nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Apr 16, 2023 12:38 pm Post subject: LightSpeed Ignition wiring Posted: Sun Apr 16, 2023 12:38 pm Post subject: LightSpeed Ignition wiring |

|

|

At 02:40 AM 4/14/2023, you wrote:

| Quote: | Bob,

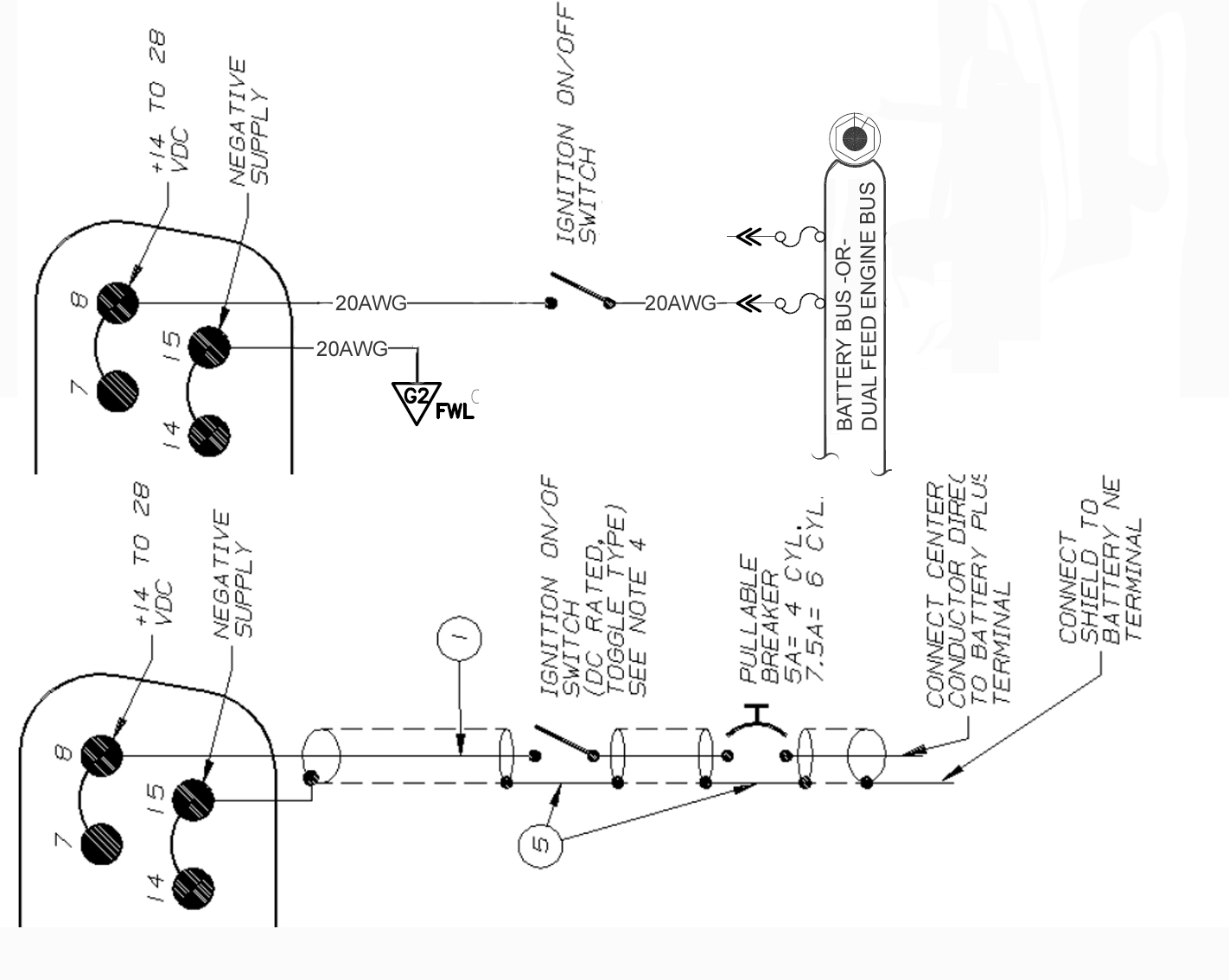

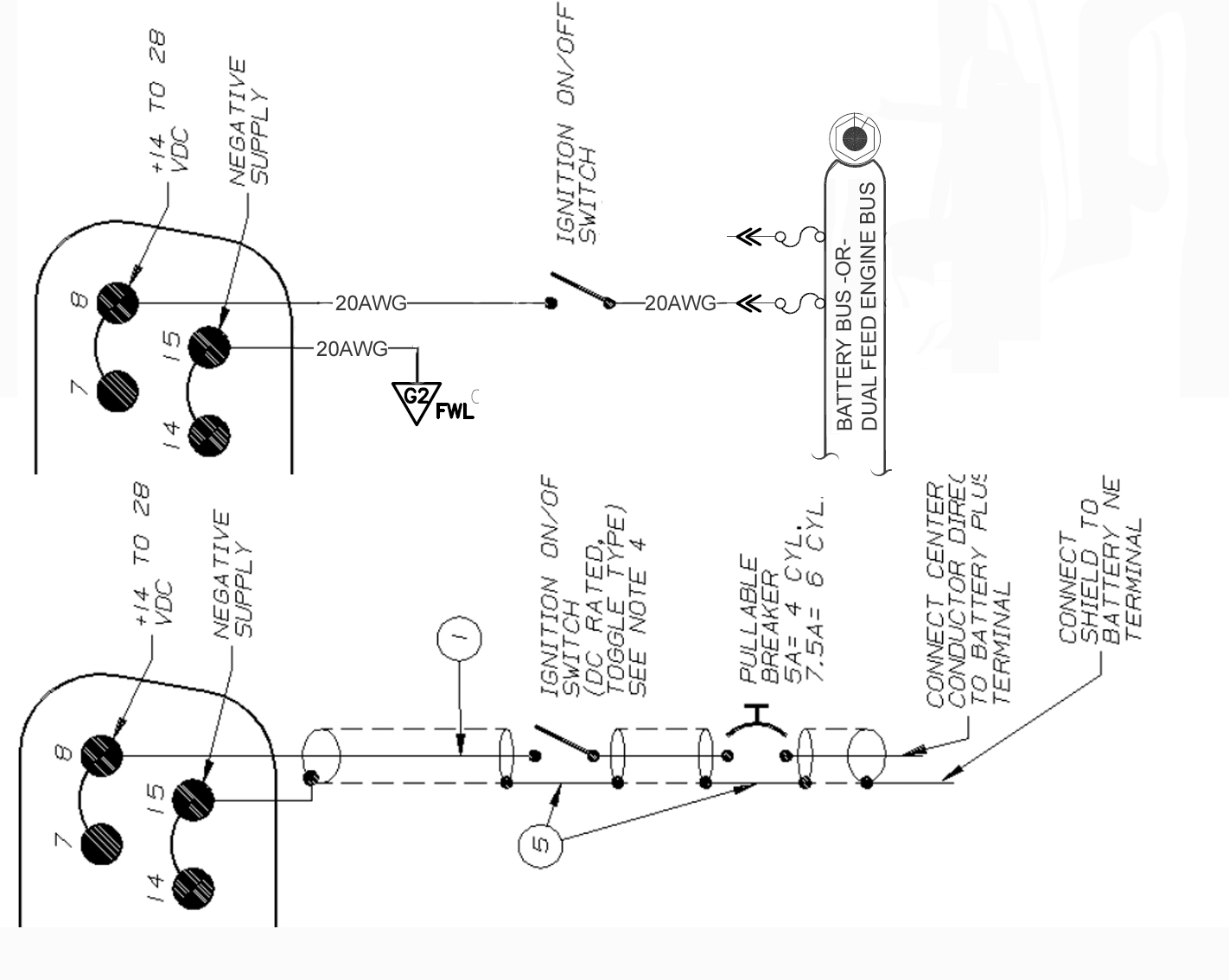

In reference to a 3/28/23 post regarding wiring for a dual LightSpeed Ignition application,

you basically replied that the use of shielded wire (for the power supply from the battery to the two boxes) was unnecessary and contrary to a 747-load of lessons learned.

Positive and Negative Connections:

Just to make sure I understand your response, I could run an

18 awg wire or larger from the positive post of the battery to PIN� 8

of the "Input <SNIP> |

If it were my airplane:

NO wires for any system need be connected to the

(+) or (-) terminals of the battery for any

reasons supported by the physics or practice

in aviation. To my knowledge, it has never

happened in either type certified or military

aircraft . . . arguments that support the

idea are weak at best.

Lightspeed systems draw about 3A maximum.

22AWG wire is electrically adequate to the

task of transporting electrons from the BUS

to the ignition system. 20AWG wire is often

preferred for mechanical robustness in some

installations . . . and D-SUB connectors

readily accept 20AWG wire. Anything larger

is completely unnecessary and most inconvenient.

| Quote: | | I recall from some of your earlier conversations with Klaus that the solder bridge from Pin 8 and 7 on the Input Connector� was� redundant and not necessary, and the same for the negative supply for Pins 15 and 14. |

At 3A max, the single D-Sub pin is quite

adequate but paralleling at the connector

body doesn't add much integrity for

current sharing. To make paralleled pins

share a potential for single pin overload,

you need to add ballasting resistance in

each of the paralleled paths. I illustrated

this here https://tinyurl.com/288uppe4

This was used successfully in boosting

the currents conducted through D-subs on

both the AQM163 target and the Hawker-Beech

4000.

But with a 3A draw, adding more pins in the

pathway is of minuscule value.

| Quote: | If this is correct, could a twisted pair� be used for these two connections? Would there be any benefit of using twisted pair here rather than two separate wires?

The positive wire would use a circuit breaker and switch as shown on the Input Connector Diagram. |

No special treatments for managing electromagnetic

compatibility are necessary or useful. Wire this

critter up the same as you might for a light

bulb.

Here's the rub: Assume the manufacturer says

shielding that wire is necessary to reduce risk of

electrostatically coupled interference either to

or by other ship's systems. What then what is the philosophy

for connecting that same wire to the battery? Batteries

are NOT good noise abatement devices. If lack of

shielding presents a risk, then there is risk

that same antagonist is hazard for propagation

out onto the bus.

At the current it takes to run this system,

any NECESSARY noise abatement could be easily

accomplished inside the device thus making it

unnecessary to shield that wire. Given the apparently

noise-free, marketplace age of this product

I submit that no such noise risk exists.

No shields, no twisting, no splicing is necessary

or useful. Keep it simple. Why 3-wire cable?

| Quote: | I am also planning on using your recommendation to replace the RG 400 coax cables to the coils.

For the wiring from the magic boxes to the ignition coils, can a 2-conductor, unshielded,

twisted or un-twisted� cable be used to drive the coils, rather than using the RG 400 coax cable? |

DO use shielded wire for the coil drive wiring.

Those wires do carry fast rise-time, high-voltage signals

and MIGHT pose a risk of electro-static coupling to

other wires in the airplane especially given the long

runs you're proposing. Klaus has claimed that

the superior high-frequency qualities of coaxial

cable are a benefit to performance of his system

but the physics do not support this notion. Ever

notice that you don't find shielded wires on any

cars/trucks?

That being said, there's nothing BAD about

substituting more generic shielded wire as

I've suggested but, you're still have to

wrestle with terminating your coil drive wires

onto UG88 coax connectors to mate with the

LSE coil output connectors. Using RG58 or

UG400 reduces the risk for installer-generated

difficulties for mating generic shielded wire

with the UG-88 connectors.

I think I'd opt for RG58 coax . . . given

your long wire runs, RG400 is pretty pricey

and adds no performance value to this

installation.

| Quote: | his application is for a 4-cylinder Lycoming, with the Dual LightSpeed boxes located behind the firewall, in fact behind the seats (2-seat airplane) under the baggage compartment.

The 4 coils will be on the engine or engine mount - a considerable distance (appx. 12 ft)� from the 2 magic boxes. |

Why so far away?

| Quote: | My takeaway from your previous postings is that with the LightSpeed Ignition System, there is no need for shielded wire anywhere in the installation.

Please correct me if I have this wrong. |

WHOA! The ONLY place I've suggested shielding to

be unnecessary is the power supply feeder. If

that were my product, I would have strived to

wire all the signal wires with twisted, unshielded

pairs to trios . . . which is entirely possible

to do. But without specific knowledge of the

input circuitry of this product, I have no

basis for arguing with the manufacturer's

installation instructions as published.

| Quote: | | I am sending this to you rather than using the list to avoid any heartburn with Klaus. |

If he's got any heartburn about this, he's most

welcome to join the conversation and defend

his position with an exchange of ideas supported

with physics and demonstrable practice.

Look my friend, if you're feeling risk of alienating

the good intentions of anyone you depend on, then

you will not be disappointed by installing

the LightSpeed system EXACTLY per manufacture's

instructions.

Certainly far more systems are successfully flying

'per instructions' than 'per AeroElectric'. I

would hope this forum is about making practical

decisions that go to reduced cost, simpler

installation/maintenance without compromising

performance. LightSpeed systems obviously perform

as advertised . . . similarly, there have been

no discussions here on the list for FAILURE to

meet expectations in LightSpeed systems installed

with more attention to convenience, legacy practice

and physics for now over 20 years.

Were I tasked with integrating the LightSpeed

hardware into a TC aircraft, then serious dialog

between LightSpeed and my employer would be dealing

with these same details. I would not be able to

'sell' the as-published power wiring to the cadre'

of airplane-police I answered to.

Bob . . .

� ////

� (o o)

===========o00o=(_)=o00o=========

< Go ahead, make my day . . . >

< show me where I'm wrong. >

=================================

In the interest of creative evolution

of the-best-we-know-how-to-do based

on physics and good practice.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

216.05 KB |

| Viewed: |

880 Time(s) |

|

|

|