|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

ventura(at)brandeis.edu

Guest

|

Posted: Wed Oct 11, 2017 10:52 am Post subject: Constructing an automatic RCA video camera feed splitter Posted: Wed Oct 11, 2017 10:52 am Post subject: Constructing an automatic RCA video camera feed splitter |

|

|

What cameras are you using?

Thanks. --Joel

On Wed, Oct 11, 2017 at 12:05 PM, Airdog77 <Airdog77(at)gmail.com (Airdog77(at)gmail.com)> wrote:

| Quote: | --> AeroElectric-List message posted by: "Airdog77" <Airdog77(at)gmail.com (Airdog77(at)gmail.com)>

Hi Bob, et al.

I recently purchased a GRT EFIS for the Long-EZ that I'm building. The GRT EFIS has an option to connect up a single video feed to it via USB (in this case, my 4-port USB hub). I've tested out some mini-video cameras I picked up off of Amazon that are about the size of a dime, and the picture quality is great for what I want to use them for.

Thanks!

Wade

--------

Airdog

Wade Parton

Building Long-EZ 916WP

www.longezpush.com

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=473469#473469

====================================

-

Electric-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

====================================

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

====================================

WIKI -

errer" target="_blank">http://wiki.matronics.com

====================================

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

====================================

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

yellowduckduo(at)gmail.co

Guest

|

Posted: Wed Oct 11, 2017 11:12 am Post subject: Constructing an automatic RCA video camera feed splitter Posted: Wed Oct 11, 2017 11:12 am Post subject: Constructing an automatic RCA video camera feed splitter |

|

|

I'm curious why you'd consider driving relays instead of a 4 into 1

analog switching chip.

Ken

On 11/10/2017 2:22 PM, Robert L. Nuckolls, III wrote:

| Quote: | >

> Somewhere in the pile on my bench, I have some of the

> development ecbs shown on the linked page.

> You could assemble one with driver transistors

> and build an array of relays to handle video

> switching.

Found one . . .

Emacs!

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

ceengland7(at)gmail.com

Guest

|

Posted: Wed Oct 11, 2017 2:33 pm Post subject: Constructing an automatic RCA video camera feed splitter Posted: Wed Oct 11, 2017 2:33 pm Post subject: Constructing an automatic RCA video camera feed splitter |

|

|

On 10/11/2017 11:05 AM, Airdog77 wrote:

| Quote: |

Hi Bob, et al.

I recently purchased a GRT EFIS for the Long-EZ that I'm building. The GRT EFIS has an option to connect up a single video feed to it via USB (in this case, my 4-port USB hub). I've tested out some mini-video cameras I picked up off of Amazon that are about the size of a dime, and the picture quality is great for what I want to use them for.

As I'm sure many of you know, most canard aircraft have fuel site gages in the back seat area. Look inside these birds parked on the ramp and invariable you'll find a mirror, which is what canard pilots often use to check out their fuel site gages in the back. I figured with such diminutive sizes on these cameras, why not hook one up focused on each site gage, and while I'm at it point a 3rd camera looking aft at the engine from atop the pilot head rest. A 4th camera on the bottom CL looking aft would be round out my initial camera installation.

My issue is that I would like to have a timed cycle display of each of these camera views in a little window on my EFIS (GRT has taken care of the EFIS display part), say 3-5 seconds per camera. However, every RCA jack 4-into-1 video channel selector I have found --while cheap-- are bulky plastic housing a large mechanical switch to select the video channel.... mainly used by video gamers. I talked with GRT and any machinations going on with the video feed is fine, as long as only one physical RCA video jack is presented to their USB video input device.

I would like to construct a 4x (or more) channel IN and 1x RCA jack channel out device that is small, and automatically cycles through each camera view, again for 3-5 seconds. Adjustable viewing times would be good, and maybe a manual pause or cycle button would be good as well.

Does anybody know of a device like this that exists? Would the circuitry for something like this be too complicated? Finally, is there any detriment to swapping out the thicker RCA cabling with 24 AWG shielded wire?

Thanks!

Wade

--------

Airdog

Wade Parton

Building Long-EZ 916WP

www.longezpush.com

There was an article on a diy 8 channel video/audio using a bank of

|

solid state switches about 30 years ago in, if memory serves, Byte

Magazine. Much easier to buy off the rack these days.

How about

http://www.ebay.com/itm/4-CH-Channel-DVR-CCTV-Quad-Video-Camera-Processor-System-Kit-Splitter-Switcher-/391156611012?epid=1839817989&hash=item5b12c037c4:g:Op4AAOxyuR5TbcoS

or

http://www.ebay.com/itm/4-Channel-Automatic-Video-Switcher-for-Automotive-Cars-/172847332805?hash=item283e80fdc5:g:UW8AAOSwmhJZqR5f

or, ask GRT why this won't work

http://www.ebay.com/itm/4-Channel-BNC-RCA-To-USB-Converter-DVR-Adapter-Camera-Video-Switcher-/191162842864?hash=item2c82317ef0:g:D3MAAOSwstxVJd7K

---

This email has been checked for viruses by Avast antivirus software.

https://www.avast.com/antivirus

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

yellowduckduo(at)gmail.co

Guest

|

Posted: Wed Oct 11, 2017 2:35 pm Post subject: Constructing an automatic RCA video camera feed splitter Posted: Wed Oct 11, 2017 2:35 pm Post subject: Constructing an automatic RCA video camera feed splitter |

|

|

Thanks for the explanation.

I've never played with USB video but I think the D+ and D- USB signals

are both normally only positive with respect to the power ground and

that the signal information is differential between those pins. Makes me

wonder if dual pole relays would be needed.

Ken

On 11/10/2017 5:28 PM, Robert L. Nuckolls, III wrote:

| Quote: | At 02:10 PM 10/11/2017, you wrote:

>

>

> I'm curious why you'd consider driving relays instead of a 4 into 1

> analog switching chip.

If I were laying out a board and doing it myself,

that's the first approach to be considered. Haven't

played video lately so I'm unsure what the constraints

might be for solid-state switching. Some applications

and switch choices called for +/- power supplies

which complicates the circuitry.

The next choice to consider would be taking the barefoot

chip and using digital outputs to drive low current

form A relays directly. This would let us craft the

1:4 sequential switcher with a grand total of 11

parts and no concerns for DC levels on the video

lines.

The approach being offered is the short-path, minimum

risk to success for a neophyte builder using junkbox

parts.

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

ceengland7(at)gmail.com

Guest

|

Posted: Wed Oct 11, 2017 3:49 pm Post subject: Constructing an automatic RCA video camera feed splitter Posted: Wed Oct 11, 2017 3:49 pm Post subject: Constructing an automatic RCA video camera feed splitter |

|

|

On 10/11/2017 6:10 PM, Robert L. Nuckolls, III wrote:

| Quote: | | Quote: | There was an article on a diy 8 channel video/audio using a bank of solid state switches about 30 years ago in, if memory serves, Byte Magazine. Much easier to buy off the rack these days.

How about |

<snip>

These appear to be capable video switches. We'd

still need to integrate some form of sequential switching

timer . . .

Bob . . . |

Don't remember if any of those links I sent include sequential switching, but I saw at least one on ebay that did include that in its functionality. Price point was in the same ~$50 range.

Virus-free. www.avast.com [url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2] [/url] Virus-free. www.avast.com [url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2] [/url]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

csmale(at)bak.rr.com

Guest

|

Posted: Wed Oct 11, 2017 4:04 pm Post subject: Constructing an automatic RCA video camera feed splitter Posted: Wed Oct 11, 2017 4:04 pm Post subject: Constructing an automatic RCA video camera feed splitter |

|

|

On 10/11/17 09:05, Airdog77 wrote:

| Quote: |

Hi Bob, et al.

I recently purchased a GRT EFIS for the Long-EZ that I'm building. The GRT EFIS has an option to connect up a single video feed to it via USB (in this case, my 4-port USB hub). I've tested out some mini-video cameras I picked up off of Amazon that are about the size of a dime, and the picture quality is great for what I want to use them for.

As I'm sure many of you know, most canard aircraft have fuel site gages in the back seat area. Look inside these birds parked on the ramp and invariable you'll find a mirror, which is what canard pilots often use to check out their fuel site gages in the back. I figured with such diminutive sizes on these cameras, why not hook one up focused on each site gage, and while I'm at it point a 3rd camera looking aft at the engine from atop the pilot head rest. A 4th camera on the bottom CL looking aft would be round out my initial camera installation.

My issue is that I would like to have a timed cycle display of each of these camera views in a little window on my EFIS (GRT has taken care of the EFIS display part), say 3-5 seconds per camera. However, every RCA jack 4-into-1 video channel selector I have found --while cheap-- are bulky plastic housing a large mechanical switch to select the video channel.... mainly used by video gamers. I talked with GRT and any machinations going on with the video feed is fine, as long as only one physical RCA video jack is presented to their USB video input device.

I would like to construct a 4x (or more) channel IN and 1x RCA jack channel out device that is small, and automatically cycles through each camera view, again for 3-5 seconds. Adjustable viewing times would be good, and maybe a manual pause or cycle button would be good as well.

Does anybody know of a device like this that exists? Would the circuitry for something like this be too complicated? Finally, is there any detriment to swapping out the thicker RCA cabling with 24 AWG shielded wire?

Thanks!

Wade

--------

Airdog

Wade Parton

Building Long-EZ 916WP

www.longezpush.com

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=473469#473469

If you have some computer skill or know someone who has, the raspberry

|

pi can do what you want.

csmale(at)bak.rr.com

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Airdog77

Joined: 24 Nov 2013

Posts: 80

Location: Northern Virginia

|

Posted: Thu Oct 12, 2017 12:03 am Post subject: Re: Constructing an automatic RCA video camera feed splitte Posted: Thu Oct 12, 2017 12:03 am Post subject: Re: Constructing an automatic RCA video camera feed splitte |

|

|

Sorry for my delayed response back. Again, didn't get any of the normal email notifications that responses were being made to my question... thanks all!

The camera I'm using is a cheap 1/4" 600TVL from Amazon... the two I bought are no longer being sold, but this is close: https://tinyurl.com/yckqk3dh

Yes, I'm looking at video RCA jack OUT feed that will then go into box that hooks to USB. So I don't need to mess with anything USB as far as video is concerned.

I need to dig into all this info to figure out a way ahead.

Bob, how would I go about getting boards like the one you posted pics of?

Regards,

Wade

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Airdog

Wade Parton

Building Long-EZ N916WP

www.longezpush.com |

|

| Back to top |

|

|

ceengland7(at)gmail.com

Guest

|

Posted: Thu Oct 12, 2017 10:19 am Post subject: Constructing an automatic RCA video camera feed splitter Posted: Thu Oct 12, 2017 10:19 am Post subject: Constructing an automatic RCA video camera feed splitter |

|

|

On 10/12/2017 11:30 AM, Airdog77 wrote:

| Quote: |

Hey Jim,

Definitely! It really is a neat little feature.

Be advised that the optional module & software to link into your EFIS runs $150 from GRT.

Cheers,

Wade

Or, there's plan B: a $10 USB camera & a $15 android cell phone.

|

---

This email has been checked for viruses by Avast antivirus software.

https://www.avast.com/antivirus

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Eric Page

Joined: 15 Feb 2017

Posts: 247

|

Posted: Fri Oct 13, 2017 8:28 pm Post subject: Re: Constructing an automatic RCA video camera feed splitte Posted: Fri Oct 13, 2017 8:28 pm Post subject: Re: Constructing an automatic RCA video camera feed splitte |

|

|

I know Wade's specific request for camera switching has been solved, but it sounded like the sort of thing that might come up again so I thought I'd take a stab at it.

So... here's an alternative for switching cameras to a monitor or EFIS input using a couple of voltage regulators and three ICs. All components are through-hole. Everything on a single PCB, and no relays.

Reference the attached schematic:

An LM2931 5V linear regulator and a TC7660 charge pump provide +/-5V rails to power the circuit. A 555 timer is configured in astable mode to provide an output with adjustable period of about 3 to 10 seconds. This output is fed to the clock input of a CD4022B octal counter. The clock signal can be interrupted by a SP3T ON-ON-(ON) switch to stop rotation of the cameras or advance them manually. Outputs 1-3 of the counter are connected to the logic inputs of an AD8184 4:1 video multiplexer such that they cause the multiplexer to cycle through its four video inputs, connecting each in turn to the output. RCA connectors provide four camera inputs and one video output.

LM2931AZ 5V Linear Regulator: http://preview.tinyurl.com/yakjxubl

TC7660CPA Inverting Charge Pump: http://preview.tinyurl.com/y7n7g6um

ICM7555IPAZ CMOS Timer: http://preview.tinyurl.com/ybrvnnq2

CD4022BE Octal Counter: http://preview.tinyurl.com/ycjsa46w

AD8184ANZ 4:1 Video Multiplexer: http://preview.tinyurl.com/ybozz2nf

SP3T Toggle Switch: http://preview.tinyurl.com/ybpazcu5

Critiques? Suggestions?

If there's any interest, I can gin up a PCB.

Eric

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

Download |

| Filename: |

4-Ch Vid Cam Mux (Rev A).pdf |

| Filesize: |

45.43 KB |

| Downloaded: |

691 Time(s) |

|

|

| Back to top |

|

|

paulf(at)hughes.net

Guest

|

Posted: Sat Oct 14, 2017 10:55 am Post subject: Constructing an automatic RCA video camera feed splitter Posted: Sat Oct 14, 2017 10:55 am Post subject: Constructing an automatic RCA video camera feed splitter |

|

|

Since my name was mentioned, I'll weigh in. I'll be happy to modify the

program Bob mentioned for this function, or more likely, just write a

new one using elements of the one Bob mentioned.

If I understand the AD8184 data sheet, we need to feed A0 and A1 one of

four states - 00, 01, 10, and 11. That's pretty easy to do with just

two pins. If we used the PIC12F683 (mostly because I'm familiar with

it!!), we could do this:

Pin 1 - Vdd

Pin 2 - High order bit to AD8184 (connect to A1)

Pin 3 - Low order bit to AD8184 (connect to A0)

Pin 4 - not used

Pin 5 - Run/Hold switch (pull low to hold)

Pin 6 - Step switch (pull low to immediately switch to the next input)

Pin 7 - Analog voltage (0-5V) to control the speed of switching in Run mode

Pin 8 - Vss

I think you could use the same switch (on-on-(on)) to ground pin 4 in

position 2, and ground pin 6 in the momentary position. Analog voltage

on pin 7 is similar to what you have on the proposed schematic.

Is this what we are looking for? I'll let you and Bob decide on the

hardware components necessary to make it all work, but the PIC software

sounds pretty straight forward.

Paul Fisher

On 10/14/2017 8:00 AM, Eric Page wrote:

| Quote: |

Eliminating the 16-DIP-packaged counter and most of the passives sounds fine to me. It will certainly shrink the PCB. If you can give me a pin-out for the uC you propose using, Iââ¬â¢ll amend the schematic. Iââ¬â¢ll need to know pin numbers for Vcc, Gnd, two outputs to the mux, how weââ¬â¢ll read user input for run/hold and rate, and if an ICSP header is needed. Iââ¬â¢m guessing you propose the same (PIC12F683?) used for the recent prop current limiter...

The AD8184 multiplexer has just one output, so I didnââ¬â¢t figure a termination resistor was necessary. The connectors shown actually are RCA jacks, despite the CAD symbol looking like a headphone...

http://preview.tinyurl.com/ycpmbhj5

They connect the AD8184 inputs to ground with an internal switch contact if no RCA is plugged in.

Eric

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=473527#473527

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

alec(at)alecmyers.com

Guest

|

Posted: Sat Oct 14, 2017 8:26 pm Post subject: Constructing an automatic RCA video camera feed splitter Posted: Sat Oct 14, 2017 8:26 pm Post subject: Constructing an automatic RCA video camera feed splitter |

|

|

Random thoughts from someone with 15 years experience designing and programming PIC projects:

| Quote: | - It would make the project considerably less accessible to many builders. Anyone without a hardware programmer and the Microchip IDE software will either have to get them, then find the code to download and learn how to program the PIC, or buy a PIC with the code already loaded.

|

| Quote: | Can anyone deliver a programmed PIC for $3 and make it worth their trouble?

|

Yep. Arizona Microchip themselves, will. Upload the code, and theyâll send you programmed parts direct from their factory in Thailand.

If youâre going to the trouble of ordering a custom PCB, then a custom PIC really isnât much extra bother.

| Quote: | - Software updates will require removing the unit from service, removing the PIC to send for reprogramming, or buying a new PIC to replace it.

|

Itâs 2017. Never socket a PIC. Solder it to the PCB for reliability and use the ICSP header to program and reprogram, until you have the software right. If you goof and let out the magic smoke throw away the $1 PCB and $0.40 PIC and grab another one. Use a SMT part to save the cost of drilling the PCB. Theyâre not *that* hard to solder. In fact if you design it right you donât need a drilled PCB at all.

| Quote: | - A PIC won't simplify the user interface. We still need a switch for the run/hold/step function and a knob to adjust scan rate. Perhaps a system using buttons or a rotary encoder could be devised, but it would probably be less intuitive than the switch and knob.

|

A one-button user interface is trivial with a PIC: press to advance to the next camera, press-and-hold to resume scanning. If you want to get fancy, double-press, double-press-and-hold are all available, for fast scan, slow scan, whatever else you want. Once you paid for the PIC you might as well load the code up with features. It doesnât cost any extra. If Paul doesnât want the challenge Iâll write it for you.

On the subject of adjusting the scanning speed: use the extra pins of whatever PIC you choose for selecting a scan rate. Get rid of extra resistors and other unnecessary components!

| Quote: | On Oct 14, 2017, at 8:32 PM, Eric Page <edpav8r(at)yahoo.com> wrote:

nuckolls.bob(at)aeroelect wrote:

> I propose we make this another open source program like the wig-wag was . . . I'll be pleased to set up a folder to host all the work product.

Great. I kinda figured we were doing an open-source effort. With that in mind, I had a good think about this while slogging for six hours against 145-knot headwinds this morning...

I think there are a few issues that argue against changing to a PIC microcontroller in this project. Wade alluded to the first one in his post this morning (which, along with one other from Clayton, has disappeared from the server) when he joked about the details being over his head:

- It would make the project considerably less accessible to many builders. Anyone without a hardware programmer and the Microchip IDE software will either have to get them, then find the code to download and learn how to program the PIC, or buy a PIC with the code already loaded. On the other hand, anyone pretty much anywhere with a soldering iron and minimal skill can put my design together for as long as its jellybean components are available.

- Software updates will require removing the unit from service, removing the PIC to send for reprogramming, or buying a new PIC to replace it.

- A PIC won't simplify the user interface. We still need a switch for the run/hold/step function and a knob to adjust scan rate. Perhaps a system using buttons or a rotary encoder could be devised, but it would probably be less intuitive than the switch and knob.

- If a PIC could replace the $7 video multiplexer chip, you could make a good case for lowering cost, but we're talking about replacing a couple of 50 to 80-cent jellybeans and a few passives that are tens of cents each -- about $3 total. Can anyone deliver a programmed PIC for $3 and make it worth their trouble?

- The size of the PCB is going to be driven largely by the five RCA jacks, so deleting a 16-DIP and a few passives probably won't shrink the board appreciably.

I think this is a case where a microcontroller may be overkill, given that suitable cheap ICs are readily available. Given the simplicity of the problem, wouldn't it make more sense to keep the solution simple?

Thoughts?

Eric

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=473555#473555

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

alec(at)alecmyers.com

Guest

|

Posted: Sat Oct 14, 2017 8:47 pm Post subject: Constructing an automatic RCA video camera feed splitter Posted: Sat Oct 14, 2017 8:47 pm Post subject: Constructing an automatic RCA video camera feed splitter |

|

|

If you use a PIC, you could (trivially) do the following:

Hold the button down for ten seconds to enter programming mode. Press the button briefly x times to set the scan period at x seconds. Press the button for two seconds to exit programming mode.

No need for resistors at all.

| Quote: | On Oct 14, 2017, at 8:38 PM, Eric Page <edpav8r(at)yahoo.com> wrote:

Wade,

Question: do you want to be able to adjust the scan rate as a matter of routine operation (i.e. with a panel-mounted knob), or do you envision setting the rate where you like it at installation, and leaving it alone?

The answer will dictate whether we put a small trimmer potentiometer on the circuit board or design for a larger panel-mounted potentiometer and knob.

Eric

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=473556#473556

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

alec(at)alecmyers.com

Guest

|

Posted: Sun Oct 15, 2017 4:19 am Post subject: Constructing an automatic RCA video camera feed splitter Posted: Sun Oct 15, 2017 4:19 am Post subject: Constructing an automatic RCA video camera feed splitter |

|

|

Another possible âgotchaâ:

The AD8184 doesnât do any kind of video buffering, and the various video sources are not frame-locked. (In this scenario there is no 60Hz ac for the camera to sync to). So what the effect of switching sources will be is uncertain. Depending on the video display it could be anything from an unnoticeable half frame glitch to several seconds of rolling display before it locks into the new frame source.

Itâs definitely worth experimenting before settling on the final parts list.

On Oct 15, 2017, at 00:43, Alec Myers <alec(at)alecmyers.com> wrote:

If you use a PIC, you could (trivially) do the following:

Hold the button down for ten seconds to enter programming mode. Press the button briefly x times to set the scan period at x seconds. Press the button for two seconds to exit programming mode.

No need for resistors at all.

| Quote: | On Oct 14, 2017, at 8:38 PM, Eric Page <edpav8r(at)yahoo.com> wrote:

Wade,

Question: do you want to be able to adjust the scan rate as a matter of routine operation (i.e. with a panel-mounted knob), or do you envision setting the rate where you like it at installation, and leaving it alone?

The answer will dictate whether we put a small trimmer potentiometer on the circuit board or design for a larger panel-mounted potentiometer and knob.

Eric

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=473556#473556

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

ceengland7(at)gmail.com

Guest

|

Posted: Sun Oct 15, 2017 4:31 am Post subject: Constructing an automatic RCA video camera feed splitter Posted: Sun Oct 15, 2017 4:31 am Post subject: Constructing an automatic RCA video camera feed splitter |

|

|

That stuff is cool as far as programming tricks go, but who will be able to use the hardware except the original designer? I, and everyone else on this list, have owned dozens of electronic gadgets over the years that are absolutely impossible to set up and use without the English-as-a-second-language printed manual that you can't find after the 1st month of ownership. I have to use google on my desktop to explore how to get my phone apps to work like I want.

Just something to consider, when designing for general use instead specifically trained fighter pilots or astronauts.Â

On Sat, Oct 14, 2017 at 11:43 PM, Alec Myers <alec(at)alecmyers.com (alec(at)alecmyers.com)> wrote:

| Quote: | --> AeroElectric-List message posted by: Alec Myers <alec(at)alecmyers.com (alec(at)alecmyers.com)>

If you use a PIC, you could (trivially) do the following:

Hold the button down for ten seconds to enter programming mode. Press the button briefly x times to set the scan period at x seconds. Press the button for two seconds to exit programming mode.

No need for resistors at all.

> On Oct 14, 2017, at 8:38 PM, Eric Page <edpav8r(at)yahoo.com (edpav8r(at)yahoo.com)> wrote:

>

> --> AeroElectric-List message posted by: "Eric Page" <edpav8r(at)yahoo.com (edpav8r(at)yahoo.com)>

>

> Wade,

>

> Question: do you want to be able to adjust the scan rate as a matter of routine operation (i.e. with a panel-mounted knob), or do you envision setting the rate where you like it at installation, and leaving it alone?

>

> The answer will dictate whether we put a small trimmer potentiometer on the circuit board or design for a larger panel-mounted potentiometer and knob.

>

> Eric

>

|

Virus-free. www.avast.com [url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2][/url] Virus-free. www.avast.com [url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2][/url]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

alec(at)alecmyers.com

Guest

|

Posted: Sun Oct 15, 2017 4:42 am Post subject: Constructing an automatic RCA video camera feed splitter Posted: Sun Oct 15, 2017 4:42 am Post subject: Constructing an automatic RCA video camera feed splitter |

|

|

Yes, you do have to make it usable.

But âpush to advance, push-and-hold to cycleâ is fairly straightforward. (If thatâs too complex, do you really want to fly with this person?!)

When it comes to changing the cycle period Iâm confident that a one-button interface can be very straightforward for that too. Certainly easier than opening the panel to adjust a twiddle pot, or getting out a soldering iron. A panel pot is simplest, but do you really want to drill your panel for a control youâre going to set on day one and then forget about?

So, itâs not about tricks. Itâs about tucking away seldom used functions but still having them at your finger tips.

On Oct 15, 2017, at 08:30, Charlie England <ceengland7(at)gmail.com> wrote:

That stuff is cool as far as programming tricks go, but who will be able to use the hardware except the original designer? I, and everyone else on this list, have owned dozens of electronic gadgets over the years that are absolutely impossible to set up and use without the English-as-a-second-language printed manual that you can't find after the 1st month of ownership. I have to use google on my desktop to explore how to get my phone apps to work like I want.

Just something to consider, when designing for general use instead specifically trained fighter pilots or astronauts.

[quote] On Sat, Oct 14, 2017 at 11:43 PM, Alec Myers <alec(at)alecmyers.com> wrote:

If you use a PIC, you could (trivially) do the following:

Hold the button down for ten seconds to enter programming mode. Press the button briefly x times to set the scan period at x seconds. Press the button for two seconds to exit programming mode.

No need for resistors at all.

> On Oct 14, 2017, at 8:38 PM, Eric Page <edpav8r(at)yahoo.com> wrote:

>

>

>

> Wade,

>

> Question: do you want to be able to adjust the scan rate as a matter of routine operation (i.e. with a panel-mounted knob), or do you envision setting the rate where you like it at installation, and leaving it alone?

>

> The answer will dictate whether we put a small trimmer potentiometer on the circuit board or design for a larger panel-mounted potentiometer and knob

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

ceengland7(at)gmail.com

Guest

|

Posted: Sun Oct 15, 2017 7:51 am Post subject: Constructing an automatic RCA video camera feed splitter Posted: Sun Oct 15, 2017 7:51 am Post subject: Constructing an automatic RCA video camera feed splitter |

|

|

Bob,

My comment was about 'buttonology'; not building. I've got a little clock that's RF linked to Federal time broadcasts. It's totally impossible to use any of the elaborate built-in functions with out the manual, because it has two or three unmarked buttons, and to access the various functions, you need to know the "combination". No one can use the thing without the book in front of them. Same thing for most kilo-function watches, etc. Even my old Icom A-4 handheld comm is like that. I seldom use it, so even though I've owned it for over 20 years, I still don't know how to program frequencies into it. If it had a keypad, anyone could pick it up and enter '122.75', or '125.25', etc. But since it doesn't, the unwashed can only hold the up or down button until they see the freq they want. For me, a perfect example of something simplified to the point of un-usability.

Charlie

Virus-free. www.avast.com [url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2][/url] Virus-free. www.avast.com [url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2][/url]

On Sun, Oct 15, 2017 at 10:22 AM, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | At 07:30 AM 10/15/2017, you wrote:

| Quote: | | That stuff is cool as far as programming tricks go, but who will be able to use the hardware except the original designer? I, and everyone else on this list, have owned dozens of electronic gadgets over the years that are absolutely impossible to set up and use without the English-as-a-second-language printed manual that you can't find after the 1st month of ownership. I have to use google on my desktop to explore how to get my phone apps to work like I want. |

This is amongst the simplest PIC applications we'll

ever encounter . . . once the first installation

has combed out the nits . . . it seems unlikely

that there would be many if any software upgrades.

Another consideration is flexibility. Suppose the

prospective end user wants only two cameras . . . or

three? Different software . . . or strapped selection

on the ECB?

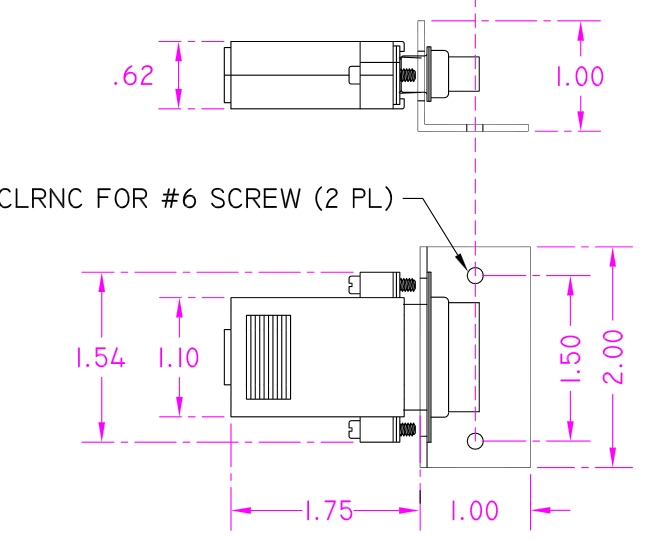

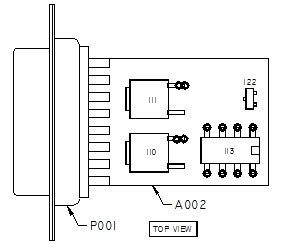

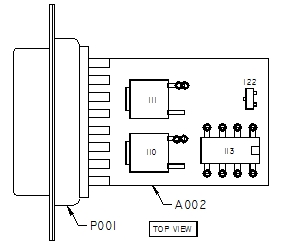

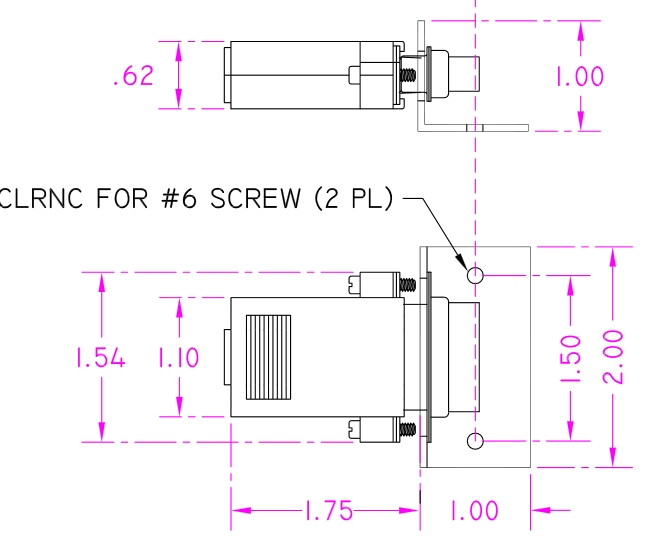

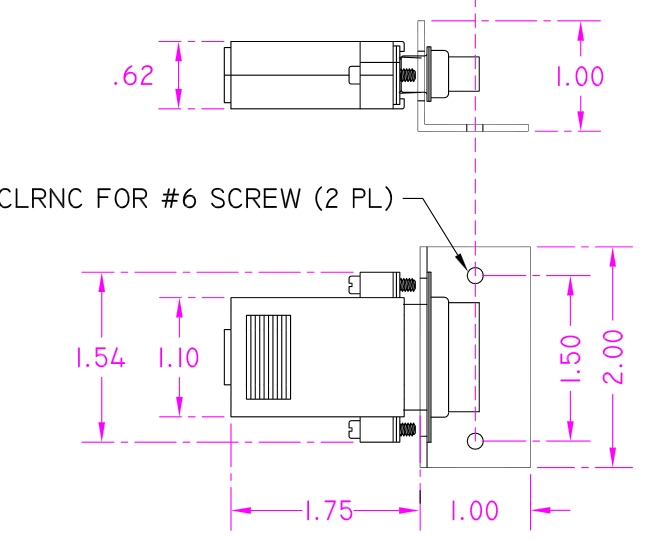

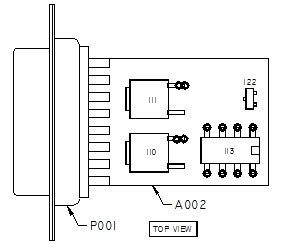

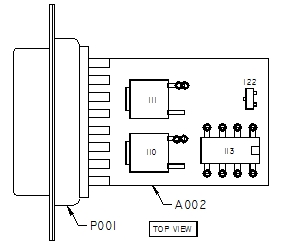

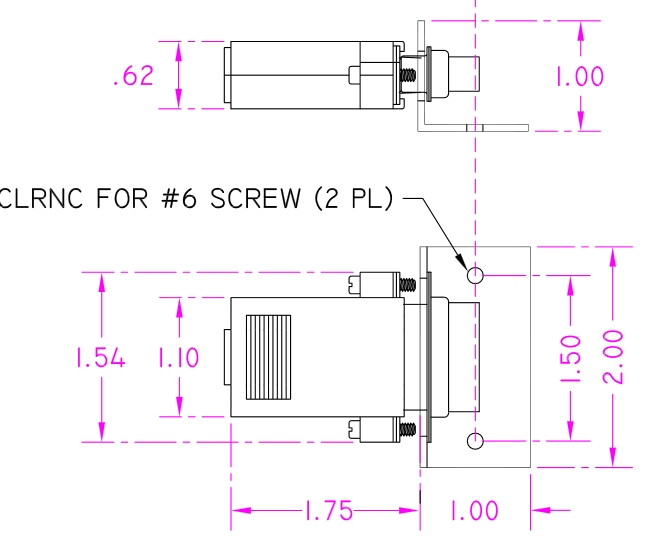

Then there's a matter of packaging. One can easily

spend more time putting a gizmo in a box and installing

it than it took to build the gizmo. Certainly, packaging

issues are a major component of a development project.

A possibility for this project is to package in a

D-sub housing. The enclosure is an off-the-shelf, inexpensive

product that simply snaps onto the final assembly.

An ECB can be soldered directly into the gap between

rows of solder-cups on a dsub.

[img]cid:.0[/img]

and dropped into a plastic housing that simply

snaps together. A product housed in a 15 pin

back shell has these dimensions.

[img]cid:.1[/img]

This project can probably be fitted into a

25 pin back shell. I perceive no particular

advantage in taking power and signals on/off

the board on RCA jacks . . . shielded

wires are just as easily dropped onto d-sub

pins. RCA plugs are not the most installer

friendly connectors.

With the extra pins, the user could intall

jumpers on the connector to select 2, 3 or 4

cameras. Other jumpers might select 3, 4 or

5 seconds per step . . . etc.

Then there's consideration for the constellation

of end users. How many would even be willing,

much less able to successfully assemble the

thing? Companies I've worked for have often

been very protective of details for how their

product was put together . . . worries about

people wanting to build it themselves. I've

observed that the $cost$ to built one-off

exceeds the selling price from a manufacturer

who is set up to build in volume while working

wayyyyyyy down on the learning curve.

It seems likely that the best way to bring

this project into the marketplace is to have

it productionized after the initial development

work is completed.

Even if supported by availability of bare

ecbs and programmed chips, it doesn't seem

like many of these things would be built.

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

90.72 KB |

| Viewed: |

22267 Time(s) |

|

| Description: |

|

| Filesize: |

26.36 KB |

| Viewed: |

22267 Time(s) |

|

|

|

| Back to top |

|

|

wtmills

Joined: 05 Feb 2007

Posts: 32

|

Posted: Sun Oct 15, 2017 9:28 am Post subject: Constructing an automatic RCA video camera feed splitter Posted: Sun Oct 15, 2017 9:28 am Post subject: Constructing an automatic RCA video camera feed splitter |

|

|

Ditto Charlie!

do not archive

On Sun, Oct 15, 2017 at 8:50 AM, Charlie England <ceengland7(at)gmail.com (ceengland7(at)gmail.com)> wrote:

| Quote: | Bob,

My comment was about 'buttonology'; not building. I've got a little clock that's RF linked to Federal time broadcasts. It's totally impossible to use any of the elaborate built-in functions with out the manual, because it has two or three unmarked buttons, and to access the various functions, you need to know the "combination". No one can use the thing without the book in front of them. Same thing for most kilo-function watches, etc. Even my old Icom A-4 handheld comm is like that. I seldom use it, so even though I've owned it for over 20 years, I still don't know how to program frequencies into it. If it had a keypad, anyone could pick it up and enter '122.75', or '125.25', etc. But since it doesn't, the unwashed can only hold the up or down button until they see the freq they want. For me, a perfect example of something simplified to the point of un-usability.

Charlie

Virus-free. www.avast.com [url=#m_3036080108603840177_DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2][/url] Virus-free. www.avast.com [url=#m_3036080108603840177_DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2][/url]

On Sun, Oct 15, 2017 at 10:22 AM, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | At 07:30 AM 10/15/2017, you wrote:

| Quote: | | That stuff is cool as far as programming tricks go, but who will be able to use the hardware except the original designer? I, and everyone else on this list, have owned dozens of electronic gadgets over the years that are absolutely impossible to set up and use without the English-as-a-second-language printed manual that you can't find after the 1st month of ownership. I have to use google on my desktop to explore how to get my phone apps to work like I want. |

This is amongst the simplest PIC applications we'll

ever encounter . . . once the first installation

has combed out the nits . . . it seems unlikely

that there would be many if any software upgrades.

Another consideration is flexibility. Suppose the

prospective end user wants only two cameras . . . or

three? Different software . . . or strapped selection

on the ECB?

Then there's a matter of packaging. One can easily

spend more time putting a gizmo in a box and installing

it than it took to build the gizmo. Certainly, packaging

issues are a major component of a development project.

A possibility for this project is to package in a

D-sub housing. The enclosure is an off-the-shelf, inexpensive

product that simply snaps onto the final assembly.

An ECB can be soldered directly into the gap between

rows of solder-cups on a dsub.

[img]cid:.0[/img]

and dropped into a plastic housing that simply

snaps together. A product housed in a 15 pin

back shell has these dimensions.

[img]cid:.1[/img]

This project can probably be fitted into a

25 pin back shell. I perceive no particular

advantage in taking power and signals on/off

the board on RCA jacks . . . shielded

wires are just as easily dropped onto d-sub

pins. RCA plugs are not the most installer

friendly connectors.

With the extra pins, the user could intall

jumpers on the connector to select 2, 3 or 4

cameras. Other jumpers might select 3, 4 or

5 seconds per step . . . etc.

Then there's consideration for the constellation

of end users. How many would even be willing,

much less able to successfully assemble the

thing? Companies I've worked for have often

been very protective of details for how their

product was put together . . . worries about

people wanting to build it themselves. I've

observed that the $cost$ to built one-off

exceeds the selling price from a manufacturer

who is set up to build in volume while working

wayyyyyyy down on the learning curve.

It seems likely that the best way to bring

this project into the marketplace is to have

it productionized after the initial development

work is completed.

Even if supported by availability of bare

ecbs and programmed chips, it doesn't seem

like many of these things would be built.

Bob . . .

|

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

26.36 KB |

| Viewed: |

22274 Time(s) |

|

| Description: |

|

| Filesize: |

90.72 KB |

| Viewed: |

22274 Time(s) |

|

|

|

| Back to top |

|

|

paulf(at)hughes.net

Guest

|

Posted: Sun Oct 15, 2017 12:06 pm Post subject: Constructing an automatic RCA video camera feed splitter Posted: Sun Oct 15, 2017 12:06 pm Post subject: Constructing an automatic RCA video camera feed splitter |

|

|

Eric,

This project was your suggestion, so I'll bow to whatever you want to

do. PIC, no PIC, one switch, two switches - whatever you like! I don't

believe I have a need for this device, so my opinion on the user

interface is irrelevant.

Just for my own "education and recreation", I wrote and tested the PIC

software I described (for a single on-on-(on) switch). It's very

simple, but does what I think you asked. You are welcome to the code if

you are interested.

Alec seems to have a lot more experience that I do, so since he

volunteered, we should let him contribute if you want to go the PIC

route. Either way, it was a fun Sunday afternoon project... especially

since the weather isn't that conducive to flying!

Please let me know if I can be of service. Otherwise, I'll go back into

lurker mode.

Paul Fisher

On 10/14/2017 7:32 PM, Eric Page wrote:

| Quote: |

nuckolls.bob(at)aeroelect wrote:

> I propose we make this another open source program like the wig-wag was . . . I'll be pleased to set up a folder to host all the work product.

Great. I kinda figured we were doing an open-source effort. With that in mind, I had a good think about this while slogging for six hours against 145-knot headwinds this morning...

I think there are a few issues that argue against changing to a PIC microcontroller in this project. Wade alluded to the first one in his post this morning (which, along with one other from Clayton, has disappeared from the server) when he joked about the details being over his head:

- It would make the project considerably less accessible to many builders. Anyone without a hardware programmer and the Microchip IDE software will either have to get them, then find the code to download and learn how to program the PIC, or buy a PIC with the code already loaded. On the other hand, anyone pretty much anywhere with a soldering iron and minimal skill can put my design together for as long as its jellybean components are available.

- Software updates will require removing the unit from service, removing the PIC to send for reprogramming, or buying a new PIC to replace it.

- A PIC won't simplify the user interface. We still need a switch for the run/hold/step function and a knob to adjust scan rate. Perhaps a system using buttons or a rotary encoder could be devised, but it would probably be less intuitive than the switch and knob.

- If a PIC could replace the $7 video multiplexer chip, you could make a good case for lowering cost, but we're talking about replacing a couple of 50 to 80-cent jellybeans and a few passives that are tens of cents each -- about $3 total. Can anyone deliver a programmed PIC for $3 and make it worth their trouble?

- The size of the PCB is going to be driven largely by the five RCA jacks, so deleting a 16-DIP and a few passives probably won't shrink the board appreciably.

I think this is a case where a microcontroller may be overkill, given that suitable cheap ICs are readily available. Given the simplicity of the problem, wouldn't it make more sense to keep the solution simple?

Thoughts?

Eric

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=473555#473555

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Eric Page

Joined: 15 Feb 2017

Posts: 247

|

Posted: Sun Oct 15, 2017 7:01 pm Post subject: Re: Constructing an automatic RCA video camera feed splitte Posted: Sun Oct 15, 2017 7:01 pm Post subject: Re: Constructing an automatic RCA video camera feed splitte |

|

|

Well, I drafted a detailed response to all the discussion over the last day or so, when Windows 10 decided -- without any warning -- to reboot for a security update. No opportunity to save work, just a sudden blank screen. Absolutely INFURIATING, and not the first time it's happened.

Anyway, I'll probably miss something, but here's what I covered, as best I can remember...

1. Alec mentioned the possibility of video glitches or rolling when the feed is switched from camera to camera, due to the lack of video sync or frame buffering. If this happens, I will have zero idea how to fix it. I'm what you might call an ambitious hobbyist, not an engineer. Is this a high-risk thing? I have no experience here; I just found the mux IC and drew a schematic around it.

2. Alec also mentioned a Hackaday project to make an A/V switch box...

https://hackaday.com/2007/03/14/diy-av-switch/

That's a neat idea, but I struggle to understand how a digital bus switch IC can handle an AC video signal when a proper video mux needs pos/neg rails to do it. It apparently worked, but I don't understand it and comments below the project suggest that it shouldn't have worked. Again, I'm not an engineer...

3. Some good discussion between Alec and Charlie WRT user interface: buttons, knobs, switches, etc. My $0.02 is this: if we stay with discrete ICs, the interface remains a single toggle switch, and either a trimmer or knob/pot for scan rate. If we use a PIC, I would advocate for a rotary encoder with a dead simple interface: pushing the encoder switch toggles between scan and hold; when in scan mode, each click of rotation increments/decrements the pause time on each camera by 1 sec; when in hold mode, each click of rotation selects the next/previous camera feed. No user programming, just immediate response to user input. It would be nice if the PIC could write the selected scan rate to non-volatile memory each time it's changed, and recall it on power-up.

4. The AD8184 datasheet...

http://www.analog.com/media/en/technical-documentation/data-sheets/AD8184.pdf

...has a section on board layout (pg 7) that suggests a bunch of RF voodoo (striplines, microstrips, guard rings, termination resistors, etc.) related to preserving the part's 700MHz bandwidth. According to this Maxim application note...

https://www.maximintegrated.com/en/app-notes/index.mvp/id/750

...a standard definition NTSC video signal occupies 4.2MHz of bandwidth and requires 18MHz of bandwidth for 0.5dB flatness (whatever that means...). So, is any of the RF voodoo necessary, or will standard PCB traces and copper ground pours suffice? Short traces will be difficult with RCA jacks, but would be easier using a D-Sub (see below).

5. Bob made some suggestions:

A. Use a 10-turn potentiometer. I have a 1-turn cermet trimmer in the BoM right now ($0.79), but it's easily changed to a 10 or 20-turn ($1.43), or to pads for a remote pot ($0.76) if desired.

B. Design for a D-25 backshell. Good idea, but will the video signals suffer on a shielded wire -vs- an RCA cable? If not, let's do it. These NorComp parts are the only ones I can find whose datasheet includes inside dimensions...

https://www.norcomp.net/rohspdfs/BackShells/InternalDimensions/ID-983Series.pdf

...and it doesn't look like I can fit everything into the space in a D-25 shell. The D-37 shell should have room to spare. Bob, if you have a deep D-25, could you give me the part number?

C. Use excess pins in the D-Sub as selection jumpers for number of cameras, scan rate, etc. I presume this would require a PIC pin to read each jumper. Or perhaps you could use a resistor ladder across multiple D-Sub pins and read the ladder voltage with a single PIC pin to determine which jumper is installed. Very good idea for setting number of camera inputs, but I don't see the point for scan rate; a trimmer (or rotary encoder) seems fine.

D. Use ExpressPCB. I haven't used them for at least 20 years. I don't like their "walled garden" model or their prices. Their closed software is the antithesis of "open source," and I'm never in a big enough hurry to justify the expense. My work will produce standard Gerber files that any board fab can use. Anyone can order 3 copies of the board from OSH Park...

http://www.oshpark.com/

...for $5/sq inch with free shipping, or upload to any of a half dozen Chinese fabs...

http://www.pcbshopper.com/

...to get 10 copies of the board in 2-3 weeks for <$20.

E. Provide "kits" of a PCB and programmed PIC. Sounds like a fine idea to me, if a PIC is the way we go.

6. Paul has a first draft of PIC software running, and Alec has volunteered to write code as well. It sounds like we're in good shape WRT wrangling ones and zeros.

More to follow...

Eric

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

Last edited by Eric Page on Sun Oct 15, 2017 7:07 pm; edited 1 time in total |

|

| Back to top |

|

|

Eric Page

Joined: 15 Feb 2017

Posts: 247

|

Posted: Sun Oct 15, 2017 7:07 pm Post subject: Re: Constructing an automatic RCA video camera feed splitte Posted: Sun Oct 15, 2017 7:07 pm Post subject: Re: Constructing an automatic RCA video camera feed splitte |

|

|

Wade,

We haven't heard from you for awhile. Since you're likely to be the guinea pig on this project, there are a few items you should have input on:

- Do you have a preference WRT discrete ICs -vs- a PIC microcontroller?

- Do you have any desires for additional features or functions that would push us in one direction or the other?

- Of the user interface options you've seen discussed, what would be your preference?

- For camera scan rate, would you prefer to set it once and forget it, or have an accessible control for routine use?

- Would you prefer to install a device with five RCA jacks for signal and a 2-position header for power, or one D-Sub connector for everything?

Clayton, you expressed interest in getting one of these also; feel free to offer your opinion on these questions too.

Eric

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|