|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

blues750

Joined: 06 Jun 2015

Posts: 56

|

Posted: Tue Jan 01, 2019 9:49 am Post subject: When / where to use dielectric grease? Posted: Tue Jan 01, 2019 9:49 am Post subject: When / where to use dielectric grease? |

|

|

Recently, while inspecting the engine compartment after some routine maintenance, I noted a section of "browned and crispy" wire insulation. This particular wire was one of the 3 phase wires which come from the 30A PMA associated with the engine. The brown and crispy portion was at the back of a plastic 6 blade connector half where crimped 1/4 female spade connectors are inserted to mate with the Regulator/Rectifier. The crimps are good, all spades firmly seated into the shell, though the spade (associated with the browned wire) location on the shell also show sign of getting too hot. But only at the one spade connection. Overheating due to high resistance is the only thing that comes to mind. I did apply dielectric grease to these particular spades to help them fully mate and as a corrosion/moisture preventative. I do this routinely on older cars up here in the Northeast with no issues. Could this be a problem? I typically draw 18-22 amps load while flying but when topping off the batteries will draw closer to 30 amps for 10-15 minutes of flying if the batteries have been drawn down for extended times during non flight activity. Note that the output from the R/R looked fine but they are a larger gauge wire. (12ga versus 14ga of the 3 phase wires into the R/R) Rather lengthy problem description for what appear to be an overheated wire, open for all thoughts or ideas. The only one I can come up with is poor connection / high resistance, though not sure of the mechanism. Thanks, Happy New Year to all!!

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

gilles.thesee(at)free.fr

Guest

|

Posted: Tue Jan 01, 2019 10:34 am Post subject: When / where to use dielectric grease? Posted: Tue Jan 01, 2019 10:34 am Post subject: When / where to use dielectric grease? |

|

|

Le 01/01/2019 à 18:49, blues750 a écrit :

| Quote: | I did apply dielectric grease to these particular spades to help them fully mate and as a corrosion/moisture preventative. I do this routinely on older cars up here in the Northeast with no issues. Could this be a problem? I routinely draw 18-22 amps while flying but when topp!

|

Hello,

Just to mention that "dielectric" means "insulating".

Don't know if this is a problem, but gas tight metal to metal is key.

| Quote: | Rather lengthy problem description for what appear to be an overheated wire, open for all thoughts or ideas. The only one I can come up with is poor connection, though not sure of the mechanism.

|

We have had the same issue with some wires off the voltage regulator

connector. We replaced the wires and spade terminal, paying attention to

the quality of the crimp.

Happy New Year !

--

Best regards,

Gilles

http://contrails.free.fr

http://lapierre.skunkworks.free.fr

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

blues750

Joined: 06 Jun 2015

Posts: 56

|

Posted: Tue Jan 01, 2019 12:54 pm Post subject: Re: When / where to use dielectric grease? Posted: Tue Jan 01, 2019 12:54 pm Post subject: Re: When / where to use dielectric grease? |

|

|

Gilles, I think you may be on to something! I likely "gobbed" on too much dielectric grease and prevented a good electrical connection as the grease heated up and spread over the metal to metal connections. My plan is to clean up and replace the connections, reassemble with no dielectric grease! Thanks for the reply. Cheers! Dave

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1927

Location: Riley TWP Michigan

|

Posted: Tue Jan 01, 2019 5:45 pm Post subject: Re: When / where to use dielectric grease? Posted: Tue Jan 01, 2019 5:45 pm Post subject: Re: When / where to use dielectric grease? |

|

|

Most common grease is dielectric. Its use should not cause a problem. A properly crimped joint forces all grease out from between the metals. I have coated automotive battery terminals with grease and the vehicle still starts fine. The problem is due to a bad crimp.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Tue Jan 01, 2019 6:42 pm Post subject: When / where to use dielectric grease? Posted: Tue Jan 01, 2019 6:42 pm Post subject: When / where to use dielectric grease? |

|

|

Joe & Gaggle:

Dielectric Grease is Silicon based all 100% synthetic. Automotive greases, and oils for that matter which are NOT 100% synthetic, and there should not be any 100% synthetics. [Yes, I know they advertise 100% synthetic but unless something has changed no, engine oil is 100% synthetic.] Petroleum Oils & Greases will trap moisture! Just like the water that is found in your engine oil. The axle grease on the battery terminals will work for a long, long time. It is just not the best way to attack the issue. Do you really need to go the route of the Ultimate Silicon Dielectric Grease path? Well, not for a automotive battery terminal. BUT! For the whole $1.00 for a Permatex packet - YES - That is the way to go. And when using the dielectric grease on terminals of different metals:- copper, silver, gold, tin, solder and mixtures of them, why take a chance of corrosion. After all, we know automotive oils do become acidic!

The posted question on WHY use dielectric grease especially since the term dielectric means Non-Conductive. GREAT QUESTION!

Slop on the dielectric grease to the point of just becoming sloppy.

THEN complete the connection... Fast-On connectors just slide them together. As they push together the CONTACT POINTS will make both a mechanical and an electrical contact pushing the dielectric grease out of the way. YET! The grease will be in enough places to create a oxygen and moisture barrier. DON'T think you solved the problem for ALL time. The dielectric grease will migrate and become washed off, by YOU - When you wash the plane or use engine de-greasers or fly through rain. Use it... Then re-use it when you cannot see the nice coating you original put on. Â

Joe - You said it! BAD CRIMP! Yup, I agree 1,000 %. Wrong size terminal. Wrong size wire for the terminal. Wrong type wire used. Wrong TOOL used for the crimp. Â

Little Trick: One job that I worked on where the terminals were in a particularly difficult location to get at for inspection or repair AND the piece of equipment was was on the deck of an Aircraft Carrier for extended periods of time. The requirement was to:

1 - Put Dielectric Grease - IN - the terminal BEFORE CRIMPING.

2 - Dip the wire into Dielectric Grease.

3 - Assemble and then CRIMP.

There were no issues of a resistive connection.

Yes, I do believe in dielectric grease.

And, it's great for keeping your hair in place on dry staticky days.

Barry

On Tue, Jan 1, 2019 at 8:50 PM user9253 <fransew(at)gmail.com (fransew(at)gmail.com)> wrote:

| Quote: | --> AeroElectric-List message posted by: "user9253" <fransew(at)gmail.com (fransew(at)gmail.com)>

Most common grease is dielectric. Its use should not cause a problem. A properly crimped joint forces all grease out from between the metals. I have coated automotive battery terminals with grease and the vehicle still starts fine. The problem is due to a bad crimp.

--------

Joe Gores

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=486643#486643

===========

br> fts!)

r> > e.com" rel="noreferrer" target="_blank">www.mypilotstore.com

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

-Matt Dralle, List Admin.

===========

-

Electric-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

===========

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

blues750

Joined: 06 Jun 2015

Posts: 56

|

Posted: Wed Jan 02, 2019 4:38 am Post subject: Re: When / where to use dielectric grease? Posted: Wed Jan 02, 2019 4:38 am Post subject: Re: When / where to use dielectric grease? |

|

|

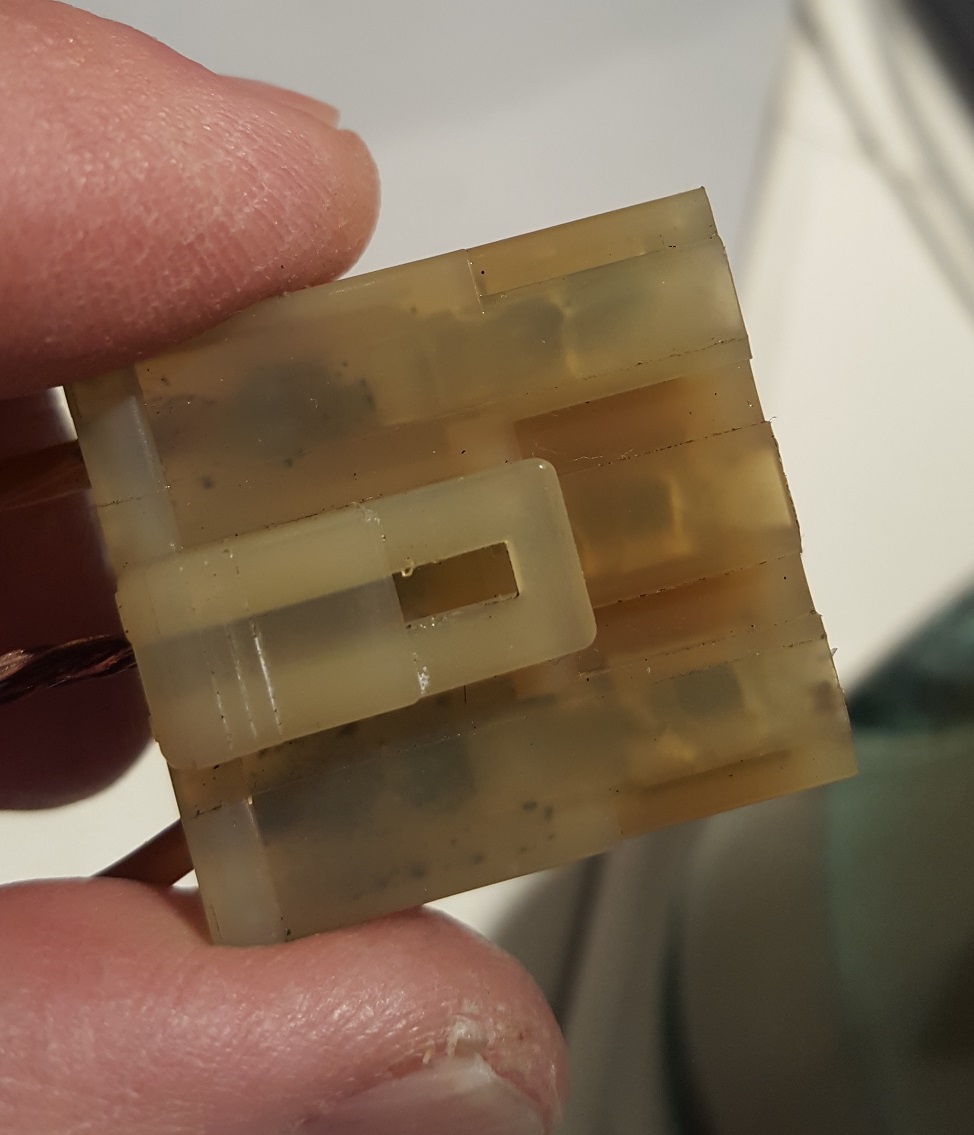

Here are a few pics of the connector in case anything can be determined by the pic. Will post pics of crimps when I remove wires and assess. Thanks for the input all. Dave

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

201.84 KB |

| Viewed: |

10035 Time(s) |

|

|

|

| Back to top |

|

|

blues750

Joined: 06 Jun 2015

Posts: 56

|

Posted: Wed Jan 02, 2019 4:36 pm Post subject: Re: When / where to use dielectric grease? Posted: Wed Jan 02, 2019 4:36 pm Post subject: Re: When / where to use dielectric grease? |

|

|

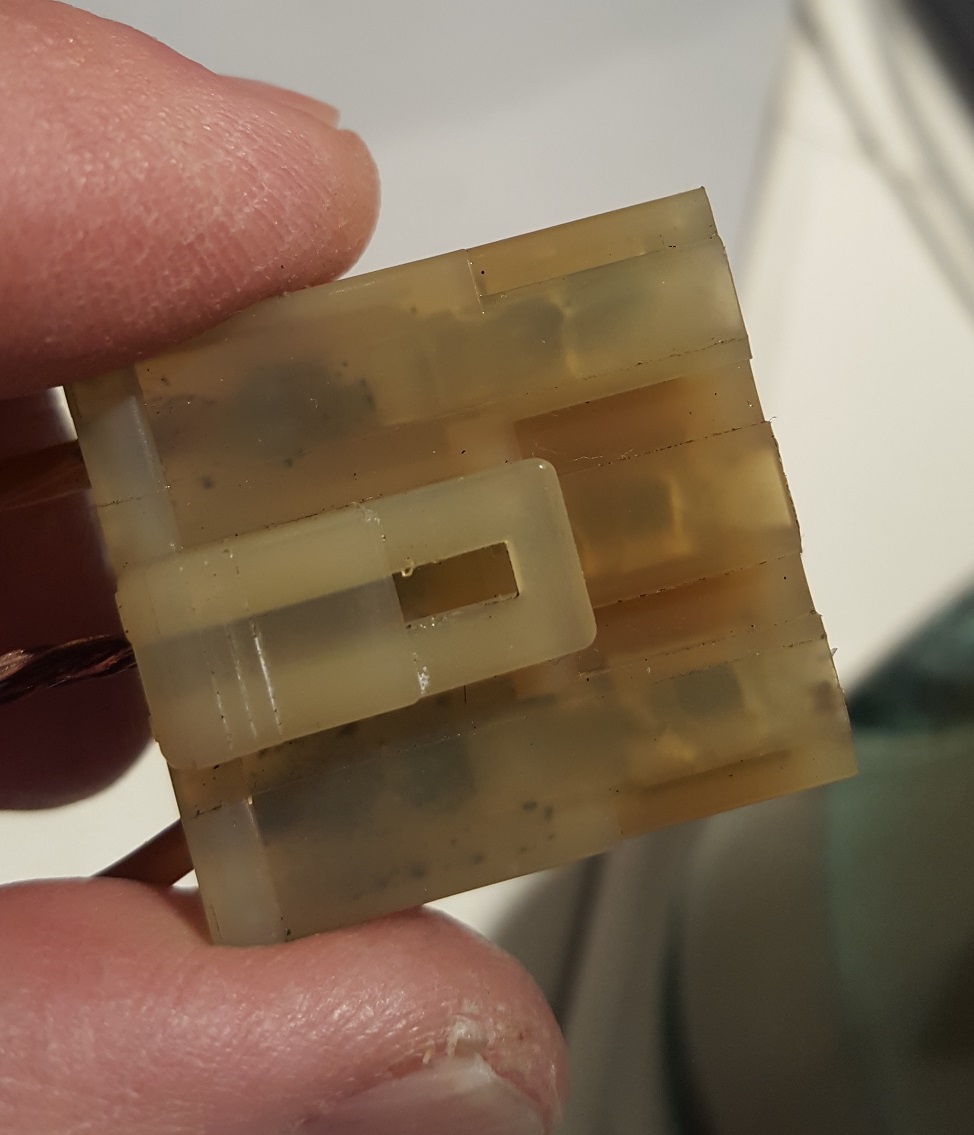

OK, had a chance to remove the wires from the connector shell. I would like to think all my crimps looked like the "good looking crimp and wire" I cannot imagine I would have proceeded without having them otherwise. But... the other wires look pretty p*ss poor! The bare wire had hardened insulation which I peeled off to inspect wire condition. Seems like a lot of corrosion for such a "young" connection! In reading Bob's related reply, I can easily be lead to believe that those (my) crimps are in the "neophyte" category for these particular terminals. I cannot recall the crimp tool name I used, but it is oe I purchased from SteinAir expressedly for doing open barrel crimps. Thoughts, insights, and opinions??

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

743.61 KB |

| Viewed: |

10008 Time(s) |

|

|

|

| Back to top |

|

|

sha664817

Joined: 23 Jan 2019

Posts: 2

Location: India

|

Posted: Thu Jan 24, 2019 3:25 am Post subject: Re: When / where to use dielectric grease? Posted: Thu Jan 24, 2019 3:25 am Post subject: Re: When / where to use dielectric grease? |

|

|

There's a lot of chatter about the use of dielectric grease. Permeate suggests that Dielectric Tune-Up Grease is a good barrier to oxidation at plugs, connectors and terminals. There are some online comments at forums that say not to place dielectric grease on connector pins.

I've gone to the Permeate site, and the information is vague:

"Protects electrical connections and wiring from salt, dirt and corrosion. Extends the life of bulb sockets. Prevents voltage leakage around any electrical connection. Also prevents spark plugs from fusing to boots. Required for modern high energy ignition systems."

Directions for Connectors: 1. Make sure ignition system is off. 2. Clean surface with Permeate Contact Cleaner. 3. Coat both parts of terminal contact with Dielectric Grease. 4. Reassemble, maintaining metal-to-metal contact.

In the PDF, Permatex cites uses for the Permatex Dielectric Tune-Up Grease:

TYPICAL APPLICATIONS

⢠Spark plug boots

⢠Distributor cap nipples

⢠Battery terminals

⢠Ignition coil connectors

⢠Headlamp connectors

⢠Trailer electrical connectors

The "metal-to-metal contact" reference may create suspicion for some about "Dielectric Tune-Up Grease". I've used this product for years around tune-up work without reservation. I searched around and found an engineer's assessment of dielectric grease that suggests Permatex Dielectric Tune-Up Grease should work well on a variety of pin connector materials without creating any kind of resistance or barrier to current flow. This commentary is worth reading: http://www.w8ji.com/...tive_grease.htm, the author seems well informed, experienced, and he uses a scientific approach. According to the engineer, metal-to-metal pin contact should result if pins are clean and not tarnished, with or without dielectric grease on the pins.

It's realistic to presume that the degree of conductivity is governed by the tension of the pin and socket fit, not whether we use dielectric grease. Whether or not you use the dielectric grease, I would use a quality electrical contact cleaner to get rid of the oozing material at your PCM plug and terminals. Make sure you flush out all residue and allow complete evaporation to prevent dilution of remaining grease or any issues with spark arc hazards. I would at least place dielectric grease on connector lips to act as an effective moisture and oxidation barrier.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Electrical engineering is a professional engineering deals with the study and application of electricity, electronics, and electromagnetism. |

|

| Back to top |

|

|

raymondj(at)frontiernet.n

Guest

|

Posted: Fri Jan 25, 2019 10:46 pm Post subject: When / where to use dielectric grease? Posted: Fri Jan 25, 2019 10:46 pm Post subject: When / where to use dielectric grease? |

|

|

I can only comment from my experience on boats and docks. I have seen

less corrosion problems on connections treated with dielectric grease.

The difference can be seen in a matter of a couple of seasons,

especially on ones that are removed and replaced frequently, such as

removable anchor lights and cigar lighter type connectors. Admitted

these are not high buck sealed connections designed for the harsh

maritime environment, but using grease changes them from problematic

designs to being reliable connectors.

Raymond Julian

Kettle River, MN

The things we admire in men, kindness and generosity, openness, honesty,

understanding and feeling are the concomitants of failure in our system.

And those traits we detest, sharpness, greed, acquisitiveness, meanness,

egotism and self-interest are the traits of success. And while men

admire the quality of the first they love the produce of the second.

-John Steinbeck, novelist, Nobel laureate (1902-1968)

On 1/25/19 12:03 PM, Robert L. Nuckolls, III wrote:

| Quote: | At 05:26 AM 1/24/2019, you wrote:

>

>

> There's a lot of chatter about the use of dielectric grease. Permeate

> suggests that Dielectric Tune-Up Grease is a good barrier to oxidation

> at plugs, connectors and terminals. There are some online comments at

> forums that say not to place dielectric grease on connector pins.

>

> I've gone to the Permeate site, and the information is vague:

>

> "Protects electrical connections and wiring from salt, dirt and

> corrosion. Extends the life of bulb sockets. Prevents voltage leakage

> around any electrical connection. Also prevents spark plugs from

> fusing to boots. Required for modern high energy ignition systems."

>

> Directions for Connectors: 1. Make sure ignition system is off. 2.

> Clean surface with Permeate Contact Cleaner. 3. Coat both parts of

> terminal contact with Dielectric Grease. 4. Reassemble, maintaining

> metal-to-metal contact.

>

> In the PDF, Permatex cites uses for the Permatex Dielectric Tune-Up

> Grease:

>

> TYPICAL APPLICATIONS

>

> ⢠Spark plug boots

>

> ⢠Distributor cap nipples

>

> ⢠Battery terminals

>

> ⢠Ignition coil connectors

>

> ⢠Headlamp connectors

>

> ⢠Trailer electrical connectors

Dielectric greases and coatings are proven prophylactics

that ward off the effects of adverse environments for

which the potential 'victim' is ill-equipped to

manage on its own.

Borrowing from the assertions of another competent

observer of really big numbers, let us consider what

must be 'billions and billions' of mated conductors

in connectors that have performed over the LIFETIMES

of the target technology with no 'extra' protection

squeezed out of a tube or brushed on from a bottle.

Does this mean that such products have no useful

place? Not at all. My FIRST experience with dielectric

grease moisture protection was 175' up on

a tower where the boss told me that filling the

mated coax connectors with DC4 before assembly

had a demonstrated value for shielding connectors

exposed to Kansas climate way up in the air.

Over the years, I have had occasion to open factory

assembled connectors that were obviously offered

the benefits of protection above and beyond those

offered by the enclosure. This includes lamp sockets

on tail and back-up lights, marker lights and

yes, trailer connectors.

These instances were most common on fixtures

especially exposed to splash or run-down. When

refurbishing equipment that succumbed to

contamination induced corrosion, the

'rule of thumb' called for protecting

the replacement hardware with a good

dielectric grease. But it was also a good

idea to see if some gasket had failed

allowing ingress of moisture.

Emacs!

In years since, designers for electrical

connectors improved designs to improve

performance in harsh environments.

The moisture seal bellows on this

connector is one example.

Emacs!

It's been a long time since I've opened

a connector that contained any previously

applied protection against moisture.

It stands to reason that suppliers of

such products want to sell as much as

the market will purchase. The marketing

problem is that it's seldom necessary/beneficial.

The only time I've used the stuff is

to provide an extra layer of protection

for components that replaced victims

of moisture damage . . . or selected

instances of extra-ordinary risk . . .

like difficult-to-access 175' up on a tower.

The short story is that these products

are best applied during replacement

of parts that have succumbed to moisture

effects. But when such damage is

discovered, be sure to evaluate

the circumstances of the failure.

Was the connector a poor choice to

begin with? Was it subjected to

environmental stresses outside original

design goals? Does a sealing feature of

the enclosure need refurbishment?

I have a 4oz tube of DC4 that is probably

40 years old and barely shows signs of having

been squeezed. Dielectric grease is

a band-aid on a marginal design.

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Kellym

Joined: 10 Jan 2006

Posts: 1705

Location: Sun Lakes AZ

|

Posted: Sat Jan 26, 2019 3:48 pm Post subject: When / where to use dielectric grease? Posted: Sat Jan 26, 2019 3:48 pm Post subject: When / where to use dielectric grease? |

|

|

That must be an old picture of DM AFB. I believe one of the arms

treaties required the tails chopped off.

On 1/26/2019 10:34 AM, Robert L. Nuckolls, III wrote:

| Quote: | At 12:45 AM 1/26/2019, you wrote:

>

There is a tank on the beach of

Culebra Island, PR that has been sitting

there since WWII. Dug around through

the interior a few years back.

Emacs!

The salt water has literally dissolved

major cross sections of steel. On the

other hand, one could have stored this

machine next to a tenant of the Davis

Monthan 'bone yard' . .

Emacs!

. . . and the machine might well be

operational with nothing more than some

fuel and a grease job.

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor # 5286

KCHD |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|