|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

Area-51

Joined: 03 May 2021

Posts: 396

|

Posted: Mon Aug 14, 2023 2:23 am Post subject: Rotax Piston Stop Tool Posted: Mon Aug 14, 2023 2:23 am Post subject: Rotax Piston Stop Tool |

|

|

Does anyone know what position of the stroke this tool stops the piston, or have the dimensions of this item used for checking crankshaft distortion on 9XX series engines?

Thanks

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

europabill

Joined: 11 Nov 2021

Posts: 4

Location: Loganville, Georgia USA

|

Posted: Mon Aug 14, 2023 3:48 am Post subject: Re: Rotax Piston Stop Tool Posted: Mon Aug 14, 2023 3:48 am Post subject: Re: Rotax Piston Stop Tool |

|

|

Download a copy of the Rotax Heavy Maintenance manual. There are instructions on how to check for crankshaft distortion, runout, etc. I ended up making my own tools to check as Rotax wants a fortune for their tools.

Bill

A010

Europa Monowheel Classic

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Area-51

Joined: 03 May 2021

Posts: 396

|

Posted: Mon Aug 14, 2023 5:00 am Post subject: Re: Rotax Piston Stop Tool Posted: Mon Aug 14, 2023 5:00 am Post subject: Re: Rotax Piston Stop Tool |

|

|

Thanks for the input, but that was not relevant to the question.

The HMM procedure and data has already been reviewed.

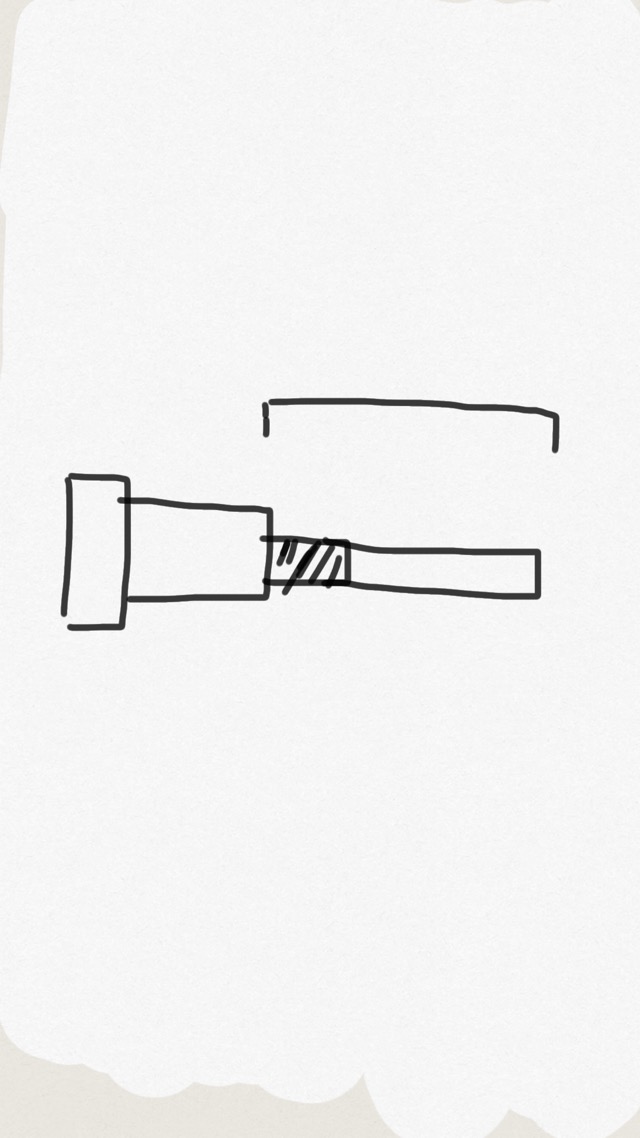

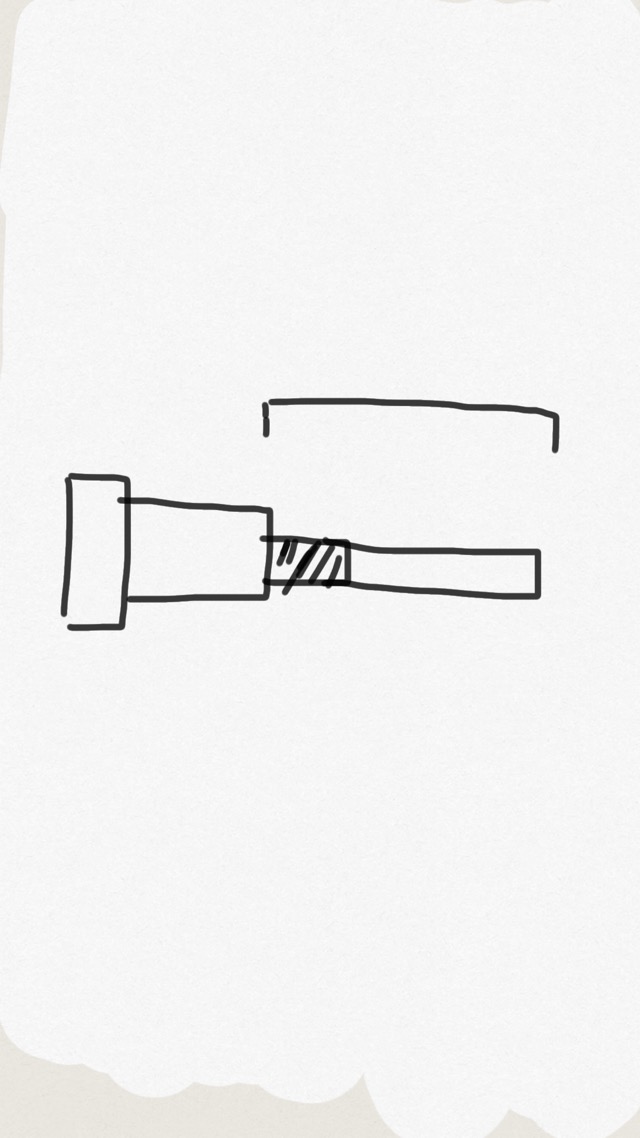

Need to fashion a piston stop; assuming it measures at 1/2 stroke position. Can anybody confirm this?

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

240.23 KB |

| Viewed: |

3432 Time(s) |

|

|

|

| Back to top |

|

|

h&jeuropa

Joined: 07 Nov 2006

Posts: 645

|

Posted: Mon Aug 14, 2023 7:38 am Post subject: Re: Rotax Piston Stop Tool Posted: Mon Aug 14, 2023 7:38 am Post subject: Re: Rotax Piston Stop Tool |

|

|

The piston stop measures from the bottom of the threads .9 cm dia and 4.86 cm long.

Jim & Heather

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Area-51

Joined: 03 May 2021

Posts: 396

|

Posted: Mon Aug 14, 2023 2:57 pm Post subject: Re: Rotax Piston Stop Tool Posted: Mon Aug 14, 2023 2:57 pm Post subject: Re: Rotax Piston Stop Tool |

|

|

Thanks Jim; greatly appreciated.

Can you tell me the length from the shoulder that butts up against the cylinder head when screwed in... or is that what you mean by "bottom of the threads"? thanks

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

86.3 KB |

| Viewed: |

3401 Time(s) |

|

|

|

| Back to top |

|

|

h&jeuropa

Joined: 07 Nov 2006

Posts: 645

|

Posted: Mon Aug 14, 2023 5:22 pm Post subject: Re: Rotax Piston Stop Tool Posted: Mon Aug 14, 2023 5:22 pm Post subject: Re: Rotax Piston Stop Tool |

|

|

The dimension you’re asking for with your sketch is 5.75 cm.

Jim

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Area-51

Joined: 03 May 2021

Posts: 396

|

Posted: Mon Aug 14, 2023 10:52 pm Post subject: Re: Rotax Piston Stop Tool Posted: Mon Aug 14, 2023 10:52 pm Post subject: Re: Rotax Piston Stop Tool |

|

|

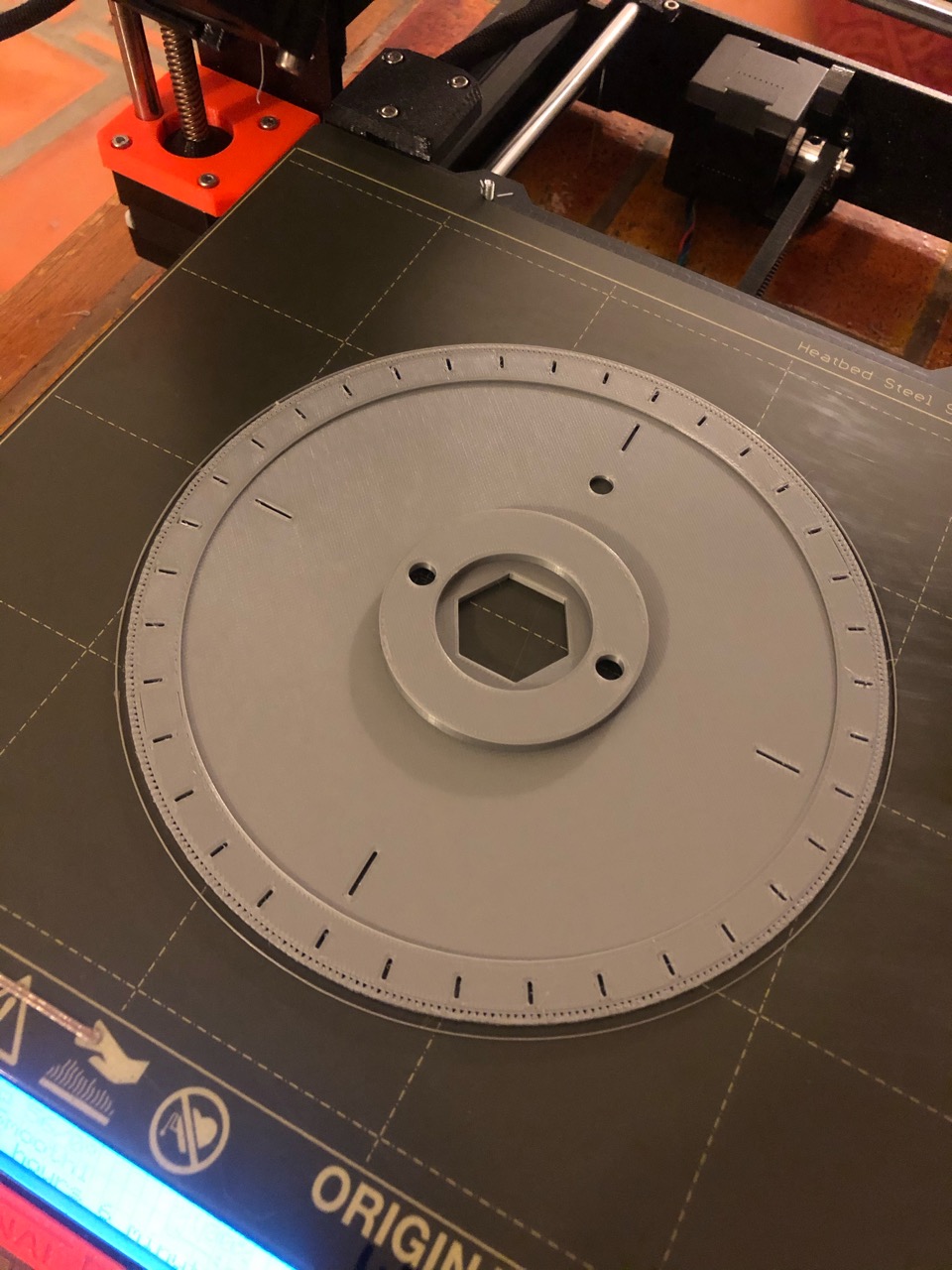

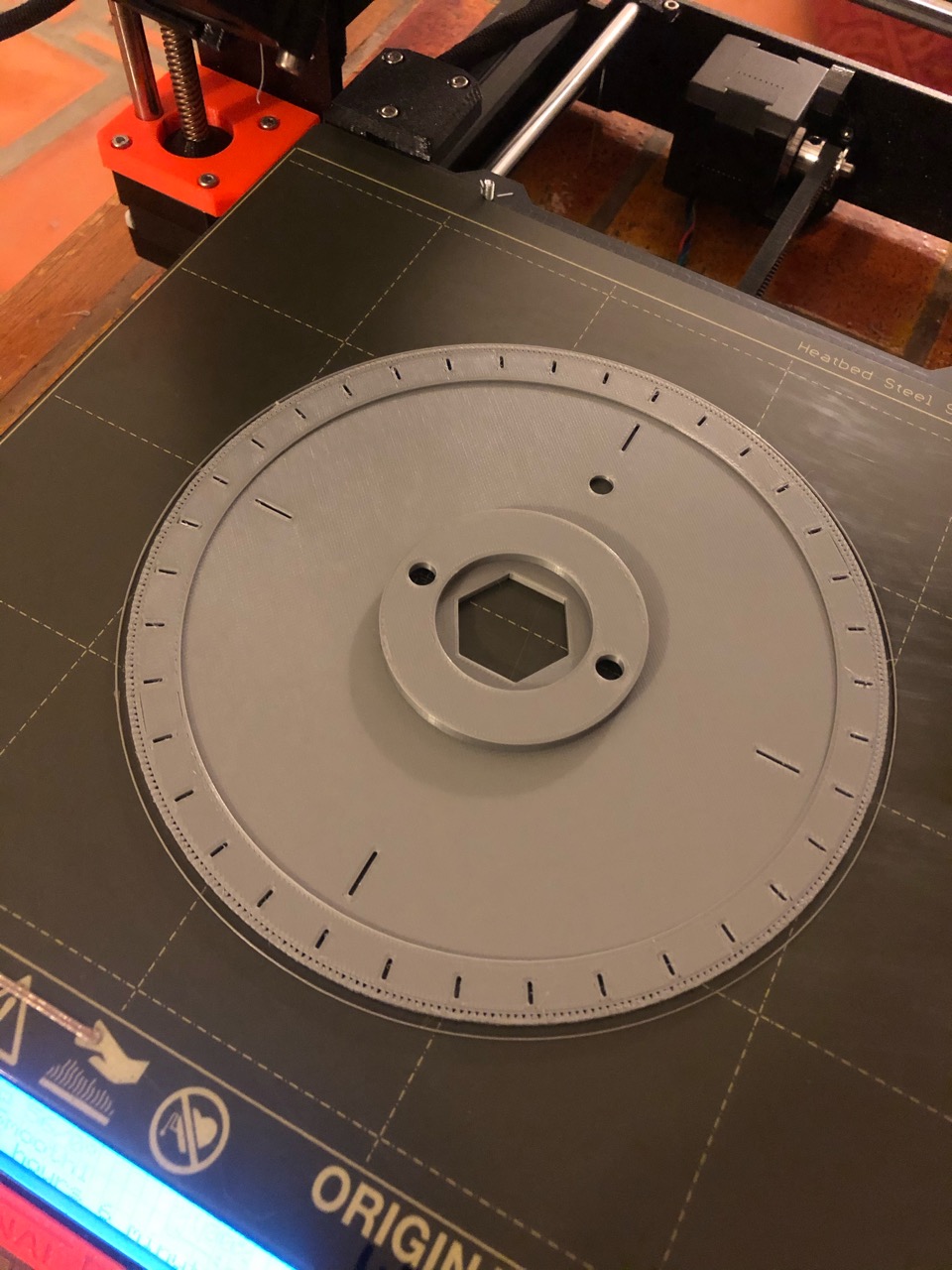

Thanks again Jim.

Made the tool twice. First pin was too short but can use it on something else.

Crank measured up 100% in alignment 0,0,0,0.

Used dial gauge to identify TDC; can use a machine feature of the dynamo bell and top water pump bolt as a position marker.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

| The unique machine feature of the dynamo bell lining up with top M6 water pump cap screw marking TDC |

|

| Filesize: |

131.17 KB |

| Viewed: |

3373 Time(s) |

|

| Description: |

| Piston Stop Crank Alignment Tool |

|

| Filesize: |

268.67 KB |

| Viewed: |

3373 Time(s) |

|

|

|

| Back to top |

|

|

Area-51

Joined: 03 May 2021

Posts: 396

|

Posted: Thu Aug 17, 2023 1:28 pm Post subject: Re: Rotax Piston Stop Tool Posted: Thu Aug 17, 2023 1:28 pm Post subject: Re: Rotax Piston Stop Tool |

|

|

The piston stop tool worked great; thanks Jim! The tool was made from a new spark plug turned down in a lathe, the porcelain core was knocked out and an M8 tap chased through. The pin was an M8 cap screw that had its thread chased all the way to the head and the the other side turned into a ball end with a locking nut added to finish it off; all worked perfectly.

Checking the crankshaft phase was relatively easy with the timing wheel located on the back of the crankshaft. Removal of the black plastic dynamo cover was required first, and the timing wheel just pushed tightly onto the 23mm bolt head.

Piston position that the piston stop affects is 65deg BTDC; which will likely be the fastest sector of piston stroke. So any deviation in crankshaft phasing will show up the most here.

My previous reference to the unique TDC timing mark is a bit dumb. Rotax supply a pin that locks the crank at that position if ever required. So finding TDC with the dial gauge was a total waste of time. I do stupid things sometimes; the race tech is still too ingrained. Oh well 🤷🏼♂️🤦🏻♂️

It was a good exercise to go through all the same. In the end the crankshaft returned 0,0,0,0. And after being informed yesterday that the engine was sent back to the factory for a bulk strip following the prop strike in 2003 it explained things and the whole session is being written off to an educational experience. 🙂🙉

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|