|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

Achille

Joined: 12 Jun 2017

Posts: 25

Location: Europe

|

Posted: Fri Aug 04, 2017 8:51 am Post subject: 2 AWG crimping tool Posted: Fri Aug 04, 2017 8:51 am Post subject: 2 AWG crimping tool |

|

|

Hello,

I have a question about crimping 2 AWG wire. I was wiring my plane and it came the time to wire my 2 AWG cable.

For that I bought a crimping tool, this : (Not the best I agree)

http://www.electricianstoolsonline.com/mini-hex-crimper-6mm2-to-50mm2

We can see that is for : 6mm², 10mm², 16mm², 25mm², 35mm², 50mm²

Hexagonal crimp

My cable was a 2 AWG mil spec and my terminal is bought on the same website bandc-aero.

I tried to crimp one with the 25mm2 jaw (for me 2 AWG it's 32mm2 ?), cable looked well maintained but terminal was deformed. With on a side a sharp edge.

So I crimped with the 50mm2, I performed a light traction test it seems to be ok terminal stay on the wire, but how could be sure that crimp is ok ? It not seems to be tightened with a good strong deformation.

I ask the question because if it was on my car, I will see with time. But on my plane, even if I have two battery, (with one small wired with standard small temrinal) I don't want to try tings.

Thank you in advance to sharing you experience on this subject.

Good flight.

Mickaël

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

JOHN TIPTON

Joined: 17 Sep 2006

Posts: 239

Location: Torquay - England

|

Posted: Fri Aug 04, 2017 9:04 am Post subject: 2 AWG crimping tool Posted: Fri Aug 04, 2017 9:04 am Post subject: 2 AWG crimping tool |

|

|

For the price you can't beat this:

http://www.ebay.co.uk/itm/Tube-Terminals-Lugs-Battery-Cable-Wire-Crimping-Force-Hydraulic-Crimper-Tool-Kit-/132282830917?hash=item1eccabd045:g:kp8AAOSwSplZgvnD

John

Sent from my iPad

----x--O--x----

| Quote: | On 4 Aug 2017, at 05:51 pm, "Achille" <mickael.t(at)live.fr> wrote:

Hello,

I have a question about crimping 2 AWG wire. I was wiring my plane and it came the time to wire my 2 AWG cable.

For that I bought a crimping tool, this : (Not the best I agree)

http://www.electricianstoolsonline.com/mini-hex-crimper-6mm2-to-50mm2

We can see that is for : 6mm², 10mm², 16mm², 25mm², 35mm², 50mm²

Hexagonal crimp

My cable was a 2 AWG mil spec and my terminal is bought on the same website bandc-aero.

I tried to crimp one with the 25mm2 jaw (for me 2 AWG it's 32mm2 ?), cable looked well maintained but terminal was deformed. With on a side a sharp edge.

So I crimped with the 50mm2, I performed a light traction test it seems to be ok terminal stay on the wire, but how could be sure that crimp is ok ? It not seems to be tightened with a good strong deformation.

I ask the question because if it was on my car, I will see with time. But on my plane, even if I have two battery, (with one small wired with standard small temrinal) I don't want to try tings.

Thank you in advance to sharing you experience on this subject.

Good flight.

Mickaël [Wink]

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=471500#471500

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

ceengland7(at)gmail.com

Guest

|

Posted: Fri Aug 04, 2017 9:24 am Post subject: 2 AWG crimping tool Posted: Fri Aug 04, 2017 9:24 am Post subject: 2 AWG crimping tool |

|

|

You can beat it pretty easily with a small propane torch (already in

your tool box), some rosin core solder, a couple of inches of shrink

tubing, and the knowledge that there's no more risk of fatigue damage

with a properly soldered joint & downstream support, than there is with

a crimped joint.

On 8/4/2017 12:03 PM, John Tipton wrote:

| Quote: |

For the price you can't beat this:

http://www.ebay.co.uk/itm/Tube-Terminals-Lugs-Battery-Cable-Wire-Crimping-Force-Hydraulic-Crimper-Tool-Kit-/132282830917?hash=item1eccabd045:g:kp8AAOSwSplZgvnD

John

Sent from my iPad

----x--O--x----

> On 4 Aug 2017, at 05:51 pm, "Achille" <mickael.t(at)live.fr> wrote:

>

>

>

> Hello,

>

> I have a question about crimping 2 AWG wire. I was wiring my plane and it came the time to wire my 2 AWG cable.

>

> For that I bought a crimping tool, this : (Not the best I agree)

>

> http://www.electricianstoolsonline.com/mini-hex-crimper-6mm2-to-50mm2

>

> We can see that is for : 6mm², 10mm², 16mm², 25mm², 35mm², 50mm²

> Hexagonal crimp

>

> My cable was a 2 AWG mil spec and my terminal is bought on the same website bandc-aero.

>

> I tried to crimp one with the 25mm2 jaw (for me 2 AWG it's 32mm2 ?), cable looked well maintained but terminal was deformed. With on a side a sharp edge.

>

> So I crimped with the 50mm2, I performed a light traction test it seems to be ok terminal stay on the wire, but how could be sure that crimp is ok ? It not seems to be tightened with a good strong deformation.

>

> I ask the question because if it was on my car, I will see with time. But on my plane, even if I have two battery, (with one small wired with standard small temrinal) I don't want to try tings.

>

> Thank you in advance to sharing you experience on this subject.

>

> Good flight.

> Mickaël [Wink]

|

---

This email has been checked for viruses by Avast antivirus software.

https://www.avast.com/antivirus

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

kjashton(at)vnet.net

Guest

|

Posted: Fri Aug 04, 2017 10:07 am Post subject: 2 AWG crimping tool Posted: Fri Aug 04, 2017 10:07 am Post subject: 2 AWG crimping tool |

|

|

I have crimped them similar to this method but I used a piece of steel with a half-hole for the anvil

http://www.thebackshed.com/forum/printer_friendly_posts.asp?FID=4&TID=8298

Or do a google images search for âcrimp large cablesâ and youâll see lots of crimpers

If you have a welding supplier nearby, they can crimp those large cables. Welding cable is often used in battery runs. Very tough and flexible.

-Kent

| Quote: | On Aug 4, 2017, at 12:51 PM, Achille <mickael.t(at)live.fr> wrote:

Hello,

I have a question about crimping 2 AWG wire. I was wiring my plane and it came the time to wire my 2 AWG cable.

For that I bought a crimping tool, this : (Not the best I agree)

http://www.electricianstoolsonline.com/mini-hex-crimper-6mm2-to-50mm2

We can see that is for : 6mmò, 10mmò, 16mmò, 25mmò, 35mmò, 50mmò

Hexagonal crimp

My cable was a 2 AWG mil spec and my terminal is bought on the same website bandc-aero.

I tried to crimp one with the 25mm2 jaw (for me 2 AWG it's 32mm2 ?), cable looked well maintained but terminal was deformed. With on a side a sharp edge.

So I crimped with the 50mm2, I performed a light traction test it seems to be ok terminal stay on the wire, but how could be sure that crimp is ok ? It not seems to be tightened with a good strong deformation.

I ask the question because if it was on my car, I will see with time. But on my plane, even if I have two battery, (with one small wired with standard small temrinal) I don't want to try tings.

Thank you in advance to sharing you experience on this subject.

Good flight.

Mickaël [Wink]

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=471500#471500

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Robert Reed

Joined: 22 Oct 2009

Posts: 331

Location: Dallas/Ft.Worth

|

Posted: Fri Aug 04, 2017 10:13 am Post subject: 2 AWG crimping tool Posted: Fri Aug 04, 2017 10:13 am Post subject: 2 AWG crimping tool |

|

|

Found similar at Harbor Freight an it works great.

Bob Reed

Sent from my iPhone

| Quote: | On Aug 4, 2017, at 1:05 PM, Kent or Jackie Ashton <kjashton(at)vnet.net> wrote:

I have crimped them similar to this method but I used a piece of steel with a half-hole for the anvil

http://www.thebackshed.com/forum/printer_friendly_posts.asp?FID=4&TID=8298

Or do a google images search for âcrimp large cablesâ and youâll see lots of crimpers

If you have a welding supplier nearby, they can crimp those large cables. Welding cable is often used in battery runs. Very tough and flexible.

-Kent

> On Aug 4, 2017, at 12:51 PM, Achille <mickael.t(at)live.fr> wrote:

>

>

>

> Hello,

>

> I have a question about crimping 2 AWG wire. I was wiring my plane and it came the time to wire my 2 AWG cable.

>

> For that I bought a crimping tool, this : (Not the best I agree)

>

> http://www.electricianstoolsonline.com/mini-hex-crimper-6mm2-to-50mm2

>

> We can see that is for : 6mmò, 10mmò, 16mmò, 25mmò, 35mmò, 50mmò

> Hexagonal crimp

>

> My cable was a 2 AWG mil spec and my terminal is bought on the same website bandc-aero.

>

> I tried to crimp one with the 25mm2 jaw (for me 2 AWG it's 32mm2 ?), cable looked well maintained but terminal was deformed. With on a side a sharp edge.

>

> So I crimped with the 50mm2, I performed a light traction test it seems to be ok terminal stay on the wire, but how could be sure that crimp is ok ? It not seems to be tightened with a good strong deformation.

>

> I ask the question because if it was on my car, I will see with time. But on my plane, even if I have two battery, (with one small wired with standard small temrinal) I don't want to try tings.

>

> Thank you in advance to sharing you experience on this subject.

>

> Good flight.

> Mickaël [Wink]

>

>

>

>

> Read this topic online here:

>

> http://forums.matronics.com/viewtopic.php?p=471500#471500

>

>

>

>

>

>

>

>

>

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

wesk

Joined: 04 Jun 2009

Posts: 3

Location: Northwestern WI

|

Posted: Sat Aug 05, 2017 7:33 pm Post subject: Re: 2 AWG crimping tool Posted: Sat Aug 05, 2017 7:33 pm Post subject: Re: 2 AWG crimping tool |

|

|

Before you decide on which wisdom (solder vs crimp terminals) to follow, try to do your own research. Most industry standards and federal guidance lean towards crimp connections for vibration prone applications in aircraft. They seem to show a preference for solder joints only on the lighter weight terminals found on circuit boards and etc.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

rv8iator(at)gmail.com

Guest

|

Posted: Mon Aug 07, 2017 7:11 am Post subject: 2 AWG crimping tool Posted: Mon Aug 07, 2017 7:11 am Post subject: 2 AWG crimping tool |

|

|

Hydraulic Crimp tool... I have used this tool with great results on AWG 2 and smaller cable.

https://www.harborfreight.com/catalogsearch/result/index/?dir=asc&order=EAScore%2Cf%2CEAFeatured+Weight%2Cf%2CSale+Rank%2Cf&q=crimp+tool

Chris Stone

RV-8

On Sat, Aug 5, 2017 at 8:33 PM, wesk <wsknettl(at)centurytel.net (wsknettl(at)centurytel.net)> wrote:

| Quote: | --> AeroElectric-List message posted by: "wesk" <wsknettl(at)centurytel.net (wsknettl(at)centurytel.net)>

Before you decide on which wisdom (solder vs crimp terminals) to follow, try to do your own research. Most industry standards and federal guidance lean towards crimp connections for vibration prone applications in aircraft. They seem to show a preference for solder joints only on the lighter weight terminals found on circuit boards and etc.

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=471538#471538

====================================

-

Electric-List" target="_blank" rel="noreferrer">http://www.matronics.com/Navigator?AeroElectric-List

====================================

FORUMS -

_blank" rel="noreferrer">http://forums.matronics.com

====================================

WIKI -

lank" rel="noreferrer">http://wiki.matronics.com

====================================

b Site -

-Matt Dralle, List Admin.

target="_blank" rel="noreferrer">http://www.matronics.com/contribution

====================================

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

ceengland7(at)gmail.com

Guest

|

Posted: Mon Aug 07, 2017 8:07 am Post subject: 2 AWG crimping tool Posted: Mon Aug 07, 2017 8:07 am Post subject: 2 AWG crimping tool |

|

|

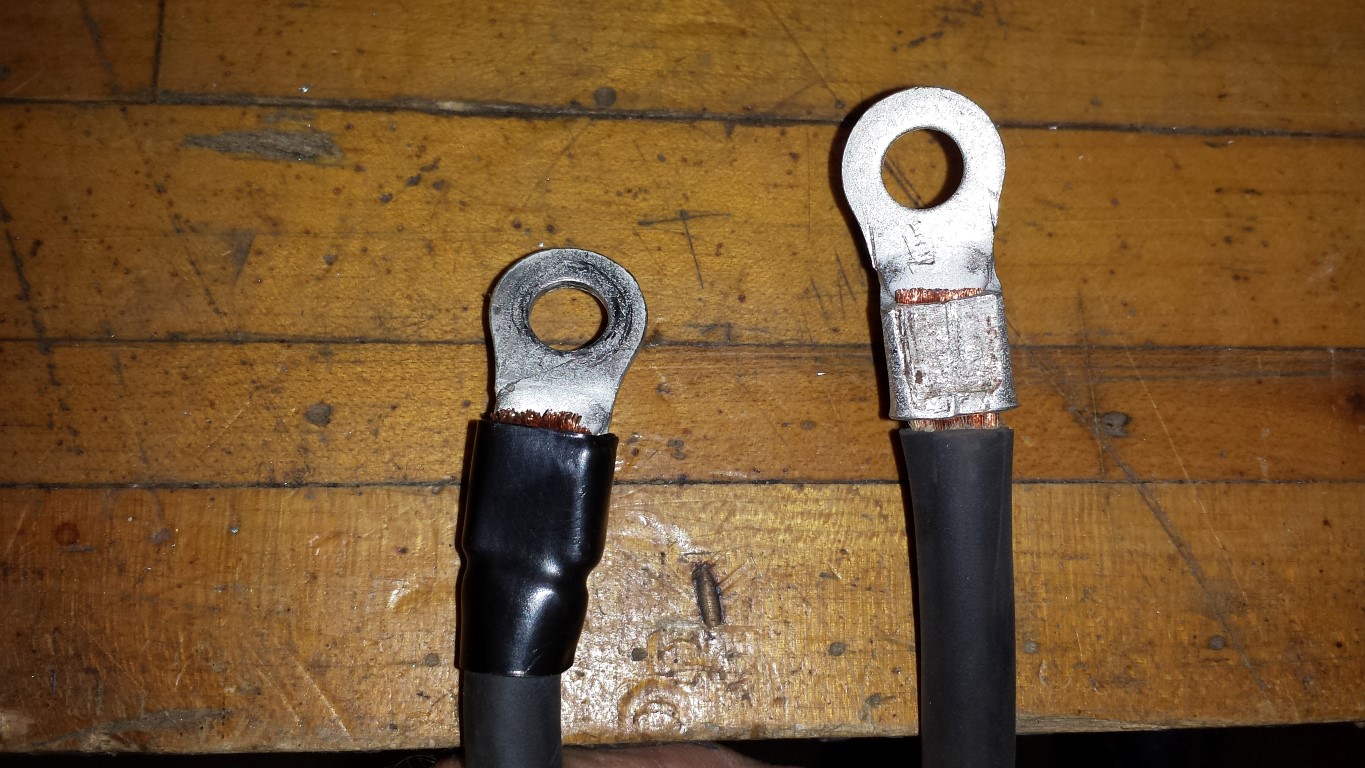

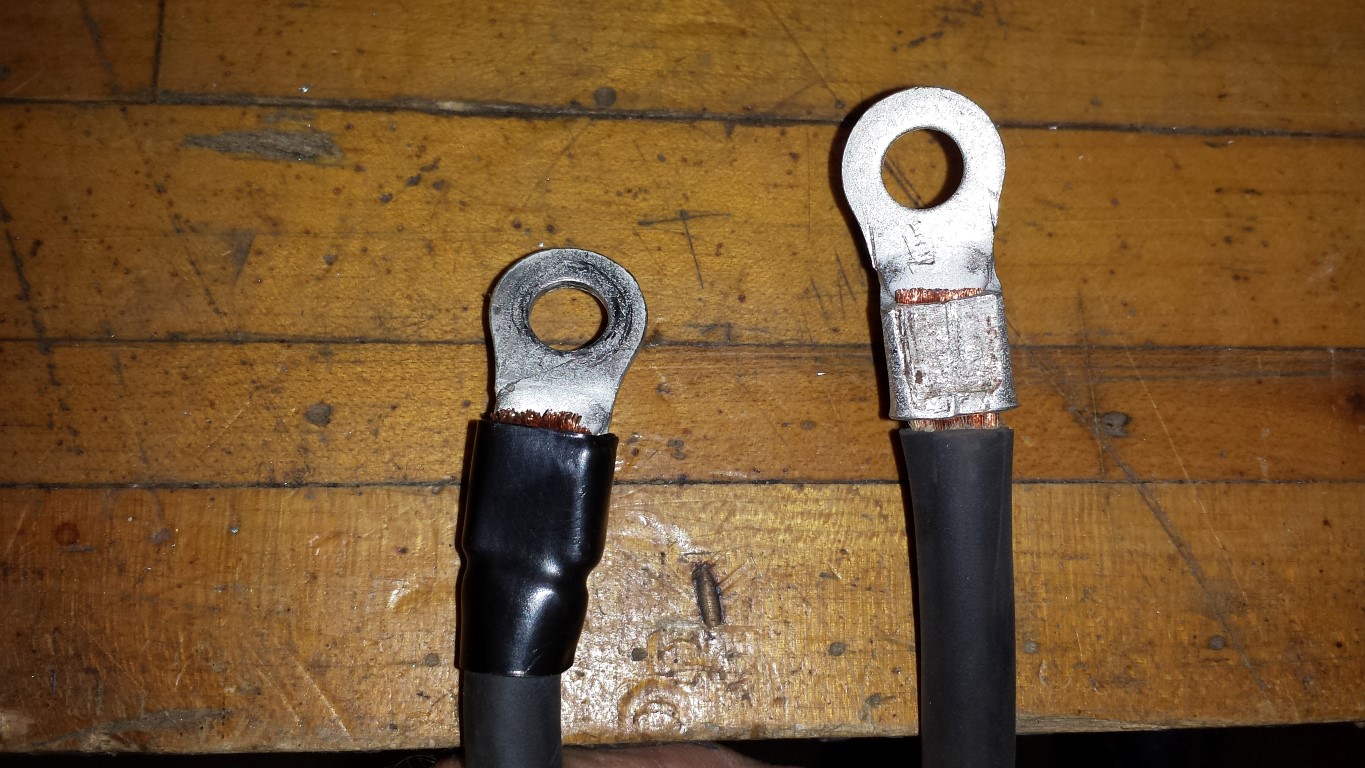

I think that if you do your research, that preference for crimps has more to do with unskilled labor, quick training time, and quicker operations in a production environment. Crimping is without a doubt, much faster than solder, even if you have the skillset to do good soldering. Problem is, purchasing expensive tools for basically 'one-off' jobs. If you've got access to a press, or even a good shop vice, you could do this...

Virus-free. www.avast.com [url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2][/url] Virus-free. www.avast.com [url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2][/url]

On Mon, Aug 7, 2017 at 10:08 AM, Christopher Cee Stone <rv8iator(at)gmail.com (rv8iator(at)gmail.com)> wrote:

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

215.16 KB |

| Viewed: |

13317 Time(s) |

|

| Description: |

|

| Filesize: |

312.33 KB |

| Viewed: |

13317 Time(s) |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue Aug 08, 2017 7:54 am Post subject: 2 AWG crimping tool Posted: Tue Aug 08, 2017 7:54 am Post subject: 2 AWG crimping tool |

|

|

At 11:04 AM 8/7/2017, you wrote:

| Quote: | | I think that if you do your research, that preference for crimps has more to do with unskilled labor, quick training time, and quicker operations in a production environment. Crimping is without a doubt, much faster than solder, even if you have the skillset to do good soldering. Problem is, purchasing expensive tools for basically 'one-off' jobs. If you've got access to a press, or even a good shop vice, you could do this... |

I bought one of these Harbor Freight

tools a few years back . . . lots of

capability for the bux. Took it back

a couple weeks later . . .

[img]cid:.0[/img]

It seems that the designers for this

tool had a poor knowledge of the die

openings appropriate to installation

of terminals on wire.

[img]cid:.1[/img]

As you can see in this excerpt, the die set

is labeled "0 AWG" . . . when in fact, the

hex opening in the closed jaws MIGHT just admit

the stranding on 2AWG wire and it's certainly

way too small to accommodate the terminal

appropriate to a 0AWG wire.

I took some wire and terminals along with me

to show the manager . . . he didn't quibble

about giving me store credit for the return.

Sadly, this latest illustration pulled from

the website suggest that nothing has been

'fixed' with the sizing of this products

die-sets.

While this tool has the mechanical 'oomph'

needed to apply large terminals to fat wires,

the die-sets suggest capabilities not

realized.

In the years since this article was published

http://tinyurl.com/ct36xen

I have installed dozens of terminals on fat wires.

Although I do have access to some pretty capable

crimp tools, I've found that the convenience

and economics of this technique are very attractive.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

38.29 KB |

| Viewed: |

13305 Time(s) |

|

| Description: |

|

| Filesize: |

77.05 KB |

| Viewed: |

13305 Time(s) |

|

|

|

| Back to top |

|

|

Robert Reed

Joined: 22 Oct 2009

Posts: 331

Location: Dallas/Ft.Worth

|

Posted: Tue Aug 08, 2017 8:13 am Post subject: 2 AWG crimping tool Posted: Tue Aug 08, 2017 8:13 am Post subject: 2 AWG crimping tool |

|

|

Bob,

While I totally agree with you regarding the indicated sizing of the dies, I made a few test crimps using the dies supplied and was able to find the appropriate die for each of the fat wires and connectors I was using. Did not require the 0AWG in my application so the die sets were sufficient and the crimps have proven to be more than adequate, especially for the limited amount of crimps I needed.

Bob Reed

From: "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com>

To: aeroelectric-list(at)matronics.com

Sent: Tuesday, August 8, 2017 10:55 AM

Subject: Re: Re: 2 AWG crimping tool

At 11:04 AM 8/7/2017, you wrote:

| Quote: | | I think that if you do your research, that preference for crimps has more to do with unskilled labor, quick training time, and quicker operations in a production environment. Crimping is without a doubt, much faster than solder, even if you have the skillset to do good soldering. Problem is, purchasing expensive tools for basically 'one-off' jobs. If you've got access to a press, or even a good shop vice, you could do this... |

I bought one of these Harbor Freight

tools a few years back . . . lots of

capability for the bux. Took it back

a couple weeks later . . .

[img]cid:.0[/img]

It seems that the designers for this

tool had a poor knowledge of the die

openings appropriate to installation

of terminals on wire.

[img]cid:.1[/img]

As you can see in this excerpt, the die set

is labeled "0 AWG" . . . when in fact, the

hex opening in the closed jaws MIGHT just admit

the stranding on 2AWG wire and it's certainly

way too small to accommodate the terminal

appropriate to a 0AWG wire.

I took some wire and terminals along with me

to show the manager . . . he didn't quibble

about giving me store credit for the return.

Sadly, this latest illustration pulled from

the website suggest that nothing has been

'fixed' with the sizing of this products

die-sets.

While this tool has the mechanical 'oomph'

needed to apply large terminals to fat wires,

the die-sets suggest capabilities not

realized.

In the years since this article was published

http://tinyurl.com/ct36xen

I have installed dozens of terminals on fat wires.

Although I do have access to some pretty capable

crimp tools, I've found that the convenience

and economics of this technique are very attractive.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

38.29 KB |

| Viewed: |

13304 Time(s) |

|

| Description: |

|

| Filesize: |

77.05 KB |

| Viewed: |

13304 Time(s) |

|

|

|

| Back to top |

|

|

rlborger(at)mac.com

Guest

|

Posted: Tue Aug 08, 2017 8:17 am Post subject: 2 AWG crimping tool Posted: Tue Aug 08, 2017 8:17 am Post subject: 2 AWG crimping tool |

|

|

Yes, I have one of those tools from Harbor Freight. I accepted the fact that the die markings are some fellows fantasy and simply select a die of a suitable size to crimp whatever terminal/wire combination Iâm using. It does a great job of crimping fat wires up to #2. Iâve never tried to do anything larger so I canât speak to them.

Blue skies & tailwinds,Bob BorgerEuropa XS Tri, Rotax 914, Airmaster C/S Prop (75 hrs).Little Toot Sport Biplane, Lycoming Thunderbolt AEIO-320 EXP3705 Lynchburg Dr.Corinth, TX 76208-5331Cel: 817-992-1117rlborger(at)mac.com (rlborger(at)mac.com)

| Quote: | On Aug 8, 2017, at 9:54 AM, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

At 11:04 AM 8/7/2017, you wrote: | Quote: | | I think that if you do your research, that preference for crimps has more to do with unskilled labor, quick training time, and quicker operations in a production environment. Crimping is without a doubt, much faster than solder, even if you have the skillset to do good soldering. Problem is, purchasing expensive tools for basically 'one-off' jobs. If you've got access to a press, or even a good shop vice, you could do this... |

I bought one of these Harbor Freight tools a few years back . . . lots of capability for the bux. Took it back a couple weeks later . . . <93bcbd6.jpg> It seems that the designers for this tool had a poor knowledge of the die openings appropriate to installation of terminals on wire. <93bcc24.jpg> As you can see in this excerpt, the die set is labeled "0 AWG" . . . when in fact, the hex opening in the closed jaws MIGHT just admit the stranding on 2AWG wire and it's certainly way too small to accommodate the terminal appropriate to a 0AWG wire. I took some wire and terminals along with me to show the manager . . . he didn't quibble about giving me store credit for the return. Sadly, this latest illustration pulled from the website suggest that nothing has been 'fixed' with the sizing of this products die-sets. While this tool has the mechanical 'oomph' needed to apply large terminals to fat wires, the die-sets suggest capabilities not realized. In the years since this article was published http://tinyurl.com/ct36xen I have installed dozens of terminals on fat wires. Although I do have access to some pretty capable crimp tools, I've found that the convenience and economics of this technique are very attractive.

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

JOHN TIPTON

Joined: 17 Sep 2006

Posts: 239

Location: Torquay - England

|

Posted: Tue Aug 08, 2017 9:38 am Post subject: 2 AWG crimping tool Posted: Tue Aug 08, 2017 9:38 am Post subject: 2 AWG crimping tool |

|

|

Are you saying the only problem is the jaw size (in AWG) are incorrect, mine has the measurements in 'sq mm' I do my own calculations

John

Sent from my iPad

----x--O--x----

On 8 Aug 2017, at 04:54 pm, "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | At 11:04 AM 8/7/2017, you wrote:

| Quote: | | I think that if you do your research, that preference for crimps has more to do with unskilled labor, quick training time, and quicker operations in a production environment. Crimping is without a doubt, much faster than solder, even if you have the skillset to do good soldering. Problem is, purchasing expensive tools for basically 'one-off' jobs. If you've got access to a press, or even a good shop vice, you could do this... |

I bought one of these Harbor Freight

tools a few years back . . . lots of

capability for the bux. Took it back

a couple weeks later . . .

<93bcbd6.jpg>

It seems that the designers for this

tool had a poor knowledge of the die

openings appropriate to installation

of terminals on wire.

<93bcc24.jpg>

As you can see in this excerpt, the die set

is labeled "0 AWG" . . . when in fact, the

hex opening in the closed jaws MIGHT just admit

the stranding on 2AWG wire and it's certainly

way too small to accommodate the terminal

appropriate to a 0AWG wire.

I took some wire and terminals along with me

to show the manager . . . he didn't quibble

about giving me store credit for the return.

Sadly, this latest illustration pulled from

the website suggest that nothing has been

'fixed' with the sizing of this products

die-sets.

While this tool has the mechanical 'oomph'

needed to apply large terminals to fat wires,

the die-sets suggest capabilities not

realized.

In the years since this article was published

http://tinyurl.com/ct36xen

I have installed dozens of terminals on fat wires.

Although I do have access to some pretty capable

crimp tools, I've found that the convenience

and economics of this technique are very attractive.

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue Aug 08, 2017 2:19 pm Post subject: 2 AWG crimping tool Posted: Tue Aug 08, 2017 2:19 pm Post subject: 2 AWG crimping tool |

|

|

At 12:36 PM 8/8/2017, you wrote:

| Quote: | Are you saying the only problem is the jaw size (in AWG) are incorrect, mine has the measurements in 'sq mm' I do my own calculations

John |

Yeah, the largest die set with the one I bought

would do 4AWG but nothing larger. It had some

smaller dies that would probably have worked down

to 10AWG . . . but I didn't need a hydraulic crimper

for wires that small.

I considered modeling the dies and cutting larger

versions on the CNC mill . . . but I didn't

need it THAT bad. The since then I've put

terminals on 2AWG wires with one of these

guys!

http://tinyurl.com/yakycxtn

It took several minutes to get it up to temperature

but the ol' 63/37 solder flowed right into the

joint.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|