|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

dlm34077(at)gmail.com

Guest

|

Posted: Tue May 23, 2017 6:13 am Post subject: cowl heat protection Posted: Tue May 23, 2017 6:13 am Post subject: cowl heat protection |

|

|

I used a silicon backed layer of fiberglass mat; after 1000 hr. it was OK; no apparent delamination. From last June to April 2017, I found three areas of delamination and had to replace multi layers both sides of the Nomex core. Unfortunately last June, I let an FBO do some work and unknown to me, the baffling was not correctly reinstalled and sealed; it is unknown whether this contributed to the delamination. The cowl has been fixed except for the new heat protection. What are other builders using? what are your results? My plan now is to use the reflective aluminum adhesive back material for the areas near (less than 3") the exhaust system. Selected areas will also have Fiberfrax beneath the reflective foil. Per the heat document from Vans, I will not be wrapping selected exhaust system areas, although an IA friend says that turbine exhaust systems are routinely wrapped. Any suggestions other than NEVER LET ANYONE ELSE TOUCH.

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

jump2(at)sbcglobal.net

Guest

|

Posted: Tue May 23, 2017 1:34 pm Post subject: cowl heat protection Posted: Tue May 23, 2017 1:34 pm Post subject: cowl heat protection |

|

|

I have reflective aluminum on inside cowl, no problems just shy of 1000 hrs. I did paint inside of cowling so it had a good base to adhere to.

Patrick Thyssen

Sent from my iPad

| Quote: | On May 23, 2017, at 9:13 AM, dlm <dlm34077(at)gmail.com> wrote:

I used a silicon backed layer of fiberglass mat; after 1000 hr. it was OK; no apparent delamination. From last June to April 2017, I found three areas of delamination and had to replace multi layers both sides of the Nomex core. Unfortunately last June, I let an FBO do some work and unknown to me, the baffling was not correctly reinstalled and sealed; it is unknown whether this contributed to the delamination. The cowl has been fixed except for the new heat protection. What are other builders using? what are your results? My plan now is to use the reflective aluminum adhesive back material for the areas near (less than 3") the exhaust system. Selected areas will also have Fiberfrax beneath the reflective foil. Per the heat document from Vans, I will not be wrapping selected exhaust system areas, although an IA friend says that turbine exhaust systems are routinely wrapped. Any suggestions other than NEVER LET ANYONE ELSE TOUCH.

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

bill.peyton

Joined: 19 Sep 2010

Posts: 198

Location: St. Louis, MO

|

Posted: Wed May 24, 2017 4:36 am Post subject: Re: cowl heat protection Posted: Wed May 24, 2017 4:36 am Post subject: Re: cowl heat protection |

|

|

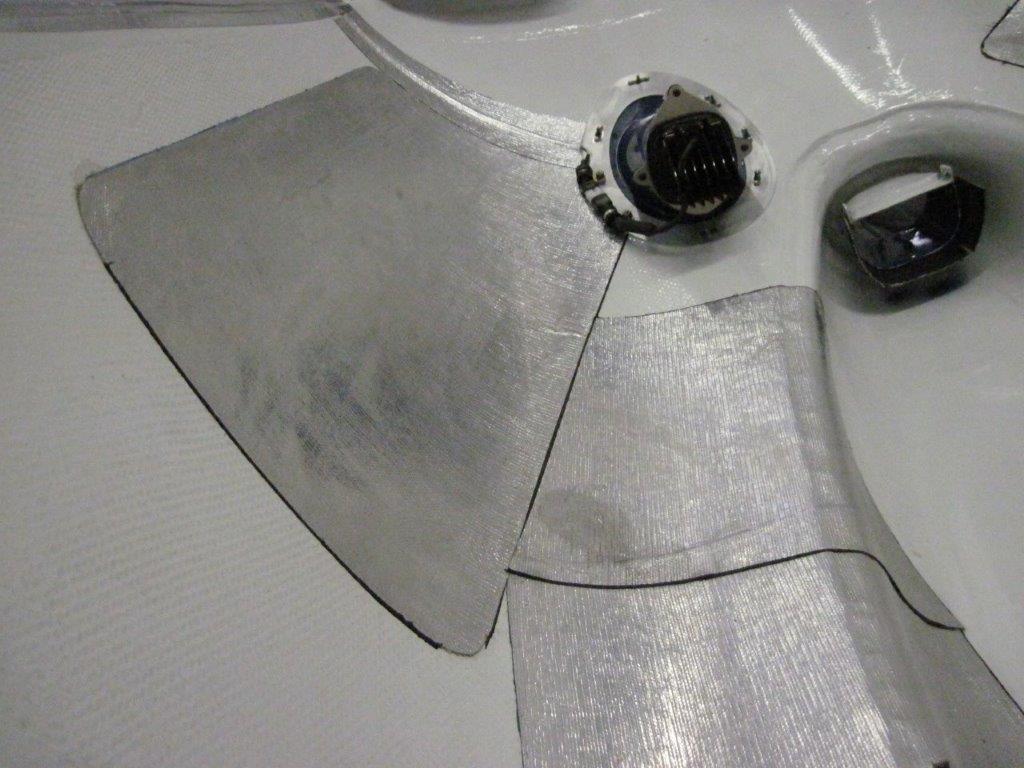

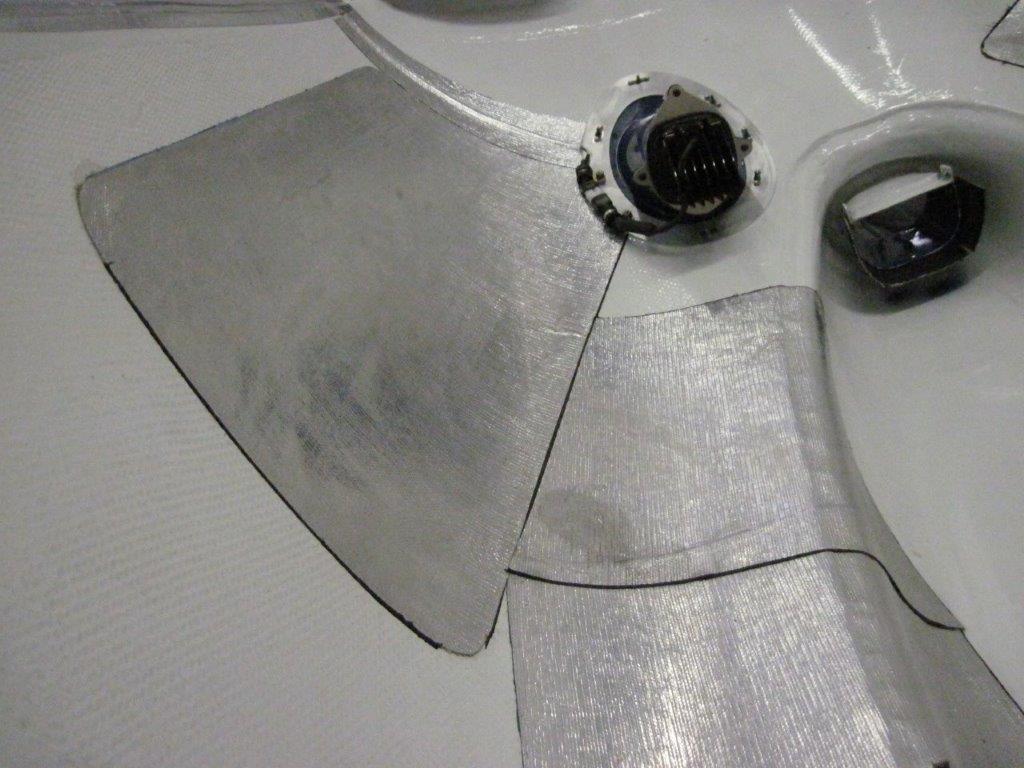

I used the adhesive reflective stuff you can purchase from ACS. 600 hours and no issues. Photo below

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

105.34 KB |

| Viewed: |

5441 Time(s) |

|

_________________

Bill

WA0SYV

Aviation Partners, LLC |

|

| Back to top |

|

|

nukeflyboy

Joined: 05 Jan 2008

Posts: 162

Location: Granbury, TX

|

Posted: Wed May 24, 2017 4:45 am Post subject: Re: cowl heat protection Posted: Wed May 24, 2017 4:45 am Post subject: Re: cowl heat protection |

|

|

I did the same as Patrick and it works well after 550 hours. The coverage needs to be fairly extensive. I also have a bolt-on heat shield where the exhaust pipe passes close to the cowl.

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Dave Moore

RV-6 built and sold

RV-10 built and flying |

|

| Back to top |

|

|

schmoboy

Joined: 26 Feb 2006

Posts: 130

|

Posted: Wed May 24, 2017 4:59 am Post subject: cowl heat protection Posted: Wed May 24, 2017 4:59 am Post subject: cowl heat protection |

|

|

In addition to the reflective foil I painted the inside of the cowl with

a few coats of white high-temp grill paint available at your local home

store. I don't have a 1000 hours of testing, but so far no issues.

-Sean #40303

| Quote: | dlm <mailto:dlm34077(at)gmail.com>

May 23, 2017 at 9:13 AM

I used a silicon backed layer of fiberglass mat; after 1000 hr. it was

OK; no apparent delamination. From last June to April 2017, I found

three areas of delamination and had to replace multi layers both sides

of the Nomex core. Unfortunately last June, I let an FBO do some work

and unknown to me, the baffling was not correctly reinstalled and

sealed; it is unknown whether this contributed to the delamination.

The cowl has been fixed except for the new heat protection. What are

other builders using? what are your results? My plan now is to use the

reflective aluminum adhesive back material for the areas near (less

than 3") the exhaust system. Selected areas will also have Fiberfrax

beneath the reflective foil. Per the heat document from Vans, I will

not be wrapping selected exhaust system areas, although an IA friend

says that turbine exhaust systems are routinely wrapped. Any

suggestions other than NEVER LET ANYONE ELSE TOUCH.

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|