|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

wdaniell.longport(at)gmai

Guest

|

Posted: Thu Jul 21, 2022 8:50 am Post subject: Fuel tank inspection plate design Posted: Thu Jul 21, 2022 8:50 am Post subject: Fuel tank inspection plate design |

|

|

Does anyone have a photo or design of a fuel tank inspection plate?

Thanks.

Wills fuel tank update for what its worth.

The options areÂ

- Europa original - waiting for cost and lead time. I think the new design is slightly larger than my tank necessitating the opening of the door sills. The issue with my tank is not the tank - it was the stress caused by bonding the tank in place per the manual. The tank material which was fabricated at the latest in 2002 is still fresh and flexible (not yellow and brittle). I did not have my tank fluorinated.  So those that followed Buds tank installation instructions can take comfort from that.

- Aluminium - I am a bit intimidated by the complexity of the tank shape.

- Composite: my research suggests ethanol is a problem for composite tanks and therefore the resin is critical. So far I see two options: EZ Poxy which is sold by ACS and used in aircraft which use composite tanks and MAX GRE which is sold specifically for fuel tanks. There is also Isophthalic Resin which is used for underground gasoline storage in gas stations. Either way I need an inspection plate in order to check the state of the resin. I see a couple of advantages to building the tank. It will fit.  I can adjust the filler and outlets. It could be slightly larger. Finally I can include internal reinforcement to stop bulging. Set against this is the issue of crash resistance.  The HDPE tank is tough...very tough. I suspect that a composite tank would fracture.

William Daniell

LONGPORT

+1 786 878 0246

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

n7188u

Joined: 15 Nov 2015

Posts: 404

|

Posted: Fri Jul 22, 2022 6:39 am Post subject: Re: Fuel tank inspection plate design Posted: Fri Jul 22, 2022 6:39 am Post subject: Re: Fuel tank inspection plate design |

|

|

Interesting work Will and sorry you have to through this. I dread the day it happens to me and I have to go through this too.

But your research will certainly help. I would really like to use composites, if possible, since it would allow any of us to be able to construct a tank to our liking. But I understand the concern. It's a scary thought that the surface could be affected.

After quite a bit of reading I honestly can't conclude whether it would be 100% safe to have a composite tank exposed to ethanol. The MAX GRE option looks promising as I read that a Novolac based epoxy is a good choice.

But underground tanks are made from polyester resin and fiberglass but couldn't find any specific resin spec.

Tough choice. Let us know how it goes.

Best,

Chris

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

wdaniell.longport(at)gmai

Guest

|

Posted: Fri Jul 22, 2022 11:08 am Post subject: Fuel tank inspection plate design Posted: Fri Jul 22, 2022 11:08 am Post subject: Fuel tank inspection plate design |

|

|

Underground tanks are made from isophthalic resin which a type of vinylester according to my research.

Will

William Daniell

+1 786 878 0246

On Fri, Jul 22, 2022, 10:42 n7188u <chmgarb(at)gmail.com (chmgarb(at)gmail.com)> wrote:

| Quote: | --> Europa-List message posted by: "n7188u" <chmgarb(at)gmail.com (chmgarb(at)gmail.com)>

Interesting work Will and sorry you have to through this. I dread the day it happens to me and I have to go through this too.

But your research will certainly help. I would really like to use composites, if possible, since it would allow any of us to be able to construct a tank to our liking. But I understand the concern. It's a scary thought that the surface could be affected.

After quite a bit of reading I honestly can't conclude whether it would be 100% safe to have a composite tank exposed to ethanol. The MAX GRE option looks promising as I read that a Novolac based epoxy is a good choice.

But underground tanks are made from polyester resin and fiberglass but couldn't find any specific resin spec.

Tough choice. Let us know how it goes.

Best,

Chris

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=507518#507518

===========

pa-List" rel="noreferrer noreferrer" target="_blank">http://www.matronics.com/Navigator?Europa-List

===========

FORUMS -

eferrer noreferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer noreferrer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

="noreferrer noreferrer" target="_blank">https://matronics.com/contribution

===========

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Dave Disney

Joined: 16 Aug 2010

Posts: 54

Location: Weston-Super-Mare

|

Posted: Sun Jul 24, 2022 2:43 am Post subject: Re: Fuel tank inspection plate design Posted: Sun Jul 24, 2022 2:43 am Post subject: Re: Fuel tank inspection plate design |

|

|

Hi Will,

Sorry to hear about your tank problem. My tank developed a split back in 2016, at first, I explored installing a bladder inside the tank as I really didnât like the idea of installing a new tank. I had studied the repair process and lots of photographs from the web and even produced the mouldings required ready to install a new tank, but I really didnât want to go that route.

I produced two or three bladders, but I couldnât produce a bladder that didnât leak. The idea was to fill the bladder with explosion proof foam as used in racing cars, it would have reduced the tank capacity a bit, but would prevent the bladder from collapsing when empty. I approached several bladder manufacturers, but they all wanted thousands to produce a bladder which is why I went the DIY route. Although the bladder idea didnât work out for me, I still think this is a great idea if someone can produce a bladder at a reasonable price.

Having spent a lot of time and effort on the bladder, I stumbled on the process of welding plastic fuel tanks in a youtube video. At this point in time, I knew that my tank was split, but I didnât know where or how bad as I hadnât cut open the top of the tank. I figured that if I had to replace the tank with a new one then cutting some holes in the tank top wasnât going to matter, and if I cut the top of the headrests off then any holes I cut could be easily repaired in the replacement process. There was already an LAA scheme for installing a fuel tank sender unit that involved cutting an inspection hole between the headrests, so I knew I wasnât breaking new ground doing this. Anyway, once the holes were cut I could see the split in the tank for the first time and I thought repairing it was feasible.

Iâve included some photos of the bladder for reference, a copy of the repair scheme that was accepted by the LAA in the UK and a pic of the inside of the tank. Itâs pretty self-explanatory, but Iâm happy to help if something isnât clear.

I should add that my original welded repair failed earlier this year after 7 years, but it was only a morningâs work to pump it out and reweld it and itâs been OK since. The repair approval dictates that I must remove the inspection panels at annual inspection to inspect the repair. I usually pump the tank out to do this which gives the opportunity to remove any debris from inside the tank and have a good look at it as well.

Good luck with your repair.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

| Inflated for leak testing. |

|

| Filesize: |

30.73 KB |

| Viewed: |

4255 Time(s) |

|

| Description: |

|

| Filesize: |

32.51 KB |

| Viewed: |

4255 Time(s) |

|

| Description: |

|

| Filesize: |

66.11 KB |

| Viewed: |

4255 Time(s) |

|

| Description: |

| The leaking bladder - front. |

|

| Filesize: |

66.82 KB |

| Viewed: |

4255 Time(s) |

|

| Description: |

| You can just see the repair in this pic - 2 years old at this point. |

|

| Filesize: |

83.01 KB |

| Viewed: |

4255 Time(s) |

|

| Description: |

|

Download |

| Filename: |

Mod 8 Redacted 1.pdf |

| Filesize: |

1.61 MB |

| Downloaded: |

157 Time(s) |

|

|

| Back to top |

|

|

Mallard

Joined: 22 Oct 2019

Posts: 52

Location: Ireland

|

Posted: Sun Jul 24, 2022 4:15 am Post subject: Fuel tank inspection plate design Posted: Sun Jul 24, 2022 4:15 am Post subject: Fuel tank inspection plate design |

|

|

Dave, how do you pump the fuel out of the tank?

Do you use the aircraft's own electric pump? Btw, it's vital that the tank is ventilated so that all petrol/gas fumes are evacuated before introducing any heat source or spark, as many a motor mechanic found out to his cost when welding the fuel tank of a petrol engined car!

Get Outlook for Android

From: owner-europa-list-server(at)matronics.com <owner-europa-list-server(at)matronics.com> on behalf of Dave Disney <davedisney(at)yahoo.co.uk>

Sent: Sunday, July 24, 2022 11:43:15 AM

To: europa-list(at)matronics.com <europa-list(at)matronics.com>

Subject: Re: Fuel tank inspection plate design

--> Europa-List message posted by: "Dave Disney" <davedisney(at)yahoo.co.uk>

Hi Will,

Sorry to hear about your tank problem. My tank developed a split back in 2016, at first, I explored installing a bladder inside the tank as I really didnât like the idea of installing a new tank. I had studied the repair process and lots of photographs from the web and even produced the mouldings required ready to install a new tank, but I really didnât want to go that route.

I produced two or three bladders, but I couldnât produce a bladder that didnât leak. The idea was to fill the bladder with explosion proof foam as used in racing cars, it would have reduced the tank capacity a bit, but would prevent the bladder from collapsing when empty. I approached several bladder manufacturers, but they all wanted thousands to produce a bladder which is why I went the DIY route. Although the bladder idea didnât work out for me, I still think this is a great idea if someone can produce a bladder at a reasonable price.

Having spent a lot of time and effort on the bladder, I stumbled on the process of welding plastic fuel tanks in a youtube video. At this point in time, I knew that my tank was split, but I didnât know where or how bad as I hadnât cut open the top of the tank. I figured that if I had to replace the tank with a new one then cutting some holes in the tank top wasnât going to matter, and if I cut the top of the headrests off then any holes I cut could be easily repaired in the replacement process. There was already an LAA scheme for installing a fuel tank sender unit that involved cutting an inspection hole between the headrests, so I knew I wasnât breaking new ground doing this. Anyway, once the holes were cut I could see the split in the tank for the first time and I thought repairing it was feasible.

Iâve included some photos of the bladder for reference, a copy of the repair scheme that was accepted by the LAA in the UK and a pic of the inside of the tank. Itâs pretty self-explanatory, but Iâm happy to help if something isnât clear.

I should add that my original welded repair failed earlier this year after 7 years, but it was only a morningâs work to pump it out and reweld it and itâs been OK since. The repair approval dictates that I must remove the inspection panels at annual inspection to inspect the repair. I usually pump the tank out to do this which gives the opportunity to remove any debris from inside the tank and have a good look at it as well.

Good luck with your repair.

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=507536#507536

Attachments:

http://forums.matronics.com//files/mod_8_redacted_1_114.pdf

http://forums.matronics.com//files/inflated_tank_rear_592.jpg

http://forums.matronics.com//files/bladder_top_180.jpg

http://forums.matronics.com//files/bladder_rear_116.jpg

http://forums.matronics.com//files/bladder_front_898.jpg

http://forums.matronics.com//files/2018_inside_of_fuel_tank_242.jpg

===========

st Email Forum -

pa-List">http://www.matronics.com/Navigator?Europa-List

===========

p; - MATRONICS WEB FORUMS -

ums.matronics.com

===========

p; - NEW MATRONICS LIST WIKI -

matronics.com

===========

p; - List Contribution Web Site -

p; -Matt Dralle, List Admin.

ps://matronics.com/contribution

===========

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

_________________

Seat of my pants |

|

| Back to top |

|

|

Dave Disney

Joined: 16 Aug 2010

Posts: 54

Location: Weston-Super-Mare

|

Posted: Sun Jul 24, 2022 7:17 am Post subject: Re: Fuel tank inspection plate design Posted: Sun Jul 24, 2022 7:17 am Post subject: Re: Fuel tank inspection plate design |

|

|

Hi Mallard,

I use the aircraft electric pump to pump out as much fuel as possible, then remove the fuel tank access cover and mop out the rest. Leave for an hour for fumes to evaporate then do what I need to do. When using a hot air gun to heat weld the plastic, I usually leave the tank empty overnight for fumes to evaporate. So far, it's not been a problem.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Mallard

Joined: 22 Oct 2019

Posts: 52

Location: Ireland

|

Posted: Sun Jul 24, 2022 4:42 pm Post subject: Fuel tank inspection plate design Posted: Sun Jul 24, 2022 4:42 pm Post subject: Fuel tank inspection plate design |

|

|

Yes Dave,

Better to be safe than sorry!

Btw,

Did you have plenty of welding material left over from the first repair?

Get Outlook for Android

From: owner-europa-list-server(at)matronics.com <owner-europa-list-server(at)matronics.com> on behalf of Dave Disney <davedisney(at)yahoo.co.uk>

Sent: Sunday, July 24, 2022 4:17:11 PM

To: europa-list(at)matronics.com <europa-list(at)matronics.com>

Subject: Re: Fuel tank inspection plate design

--> Europa-List message posted by: "Dave Disney" <davedisney(at)yahoo.co.uk>

Hi Mallard,

I use the aircraft electric pump to pump out as much fuel as possible, then remove the fuel tank access cover and mop out the rest. Leave for an hour for fumes to evaporate then do what I need to do. When using a hot air gun to heat weld the plastic, I usually leave the tank empty overnight for fumes to evaporate. So far, it's not been a problem.

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=507541#507541

===========

st Email Forum -

pa-List">http://www.matronics.com/Navigator?Europa-List

===========

p; - MATRONICS WEB FORUMS -

ums.matronics.com

===========

p; - NEW MATRONICS LIST WIKI -

matronics.com

===========

p; - List Contribution Web Site -

p; -Matt Dralle, List Admin.

ps://matronics.com/contribution

===========

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

_________________

Seat of my pants |

|

| Back to top |

|

|

Dave Disney

Joined: 16 Aug 2010

Posts: 54

Location: Weston-Super-Mare

|

Posted: Mon Jul 25, 2022 12:57 pm Post subject: Re: Fuel tank inspection plate design Posted: Mon Jul 25, 2022 12:57 pm Post subject: Re: Fuel tank inspection plate design |

|

|

Hi Mallard,

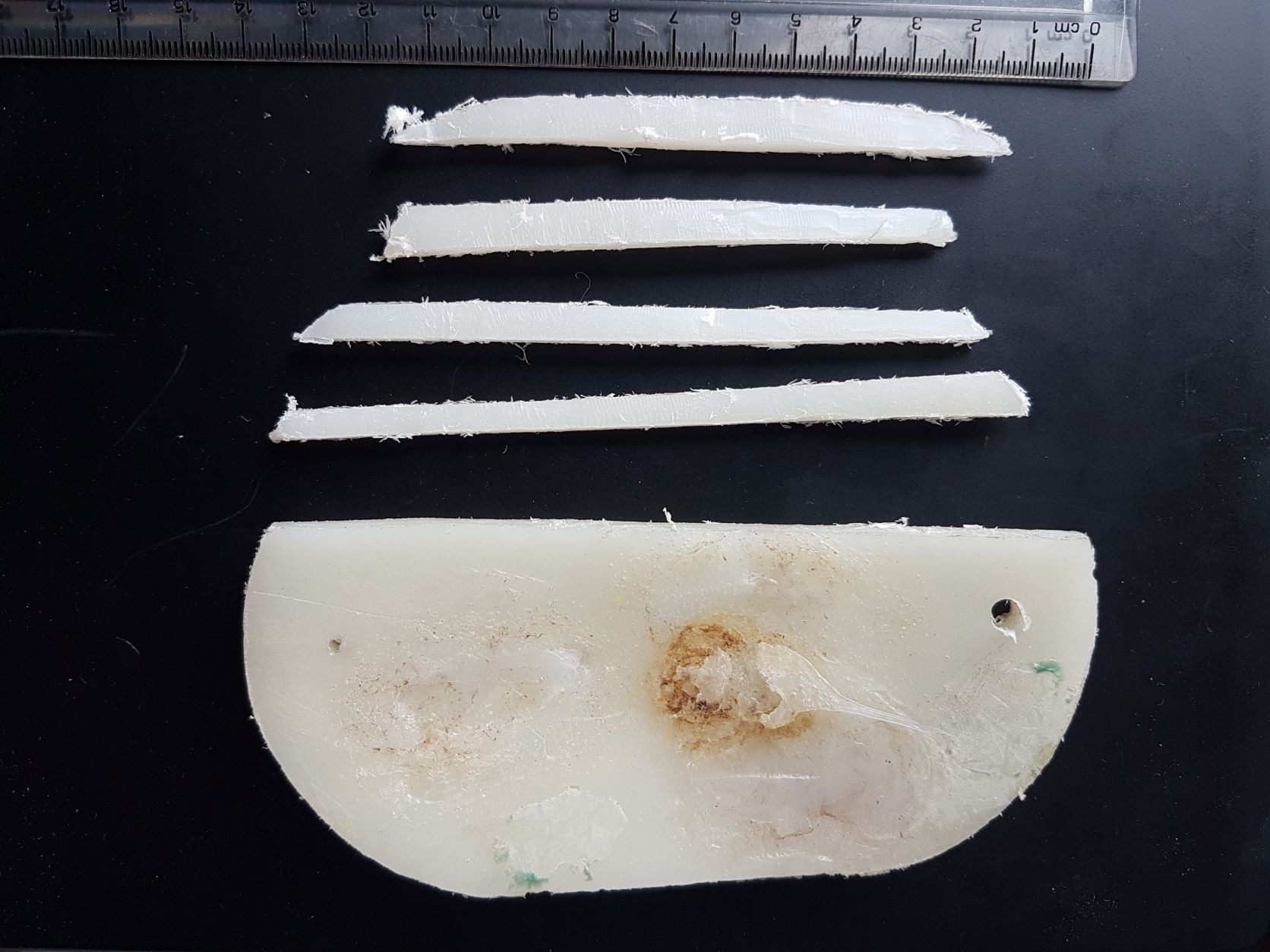

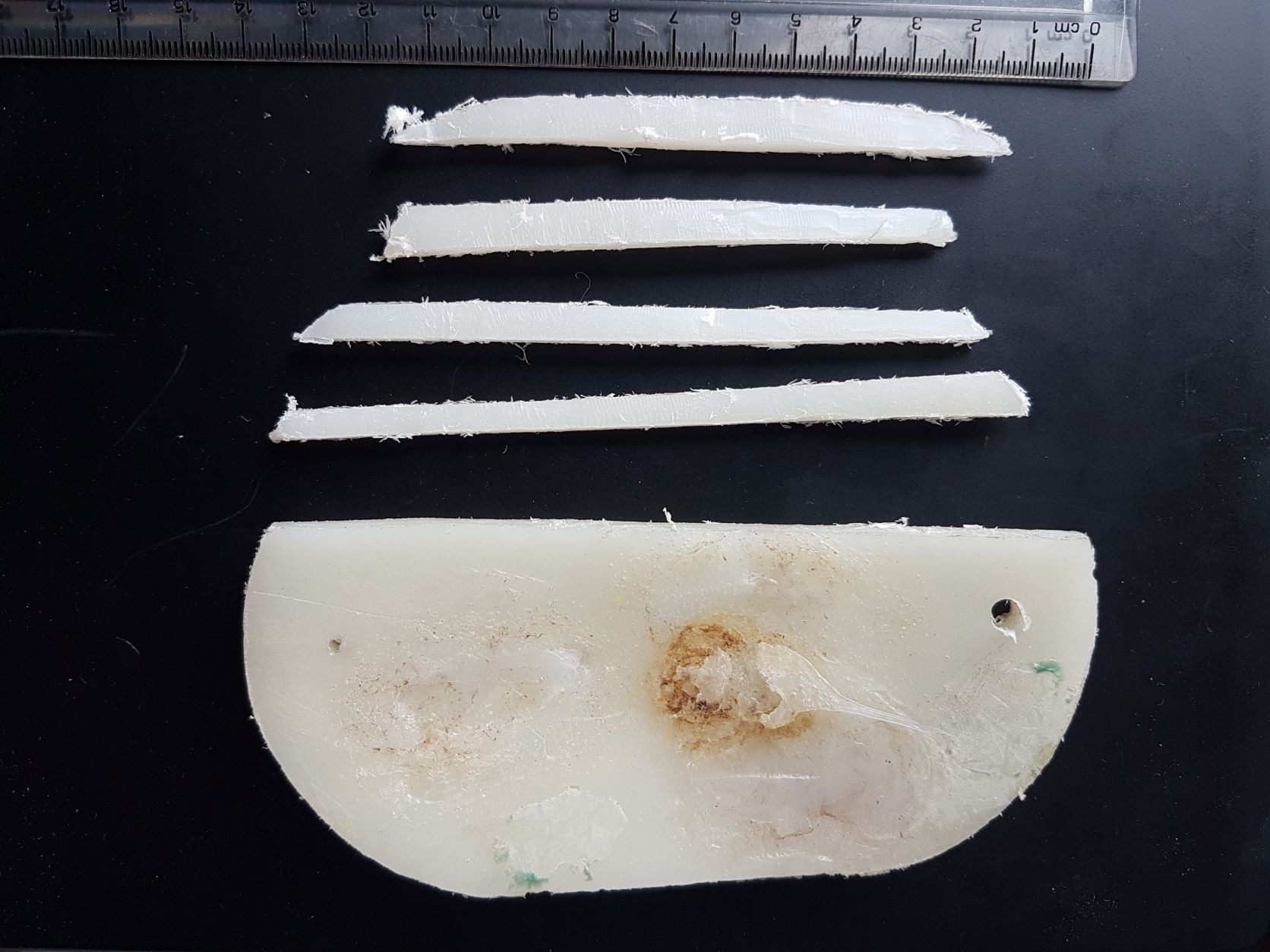

I just cut some strips of material from the panel I cut out. I figured that it's the same material so should be OK. From the pic you can see that I was able to use the panel to practice welding before attempting the main event.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

221.65 KB |

| Viewed: |

4214 Time(s) |

|

|

|

| Back to top |

|

|

ppsel03

Joined: 23 May 2014

Posts: 9

|

Posted: Fri Sep 16, 2022 8:44 am Post subject: Re: Fuel tank inspection plate design Posted: Fri Sep 16, 2022 8:44 am Post subject: Re: Fuel tank inspection plate design |

|

|

If available can you send the inspection plate instructions? N914XS sprung a leak.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

_________________

EuropaXS 914UL Turbo |

|

| Back to top |

|

|

wdaniell.longport(at)gmai

Guest

|

Posted: Fri Sep 16, 2022 9:05 am Post subject: Fuel tank inspection plate design Posted: Fri Sep 16, 2022 9:05 am Post subject: Fuel tank inspection plate design |

|

|

I am making it up as I go along!

But essentially I bought some sealed 10-32 nut plates, I made a ring of 1/8 aluminium which will hold the nutplates. I plan to glue and rivett the ring/nut plate assembly to the inside.  I have a sheet of nitrile for the gasket and the cover will also be 1/8 aluminium.

William Daniell

LONGPORT

+1 786 878 0246

On Fri, Sep 16, 2022 at 12:46 PM ppsel03 <ppsel03(at)gmail.com (ppsel03(at)gmail.com)> wrote:

| Quote: | --> Europa-List message posted by: "ppsel03" <ppsel03(at)gmail.com (ppsel03(at)gmail.com)>

If available can you send the inspection plate instructions? N914XS sprung a leak.

--------

EuropaXS 914UL Turbo

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=507897#507897

===========

pa-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?Europa-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

="noreferrer" target="_blank">https://matronics.com/contribution

===========

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

ppsel03

Joined: 23 May 2014

Posts: 9

|

Posted: Fri Sep 16, 2022 3:41 pm Post subject: Re: Fuel tank inspection plate design Posted: Fri Sep 16, 2022 3:41 pm Post subject: Re: Fuel tank inspection plate design |

|

|

No response, so removed...

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

_________________

EuropaXS 914UL Turbo

Last edited by ppsel03 on Sat Sep 17, 2022 8:43 pm; edited 1 time in total |

|

| Back to top |

|

|

ppsel03

Joined: 23 May 2014

Posts: 9

|

Posted: Fri Sep 16, 2022 5:02 pm Post subject: Re: Fuel tank inspection plate design Posted: Fri Sep 16, 2022 5:02 pm Post subject: Re: Fuel tank inspection plate design |

|

|

Submitted Tank Drawing to "Fuel Safe" custom. (https://www.theeuropaclub.org/document/174)

Fuel Safe sell two different "nut rings" for a 6x10" hole.

One lighter (that will probably leak)

One heavier cast with sealed nuts (https://fuelsafe.com/nutring-nr06x10-i/)

and a matching cover (https://fuelsafe.com/1pla13/)

Chemical-Resistant Viton® Gasket Sheet, 12" X12" X1/16" (https://www.mcmaster.com/9473K61/)

6x10 hole might be large enough to do a layup assuming I can find the crack... Unlikely It'll be large enough to plastic weld. 100UL & LL from here on.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

_________________

EuropaXS 914UL Turbo |

|

| Back to top |

|

|

ppsel03

Joined: 23 May 2014

Posts: 9

|

Posted: Tue Sep 27, 2022 2:39 pm Post subject: Re: Fuel tank inspection plate design Posted: Tue Sep 27, 2022 2:39 pm Post subject: Re: Fuel tank inspection plate design |

|

|

(at)Dave, do you or anyone have a 3D Model of the fuel tank? ( autocad, solidworks, STL file) I submitted the PDF to Fuel Safe .... crickets so far. Would love to have at least one bladder that didn't leak...

| Dave Disney wrote: | .....at first, I explored installing a bladder inside the tank as I really didnât like the idea of installing a new tank. .....

I approached several bladder manufacturers, but they all wanted thousands to produce a bladder .....

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

_________________

EuropaXS 914UL Turbo |

|

| Back to top |

|

|

Dave Disney

Joined: 16 Aug 2010

Posts: 54

Location: Weston-Super-Mare

|

Posted: Wed Sep 28, 2022 8:32 am Post subject: Re: Fuel tank inspection plate design Posted: Wed Sep 28, 2022 8:32 am Post subject: Re: Fuel tank inspection plate design |

|

|

No I don't have a 3D file or the tank. I mocked up the internal shape of the tank using plywood and mouldings from the inside of the tank using modeling clay which I was able to do once I had cut the access hole in the tank top, this I did on a new tank from Europa but id could be done in situ. I then used the mouldings (front, back and saddle area) to weld up the bladder which I could do by leaving a tank top seal unwelded to get the formers out. That just left one straight seam to weld which I could do over a former that was retrieved through the access hole after welding.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|