|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

bmsim

Joined: 02 Jun 2009

Posts: 32

Location: Alabama

|

Posted: Tue Nov 20, 2018 5:33 am Post subject: Snot valve, constantly builds pressure. Normal/Not? Posted: Tue Nov 20, 2018 5:33 am Post subject: Snot valve, constantly builds pressure. Normal/Not? |

|

|

Hello Everyone!

In searching for an air leak and rebuilding a couple of things already, I found something I have a question about. Whenever I open the snot valve, air blows out. This is regardless of if the engine has ran or not, if I dump it and let it sit for 10 min, I can open the valve and it has pressure. Is that normal, or might I be leaking air there?

Brandon

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

dougsappllc(at)gmail.com

Guest

|

Posted: Tue Nov 20, 2018 6:53 am Post subject: Snot valve, constantly builds pressure. Normal/Not? Posted: Tue Nov 20, 2018 6:53 am Post subject: Snot valve, constantly builds pressure. Normal/Not? |

|

|

Check valve (s) on the PRV are most likely leaking.

Doug

On Tue, Nov 20, 2018 at 5:41 AM bmsim <bmsim(at)hotmail.com (bmsim(at)hotmail.com)> wrote:

| Quote: | --> Yak-List message posted by: "bmsim" <bmsim(at)hotmail.com (bmsim(at)hotmail.com)>

Hello Everyone!

In searching for an air leak and rebuilding a couple of things already, I found something I have a question about. Whenever I open the snot valve, air blows out. This is regardless of if the engine has ran or not, if I dump it and let it sit for 10 min, I can open the valve and it has pressure. Is that normal, or might I be leaking air there?

Brandon

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=485342#485342

===========

br> fts!)

r> > e.com" rel="noreferrer" target="_blank">www.mypilotstore.com

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

-Matt Dralle, List Admin.

===========

List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?Yak-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

===========

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

dsavarese0812(at)bellsout

Guest

|

Posted: Tue Nov 20, 2018 9:12 am Post subject: Snot valve, constantly builds pressure. Normal/Not? Posted: Tue Nov 20, 2018 9:12 am Post subject: Snot valve, constantly builds pressure. Normal/Not? |

|

|

No, that is not normal. You have a check valve leaking.

Dennis

A. Dennis Savarese

334-546-8182 (mobile)

www.yak-52.com

Skype - Yakguy1

On 11/20/2018 8:33 AM, bmsim wrote:

| Quote: |

Hello Everyone!

In searching for an air leak and rebuilding a couple of things already, I found something I have a question about. Whenever I open the snot valve, air blows out. This is regardless of if the engine has ran or not, if I dump it and let it sit for 10 min, I can open the valve and it has pressure. Is that normal, or might I be leaking air there?

Brandon

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=485342#485342

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

bmsim

Joined: 02 Jun 2009

Posts: 32

Location: Alabama

|

Posted: Wed Nov 21, 2018 9:37 am Post subject: Re: Snot valve, constantly builds pressure. Normal/Not? Posted: Wed Nov 21, 2018 9:37 am Post subject: Re: Snot valve, constantly builds pressure. Normal/Not? |

|

|

Thanks guys!

I have rebuild kits and filter for the T assembly. For the individual sides, do the check valves just screw apart? I disassembled the T the other day and tried to take one of the valves apart but it was so hard to turn that it appears to need a vise. I didn't know if that's normal or if I'd be tearing something up, so I stopped until I could ask.

Should the individual sides of the T assembly require a vise to disassemble, or am I missing something on how to disassemble?

Brandon

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

hkgibby(at)yahoo.com

Guest

|

Posted: Wed Nov 21, 2018 10:23 am Post subject: Snot valve, constantly builds pressure. Normal/Not? Posted: Wed Nov 21, 2018 10:23 am Post subject: Snot valve, constantly builds pressure. Normal/Not? |

|

|

Hi Brandon-

Yes a vise will help in disassembly and rebuild of your check valves and pop off valve. You really ought to have the CJ parts manuals. Refer to Parts Book Vol 1, pages 442-448 for all things check valves. Will all make sense. I sent you Vol 1 direct to your email.

Hoot

Sent from my iPhone

| Quote: | On Nov 21, 2018, at 12:37 PM, bmsim <bmsim(at)hotmail.com> wrote:

Thanks guys!

I have rebuild kits and filter for the T assembly. For the individual sides, do the check valves just screw apart? I disassembled the T the other day and tried to take one of the valves apart but it was so hard to turn that it appears to need a vise. I didn't know if that's normal or if I'd be tearing something up, so I stopped until I could ask.

Should the individual sides of the T assembly require a vise to disassemble, or am I missing something on how to disassemble?

Brandon

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=485478#485478

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

bmsim

Joined: 02 Jun 2009

Posts: 32

Location: Alabama

|

Posted: Wed Nov 21, 2018 11:07 am Post subject: Re: Snot valve, constantly builds pressure. Normal/Not? Posted: Wed Nov 21, 2018 11:07 am Post subject: Re: Snot valve, constantly builds pressure. Normal/Not? |

|

|

Thank you very much!

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

hill(at)doctor-hill.com

Guest

|

Posted: Wed Nov 21, 2018 11:44 am Post subject: Snot valve, constantly builds pressure. Normal/Not? Posted: Wed Nov 21, 2018 11:44 am Post subject: Snot valve, constantly builds pressure. Normal/Not? |

|

|

Brandon,

On occasion, after rebuilding the CJ check valves, they will continue to leak for a week or two. The hard rubber disk over the metal cap on top of the spring may take a while to properly seat. Soaking the hard rubber cap in glycerine sometimes helps. A few will continue to leak no matter what and need to be replaced. A simple test of individual check values before going through the trouble of installing them is to connect an air pressure gauge via a B-nut on the outflow side and then pressurize the inflow side to 50 ATM (735 PSI). After turning off and removing the air source, the pressure on the outflow side should hold. A common point of failure and annoyance is on the right side of the oil tank where a pair of check valves separate air flow into the main and the emergency systems.

It’s also not a bad idea to replace check values that have been in place for a long time. The amount of internal corrosion can be astonishing. Attached is a picture of what typical check valve corrosion looks like.

Hope this helps,

Warren Hill

N464TW

Mesa, AZ

[img]cid:DF4C9940-B54B-4241-B05B-DAD8B38D1035[/img]

| Quote: | On Nov 21, 2018, at 11:22 AM, Hank Gibson <hkgibby(at)yahoo.com (hkgibby(at)yahoo.com)> wrote:

--> Yak-List message posted by: Hank Gibson <hkgibby(at)yahoo.com (hkgibby(at)yahoo.com)>Hi Brandon-Yes a vise will help in disassembly and rebuild of your check valves and pop off valve. You really ought to have the CJ parts manuals. Refer to Parts Book Vol 1, pages 442-448 for all things check valves. Will all make sense. I sent you Vol 1 direct to your email.HootSent from my iPhone | Quote: | | On Nov 21, 2018, at 12:37 PM, bmsim <bmsim(at)hotmail.com (bmsim(at)hotmail.com)> wrote:--> Yak-List message posted by: "bmsim" <bmsim(at)hotmail.com (bmsim(at)hotmail.com)>Thanks guys!I have rebuild kits and filter for the T assembly. For the individual sides, do the check valves just screw apart? I disassembled the T the other day and tried to take one of the valves apart but it was so hard to turn that it appears to need a vise. I didn't know if that's normal or if I'd be tearing something up, so I stopped until I could ask. Should the individual sides of the T assembly require a vise to disassemble, or am I missing something on how to disassemble?BrandonRead this topic online here:http://forums.matronics.com/viewtopic.php?p=485478#485478 |

http://wiki.matronics.com

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

| Description: |

|

| Filesize: |

159.94 KB |

| Viewed: |

7553 Time(s) |

|

|

|

| Back to top |

|

|

hkgibby(at)yahoo.com

Guest

|

Posted: Wed Nov 21, 2018 12:32 pm Post subject: Snot valve, constantly builds pressure. Normal/Not? Posted: Wed Nov 21, 2018 12:32 pm Post subject: Snot valve, constantly builds pressure. Normal/Not? |

|

|

Brandon-

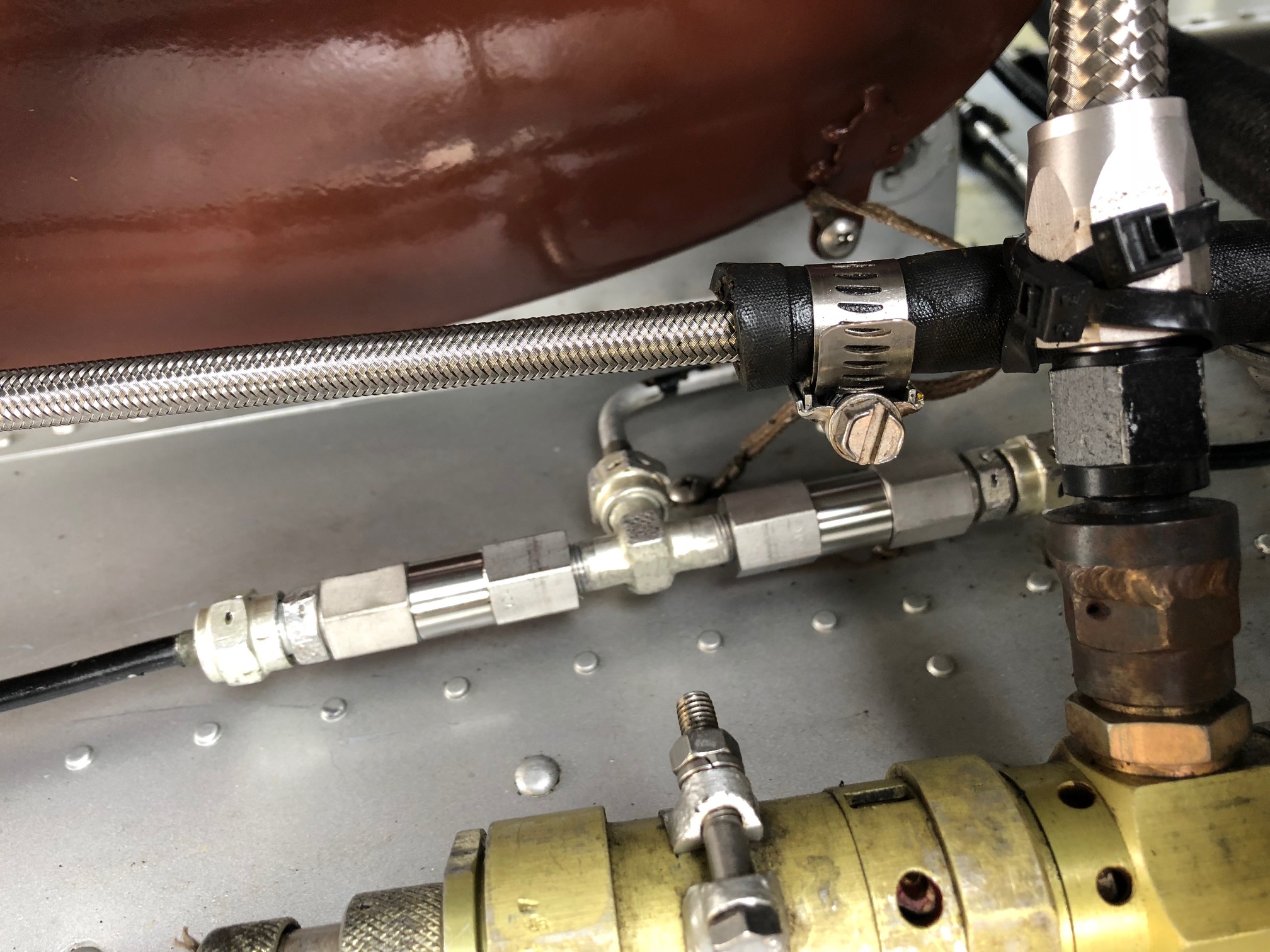

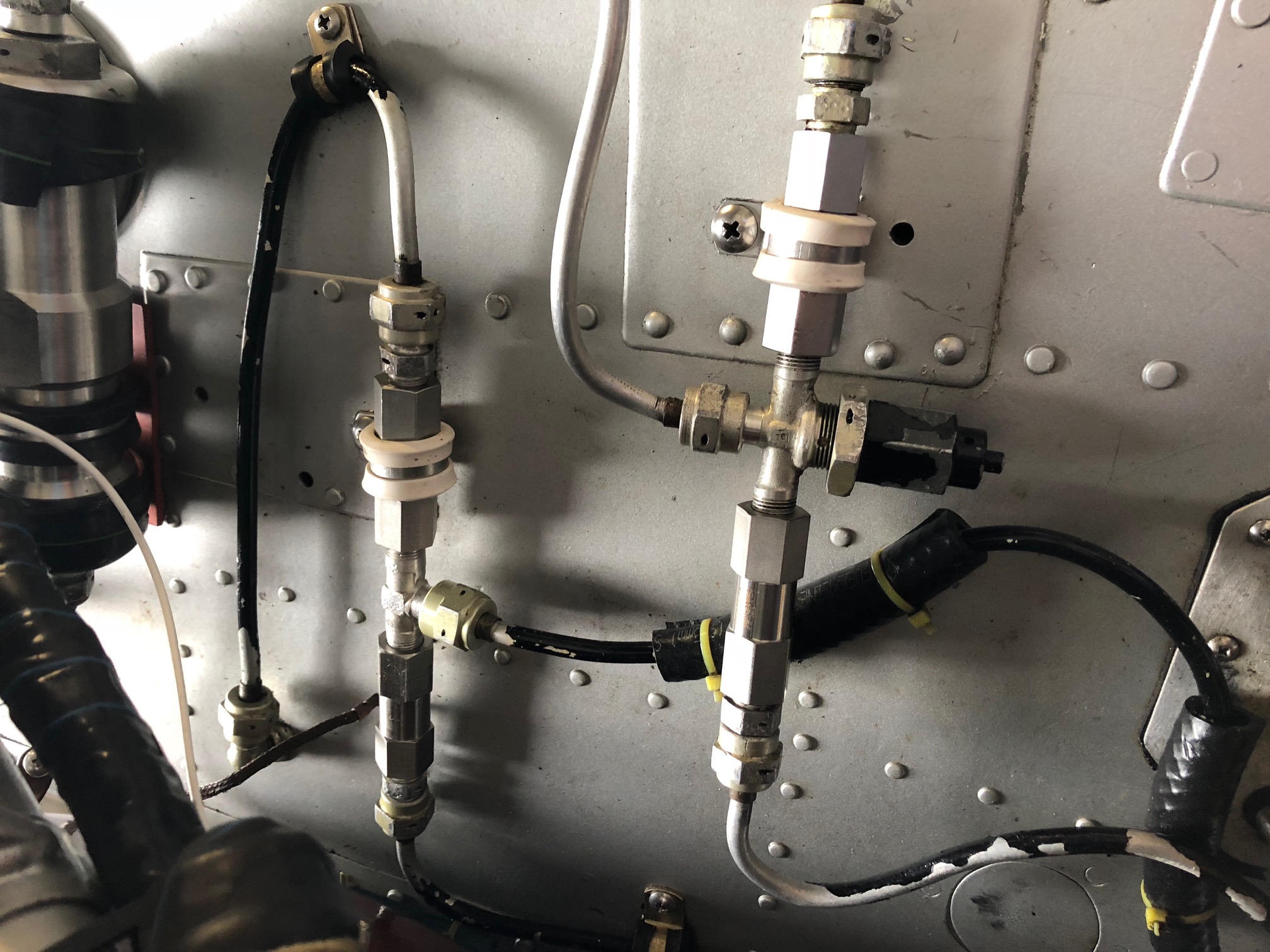

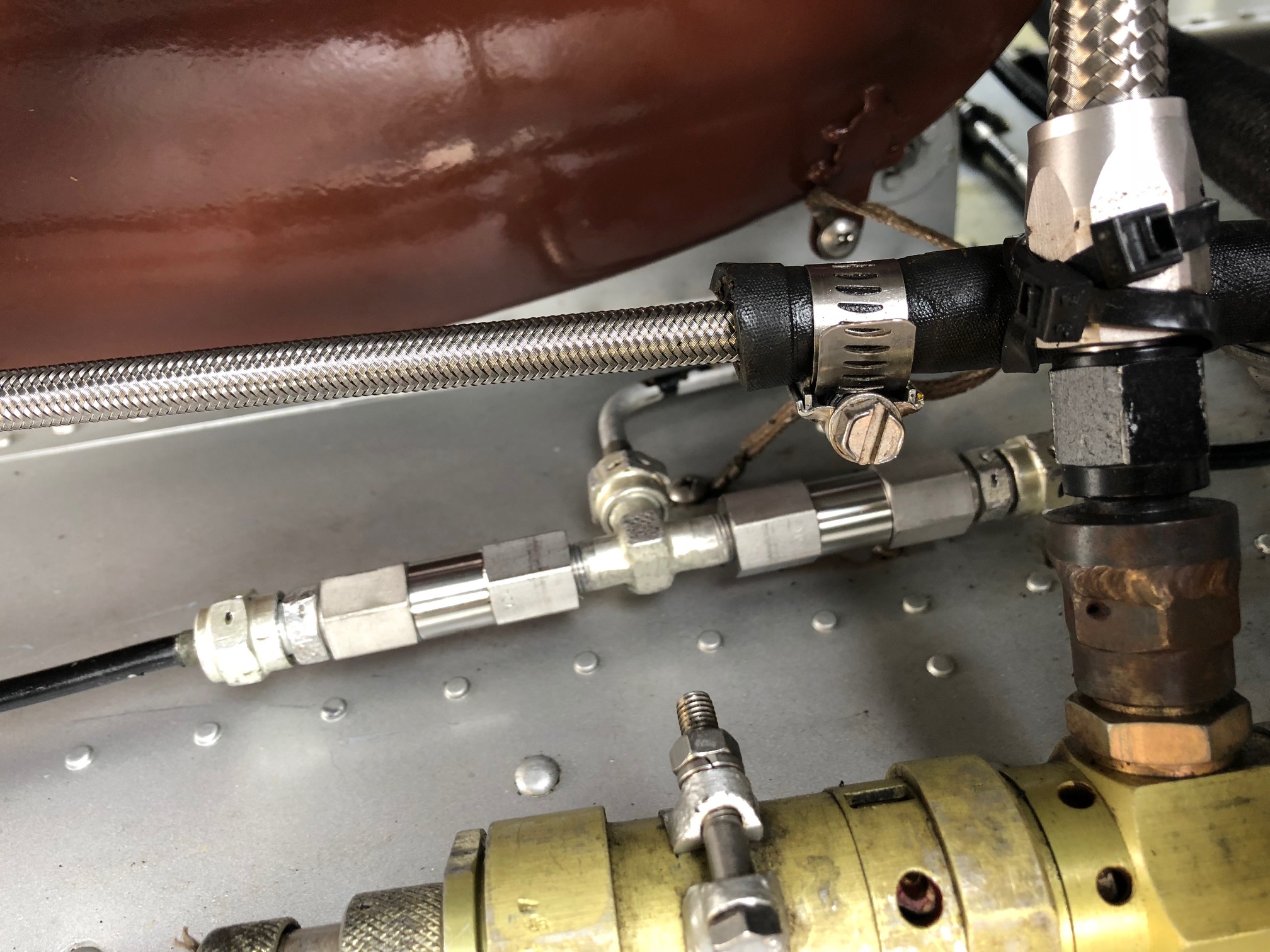

You could also replace all check valves with Swagelok check valves which are an easy drop in. Problems solved and no more fiddling with rubber discs/crush seals and bodies which loosen. All six for about $280. To me worth the price to improve health of pneumatic system. Old nipples with flare are transferred and work with a 1/8” NPT Swagelok. Part number is “SS-2C4-xx (last number is “cracking pressure” which is not critical, may be 1/3, 1, 10 and 25 , I believe). See pics.

[img]cid:B9CAA587-2B29-4D67-8B05-81B36318EA85[/img]

[img]cid:881E5241-4750-45B9-9506-427AFD0FA716[/img]

Sent from my iPhone[img]cid:98D9F294-EEDB-4B2A-ADE5-84AD48D13AD5[/img]

Good luck- Hoot

On Nov 21, 2018, at 2:18 PM, Warren Hill <hill(at)doctor-hill.com (hill(at)doctor-hill.com)> wrote:

| Quote: | Brandon,

On occasion, after rebuilding the CJ check valves, they will continue to leak for a week or two. The hard rubber disk over the metal cap on top of the spring may take a while to properly seat. Soaking the hard rubber cap in glycerine sometimes helps. A few will continue to leak no matter what and need to be replaced. A simple test of individual check values before going through the trouble of installing them is to connect an air pressure gauge via a B-nut on the outflow side and then pressurize the inflow side to 50 ATM (735 PSI). After turning off and removing the air source, the pressure on the outflow side should hold. A common point of failure and annoyance is on the right side of the oil tank where a pair of check valves separate air flow into the main and the emergency systems.

It’s also not a bad idea to replace check values that have been in place for a long time. The amount of internal corrosion can be astonishing. Attached is a picture of what typical check valve corrosion looks like.

Hope this helps,

Warren Hill

N464TW

Mesa, AZ

<Check_Valve.jpg>

| Quote: | On Nov 21, 2018, at 11:22 AM, Hank Gibson <hkgibby(at)yahoo.com (hkgibby(at)yahoo.com)> wrote:

--> Yak-List message posted by: Hank Gibson <hkgibby(at)yahoo.com (hkgibby(at)yahoo.com)>Hi Brandon-Yes a vise will help in disassembly and rebuild of your check valves and pop off valve. You really ought to have the CJ parts manuals. Refer to Parts Book Vol 1, pages 442-448 for all things check valves. Will all make sense. I sent you Vol 1 direct to your email.HootSent from my iPhone | Quote: | | On Nov 21, 2018, at 12:37 PM, bmsim <bmsim(at)hotmail.com (bmsim(at)hotmail.com)> wrote:--> Yak-List message posted by: "bmsim" <bmsim(at)hotmail.com (bmsim(at)hotmail.com)>Thanks guys!I have rebuild kits and filter for the T assembly. For the individual sides, do the check valves just screw apart? I disassembled the T the other day and tried to take one of the valves apart but it was so hard to turn that it appears to need a vise. I didn't know if that's normal or if I'd be tearing something up, so I stopped until I could ask. Should the individual sides of the T assembly require a vise to disassemble, or am I missing something on how to disassemble?BrandonRead this topic online here:http://forums.matronics.com/viewtopic.php?p=485478#485478 |

http://www.matronics.com/Navigator?Yak-Listhttp://wiki.matronics.comhttp://www.matronics.com/contribution

|

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

| Description: |

|

| Filesize: |

690.07 KB |

| Viewed: |

7548 Time(s) |

|

| Description: |

|

| Filesize: |

588.72 KB |

| Viewed: |

7548 Time(s) |

|

| Description: |

|

| Filesize: |

636.24 KB |

| Viewed: |

7548 Time(s) |

|

|

|

| Back to top |

|

|

Viperdoc

Joined: 19 Apr 2014

Posts: 484

Location: 08A

|

Posted: Wed Nov 21, 2018 6:42 pm Post subject: Snot valve, constantly builds pressure. Normal/Not? Posted: Wed Nov 21, 2018 6:42 pm Post subject: Snot valve, constantly builds pressure. Normal/Not? |

|

|

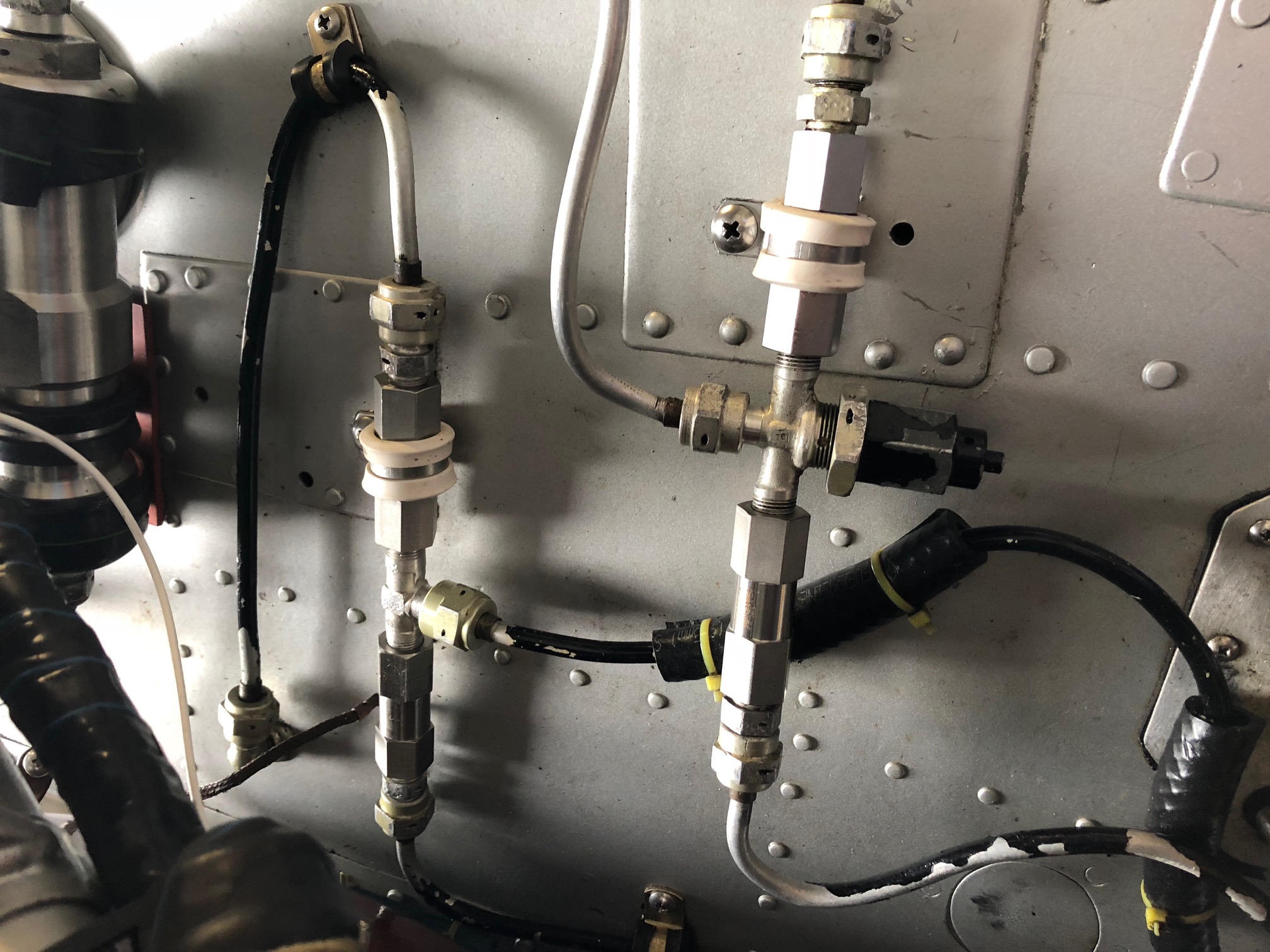

Sounds like the system check valves on the firewall are leaking. If one is leaking they all will eventually leak. May as well replace all three.

This is the T rebuild using CJ new SS check valves from Doug Sapp. You will have to wrap the valves with anti chaff tape to get the correct diameter when you anchor the adell clamps on the firewall. There is a L beam firewall stiffener that the B nut will chaff on if you do not put a chaff tape spacer on the check valve barrels.

Doug has a kit that has all the needed check valves to replace your existing leakers.

Doc

Sent from my iPad

| Quote: | On Nov 20, 2018, at 7:33 AM, bmsim <bmsim(at)hotmail.com> wrote:

Hello Everyone!

In searching for an air leak and rebuilding a couple of things already, I found something I have a question about. Whenever I open the snot valve, air blows out. This is regardless of if the engine has ran or not, if I dump it and let it sit for 10 min, I can open the valve and it has pressure. Is that normal, or might I be leaking air there?

Brandon

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=485342#485342

====================================

|

====================================

====================================

====================================

====================================

====================================

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

| Description: |

|

| Filesize: |

1.34 MB |

| Viewed: |

7544 Time(s) |

|

_________________

Viperdoc |

|

| Back to top |

|

|

hill(at)doctor-hill.com

Guest

|

Posted: Thu Nov 22, 2018 12:54 pm Post subject: Snot valve, constantly builds pressure. Normal/Not? Posted: Thu Nov 22, 2018 12:54 pm Post subject: Snot valve, constantly builds pressure. Normal/Not? |

|

|

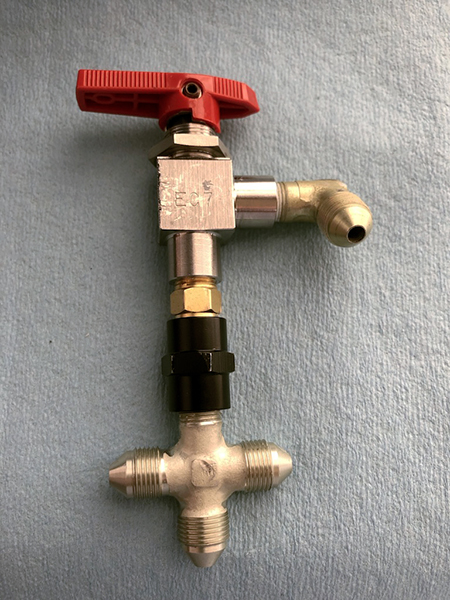

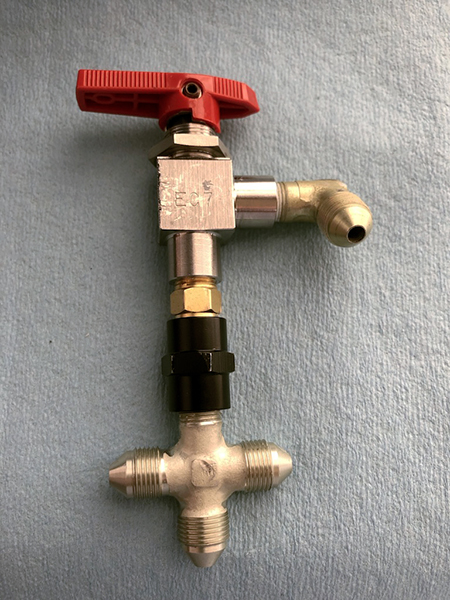

Hank,

Some have not had good luck with the Swagelok check valves. One member of our group had four of these fail on a trip to Oskkosh several years ago. The more robust Chinese replacements are still working. Where Swagelok does a great job is for replacing the original Chinese main and emergency air on-off valves as described by Jason Berman. Mine have been fine for years. The smaller size requires two simple adaptors so the connecting air lines don’t have to be re-done. Attached is a picture of my emergency on-off valve with adaptors that duplicate the original line positions. For those who have not yet done this replacement, the current black handle valve for the main air is part number SS-42GF2-A-WN2 and the red handle part number is SS-42GF2-A-RD-WN2. Replace and forget. Really nice. One less thing to cause problems.

Warren Hill

N464TW

Mesa, AZ

[img]cid:EAE9B400-E834-43EA-9F8E-4560C6ABBEC3(at)Home[/img]

| Quote: | On Nov 21, 2018, at 1:30 PM, Hank Gibson <hkgibby(at)yahoo.com (hkgibby(at)yahoo.com)> wrote:

Brandon-

You could also replace all check valves with Swagelok check valves which are an easy drop in. Problems solved and no more fiddling with rubber discs/crush seals and bodies which loosen. All six for about $280. To me worth the price to improve health of pneumatic system. Old nipples with flare are transferred and work with a 1/8” NPT Swagelok. Part number is “SS-2C4-xx (last number is “cracking pressure” which is not critical, may be 1/3, 1, 10 and 25 , I believe). See pics.

<image1.jpeg>

<image3.jpeg>Sent from my iPhone<image4.jpeg>

Good luck- Hoot

On Nov 21, 2018, at 2:18 PM, Warren Hill <hill(at)doctor-hill.com (hill(at)doctor-hill.com)> wrote:

| Quote: | Brandon,

On occasion, after rebuilding the CJ check valves, they will continue to leak for a week or two. The hard rubber disk over the metal cap on top of the spring may take a while to properly seat. Soaking the hard rubber cap in glycerine sometimes helps. A few will continue to leak no matter what and need to be replaced. A simple test of individual check values before going through the trouble of installing them is to connect an air pressure gauge via a B-nut on the outflow side and then pressurize the inflow side to 50 ATM (735 PSI). After turning off and removing the air source, the pressure on the outflow side should hold. A common point of failure and annoyance is on the right side of the oil tank where a pair of check valves separate air flow into the main and the emergency systems.

It’s also not a bad idea to replace check values that have been in place for a long time. The amount of internal corrosion can be astonishing. Attached is a picture of what typical check valve corrosion looks like.

Hope this helps,

Warren Hill

N464TW

Mesa, AZ

<Check_Valve.jpg>

| Quote: | On Nov 21, 2018, at 11:22 AM, Hank Gibson <hkgibby(at)yahoo.com (hkgibby(at)yahoo.com)> wrote:

--> Yak-List message posted by: Hank Gibson <hkgibby(at)yahoo.com (hkgibby(at)yahoo.com)>Hi Brandon-Yes a vise will help in disassembly and rebuild of your check valves and pop off valve. You really ought to have the CJ parts manuals. Refer to Parts Book Vol 1, pages 442-448 for all things check valves. Will all make sense. I sent you Vol 1 direct to your email.HootSent from my iPhone | Quote: | | On Nov 21, 2018, at 12:37 PM, bmsim <bmsim(at)hotmail.com (bmsim(at)hotmail.com)> wrote:--> Yak-List message posted by: "bmsim" <bmsim(at)hotmail.com (bmsim(at)hotmail.com)>Thanks guys!I have rebuild kits and filter for the T assembly. For the individual sides, do the check valves just screw apart? I disassembled the T the other day and tried to take one of the valves apart but it was so hard to turn that it appears to need a vise. I didn't know if that's normal or if I'd be tearing something up, so I stopped until I could ask. Should the individual sides of the T assembly require a vise to disassemble, or am I missing something on how to disassemble?BrandonRead this topic online here:http://forums.matronics.com/viewtopic.php?p=485478#485478 |

http://www.matronics.com/Navigator?Yak-Listhttp://wiki.matronics.comhttp://www.matronics.com/contribution

|

|

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

| Description: |

|

| Filesize: |

244.06 KB |

| Viewed: |

7533 Time(s) |

|

|

|

| Back to top |

|

|

Viperdoc

Joined: 19 Apr 2014

Posts: 484

Location: 08A

|

Posted: Thu Nov 22, 2018 9:53 pm Post subject: Snot valve, constantly builds pressure. Normal/Not? Posted: Thu Nov 22, 2018 9:53 pm Post subject: Snot valve, constantly builds pressure. Normal/Not? |

|

|

CJ or YAK? The YAK check valves that have been in use for a few bears are a bitch to get apart. I personally think they use epoxy on the groves. It takes a vice and a torc to get them apart on occasion. Be prepared to replace all of the guts in that case.

You can just send them to Cliff Coy to rebuild with Parker air system parts. They hone the case to do that.

Or you could replace the with Dzongkha Sapps Kit.

Doc

Sent from my iPad

| Quote: | On Nov 21, 2018, at 11:37 AM, bmsim <bmsim(at)hotmail.com> wrote:

Thanks guys!

I have rebuild kits and filter for the T assembly. For the individual sides, do the check valves just screw apart? I disassembled the T the other day and tried to take one of the valves apart but it was so hard to turn that it appears to need a vise. I didn't know if that's normal or if I'd be tearing something up, so I stopped until I could ask.

Should the individual sides of the T assembly require a vise to disassemble, or am I missing something on how to disassemble?

Brandon

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=485478#485478

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

_________________

Viperdoc |

|

| Back to top |

|

|

bmsim

Joined: 02 Jun 2009

Posts: 32

Location: Alabama

|

Posted: Fri Nov 23, 2018 6:27 am Post subject: Re: Snot valve, constantly builds pressure. Normal/Not? Posted: Fri Nov 23, 2018 6:27 am Post subject: Re: Snot valve, constantly builds pressure. Normal/Not? |

|

|

Thank you guys all so much for the help! Lots of options and great ideas here.

Yes, this is a Yak.

Brandon

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

hill(at)doctor-hill.com

Guest

|

Posted: Mon Nov 26, 2018 8:02 am Post subject: Snot valve, constantly builds pressure. Normal/Not? Posted: Mon Nov 26, 2018 8:02 am Post subject: Snot valve, constantly builds pressure. Normal/Not? |

|

|

Jill Gernetzke can also repair/rebuild them, but it takes the force of a pneumatic hammer to get them apart.

Warren Hill

| Quote: | On Nov 22, 2018, at 10:53 PM, Roger Kemp <f16viperdoc(at)me.com> wrote:

CJ or YAK? The YAK check valves that have been in use for a few bears are a bitch to get apart. I personally think they use epoxy on the groves. It takes a vice and a torc to get them apart on occasion. Be prepared to replace all of the guts in that case.

You can just send them to Cliff Coy to rebuild with Parker air system parts. They hone the case to do that.

Or you could replace the with Dzongkha Sapps Kit.

Doc

Sent from my iPad

> On Nov 21, 2018, at 11:37 AM, bmsim <bmsim(at)hotmail.com> wrote:

>

>

>

> Thanks guys!

>

> I have rebuild kits and filter for the T assembly. For the individual sides, do the check valves just screw apart? I disassembled the T the other day and tried to take one of the valves apart but it was so hard to turn that it appears to need a vise. I didn't know if that's normal or if I'd be tearing something up, so I stopped until I could ask.

>

> Should the individual sides of the T assembly require a vise to disassemble, or am I missing something on how to disassemble?

>

> Brandon

>

>

>

>

> Read this topic online here:

>

> http://forums.matronics.com/viewtopic.php?p=485478#485478

>

>

>

>

>

>

>

>

>

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|