|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

cluros(at)gmail.com

Guest

|

Posted: Mon Dec 24, 2018 5:15 pm Post subject: Relay sticking Posted: Mon Dec 24, 2018 5:15 pm Post subject: Relay sticking |

|

|

We had a strange event last week with our O-200 powered CH750. After running the battery down during a fuel gauge calibration that lasted over an hour, one of our pilots tried to start the engine to taxi back but with the already depleted battery and a less than perfect start procedure they gave up after a couple weak start attempts. I walked over to the aircraft to brief them on a prop start and when I asked for the master on the starter ran. Shut the master off, cycled the start button rapidly a dozen times, master on again and the starter ran again. I could hear the starter relay clicking loudly each time power was applied so it does not seem like there was a physical failure of the relay but more some electrical short activating the relay each time power was applied.

The build team inspected the relay and found a loose connection. Tightening it took the problem from continuous to intermittent; in their words "it's fixed but it did it again once".

We have removed the relay for replacement, I still think the switch is suspect but they've decided the problem is the relay. Does the aeroelectric list think there would be value in cutting open the relay and examining it? Any suggestions on how best to do so?

Thank you,

Sebastien

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Kellym

Joined: 10 Jan 2006

Posts: 1705

Location: Sun Lakes AZ

|

Posted: Mon Dec 24, 2018 6:12 pm Post subject: Relay sticking Posted: Mon Dec 24, 2018 6:12 pm Post subject: Relay sticking |

|

|

I don't think you have a problem. I think that if the engine didn't

actually start, the starter might not reach enough speed to disengage.

Also, extended cranking at low voltage probably heated the solenoid a

lot, causing sticking in it. After the battery is fully recharged, give

it another try, without cranking more than 10-15 seconds on any try. It

is likely to start, and the starter will disengage normally. You can

test the relay on the bench, without a starter connected, just battery

cable on input side and switchable 12V on ignition terminal, just

activating long enough to see your multi-meter show voltage on the

output terminal.

On 12/24/2018 6:14 PM, Sebastien wrote:

| Quote: | We had a strange event last week with our O-200 powered CH750. After

running the battery down during a fuel gauge calibration that lasted

over an hour, one of our pilots tried to start the engine to taxi back

but with the already depleted battery and a less than perfect start

procedure they gave up after a couple weak start attempts. I walked over

to the aircraft to brief them on a prop start and when I asked for the

master on the starter ran. Shut the master off, cycled the start button

rapidly a dozen times, master on again and the starter ran again. I

could hear the starter relay clicking loudly each time power was applied

so it does not seem like there was a physical failure of the relay but

more some electrical short activating the relay each time power was applied.

The build team inspected the relay and found a loose connection.

Tightening it took the problem from continuous to intermittent; in their

words "it's fixed but it did it again once".

We have removed the relay for replacement, I still think the switch is

suspect but they've decided the problem is the relay. Does the

aeroelectric list think there would be value in cutting open the relay

and examining it? Any suggestions on how best to do so?

Thank you,

Sebastien

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor # 5286

KCHD |

|

| Back to top |

|

|

alec(at)alecmyers.com

Guest

|

Posted: Mon Dec 24, 2018 8:46 pm Post subject: Relay sticking Posted: Mon Dec 24, 2018 8:46 pm Post subject: Relay sticking |

|

|

I say change the relay. (And have done, on two different aircraft, for identical symptoms.) If the relay sticks on a good engine start it will take the starter motor with it, unless you shut it down soon, and itâs hard to spot unless you have a âstarter energizedâ lamp. In my case I was lucky, the massive current drain took the radio out before I took off, but I only worked out why when I heard the weird grinding noise of the engine driving the locked up starter when I took my headset off.

That was an O235 engine, similar starter configuration to yours.

Do you have a âstarter energizedâ lamp?

On Dec 24, 2018, at 21:04, Kelly McMullen <kellym(at)aviating.com> wrote:

I don't think you have a problem. I think that if the engine didn't actually start, the starter might not reach enough speed to disengage.

Also, extended cranking at low voltage probably heated the solenoid a lot, causing sticking in it. After the battery is fully recharged, give it another try, without cranking more than 10-15 seconds on any try. It is likely to start, and the starter will disengage normally. You can test the relay on the bench, without a starter connected, just battery cable on input side and switchable 12V on ignition terminal, just activating long enough to see your multi-meter show voltage on the output terminal.

| Quote: | On 12/24/2018 6:14 PM, Sebastien wrote:

We had a strange event last week with our O-200 powered CH750. After running the battery down during a fuel gauge calibration that lasted over an hour, one of our pilots tried to start the engine to taxi back but with the already depleted battery and a less than perfect start procedure they gave up after a couple weak start attempts. I walked over to the aircraft to brief them on a prop start and when I asked for the master on the starter ran. Shut the master off, cycled the start button rapidly a dozen times, master on again and the starter ran again. I could hear the starter relay clicking loudly each time power was applied so it does not seem like there was a physical failure of the relay but more some electrical short activating the relay each time power was applied.

The build team inspected the relay and found a loose connection. Tightening it took the problem from continuous to intermittent; in their words "it's fixed but it did it again once".

We have removed the relay for replacement, I still think the switch is suspect but they've decided the problem is the relay. Does the aeroelectric list think there would be value in cutting open the relay and examining it? Any suggestions on how best to do so?

Thank you,

Sebastien

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

cluros(at)gmail.com

Guest

|

Posted: Mon Dec 24, 2018 9:09 pm Post subject: Relay sticking Posted: Mon Dec 24, 2018 9:09 pm Post subject: Relay sticking |

|

|

We do not have a starter energized light but we do have a Dynon Skyview so I'm thinking there must be a way of connecting it to a GP input to display a warning. Have not checked the Dynon install manual yet.

On Mon, Dec 24, 2018, 20:50 Alec Myers <alec(at)alecmyers.com (alec(at)alecmyers.com) wrote:

| Quote: | --> AeroElectric-List message posted by: Alec Myers <alec(at)alecmyers.com (alec(at)alecmyers.com)>

I say change the relay. (And have done, on two different aircraft, for identical symptoms.) If the relay sticks on a good engine start it will take the starter motor with it, unless you shut it down soon, and itâs hard to spot unless you have a âstarter energizedâ lamp. In my case I was lucky, the massive current drain took the radio out before I took off, but I only worked out why when I heard the weird grinding noise of the engine driving the locked up starter when I took my headset off.

That was an O235 engine, similar starter configuration to yours.

Do you have a âstarter energizedâ lamp?

On Dec 24, 2018, at 21:04, Kelly McMullen <kellym(at)aviating.com (kellym(at)aviating.com)> wrote:

--> AeroElectric-List message posted by: Kelly McMullen <kellym(at)aviating.com (kellym(at)aviating.com)>

I don't think you have a problem. I think that if the engine didn't actually start, the starter might not reach enough speed to disengage.

Also, extended cranking at low voltage probably heated the solenoid a lot, causing sticking in it. After the battery is fully recharged, give it another try, without cranking more than 10-15 seconds on any try. It is likely to start, and the starter will disengage normally. You can test the relay on the bench, without a starter connected, just battery cable on input side and switchable 12V on ignition terminal, just activating long enough to see your multi-meter show voltage on the output terminal.

> On 12/24/2018 6:14 PM, Sebastien wrote:

> We had a strange event last week with our O-200 powered CH750. After running the battery down during a fuel gauge calibration that lasted over an hour, one of our pilots tried to start the engine to taxi back but with the already depleted battery and a less than perfect start procedure they gave up after a couple weak start attempts. I walked over to the aircraft to brief them on a prop start and when I asked for the master on the starter ran. Shut the master off, cycled the start button rapidly a dozen times, master on again and the starter ran again. I could hear the starter relay clicking loudly each time power was applied so it does not seem like there was a physical failure of the relay but more some electrical short activating the relay each time power was applied.

> The build team inspected the relay and found a loose connection. Tightening it took the problem from continuous to intermittent; in their words "it's fixed but it did it again once".

> We have removed the relay for replacement, I still think the switch is suspect but they've decided the problem is the relay. Does the aeroelectric list think there would be value in cutting open the relay and examining it? Any suggestions on how best to do so?

> Thank you,

> Sebastien

===========

br> fts!)

r> > e.com" rel="noreferrer noreferrer noreferrer" target="_blank">www.mypilotstore.com

rel="noreferrer noreferrer noreferrer" target="_blank">http://www.matronics.com/contribution

-Matt Dralle, List Admin.

===========

-

Electric-List" rel="noreferrer noreferrer noreferrer" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

===========

FORUMS -

eferrer noreferrer noreferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer noreferrer noreferrer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer noreferrer noreferrer" target="_blank">http://www.matronics.com/contribution

===========

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Kellym

Joined: 10 Jan 2006

Posts: 1705

Location: Sun Lakes AZ

|

Posted: Tue Dec 25, 2018 7:46 am Post subject: Relay sticking Posted: Tue Dec 25, 2018 7:46 am Post subject: Relay sticking |

|

|

Be very careful with your generalizations. A Continental starter is very

different than a Lycoming starter. There are no models I know of shared

between those brands. So it is pretty unlikely that they are "similar

configuration". Lycoming starters are on the front of the engine,

Continentals on the rear of the engine, just for example. Some may have

a relay (solenoid) mounted on the starter, some do not. You may be right

about replacing relay, given the generally low cost.

Yes, having a starter energized lamp is a good suggestion regardless.

On 12/24/2018 9:45 PM, Alec Myers wrote:

| Quote: |

I say change the relay.

That was an O235 engine, similar starter configuration to yours.

Do you have a âstarter energizedâ lamp?

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor # 5286

KCHD |

|

| Back to top |

|

|

alec(at)alecmyers.com

Guest

|

Posted: Tue Dec 25, 2018 9:36 am Post subject: Relay sticking Posted: Tue Dec 25, 2018 9:36 am Post subject: Relay sticking |

|

|

On Dec 25, 2018, at 10:45 AM, Kelly McMullen <kellym(at)aviating.com> wrote:

| Quote: | Be very careful with your generalizations. A Continental starter is very different than a Lycoming starter. There are no models I know of shared between those brands. So it is pretty unlikely that they are "similar configurationâ.

|

For sure. I understood Sebastien had a Lycoming O-200, and the aircraft I was writing about has a lycoming O-235. If he has a Continental O-200 then theyâre not similar.

However the second engine wth which I had a sticky starter solenoid problem was a Continental IO-470, where the starter adapter is damaged within a few seconds of a locked up starter contactor, The starter adapter is impossible to reach without removing the engine from the aircraft. Lycoming - or Continental - I would take absolutely no chances with running either engine with the slightest suspicion of a sticky solenoid.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

alec(at)alecmyers.com

Guest

|

Posted: Tue Dec 25, 2018 9:38 am Post subject: Relay sticking Posted: Tue Dec 25, 2018 9:38 am Post subject: Relay sticking |

|

|

Sorry - I should be less ambiguous. Weâre talking about sticky starter *contactors* - regardless of whether the starter has a solenoid or some other engagement mechanism. A new contactor is about $100 for a PMA one. Princess Auto (I know Sebastien is in Canada) used to do an intermittent duty 12v contactor of identical dimensions for CDN$16.

On Dec 25, 2018, at 11:55 AM, Alec Myers <alec(at)alecmyers.com> wrote:

On Dec 25, 2018, at 10:45 AM, Kelly McMullen <kellym(at)aviating.com> wrote:

| Quote: | Be very careful with your generalizations. A Continental starter is very different than a Lycoming starter. There are no models I know of shared between those brands. So it is pretty unlikely that they are "similar configurationâ.

|

For sure. I understood Sebastien had a Lycoming O-200, and the aircraft I was writing about has a lycoming O-235. If he has a Continental O-200 then theyâre not similar.

However the second engine wth which I had a sticky starter solenoid problem was a Continental IO-470, where the starter adapter is damaged within a few seconds of a locked up starter contactor, The starter adapter is impossible to reach without removing the engine from the aircraft. Lycoming - or Continental - I would take absolutely no chances with running either engine with the slightest suspicion of a sticky solenoid.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

cluros(at)gmail.com

Guest

|

Posted: Tue Dec 25, 2018 9:58 am Post subject: Relay sticking Posted: Tue Dec 25, 2018 9:58 am Post subject: Relay sticking |

|

|

Sorry, I didn't know Lycoming made an O-200, this one is a Continental. In any case we think the problem is in the relay or switch, not the starter itself.

We are planning on replacing the relay with one of these:

https://aircraftspruce.ca/catalog/elpages/starterrelay.php

At $20Â it seems a good idea.

What I'm wondering about is how to best cut open the old one in order to see how the failure may have occurred?

On Tue, Dec 25, 2018, 09:43 Alec Myers <alec(at)alecmyers.com (alec(at)alecmyers.com) wrote:

| Quote: | --> AeroElectric-List message posted by: Alec Myers <alec(at)alecmyers.com (alec(at)alecmyers.com)>

Sorry - I should be less ambiguous. Weâre talking about sticky starter *contactors* - regardless of whether the starter has a solenoid or some other engagement mechanism. A new contactor is about $100 for a PMA one. Princess Auto (I know Sebastien is in Canada) used to do an intermittent duty 12v contactor of identical dimensions for CDN$16.

On Dec 25, 2018, at 11:55 AM, Alec Myers <alec(at)alecmyers.com (alec(at)alecmyers.com)> wrote:

On Dec 25, 2018, at 10:45 AM, Kelly McMullen <kellym(at)aviating.com (kellym(at)aviating.com)> wrote:

--> AeroElectric-List message posted by: Kelly McMullen <kellym(at)aviating.com (kellym(at)aviating.com)>

> Be very careful with your generalizations. A Continental starter is very different than a Lycoming starter. There are no models I know of shared between those brands. So it is pretty unlikely that they are "similar configurationâ.

For sure. I understood Sebastien had a Lycoming O-200, and the aircraft I was writing about has a lycoming O-235. If he has a Continental O-200 then theyâre not similar.

However the second engine wth which I had a sticky starter solenoid problem was a Continental IO-470, where the starter adapter is damaged within a few seconds of a locked up starter contactor, The starter adapter is impossible to reach without removing the engine from the aircraft. Lycoming - or Continental - I would take absolutely no chances with running either engine with the slightest suspicion of a sticky solenoid.

===========

br> fts!)

r> > e.com" rel="noreferrer noreferrer noreferrer" target="_blank">www.mypilotstore.com

rel="noreferrer noreferrer noreferrer" target="_blank">http://www.matronics.com/contribution

-Matt Dralle, List Admin.

===========

-

Electric-List" rel="noreferrer noreferrer noreferrer" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

===========

FORUMS -

eferrer noreferrer noreferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer noreferrer noreferrer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer noreferrer noreferrer" target="_blank">http://www.matronics.com/contribution

===========

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

alec(at)alecmyers.com

Guest

|

Posted: Tue Dec 25, 2018 10:07 am Post subject: Relay sticking Posted: Tue Dec 25, 2018 10:07 am Post subject: Relay sticking |

|

|

| Quote: | Sorry, I didn't know Lycoming made an O-200,

|

After checking, I guess they donât! Sorry for the confusion.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Tue Dec 25, 2018 7:21 pm Post subject: Relay sticking Posted: Tue Dec 25, 2018 7:21 pm Post subject: Relay sticking |

|

|

Sabastien:

There are three test you should do:

1 - Test the Relay

2 - Test the Start Switch

3 - Test the wiring for the Start Switch

Test the Relay - Test 1:

a> Remove the wires connected to the relay.

b> Using an Ohm Meter read across the Contacts

Without power applied to the relay you should read an open. Â

c> Using an Ohm Meter read across the Coil

You should read some value of resistance.

The issue is:Â IS there one contact or two?

If one, then the case is your other contact.

AND one contact COULD BE off the INPUT side which would be your B+

d> Using an Ohm Meter read across ONE Coil to Ground (CASE) and then Â

e> Using an Ohm Meter read across ONE (the other ) Coil to Ground (CASE)

Start Switch Test 2:

a> Remove the wires to the Start Switch.

b> Using an Ohm Meter read across the Contacts

With the switch NOT pressed it should read open

c> Press the Switch.

With the switch pressed it should read closed (zero ohms).

If anything other than above replace the switch.

Test the wiring for the Start Switch Test 3:

a> Since you have the wires already disconnected from the Switch and the Relay you can do two checks

a1> Across the wires that came off the Start Switch.

They should read open.

a2> From ONE end of a wire from the switch to the other end of the wire where it connects to the Start Relay.Â

You should read a close (zero ohms) for each wire.

IF you get anything other than the above - Replace the wires.

OK - Are you ready to POWER TEST the Starter Relay?

IF SO - DISCONNECT IT FROM THE STARTER MOTOR.

Well, it already should have been done if you followed instructions in Test 1.

Using a set of jumper leads.

Run a lead from the Battery + to the INPUT side of the Start Relay.

Run a second lead from the Battery - (Ground) to the Coil terminal of the relay.

It should snap CLOSED.

Well, it may not IF you have a relay that has two (2) Coil Terminals. Some relays use an independent + & - connections.  Â

IF you have a single coil terminal your INPUT Battery B+ will be readable on the OUTPUT relay terminal. Now, here is a TRICK -Â

Step 1: Read the Voltage across the CLOSED relay terminals. It should read ZERO!

If you have a voltage that means there is a RESISTANCE internally in the relay contacts. Â

Throw the relay away!

Step 2: While CLOSED, take a resistance reading Across the Input & Output.

You should read ZERO Ohms. Why do I call this a TRICK? Because you are reading a Resistance while there is a voltage on the same terminals. YEAH! It is possible to read resistance. And, if you do... Throw the relay away. You want ZERO resistance.

Last test: Does the relay have Diode across the Coil? Â

1 - It should be installed with the + side of the Diode on the Negative - side of the Coil.

2 - Check the Diode for Forward to Reverse Bias Resistance. There should be a Minimum of 10:1 Reverse to Forward. Â

OR... Just throw it away and replace it with a New Diode.

OR... Of course you could just replace the relay and diode without testing it. That way you know the circuit has a good relay - But, you have no proof that the old relay is bad. What about the wires and the Start Switch?

Side Note: I always, well, almost always, use the above procedure ONLY because sometimes the R&R of the relay is way more time consuming and/or requires two people. AND, I hate being a Pull & Replace Mechanic. You would never know if it was the relay or just a bad ground.

Barry

On Mon, Dec 24, 2018 at 8:19 PM Sebastien <cluros(at)gmail.com (cluros(at)gmail.com)> wrote:

| Quote: | We had a strange event last week with our O-200 powered CH750. After running the battery down during a fuel gauge calibration that lasted over an hour, one of our pilots tried to start the engine to taxi back but with the already depleted battery and a less than perfect start procedure they gave up after a couple weak start attempts. I walked over to the aircraft to brief them on a prop start and when I asked for the master on the starter ran. Shut the master off, cycled the start button rapidly a dozen times, master on again and the starter ran again. I could hear the starter relay clicking loudly each time power was applied so it does not seem like there was a physical failure of the relay but more some electrical short activating the relay each time power was applied.

The build team inspected the relay and found a loose connection. Tightening it took the problem from continuous to intermittent; in their words "it's fixed but it did it again once".

We have removed the relay for replacement, I still think the switch is suspect but they've decided the problem is the relay. Does the aeroelectric list think there would be value in cutting open the relay and examining it? Any suggestions on how best to do so?

Thank you,

Sebastien

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Dec 27, 2018 9:11 am Post subject: Relay sticking Posted: Thu Dec 27, 2018 9:11 am Post subject: Relay sticking |

|

|

At 07:14 PM 12/24/2018, you wrote:

| Quote: | | We had a strange event last week with our O-200 powered CH750. After running the battery down during a fuel gauge calibration that lasted over an hour, one of our pilots tried to start the engine to taxi back but with the already depleted battery and a less than perfect start procedure they gave up after a couple weak start attempts. I walked over to the aircraft to brief them on a prop start and when I asked for the master on the starter ran. |

The vast majority of starter contactor

sticking events occur during an attempt

to crank the engine with a weak battery.

The fact that you got immediate starter

action on closure of the master switch

says your starter contactor was 'stuck'

shut.

| Quote: | | Shut the master off, cycled the start button rapidly a dozen times, master on again and the starter ran again. I could hear the starter relay clicking loudly each time power was applied so it does not seem like there was a physical failure of the relay but more some electrical short activating the relay each time power was applied. |

Contacts are welded . . .

| Quote: | The build team inspected the relay and found a loose connection. Tightening it took the problem from continuous to intermittent; in their words "it's fixed but it did it again once".

We have removed the relay for replacement, I still think the switch is suspect but they've decided the problem is the relay. Does the aeroelectric list think there would be value in cutting open the relay and examining it? Any suggestions on how best to do so? |

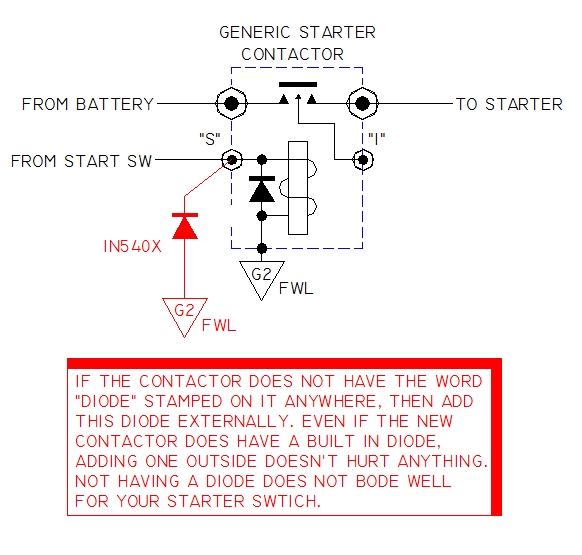

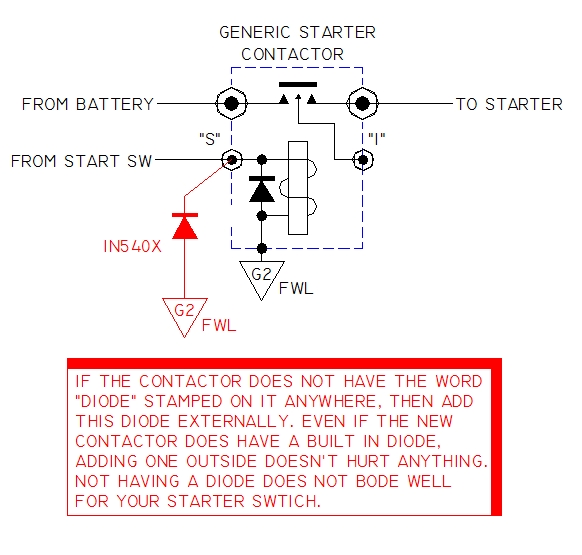

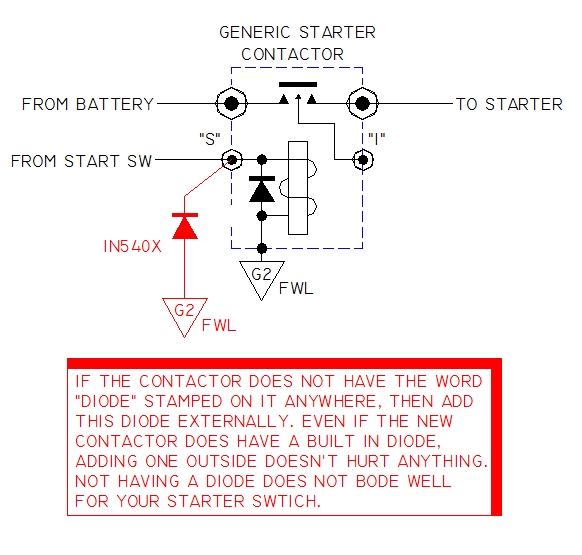

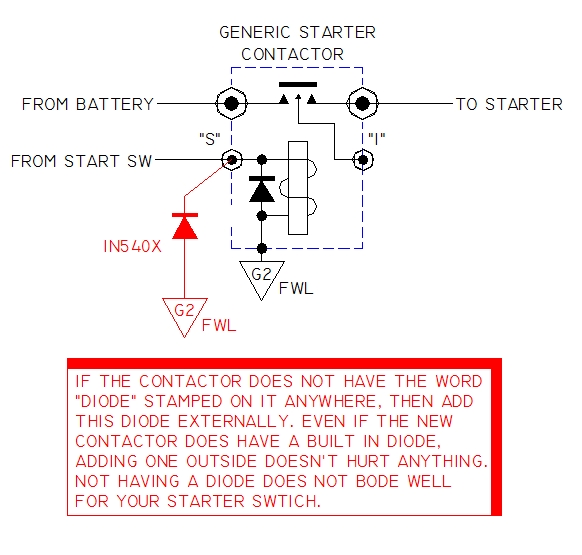

Go to a car parts store and pick

up a starter contactor that looks

like the one in the aircraft spruce

catalog . . . it will work just fine.

See if the contactor is marked "diode

suppressed" or has the word diode on it

anywhere or on the packaging.

[img]cid:.0[/img]

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

156.73 KB |

| Viewed: |

12311 Time(s) |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Dec 27, 2018 9:12 am Post subject: Relay sticking Posted: Thu Dec 27, 2018 9:12 am Post subject: Relay sticking |

|

|

At 11:56 AM 12/25/2018, you wrote:

| Quote: | Sorry, I didn't know Lycoming made an O-200, this one is a Continental. In any case we think the problem is in the relay or switch, not the starter itself.

We are planning on replacing the relay with one of these:

https://aircraftspruce.ca/catalog/elpages/starterrelay.php

At $20Â it seems a good idea. |

Any similar contactor from your local car-parts

emporium will do nicely . . .

| Quote: | | What I'm wondering about is how to best cut open the old one in order to see how the failure may have occurred? |

Send it to me and I'll conduct an

'up town' failure analysis and report

back.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Thu Dec 27, 2018 6:04 pm Post subject: Relay sticking Posted: Thu Dec 27, 2018 6:04 pm Post subject: Relay sticking |

|

|

Bob,

Cutting open of a relay depends on the design of the relay. If you are talking the standard hermetically sealed / rolled over edge type, you do NOT cut it open... You simply grind off the rolled over edge. This can be done very carefully so none of the metal filings enter the relay. If done carefully you may even find water inside the relay. That is what I found in mine! Â

Next trick: Â If you replace the relay with the same kind (hermetically sealed) do the following:

Get a pint of epoxy paint.

Mask the terminals of the relay.

Using a heat gun heat the relay hot enough that you can not touch it.

Then totally submerge the relay in the epoxy paint.

As the relay cools it will suck in the epoxy paint into the rolled edge and seal out any paint.

NOW! You have a hermetically sealed relay.

Not done yet... Next trick:  Make sure you mount the relay so the edge of the rolled edge is facing DOWN. Now water and ice will not collect.

Barry

On Thursday, December 27, 2018, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | At 11:56 AM 12/25/2018, you wrote:

| Quote: | Sorry, I didn't know Lycoming made an O-200, this one is a Continental. In any case we think the problem is in the relay or switch, not the starter itself.

We are planning on replacing the relay with one of these:

https://aircraftspruce.ca/catalog/elpages/starterrelay.php

At $20Ã it seems a good idea. |

Any similar contactor from your local car-parts

emporium will do nicely . . .

| Quote: | | What I'm wondering about is how to best cut open the old one in order to see how the failure may have occurred? |

Send it to me and I'll conduct an

'up town' failure analysis and report

back.

Bob . . .

|

--

Barry

"Chop'd Liver"

If you wash your hands before you go to the bathroom you may have the makings of a Crew Chief.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Dec 27, 2018 7:02 pm Post subject: Relay sticking Posted: Thu Dec 27, 2018 7:02 pm Post subject: Relay sticking |

|

|

At 08:02 PM 12/27/2018, you wrote:

| Quote: | Bob,

Cutting open of a relay depends on the design of the relay. If you are talking the standard hermetically sealed |

hermetically sealed implies

absolute atmospheric isolation

between interior and the

environment. Contactors with

rolled on caps are not 'hermetic',

only very secure.

| Quote: | | / rolled over edge type, you do NOT cut it open... You simply grind off the rolled over edge. This can be done very carefully so none of the metal filings enter the relay. If done carefully you may even find water inside the relay. That is what I found in mine!  |

Yep . . . been there a few dozen times.

https://tinyurl.com/p2x7fbl

https://tinyurl.com/kcc26jt

Cessna attempted some DIY sealing techniques

on the whisky barrel relays . . . right

after the noise reducing, floating cowl

was incorporated onto the SE aircraft.

Virtually no help. You could not guarantee

quality of seal. Liquid water sucked in

during a cooling event had to exit as a vapor

over successive atmospheric 'breathing'

cycles . . . i.e. once inside it stayed

inside.

| Quote: | Not done yet... Next trick:  Make sure you mount the relay so the edge of the rolled edge is facing DOWN. Now water and ice will not collect.

|

or cap facing down with a #40 drain

hole added right in the center. Now

trapped liquid had a place to get

out.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Jan 02, 2019 6:17 am Post subject: Relay sticking Posted: Wed Jan 02, 2019 6:17 am Post subject: Relay sticking |

|

|

| Quote: |

or cap facing down with a #40 drain

hole added right in the center. Now

trapped liquid had a place to get

out.

Barry - You must be associated with the Three Stooges... Remember when they were sitting in a row boat and it sprung

a leak... If you have a hole at one end of the boat leaking water in, all you have to do is drill another hole at

the other end to let the water out! Isn't that correct? That is EXACTLY what you are suggesting. Also, you did

not address the issue of having the rolled edge facing Up where water and ice can accumulate.

Bob, if you continue to attack me with your warped logic I will be forced to sink your rubber ducky. As much of

your logic has already has discrepancy holes. BUT! If I am incorrect on something and after you thoughtfully

review my point AND if you have a true improvement to my suggestion please post it. Other wise you look like

you are criticizing just to attack.

Barry |

Barry, I have not 'attacked' you, nor have I

suggested any short-falls in your intelligence

or integrity laced with derisive or pejorative

prose.

I have attempted to offer explanations

of cause/effect/remedy for a constellation

of failures. Analysis of those failures

was a prime-directive in my 45+ years at

Cessna (3x), Beech (2x), Lear, Boeing

and Electro-Mech (3x) where my work not

only had to produce beneficial outcomes

but was subject to review by my peers.

Recall that this thread began

with discussions about welding

in a starter contactor (high pressure, small

area contacts) due to weak battery

condition . . . but morphed into

some discussion about failures in

battery contactors (low pressure,

large area contacts) with an entirely

different failure mode.

You first stated that the rolled closure

on the metal housing of a contactor

was 'hermetic' then you suggest

there is some value in orienting that

joint to ward off effects of accumlated

of 'water and ice'?

Moisture gets into non-hermetic devices

with a combination water vapor/liquid

at the leak site AND a pressure differential

due to effects atmosphere (weak) or temperature

(strong). Battery contactors heat up

significantly while energized. When

de-energized, a substantial pressure

differential occurs as the device

cools. If there is moisture at

the location of any leak, it is

sucked inside.

Drilling the hole in the low spot on

a contactor cap facing down has two

benefits. It provides a drain for

liquid condensate AND a pressure

relief that stops a cooling contactor

from 'sucking' moisture across the

non-hermetic seal at the housing-to-

cap interface.

I'm sorry if you feel 'attacked'.

That's not my mission here. This is all

about the simple-ideas in physics that

drive the utility of our favorite machines.

Ideas that were a foundation for a

successful career and, I believe, worthy

of sharing in the OBAM aviation community.

If I mis-understand something, I'm intently

interested in knowing it . . . as a teacher

I have a duty to NOT propagate bad data.

So I invite you to help sift the sands of simple-

ideas and forego disparaging remarks.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

trigo(at)mail.telepac.pt

Guest

|

Posted: Wed Jan 02, 2019 9:13 am Post subject: Relay sticking Posted: Wed Jan 02, 2019 9:13 am Post subject: Relay sticking |

|

|

Bob

It is more than obvious that you (and everyone else) should not waste our time with this gentleman (Barry) opinions.

Just delete them.

Nothing personal, just by having read some of them.

Have an excellent 2019!

Carlos

No dia 02/01/2019, Ã s 14:16, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> escreveu:

| Quote: | | Quote: |

or cap facing down with a #40 drain

hole added right in the center. Now

trapped liquid had a place to get

out.

Barry - You must be associated with the Three Stooges... Remember when they were sitting in a row boat and it sprung

a leak... If you have a hole at one end of the boat leaking water in, all you have to do is drill another hole at

the other end to let the water out! Isn't that correct? That is EXACTLY what you are suggesting. Also, you did

not address the issue of having the rolled edge facing Up where water and ice can accumulate.

Bob, if you continue to attack me with your warped logic I will be forced to sink your rubber ducky. As much of

your logic has already has discrepancy holes. BUT! If I am incorrect on something and after you thoughtfully

review my point AND if you have a true improvement to my suggestion please post it. Other wise you look like

you are criticizing just to attack.

Barry |

Barry, I have not 'attacked' you, nor have I

suggested any short-falls in your intelligence

or integrity laced with derisive or pejorative

prose.

I have attempted to offer explanations

of cause/effect/remedy for a constellation

of failures. Analysis of those failures

was a prime-directive in my 45+ years at

Cessna (3x), Beech (2x), Lear, Boeing

and Electro-Mech (3x) where my work not

only had to produce beneficial outcomes

but was subject to review by my peers.

Recall that this thread began

with discussions about welding

in a starter contactor (high pressure, small

area contacts) due to weak battery

condition . . . but morphed into

some discussion about failures in

battery contactors (low pressure,

large area contacts) with an entirely

different failure mode.

You first stated that the rolled closure

on the metal housing of a contactor

was 'hermetic' then you suggest

there is some value in orienting that

joint to ward off effects of accumlated

of 'water and ice'?

Moisture gets into non-hermetic devices

with a combination water vapor/liquid

at the leak site AND a pressure differential

due to effects atmosphere (weak) or temperature

(strong). Battery contactors heat up

significantly while energized. When

de-energized, a substantial pressure

differential occurs as the device

cools. If there is moisture at

the location of any leak, it is

sucked inside.

Drilling the hole in the low spot on

a contactor cap facing down has two

benefits. It provides a drain for

liquid condensate AND a pressure

relief that stops a cooling contactor

from 'sucking' moisture across the

non-hermetic seal at the housing-to-

cap interface.

I'm sorry if you feel 'attacked'.

That's not my mission here. This is all

about the simple-ideas in physics that

drive the utility of our favorite machines.

Ideas that were a foundation for a

successful career and, I believe, worthy

of sharing in the OBAM aviation community.

If I mis-understand something, I'm intently

interested in knowing it . . . as a teacher

I have a duty to NOT propagate bad data.

So I invite you to help sift the sands of simple-

ideas and forego disparaging remarks.

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Jan 02, 2019 10:15 am Post subject: Relay sticking Posted: Wed Jan 02, 2019 10:15 am Post subject: Relay sticking |

|

|

At 11:11 AM 1/2/2019, you wrote:

| Quote: | Bob

It is more than obvious that you (and everyone else) should not waste our time with this gentleman (Barry) opinions.

Just delete them.

Nothing personal, just by having read some of them.

Have an excellent 2019!

Carlos

|

At last count, there were about 1200 subscribers

to the list . . . obviously, ACTIVE participants

number much less but I think it's important to make

sure that poor or unclear data does not go

unchallenged. Of course, any who wish

to bypass the thread are encouraged to do so.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1929

Location: Riley TWP Michigan

|

Posted: Wed Jan 02, 2019 11:06 am Post subject: Re: Relay sticking Posted: Wed Jan 02, 2019 11:06 am Post subject: Re: Relay sticking |

|

|

Quote from Official AeroElectric-List Usage Guidelines

"Feel free to disagree with other viewpoints, BUT keep your tone

polite and respectful. Don't make snide comments, personally attack

other listers,"

If someone posts something that you disagree with, it is best not to quote

them or mention their name. Just state the facts about the electrical subject.

Follow Bob's example. He has contradicted my postings in the past without

offending me. (Although I do not like to admit being wrong. LOL)

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Wed Jan 02, 2019 11:35 am Post subject: Relay sticking Posted: Wed Jan 02, 2019 11:35 am Post subject: Relay sticking |

|

|

Exactly Joe!

Check your emails, I did not post my response to the gaggle. It was sent directly to Bob. After his snide comments.

So, who is attacking whom?

Barry

On Wednesday, January 2, 2019, user9253 <fransew(at)gmail.com (fransew(at)gmail.com)> wrote:

| Quote: | --> AeroElectric-List message posted by: "user9253" <fransew(at)gmail.com (fransew(at)gmail.com)>

Quote from Official AeroElectric-List Usage Guidelines

"Feel free to disagree with other viewpoints, BUT keep your tone

polite and respectful. Don't make snide comments, personally attack

other listers,"

If someone posts something that you disagree with, it is best not to quote

them or mention their name. Just state the facts about the electrical subject.

Follow Bob's example. He has contradicted my postings in the past without

offending me. (Although I do not like to admit being wrong. LOL)

--------

Joe Gores

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=486660#486660

====================================

br> fts!)

r> > e.com" target="_blank">www.mypilotstore.com

target="_blank">http://www.matronics.com/contribution

-Matt Dralle, List Admin.

====================================

-

Electric-List" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

====================================

FORUMS -

_blank">http://forums.matronics.com

====================================

WIKI -

lank">http://wiki.matronics.com

====================================

b Site -

-Matt Dralle, List Admin.

target="_blank">http://www.matronics.com/contribution

====================================

|

--

Barry

"Chop'd Liver"

If you wash your hands before you go to the bathroom you may have the makings of a Crew Chief.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

cluros(at)gmail.com

Guest

|

Posted: Fri Jan 04, 2019 2:44 pm Post subject: Relay sticking Posted: Fri Jan 04, 2019 2:44 pm Post subject: Relay sticking |

|

|

Upon examination of the removed starter relay I see that it is a continuous duty relay. It has now been replaced with an intermittent duty relay of appropriate capacity. Thank you for the help everyone but looks like this one was obvious.

On Thu, Dec 27, 2018 at 9:18 AM Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | At 07:14 PM 12/24/2018, you wrote:

| Quote: | | We had a strange event last week with our O-200 powered CH750. After running the battery down during a fuel gauge calibration that lasted over an hour, one of our pilots tried to start the engine to taxi back but with the already depleted battery and a less than perfect start procedure they gave up after a couple weak start attempts. I walked over to the aircraft to brief them on a prop start and when I asked for the master on the starter ran. |

The vast majority of starter contactor

sticking events occur during an attempt

to crank the engine with a weak battery.

The fact that you got immediate starter

action on closure of the master switch

says your starter contactor was 'stuck'

shut.

| Quote: | | Â Shut the master off, cycled the start button rapidly a dozen times, master on again and the starter ran again. I could hear the starter relay clicking loudly each time power was applied so it does not seem like there was a physical failure of the relay but more some electrical short activating the relay each time power was applied. |

Contacts are welded . . .

| Quote: | The build team inspected the relay and found a loose connection. Tightening it took the problem from continuous to intermittent; in their words "it's fixed but it did it again once".

We have removed the relay for replacement, I still think the switch is suspect but they've decided the problem is the relay. Does the aeroelectric list think there would be value in cutting open the relay and examining it? Any suggestions on how best to do so? |

Go to a car parts store and pick

up a starter contactor that looks

like the one in the aircraft spruce

catalog . . . it will work just fine.

See if the contactor is marked "diode

suppressed" or has the word diode on it

anywhere or on the packaging.

[img]cid:1681b04e58bd7b6b1d31[/img]

Â

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

156.73 KB |

| Viewed: |

12241 Time(s) |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|