternator switch |

|

|

Why is it recommended Joe?

Kind Regards, Stu

Sent from my iPhone

| Quote: | On 8 Mar 2017, at 00:46, user9253 <fransew(at)gmail.com> wrote:

> Would there be any harm in starting with the PM alternator online?

No, in fact that is common practice and is recommended.

--------

Joe Gores

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=466963#466963

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1927

Location: Riley TWP Michigan

|

Posted: Tue Mar 07, 2017 6:11 pm Post subject: Re: Z-17 battery/ alternator switch Posted: Tue Mar 07, 2017 6:11 pm Post subject: Re: Z-17 battery/ alternator switch |

|

|

Recommended so that the pilot does not forget to turn it on.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

stuart(at)stuarthutchison

Guest

|

Posted: Wed Mar 08, 2017 3:28 am Post subject: Z-17 battery/ alternator switch Posted: Wed Mar 08, 2017 3:28 am Post subject: Z-17 battery/ alternator switch |

|

|

Thanks Joe.

I’d be interested to know yours and Bob's thoughts on the legitimacy of an article I read in the club house a few years back.

The author explained that aeroplane alternators seem have a higher rate of failure compared to motor vehicle alternators that are also more commonly subjected to mud, water and dust ingress. His reasoning was that in a car the alternator field is isolated during the start sequence (as are the lights and most other power hungry devices that add to the battery load) until the key is released to its normal position. By contrast, when cranking an aeroplane engine with the alternator field excited, the voltage regulator senses a substantial sag in bus voltage and attempts to draw max output from the alternator to fix the problem before the alternator has sufficient RPM to provide the required output. I reasoned that this was why some manufacturers have split or separate alternator switches. Any truth to this concept then?

Cheers, Stu

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jpoint(at)wi.rr.com

Guest

|

Posted: Wed Mar 08, 2017 4:55 am Post subject: Z-17 battery/ alternator switch Posted: Wed Mar 08, 2017 4:55 am Post subject: Z-17 battery/ alternator switch |

|

|

Thanks for the detailed answer Bob, that makes a lot of sense. One of

my design goals is to keep the switch position and function as similar

as I can to my other airplane, especially the power and ignition

switches. A single throw it will be.

Jeff Point

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1927

Location: Riley TWP Michigan

|

Posted: Wed Mar 08, 2017 7:33 am Post subject: Re: Z-17 battery/ alternator switch Posted: Wed Mar 08, 2017 7:33 am Post subject: Re: Z-17 battery/ alternator switch |

|

|

| Quote: | | Thanks Joe. I’d be interested to know yours and Bob's thoughts on the legitimacy of an article I read in the club house a few years back. |

I am no expert on alternators. But it would seem to me that maximum field current for several seconds should not cause premature failure.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Mar 08, 2017 9:15 am Post subject: Z-17 battery/ alternator switch Posted: Wed Mar 08, 2017 9:15 am Post subject: Z-17 battery/ alternator switch |

|

|

| Quote: | | The author explained that aeroplane alternators seem have a higher rate of failure compared to motor vehicle alternators that are also more commonly subjected to mud, water and dust ingress. His reasoning was that in a car the alternator field is isolated during the start sequence (as are the lights and most other power hungry devices that add to the battery load) until the key is released to its normal position. By contrast, when cranking an aeroplane engine with the alternator field excited, the voltage regulator senses a substantial sag in bus voltage and attempts to draw max output from the alternator to fix the problem before the alternator has sufficient RPM to provide the required output. I reasoned that this was why some manufacturers have split or separate alternator switches. Any truth to this concept then? |

"higher rates of failure" is not very descriptive

of cause and effect. While it's true that some

alternators in aircraft have been problematic,

most of my encounters have been grounded in

design or manufacturing defect. We used to break

a lot of brackets on some installations. Piper's

love affair with the Chrysler 'pancake' alternators

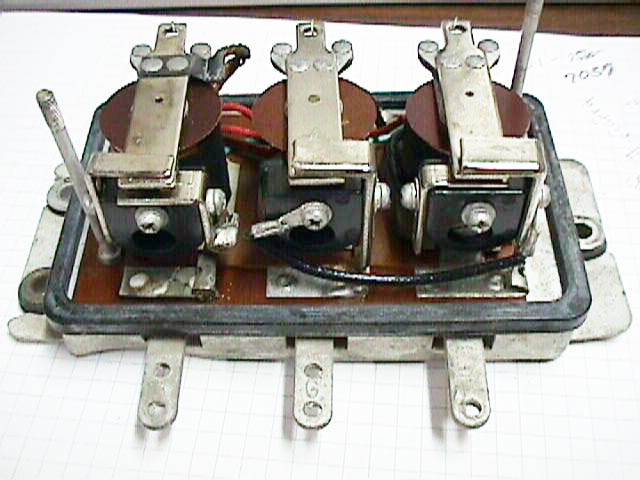

led to short service life on attach brackets. An

alternator I conducted failure analysis on a

few months back had press fit diodes pushed into

oversized holes at odd angles using a hand-tool

as opposed to the recommended hydraulic press.

[img]cid:.0[/img]

The diodes were deprived of good heat sinking and in

some cases, good electrical conductivity.

The last task I mounted in TC aviation concerned alternators

that wouldn't stay on line . . . a problem I'd worked at

least two previous times over 30 years. Focus

of the investigation was on alternators that had

demonstrated problems over the years, but in this case

it was the regulator's o.v. sense system that was

overly sensitive to normal brush noise from this

alternator . . . they struggled for weeks to "filter"

the field leads (with limited success) while in fact,

it was the regulator that needed to be changed out.

At the same time, alternators supplied by B&C (and

no doubt others) have an exceedingly low return

rate.

The hypothesis offered in the article is without

foundation in physics or practice. If the author

went to the lab, he would not be able to reproduce

a failure by duplication of conditions cited in the

hypothesis.

It's all physics. For every failure there IS a

combination of conditions leading up to that failure.

Proper operations of switches by crew are exceedingly

unlikely to be in the chorus of conditions. Joe is

correct, a few seconds of full-field operation is

of no particular hardship on an alternator.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

153 KB |

| Viewed: |

9527 Time(s) |

|

|

|

| Back to top |

|

|

stuart(at)stuarthutchison

Guest

|

Posted: Thu Mar 09, 2017 4:29 am Post subject: Z-17 battery/ alternator switch Posted: Thu Mar 09, 2017 4:29 am Post subject: Z-17 battery/ alternator switch |

|

|

Thanks Joe & Bob.

I’ve bought lots of parts from B&C, but in this case my PlanePower 70A (internally regulated) also seems very well made, with cooling air intake through the windings, hot air extracted by fans at both front and back ends, plus a ram-air cooling duct directly targeting the potted regulator.

The mounting brackets are very solid too, so hopefully the drive belt is the only part I’ll ever have to replace.

V/R, Stu

| Quote: | On 9 Mar 2017, at 04:12, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | | The author explained that aeroplane alternators seem have a higher rate of failure compared to motor vehicle alternators that are also more commonly subjected to mud, water and dust ingress. His reasoning was that in a car the alternator field is isolated during the start sequence (as are the lights and most other power hungry devices that add to the battery load) until the key is released to its normal position. By contrast, when cranking an aeroplane engine with the alternator field excited, the voltage regulator senses a substantial sag in bus voltage and attempts to draw max output from the alternator to fix the problem before the alternator has sufficient RPM to provide the required output. I reasoned that this was why some manufacturers have split or separate alternator switches. Any truth to this concept then? |

"higher rates of failure" is not very descriptive of cause and effect. While it's true that some alternators in aircraft have been problematic, most of my encounters have been grounded in design or manufacturing defect. We used to break a lot of brackets on some installations. Piper's love affair with the Chrysler 'pancake' alternators led to short service life on attach brackets. An alternator I conducted failure analysis on a few months back had press fit diodes pushed into oversized holes at odd angles using a hand-tool as opposed to the recommended hydraulic press. <8e94c69.jpg> The diodes were deprived of good heat sinking and in some cases, good electrical conductivity. The last task I mounted in TC aviation concerned alternators that wouldn't stay on line . . . a problem I'd worked at least two previous times over 30 years. Focus of the investigation was on alternators that had demonstrated problems over the years, but in this case it was the regulator's o.v. sense system that was overly sensitive to normal brush noise from this alternator . . . they struggled for weeks to "filter" the field leads (with limited success) while in fact, it was the regulator that needed to be changed out. At the same time, alternators supplied by B&C (and no doubt others) have an exceedingly low return rate. The hypothesis offered in the article is without foundation in physics or practice. If the author went to the lab, he would not be able to reproduce a failure by duplication of conditions cited in the hypothesis. It's all physics. For every failure there IS a combination of conditions leading up to that failure. Proper operations of switches by crew are exceedingly unlikely to be in the chorus of conditions. Joe is correct, a few seconds of full-field operation is of no particular hardship on an alternator.

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|