|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

jonboede(at)hotmail.com

Guest

|

Posted: Wed Oct 16, 2019 1:21 pm Post subject: any reason NOT to go Swagelok check valves? Posted: Wed Oct 16, 2019 1:21 pm Post subject: any reason NOT to go Swagelok check valves? |

|

|

I'm a "stock" guy. I like to keep things the way the design bureau designed them.

That having been said, over the years I've replaced or overhauled enough Chinese check valves to fill a trick-or-treater's plastic pumpkin. It's getting old.

The Swagelok replacement check valves seem like a good idea, but I'm cautious, so:

Does anybody have a single experience, observation, or reason NOT to go with the Swagelok replacement one-way check valves?

The only thing I can think of is, "We don't have enough total hours as a community to know what the down-side of the Swagelok valves is going to be" -- but that argument is fading.

Jon

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

hill(at)doctor-hill.com

Guest

|

Posted: Wed Oct 16, 2019 3:01 pm Post subject: any reason NOT to go Swagelok check valves? Posted: Wed Oct 16, 2019 3:01 pm Post subject: any reason NOT to go Swagelok check valves? |

|

|

Hello Jon,

Itâs a simple thing to rebuild them. Doug Sapp provides the parts and all thatâs needed are two 17 mm wrenches. For those check valves that are too far gone from internal corrosion, the replacements that Doug builds are excellent. Regardless, whether you rebuild or replace, they still need to be swapped out every few years. No way around that no matter who makes them.

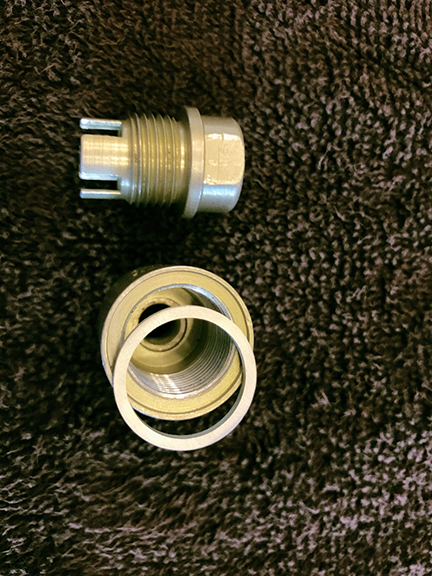

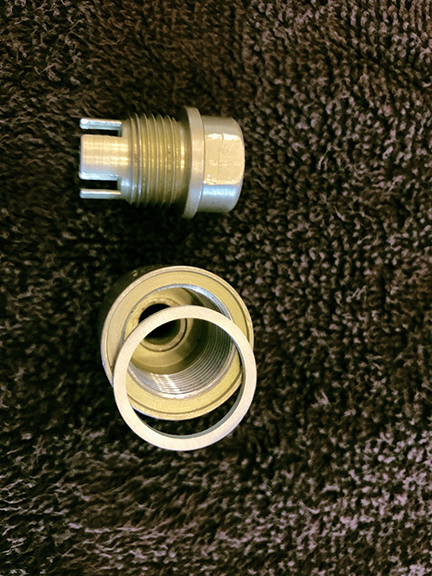

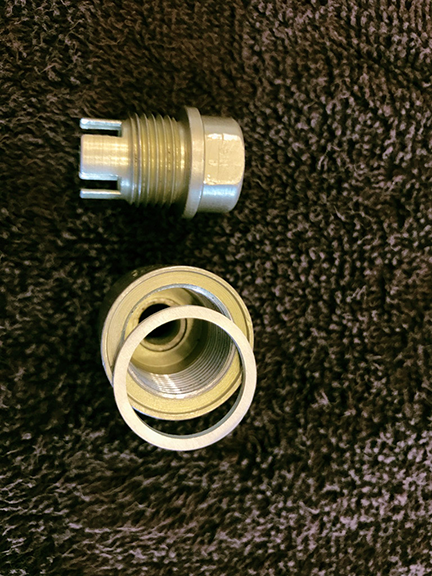

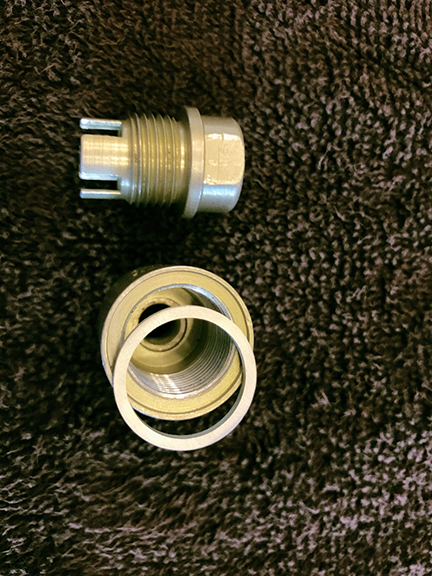

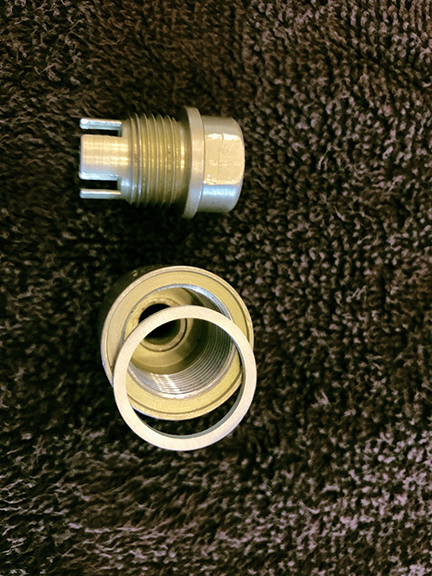

Just me, but I like to replace the soft lead washer with a soft aluminum crush washer thatâs been coated in WD40 to reduce deforming during tightening. Very solid seal. Attached is an image.

Personally, Iâm not a big fan of the Swagelok check valves. They are not very robust. Have seen too many fail. On a flight to Oshkosh a few years ago one of the members of our group had several fail by the time we got to Nebraska from Arizona. Spent a long time on the tarmac at the Lincoln airport replacing them with Chinese ones, which kept working for the next three years.

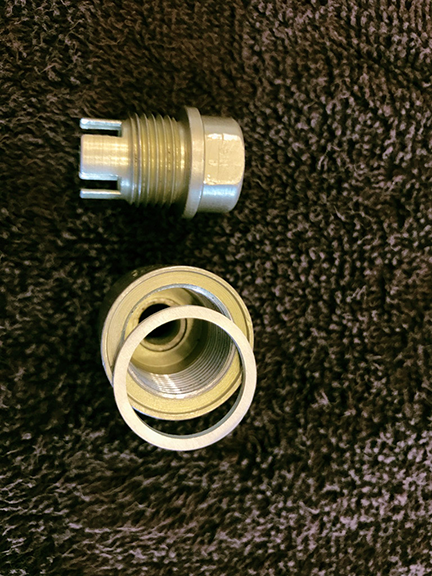

Exceptions are the Swagelok main and emergency on-off valves. They are fantastic and seem to last forever. The 90 degree, 2-port one is SS-42GF2-A-WN2 with the black handle. Attached is an image of one configured for the main air.

Warren Hill

N464TW

Mesa, AZ

[img]cid:8A6EDB2E-8C4B-47DF-B406-C7DE81B0C538[/img]

[img]cid:F9CAE3B5-AB36-4D90-9BD2-A205EC5EA78A[/img]

| Quote: | On Oct 16, 2019, at 2:21 PM, Jon Boede <jonboede(at)hotmail.com (jonboede(at)hotmail.com)> wrote:

I'm a "stock" guy. I like to keep things the way the design bureau designed them.

That having been said, over the years I've replaced or overhauled enough Chinese check valves to fill a trick-or-treater's plastic pumpkin. It's getting old.

The Swagelok replacement check valves seem like a good idea, but I'm cautious, so:

Does anybody have a single experience, observation, or reason NOT to go with the Swagelok replacement one-way check valves?

The only thing I can think of is, "We don't have enough total hours as a community to know what the down-side of the Swagelok valves is going to be" -- but that argument is fading.

Jon

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

| Description: |

|

| Filesize: |

501.81 KB |

| Viewed: |

4255 Time(s) |

|

| Description: |

|

| Filesize: |

473.27 KB |

| Viewed: |

4255 Time(s) |

|

|

|

| Back to top |

|

|

pennington.construction.i

Guest

|

Posted: Wed Oct 16, 2019 3:53 pm Post subject: any reason NOT to go Swagelok check valves? Posted: Wed Oct 16, 2019 3:53 pm Post subject: any reason NOT to go Swagelok check valves? |

|

|

Warren

I agree the Chinese check valves. Â

I use the lead seals and I also use WD40 while tightening. Â

Do you have a part number for the aluminum seals. ?

Thanks

Mark

N621CJ

Richmond VA

On Wed, Oct 16, 2019 at 7:08 PM Warren Hill <hill(at)doctor-hill.com (hill(at)doctor-hill.com)> wrote:

| Quote: | Hello Jon,

Itâs a simple thing to rebuild them. Doug Sapp provides the parts and all thatâs needed are two 17 mm wrenches. For those check valves that are too far gone from internal corrosion, the replacements that Doug builds are excellent. Regardless, whether you rebuild or replace, they still need to be swapped out every few years. No way around that no matter who makes them.Â

Just me, but I like to replace the soft lead washer with a soft aluminum crush washer thatâs been coated in WD40 to reduce deforming during tightening. Very solid seal. Attached is an image.Â

Personally, Iâm not a big fan of the Swagelok check valves. They are not very robust. Have seen too many fail. On a flight to Oshkosh a few years ago one of the members of our group had several fail by the time we got to Nebraska from Arizona. Spent a long time on the tarmac at the Lincoln airport replacing them with Chinese ones, which kept working for the next three years.

Exceptions are the Swagelok main and emergency on-off valves. They are fantastic and seem to last forever. The 90 degree, 2-port one is SS-42GF2-A-WN2 with the black handle. Attached is an image of one configured for the main air.Â

Warren Hill

N464TW

Mesa, AZ

[img]cid:16dd6faf95b49f117711[/img]

[img]cid:16dd6faf95bdeaecbf52[/img]

| Quote: | On Oct 16, 2019, at 2:21 PM, Jon Boede <jonboede(at)hotmail.com (jonboede(at)hotmail.com)> wrote:

I'm a "stock" guy. I like to keep things the way the design bureau designed them.

That having been said, over the years I've replaced or overhauled enough Chinese check valves to fill a trick-or-treater's plastic pumpkin. It's getting old.

The Swagelok replacement check valves seem like a good idea, but I'm cautious, so:

Does anybody have a single experience, observation, or reason NOT to go with the Swagelok replacement one-way check valves?

The only thing I can think of is, "We don't have enough total hours as a community to know what the down-side of the Swagelok valves is going to be" -- but that argument is fading.

Jon

|

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

| Description: |

|

| Filesize: |

473.27 KB |

| Viewed: |

4254 Time(s) |

|

| Description: |

|

| Filesize: |

501.81 KB |

| Viewed: |

4254 Time(s) |

|

|

|

| Back to top |

|

|

hill(at)doctor-hill.com

Guest

|

Posted: Wed Oct 16, 2019 6:39 pm Post subject: any reason NOT to go Swagelok check valves? Posted: Wed Oct 16, 2019 6:39 pm Post subject: any reason NOT to go Swagelok check valves? |

|

|

Hello Mark,

The aluminum crush washers are generally available on Amazon, searching first by outer diameter in mm.

Warren

| Quote: | On Oct 16, 2019, at 4:52 PM, Mark Pennington <pennington.construction.inc.1(at)gmail.com (pennington.construction.inc.1(at)gmail.com)> wrote:

Warren

I agree the Chinese check valves.

I use the lead seals and I also use WD40 while tightening.

Do you have a part number for the aluminum seals. ?

Thanks

Mark

N621CJ

Richmond VA

On Wed, Oct 16, 2019 at 7:08 PM Warren Hill <hill(at)doctor-hill.com (hill(at)doctor-hill.com)> wrote:

| Quote: | Hello Jon,

Itâs a simple thing to rebuild them. Doug Sapp provides the parts and all thatâs needed are two 17 mm wrenches. For those check valves that are too far gone from internal corrosion, the replacements that Doug builds are excellent. Regardless, whether you rebuild or replace, they still need to be swapped out every few years. No way around that no matter who makes them.

Just me, but I like to replace the soft lead washer with a soft aluminum crush washer thatâs been coated in WD40 to reduce deforming during tightening. Very solid seal. Attached is an image.

Personally, Iâm not a big fan of the Swagelok check valves. They are not very robust. Have seen too many fail. On a flight to Oshkosh a few years ago one of the members of our group had several fail by the time we got to Nebraska from Arizona. Spent a long time on the tarmac at the Lincoln airport replacing them with Chinese ones, which kept working for the next three years.

Exceptions are the Swagelok main and emergency on-off valves. They are fantastic and seem to last forever. The 90 degree, 2-port one is SS-42GF2-A-WN2 with the black handle. Attached is an image of one configured for the main air.

Warren Hill

N464TW

Mesa, AZ

<Crush_washer.png>

<on-off2.png>

| Quote: | On Oct 16, 2019, at 2:21 PM, Jon Boede <jonboede(at)hotmail.com (jonboede(at)hotmail.com)> wrote:

I'm a "stock" guy. I like to keep things the way the design bureau designed them.

That having been said, over the years I've replaced or overhauled enough Chinese check valves to fill a trick-or-treater's plastic pumpkin. It's getting old.

The Swagelok replacement check valves seem like a good idea, but I'm cautious, so:

Does anybody have a single experience, observation, or reason NOT to go with the Swagelok replacement one-way check valves?

The only thing I can think of is, "We don't have enough total hours as a community to know what the down-side of the Swagelok valves is going to be" -- but that argument is fading.

Jon

|

|

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

wlannon(at)shaw.ca

Guest

|

Posted: Wed Oct 16, 2019 7:01 pm Post subject: any reason NOT to go Swagelok check valves? Posted: Wed Oct 16, 2019 7:01 pm Post subject: any reason NOT to go Swagelok check valves? |

|

|

Hi Mark;

You will find a large selection of both copper and alum. Metric crush washers at McMaster Carr. They are listed by ID, OD and thickness. I could give you a part number now but not in the hangar so may guess wrong.

I have been using the alum. ones for years for all the check valves and numerous other locations like rocker shafts and various plumbing fittings, etc.

Cheers;

Walt

From: Mark Pennington (pennington.construction.inc.1(at)gmail.com)

Sent: Wednesday, October 16, 2019 4:52 PM

To: yak-list(at)matronics.com (yak-list(at)matronics.com)

Subject: Re: any reason NOT to go Swagelok check valves?

Warren

I agree the Chinese check valves.

I use the lead seals and I also use WD40 while tightening.

Do you have a part number for the aluminum seals. ?

Thanks

Mark

N621CJ

Richmond VA

On Wed, Oct 16, 2019 at 7:08 PM Warren Hill <hill(at)doctor-hill.com (hill(at)doctor-hill.com)> wrote:

| Quote: | Hello Jon,

Itâs a simple thing to rebuild them. Doug Sapp provides the parts and all thatâs needed are two 17 mm wrenches. For those check valves that are too far gone from internal corrosion, the replacements that Doug builds are excellent. Regardless, whether you rebuild or replace, they still need to be swapped out every few years. No way around that no matter who makes them.

Just me, but I like to replace the soft lead washer with a soft aluminum crush washer thatâs been coated in WD40 to reduce deforming during tightening. Very solid seal. Attached is an image.

Personally, Iâm not a big fan of the Swagelok check valves. They are not very robust. Have seen too many fail. On a flight to Oshkosh a few years ago one of the members of our group had several fail by the time we got to Nebraska from Arizona. Spent a long time on the tarmac at the Lincoln airport replacing them with Chinese ones, which kept working for the next three years.

Exceptions are the Swagelok main and emergency on-off valves. They are fantastic and seem to last forever. The 90 degree, 2-port one is SS-42GF2-A-WN2 with the black handle. Attached is an image of one configured for the main air.

Warren Hill

N464TW

Mesa, AZ

[img]cid:FD652E6ED19944EF85DDFE4671BDCCAD(at)WalterHP[/img]

[img]cid:A47D95B845DE44A8AA1CD1DCAEFB6970(at)WalterHP[/img]

| Quote: | On Oct 16, 2019, at 2:21 PM, Jon Boede <jonboede(at)hotmail.com (jonboede(at)hotmail.com)> wrote:

I'm a "stock" guy. I like to keep things the way the design bureau designed them.

That having been said, over the years I've replaced or overhauled enough Chinese check valves to fill a trick-or-treater's plastic pumpkin. It's getting old.

The Swagelok replacement check valves seem like a good idea, but I'm cautious, so:

Does anybody have a single experience, observation, or reason NOT to go with the Swagelok replacement one-way check valves?

The only thing I can think of is, "We don't have enough total hours as a community to know what the down-side of the Swagelok valves is going to be" -- but that argument is fading.

Jon

|

|

Virus-free. www.avast.com [url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2] [/url] Virus-free. www.avast.com [url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2] [/url]

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

| Description: |

|

| Filesize: |

501.81 KB |

| Viewed: |

4249 Time(s) |

|

| Description: |

|

| Filesize: |

473.27 KB |

| Viewed: |

4249 Time(s) |

|

|

|

| Back to top |

|

|

pennington.construction.i

Guest

|

Posted: Wed Oct 16, 2019 9:34 pm Post subject: any reason NOT to go Swagelok check valves? Posted: Wed Oct 16, 2019 9:34 pm Post subject: any reason NOT to go Swagelok check valves? |

|

|

Thank you Walt and Warren

On Wed, Oct 16, 2019 at 11:07 PM Walter Lannon <wlannon(at)shaw.ca> wrote:

[quote] Hi Mark;

You will find a large selection of both copper and alum. Metric crush

washers at McMaster Carr. They are listed by ID, OD and thickness. I

could give you a part number now but not in the hangar so may guess wrong

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|