|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

erik(at)erikdahlbeck.com

Guest

|

Posted: Sun Sep 06, 2020 1:11 pm Post subject: Rear wing root socket problems Posted: Sun Sep 06, 2020 1:11 pm Post subject: Rear wing root socket problems |

|

|

Hello,

First time posting here, hoping my attached photos are small enough, etc...

I'm trying to get Europa SE-XRX airworthy again after being grounded for

two years. At first due to some hard-to-diagnose carburettor problems.

914 float bowls, enough said... If interested, I have a post about it

over at Rotax-Owners:

https://www.rotax-owner.com/en/912-914-technical-questions/6881-914ul-carburettor-gremlins?start=15

PROBLEM NO 1

Anyway, after fixing the engine and while doing the annual together with

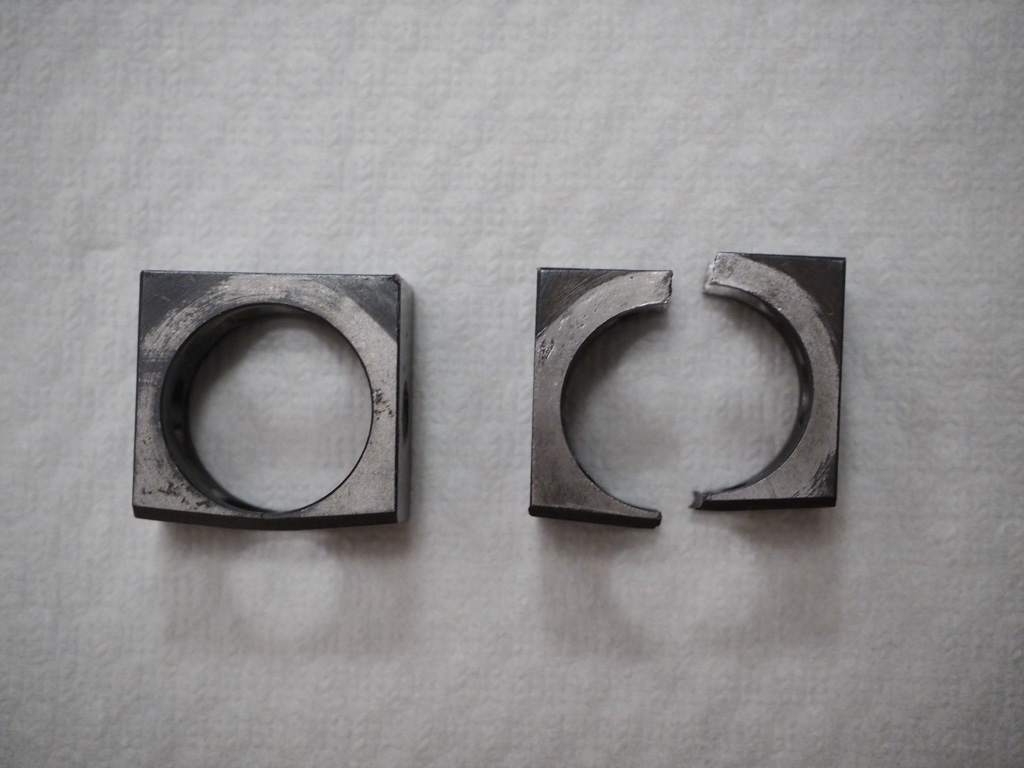

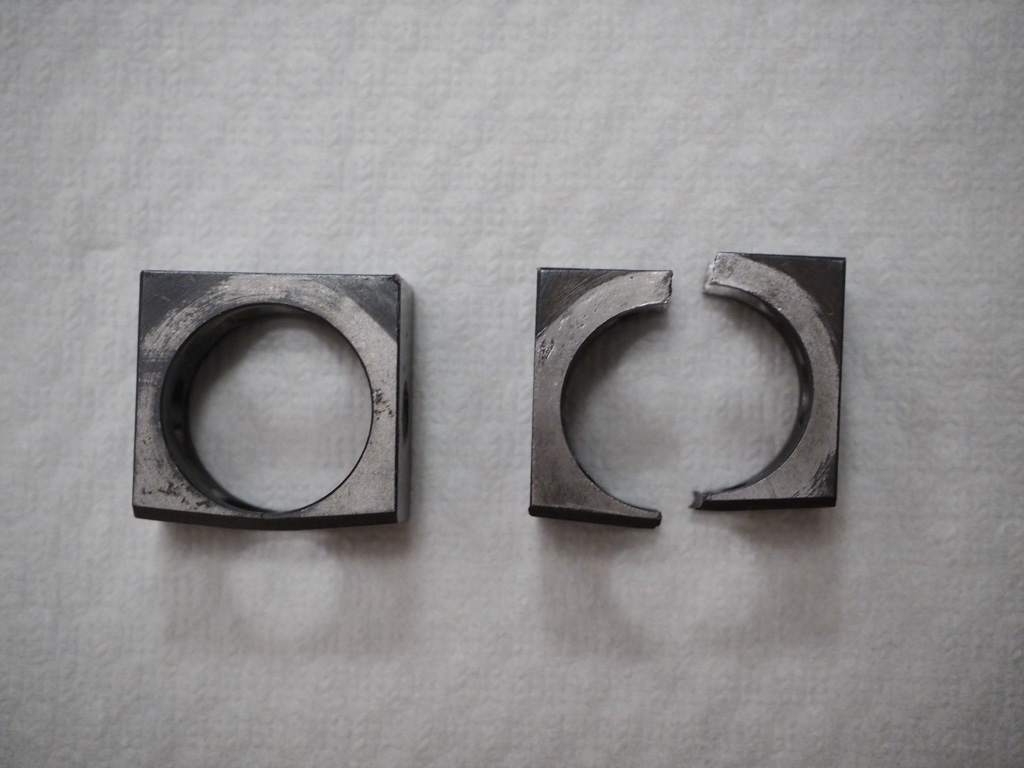

the previous owner/builder, it was discovered that the rear wing socket

housing, part W26B, starboard side, was cracked in two parts. Further

inspection showed that also the port side was cracked, albeit not having

split in two just yet. Please see attached photos.

I've got the spares from the manufacturer however, I'm curious if this

is a known problem? Any thoughts on what could be the cause? Anything

further to look out for?

My local mechanic seemed just as puzzled as I was when looking at how

thin this part is. I mean what is it, 2 mm?

One thing to consider: The aircraft was built as a monowheel but crashed

on takeoff during flight testing, making a hard landing and a ground

loop. The incident was traced to a construction error in the control

line attachment to the rudder, causing alterations in the design (some

of might be familiar with this). The aircraft was then repaired (by some

sailplane workshop that seemed to know what they were doing, I've seen

the photos at least). Among other things it got a new tail, a CS prop

and was rebuilt as a trigear. Might this new discovery simply be residue

of that old incident?

Also, the builder's manual states that the W26B and C parts should be

loctited together. However, there was no trace of this. I'm not sure if

that instruction has been there since the beginning or if it could be a

later revision? However, I sort of have my doubts as to some loctite

being able to strenghten this construction enough to not break from

whatever broke this...?

Finally, any thoughts on how to reassemble these parts? Where does the

Loctite go? Just on the barrel and make sure the holes align before i

dries? How to you avoid getting loctite on the surfaces between the

barrel and the socket body (W26A)?

PROBLEM NO 2

Due to various reasons, I only got around to cleaning the grease off the

rear socket assemblies, in preparation for reassembly, but doing the

loctite-work in a cold hangar, etc, and also enlisting the help of the

very busy local mechanic, was more than I could get done before last winter.

Now, on inspection, the W26A socket bodies show signs of corrosion.

Please see the other attached photos. Anyone have an opinion on just how

bad this is? Do they also need changing? And does that require

composite-work? I've been looking through the builder's manual but I'm

afraid I'm not quite up to understanding all of it.

Any thoughts on both of the above issues would be greatly appreciated!

Sincerely,

Erik Gunneland Dahlbäck

Linköping, Sweden

Europa SE-XRX

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

196.33 KB |

| Viewed: |

2425 Time(s) |

|

| Description: |

|

| Filesize: |

192.21 KB |

| Viewed: |

2425 Time(s) |

|

| Description: |

|

| Filesize: |

169.97 KB |

| Viewed: |

2425 Time(s) |

|

| Description: |

|

| Filesize: |

166.57 KB |

| Viewed: |

2425 Time(s) |

|

| Description: |

|

| Filesize: |

174.72 KB |

| Viewed: |

2425 Time(s) |

|

| Description: |

|

| Filesize: |

190.52 KB |

| Viewed: |

2425 Time(s) |

|

|

|

| Back to top |

|

|

budyerly@msn.com

Joined: 05 Oct 2019

Posts: 288

Location: Florida USA

|

Posted: Mon Sep 07, 2020 5:32 am Post subject: Rear wing root socket problems Posted: Mon Sep 07, 2020 5:32 am Post subject: Rear wing root socket problems |

|

|

Sorry to hear of your issues.

The failure of the socket indicates the crash may have been more severe than anticipated.

In all my years, Ive seen corrosion on older socket parts that were not as well protected as the new bits are. I have never seen a failure in the 26A as this was a well engineered and tested part by Europa. If installed backwards, this can happen.

Please contact Europa Aircraft because the W26 part assembly has not been an issue and replacement of the corroded items may be smart. This area is a critical flight component and the annual inspection and repair may have missed this part may have been damaged or assembled incorrectly. If the socket inner W26B failed, was the interior tube and attachments properly installed, checked and inspected is the question.

Loctite is between the barrel and that thin rectangular piece you call it so they operate as a unit. The wing pin goes into the fully assembled socket and allows it to move up and down just a bit. If not Loctited the barrel can rotate and make pin insertion more difficult. (Frankly, during wing install, simply note the orientation of the barrel is all that is needed.) Note that the assembly thin side goes on the fuselage side. Dont get that backwards as it builds up stress and may be a part of the failure you see

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Duncan McFadyean

Joined: 18 Jan 2011

Posts: 220

|

Posted: Mon Sep 07, 2020 7:11 am Post subject: Rear wing root socket problems Posted: Mon Sep 07, 2020 7:11 am Post subject: Rear wing root socket problems |

|

|

The (substantial) wear marks on W26A show that is was installed the correct way around.

The wear mark on the inside vertical surface of W26 just above the central bolt indicate that at some point W26A was leaning heavily on W26 in a 'negative g' direction of loading, which may explain how it then broke i.e. the weight of the wing transmitted in bending through the lift pin caused W26A to lever against W26.

That wouldn't occur during a normal flight maneuver and when properly rigged. Perhaps the downward leverage occurred during derigging after removing the spar pins, and assuming the spar cups were misplaced.

I'd check the lift pins for bending too and that these are not angled (or bent) above the centreline of the inboard spar projections (and/or that W26 has been set vertically).

Duncan Mcf.

[quote] On 07 September 2020 at 14:31 Bud Yerly <budyerly(at)msn.com> wrote:

Sorry to hear of your issues.

The failure of the socket indicates the crash may have been more severe than anticipated.

In all my years, Iâve seen corrosion on older socket parts that were not as well protected as the new bits are. I have never seen a failure in the 26A as this was a well engineered and tested part by Europa. If installed backwards, this can happen.

Please contact Europa Aircraft because the W26 part assembly has not been an issue and replacement of the corroded items may be smart. This area is a critical flight component and the annual inspection and repair may have missed this part may have been damaged or assembled incorrectly. If the socket inner W26B failed, was the interior tube and attachments properly installed, checked and inspected is the question.

Loctite is between the barrel and that thin rectangular piece you call it so they operate as a unit. The wing pin goes into the fully assembled socket and allows it to move up and down just a bit. If not Loctited the barrel can rotate and make pin insertion more difficult. (Frankly, during wing install, simply note the orientation of the barrel is all that is needed.) Note that the assembly thin side goes on the fuselage side. Donât get that backwards as it builds up stress and may be a part of the failure you see.

As far as the structural strength, the yoke piece 26A and the barrel 26C carry the load of the wing pulling forward under max G load. This barrel is designed to move up and down.

As for the Rotax 914:

There is a long and boring troubleshooting guide on my website on keeping the 914 running true. The carbs are easily rebuilt with proper attention to detail. I find the Rotax engine forum informational, but doesnât cover in enough detail. I do find the videos provided by Rotax to be quite complete. The paper I did covers various phases and expands troubleshooting. See the techniques section for an updated version since published in the Europa Club magazine.

Bud Yerly

www.customflightcreations.com

Sent from Mail https://go.microsoft.com/fwlink/?LinkId=550986 for Windows 10

From: Erik Dahlbäck mailto:erik(at)erikdahlbeck.com

Sent: Sunday, September 6, 2020 5:18 PM

To: europa-list(at)matronics.com mailto:europa-list(at)matronics.com

Subject: Rear wing root socket problems

Hello,

First time posting here, hoping my attached photos are small enough, etc...

I'm trying to get Europa SE-XRX airworthy again after being grounded for

two years. At first due to some hard-to-diagnose carburettor problems

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

erik(at)erikdahlbeck.com

Guest

|

Posted: Sun Sep 13, 2020 1:29 pm Post subject: Rear wing root socket problems Posted: Sun Sep 13, 2020 1:29 pm Post subject: Rear wing root socket problems |

|

|

Thank you Bud, Duncan and others for your input.

David Stanbridge reached out to me in response to my post here and I've E-mailed them the pictures as well. Their recommendation was to remove the rust and oil it to prevent further corrosion.

Now, my local mechanic and I decided to have me paint the W26A using "hammer paint" after sanding. Here's to hoping that the parts will still fit. It shouldn't rust anymore anyway...

The way I recall it, the W26B was correctly oriented when we found the totally broken one. However, it had almost fallen off so I can't be sure. The port side one however, which I later discovered to be cracked as well, was correctly oriented. That is if I remember correctly. I might again here just be assuming it was installed correctly due to having read the builder's manual afterwards.

And yes, I am a member of the Europa Club and will sure check out the 914-tips, thank you all.

/ Erik

On 2020-09-07 17:10, D McFadyean wrote:

| Quote: |

The (substantial) wear marks on W26A show that is was installed the correct way around.

The wear mark on the inside vertical surface of W26 just above the central bolt indicate that at some point W26A was leaning heavily on W26 in a 'negative g' direction of loading, which may explain how it then broke i.e. the weight of the wing transmitted in bending through the lift pin caused W26A to lever against W26.

That wouldn't occur during a normal flight maneuver and when properly rigged. Perhaps the downward leverage occurred during derigging after removing the spar pins, and assuming the spar cups were misplaced.

I'd check the lift pins for bending too and that these are not angled (or bent) above the centreline of the inboard spar projections (and/or that W26 has been set vertically).

Duncan Mcf. | Quote: | On 07 September 2020 at 14:31 Bud Yerly <budyerly(at)msn.com> (budyerly(at)msn.com) wrote:

Sorry to hear of your issues.

Â

The failure of the socket indicates the crash may have been more severe than anticipated.Â

In all my years, Iâve seen corrosion on older socket parts that were not as well protected as the new bits are. I have never seen a failure in the 26A as this was a well engineered and tested part by Europa. If installed backwards, this can happen.

Â

Please contact Europa Aircraft because the W26 part assembly has not been an issue and replacement of the corroded items may be smart. This area is a critical flight component and the annual inspection and repair may have missed this part may have been damaged or assembled incorrectly. If the socket inner W26B failed, was the interior tube and attachments properly installed, checked and inspected is the question.Â

Â

Loctite is between the barrel and that thin rectangular piece you call it so they operate as a unit. The wing pin goes into the fully assembled socket and allows it to move up and down just a bit. If not Loctited the barrel can rotate and make pin insertion more difficult. (Frankly, during wing install, simply note the orientation of the barrel is all that is needed.) Note that the assembly thin side goes on the fuselage side.  Donât get that backwards as it builds up stress and may be a part of the failure you see.Â

Â

As far as the structural strength, the yoke piece 26A and the barrel 26C carry the load of the wing pulling forward under max G load. This barrel is designed to move up and down.

Â

As for the Rotax 914:

There is a long and boring troubleshooting guide on my website on keeping the 914 running true. The carbs are easily rebuilt with proper attention to detail. I find the Rotax engine forum informational, but doesnât cover in enough detail. I do find the videos provided by Rotax to be quite complete. The paper I did covers various phases and expands troubleshooting. See the techniques section for an updated version since published in the Europa Club magazine.

Â

Bud Yerly

www.customflightcreations.com

Sent from Mail for Windows 10

Â

From: Erik Dahlbäck (erik(at)erikdahlbeck.com)

Sent: Sunday, September 6, 2020 5:18 PM

To: europa-list(at)matronics.com (europa-list(at)matronics.com)

Subject: Rear wing root socket problems

Â

Hello,

First time posting here, hoping my attached photos are small enough, etc...

I'm trying to get Europa SE-XRX airworthy again after being grounded for

two years. At first due to some hard-to-diagnose carburettor problems.

914 float bowls, enough said... If interested, I have a post about it

over at Rotax-Owners:

https://nam11.safelinks.protection.outlook.com/?url=https%3A%2F%2Fwww.rotax-owner.com%2Fen%2F912-914-technical-questions%2F6881-914ul-carburettor-gremlins%3Fstart%3D15&data=02%7C01%7C%7C8482b0ef213641821e7208d852aa5b72%7C84df9e7fe9f640afb435aaaaaaaaaaaa%7C1%7C0%7C637350238926500351&sdata=pMvGV5%2BI41Zjnn3nQnSV8Wo37dGxDwnn9%2Ff%2Bu5P7T%2F0%3D&reserved=0

PROBLEM NO 1

Anyway, after fixing the engine and while doing the annual together with

the previous owner/builder, it was discovered that the rear wing socket

housing, part W26B, starboard side, was cracked in two parts. Further

inspection showed that also the port side was cracked, albeit not having

split in two just yet. Please see attached photos.

I've got the spares from the manufacturer however, I'm curious if this

is a known problem? Any thoughts on what could be the cause? Anything

further to look out for?

My local mechanic seemed just as puzzled as I was when looking at how

thin this part is. I mean what is it, 2 mm?

One thing to consider: The aircraft was built as a monowheel but crashed

on takeoff during flight testing, making a hard landing and a ground

loop. The incident was traced to a construction error in the control

line attachment to the rudder, causing alterations in the design (some

of might be familiar with this). The aircraft was then repaired (by some

sailplane workshop that seemed to know what they were doing, I've seen

the photos at least). Among other things it got a new tail, a CS prop

and was rebuilt as a trigear. Might this new discovery simply be residue

of that old incident?

Also, the builder's manual states that the W26B and C parts should be

loctited together. However, there was no trace of this. I'm not sure if

that instruction has been there since the beginning or if it could be a

later revision? However, I sort of have my doubts as to some loctite

being able to strenghten this construction enough to not break from

whatever broke this...?

Finally, any thoughts on how to reassemble these parts? Where does the

Loctite go? Just on the barrel and make sure the holes align before i

dries? How to you avoid getting loctite on the surfaces between the

barrel and the socket body (W26A)?

PROBLEM NO 2

Due to various reasons, I only got around to cleaning the grease off the

rear socket assemblies, in preparation for reassembly, but doing the

loctite-work in a cold hangar, etc, and also enlisting the help of the

very busy local mechanic, was more than I could get done before last winter.

Now, on inspection, the W26A socket bodies show signs of corrosion.

Please see the other attached photos. Anyone have an opinion on just how

bad this is? Do they also need changing? And does that require

composite-work? I've been looking through the builder's manual but I'm

afraid I'm not quite up to understanding all of it.

Any thoughts on both of the above issues would be greatly appreciated!

Sincerely,

Erik Gunneland Dahlbäck

Linköping, Sweden

Europa SE-XRX

Â

|

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|