|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

Scooter

Joined: 10 Jan 2006

Posts: 155

|

Posted: Sun Sep 03, 2006 3:26 pm Post subject: Prop seal replacement and subsequent vibration Posted: Sun Sep 03, 2006 3:26 pm Post subject: Prop seal replacement and subsequent vibration |

|

|

Okay. Thought i was doing something simple but apparently not so.

I replaced the two seals in the prop "piston" and now have some substantial vibration. Here's the scenario:

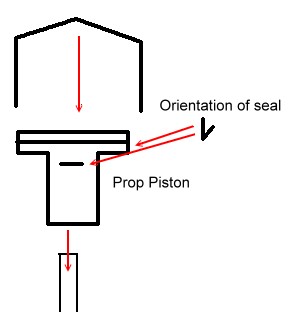

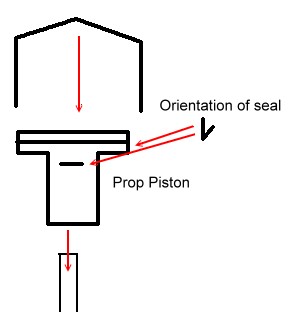

1. Replaced two seals in piston (see diagram for orientation of the v-shape of the seals). Note: I did not disassemble the blades or change blade angle in any way.

2. Ran the engine and noticed prop vibration.

3. Disassembled prop piston and found oil in the hub. The seals looked fine so I assumed a pinched seal or I dumped it in when i pulled the piston off?

4. Reassembled, ran engine and same vibration.

5. Disassembled prop piston and found no oil in hub.

6. Reassembled, ran engine and same vibration.

The vibration is minimal from 35 to 45%, peaks at 50% and subsides up to 60 and 70%. Mag drops are normal and prop cycles normally at 70%. The vibration at 50% is significant - definately not healthy for any period.

On disassembly there appears to be roughly 16 fluid ounces of oil in the prop piston but, again, none in the hub.

Any ideas? This one has me baffled.

Thanks!

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

| Description: |

|

| Filesize: |

8.77 KB |

| Viewed: |

8379 Time(s) |

|

|

|

| Back to top |

|

|

cjpilot710(at)aol.com

Guest

|

Posted: Mon Sep 04, 2006 4:23 am Post subject: Prop seal replacement and subsequent vibration Posted: Mon Sep 04, 2006 4:23 am Post subject: Prop seal replacement and subsequent vibration |

|

|

Scooter,

First - Is this an M-14 or HS-6?

Second - Are you sure this vibration was not in the engine before? You may be noticing it now that you're 'sensitive' to the fact that you've worked on worked on it for the first time.

If its an M-14 did you leave the prop level while working on it. Moisture in the wood blades can 'flow' to the tip of one blade and the hub of the other, if left vertical. Maybe this is the vibration you feel.

If there is no oil in the hub than its fairly assured that the seals are working as they should.

If this is M-14 check that all the prop bolts on the prop flange are there - tight and secured.

Also check to see if you may have inadvertently removed any balance weights.

This will be interesting. Good luck

Jim "Pappy" Goolsby

--> Yak-List message posted by: "Scooter" <yakk52(at)verizon.net>

Okay. Thought i was doing something simple but apparently not so.

I replaced the two seals in the prop "piston" and now have some substantial vibration. Here's the scenario:

1. Replaced two seals in piston (see diagram for orientation of the v-shape of the seals). Note: I did not disassemble the blades or change blade angle in any way.

2. Ran the engine and noticed prop vibration.

3. Disassembled prop piston and found oil in the hub. The seals looked fine so I assumed a pinched seal or I dumped it in when i pulled the piston off?

4. Reassembled, ran engine and same vibration.

5. Disassembled prop piston and found no oil in hub.

6. Reassembled, ran engine and same vibration.

The vibration is minimal from 35 to 45%, peaks at 50% and subsides up to 60 and 70%. Mag drops are normal and prop cycles normally at 70%. The vibration at 50% is significant - definately not healthy for any period.

On disassembly there appears to be roughly 16 fluid ounces of oil in the prop piston but, again, none in the hub.

Any ideas? This one has me baffled.

Thanks!

[quote][b]

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

Scooter

Joined: 10 Jan 2006

Posts: 155

|

Posted: Mon Sep 04, 2006 4:39 am Post subject: Re: Prop seal replacement and subsequent vibration Posted: Mon Sep 04, 2006 4:39 am Post subject: Re: Prop seal replacement and subsequent vibration |

|

|

I don't have a good feeling about this (it's been a long night). It is an M-14p. The vibration at 50% is significant - I definately would have noticed before. I can't imagine that I inadvertantly removed anything since the job was so simple (cotter-pin, nut, safety wire, screw).

Unfortunately I'm starting to think worst case. I am religious about pulling the prop through and I did this prior to starting (with the intake drain open). The engine hadn't been run in a week and the drain was left open over that week. I used four shots of primer but i'm a little fuzzy on whether i pulled the prop through after that. Could this have caused a hydraulic lock and bent rod? How do I go about checking this or what do I tell the local A&P to check?

Thanks.

[quote="cjpilot710(at)aol.com"]Scooter,

First - Is this an M-14 or HS-6?

Second - Are you sure this vibration was not in the engine before? You may be noticing it now that you're 'sensitive' to the fact that you've worked on worked on it for the first time.

If its an M-14 did you leave the prop level while working on it. Moisture in the wood blades can 'flow' to the tip of one blade and the hub of the other, if left vertical.? Maybe this is the vibration you feel.

If there is no oil in the hub than its fairly assured that the seals are working as they should.

If this is M-14 check that all the prop bolts on the prop flange are there - tight and secured.

Also check to see if you may have inadvertently removed any balance weights.

This will be interesting. Good luck

Jim "Pappy" Goolsby

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

dsavarese(at)elmore.rr.co

Guest

|

Posted: Mon Sep 04, 2006 6:53 am Post subject: Prop seal replacement and subsequent vibration Posted: Mon Sep 04, 2006 6:53 am Post subject: Prop seal replacement and subsequent vibration |

|

|

Scooter,

Since you say the vibration started after you removed and replaced the seals

in the dome and piston and you said you did nothing else, the only other

possibility which is rather remote is to remove the dome and rotate it 90

degrees and see if that changes anything. I doubt it will, but it won't

hurt to try.

Check to see if you have any "slop" in the counter weight arms. That is,

try moving one side and see if there is any play. Now try the other

counterweight. You may just have a worn hub. BTW, did you try moving the

counterweights fore and aft when you had the dome and piston removed. They

should move with some reasonable restriction. Most importantly, they should

move and you should be able to push/pull on one counterweight and be able to

move both blades.

It is not logical that you have had a hydraulic lock that is causing the

vibration. I have seen several Yak 52's that have the vibration somewhere

between 47% to 53%. As an experiment, try putting a wrap of duct tape on

one of the blades about 1-2" in from the tip. Run the engine and see if it

gets worse or better. If better, add another wrap of duct tape. If worse,

try the same thing on the other blade. Once you determine which blade needs

the weight, you can add weights to that side of the hub or if it requires

very little weight, you can use spray paint on the back side of the blade to

balance the blade.

Make sure all the parts labeled "1" and "2" are all on the same side of the

hub. That includes the blades which have a "1" or "2" stamped in the metal

blade shanks. Even the small locking plates on each side of the front of

the hub are labeled "1" and "2". If you removed the blades by unscrewing

just the blades from the hub, use a digital level or protractor to reset the

blade angles. This is not the same as removing the large castellated nuts

to access the bearings and races.

Finally, find someone to dynamically balance the prop.

Dennis

---

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

viperdoc(at)mindspring.co

Guest

|

Posted: Mon Sep 04, 2006 11:47 am Post subject: Prop seal replacement and subsequent vibration Posted: Mon Sep 04, 2006 11:47 am Post subject: Prop seal replacement and subsequent vibration |

|

|

Scooter,

Talk to Shane Golden about this. He had a similar problem after servicing

his prop (changing the seals, repacking the races and bearings).

Even though you did not pull the blades, are the slides still engaged with

the hub of the blade. If I remember correctly, they allow the coordinated

change in the pitch of the two prop blades. Sorry I do not have 52

Maintenance manual at hand to give the exact part names. I will dig it out

when I go up to the hanger today and correct my errors above.

Doc

| Quote: | [Original Message]

From: Scooter <yakk52(at)verizon.net>

To: <yak-list(at)matronics.com>

Date: 9/3/2006 6:40:29 PM

Subject: Prop seal replacement and subsequent vibration

Okay. Thought i was doing something simple but apparently not so.

I replaced the two seals in the prop "piston" and now have some

substantial vibration. Here's the scenario:

|

| Quote: |

1. Replaced two seals in piston (see diagram for orientation of the

v-shape of the seals). Note: I did not disassemble the blades or change

|

blade angle in any way.

| Quote: | 2. Ran the engine and noticed prop vibration.

3. Disassembled prop piston and found oil in the hub. The seals looked

fine so I assumed a pinched seal or I dumped it in when i pulled the piston

|

off?

| Quote: | 4. Reassembled, ran engine and same vibration.

5. Disassembled prop piston and found no oil in hub.

6. Reassembled, ran engine and same vibration.

The vibration is minimal from 35 to 45%, peaks at 50% and subsides up to

60 and 70%. Mag drops are normal and prop cycles normally at 70%. The

|

vibration at 50% is significant - definately not healthy for any period.

| Quote: |

On disassembly there appears to be roughly 16 fluid ounces of oil in the

prop piston but, again, none in the hub.

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

Scooter

Joined: 10 Jan 2006

Posts: 155

|

Posted: Mon Sep 04, 2006 2:03 pm Post subject: Re: Prop seal replacement and subsequent vibration Posted: Mon Sep 04, 2006 2:03 pm Post subject: Re: Prop seal replacement and subsequent vibration |

|

|

Thanks. I'm beginning to think that the vibration problem is coincidental to the seal replacement. The blade angle can be changed by pulling on the counterweights - the blades move together and I didn't detect any slop. The prop doesn't have any knicks or missing hardware. If I run it up to 70% and cycle the prop it goes between 70% and 50% (pretty much like it always has).

The vibration is pretty significant. It's hard to quantify but it bounces me around pretty good. I took the piston out yet again today (5th time?) and didn't find any oil in the hub.

I spoke with a mechanic at the airport who is leaning towards a stuck valve. He's going to do a compression test on wednesday. A stuck valve sounds better than a bent rod...

| dsavarese(at)elmore.rr.co wrote: | Scooter,

Since you say the vibration started after you removed and replaced the seals

in the dome and piston and you said you did nothing else, the only other

--- |

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

JOE HOWSE

Joined: 10 Jan 2006

Posts: 140

Location: DUNCAN BC CANADA

|

Posted: Mon Sep 04, 2006 2:35 pm Post subject: Prop seal replacement and subsequent vibration Posted: Mon Sep 04, 2006 2:35 pm Post subject: Prop seal replacement and subsequent vibration |

|

|

Sounds like an engine problem,

Try changing the mag coil which also incorporates the condenser.

Joe

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

_________________

J.C. HOWSE |

|

| Back to top |

|

|

viperdoc(at)mindspring.co

Guest

|

Posted: Mon Sep 04, 2006 3:27 pm Post subject: Prop seal replacement and subsequent vibration Posted: Mon Sep 04, 2006 3:27 pm Post subject: Prop seal replacement and subsequent vibration |

|

|

Scooter,

Did you not say the mag check did not change the engine vibrations?

Viperdoc

| Quote: | [Original Message]

From: JOE HOWSE <joeh(at)shaw.ca>

To: <yak-list(at)matronics.com>

Date: 9/4/2006 5:47:00 PM

Subject: Re: Re: Prop seal replacement and subsequent vibration

Sounds like an engine problem,

Try changing the mag coil which also incorporates the condenser.

Joe

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

dsavarese(at)elmore.rr.co

Guest

|

Posted: Mon Sep 04, 2006 3:33 pm Post subject: Prop seal replacement and subsequent vibration Posted: Mon Sep 04, 2006 3:33 pm Post subject: Prop seal replacement and subsequent vibration |

|

|

Stuck valve? hummmmm..... I seriously doubt a stuck valve is going to

work properly at 60% and above and not work properly at only 50%.

No oil in the hub means you installed the inner seal correctly. And outer

seal improperly installed will cause the worst oil leak you ever saw when

you run the engine. When you remove the dome and piston, separate the

piston from the dome. Then dump out all the oil from the dome. Now insert

the piston only back on the oil tube and look at the gaps on the top,

bottom, left and right. They should all be pretty close to the same. If

the gaps are way off, the oil tube is bent and should be replaced. You'll

have to remove the prop to remove the oil tube unless you have a VERY deep

well socket.

With oil in the hub dome and piston, is there any play in the counterweight

movement. There shouldn't be any play. If there is, the hub may need to be

overhauled.

Try the duck tape tests I mentioned earlier.

Dennis

---

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

dsavarese(at)elmore.rr.co

Guest

|

Posted: Mon Sep 04, 2006 3:38 pm Post subject: Prop seal replacement and subsequent vibration Posted: Mon Sep 04, 2006 3:38 pm Post subject: Prop seal replacement and subsequent vibration |

|

|

If it's a mag coil problem, it can be eliminated from the ground tests by

turning off one or the other mag. If it doesn't go away, it isn't mag

related. Mag coils either work or they don't work. They typically don't

exhibit a failure at 50% rpm and then work well at 60% and above. When a

coil fails the symptom is a complete engine shutdown for a split second.

Everyone that has experience a coil failure knows precisely what I'm talking

about. Right Doc?

Dennis

---

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

Scooter

Joined: 10 Jan 2006

Posts: 155

|

Posted: Mon Sep 04, 2006 4:08 pm Post subject: Re: Prop seal replacement and subsequent vibration Posted: Mon Sep 04, 2006 4:08 pm Post subject: Re: Prop seal replacement and subsequent vibration |

|

|

Actually the vibration peaks at 50%. It is present from idle to 70% (I haven't pushed it any higher). It ramps up from idle to 50% then ramps down. It's difficult to quantify exactly.

Mag drops at 70% were normal.

I'll try those tests. Any other advice will be greatly appreciated. Keep in mind that everything was absolutely normal prior to removing the dome and piston.

Thanks.

| dsavarese(at)elmore.rr.co wrote: | Stuck valve? hummmmm..... I seriously doubt a stuck valve is going to

work properly at 60% and above and not work properly at only 50%.

No oil in the hub means you installed the inner seal correctly. And outer

seal improperly installed will cause the worst oil leak you ever saw when

you run the engine. When you remove the dome and piston, separate the

piston from the dome. Then dump out all the oil from the dome. Now insert

the piston only back on the oil tube and look at the gaps on the top,

bottom, left and right. They should all be pretty close to the same. If

the gaps are way off, the oil tube is bent and should be replaced. You'll

have to remove the prop to remove the oil tube unless you have a VERY deep

well socket.

With oil in the hub dome and piston, is there any play in the counterweight

movement. There shouldn't be any play. If there is, the hub may need to be

overhauled.

Try the duck tape tests I mentioned earlier.

Dennis

--- |

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

viperdoc(at)mindspring.co

Guest

|

Posted: Mon Sep 04, 2006 4:08 pm Post subject: Prop seal replacement and subsequent vibration Posted: Mon Sep 04, 2006 4:08 pm Post subject: Prop seal replacement and subsequent vibration |

|

|

Scooter,

Wth the radial you may never feel a struck or burned valve. Been there, got

the T shirt. Did not even feel the dead cylinder (#4, home of the master

rod). Definately felt the dead mag but certainly not to the point of

causing violent airframe vibration. It was just miss firing a bunch.

Definately felt the bad coil when the engine misfired (backfired) causing a

heartbeat engine shutdown. These engines do not act like flat ones when

they have a stuck valve. Where as the flat engine will either completely

shutdown or vibrate your eye teeth out, the radial does not generally do

that. To date with my limited experience, seems that each of the engines

that I know of that had a connecting rod failure sucked a piston into the

nosecase, sheared the prop shaft and ended up with a freewheeling prop.

They did it pretty much without much warning.

Are you seeing a chip detector light? Granted it only sees the chunks of

metal not the fine shavings. .

You are correct to do a compression check. That will tell you if you have a

cylinder related problem. When you pull the prop thru, is it free moving

with the normal resistance on pull through with the plugs in? Do you hear a

hissing in the exhaust stacks when you are pulling through compression

strokes? Is it harder to pull through than normal? With all the plugs

pulled for the compression test, pull the blades all the way thru for a

minimum of 8 blades, do you feel resistance to the free movement of the

prop? If so, then there is problem with the connecting rods or the pleniary

gears. Just a theory on my part though.

This was not happening prior to you pulling the piston out of your prop to

change the seals? No missing bolts from the prop hub? Still sounds like a

prop issue but as I said above, I can be wrong.

Dennis Savarese, Doug Sapp, Steve Culp, Carl Hayes, or George Coy are a lot

smarter than me on this one. Need to keep picking their brains. Will be

interested to hear what you find.

Viperdoc

| Quote: | [Original Message]

From: Scooter <yakk52(at)verizon.net>

To: <yak-list(at)matronics.com>

Date: 9/4/2006 5:17:45 PM

Subject: Re: Prop seal replacement and subsequent vibration

Thanks. I'm beginning to think that the vibration problem is

coincidental to the seal replacement. The blade angle can be changed by

|

pulling on the counterweights - the blades move together and I didn't

detect any slop. The prop doesn't have any knicks or missing hardware. If

I run it up to 70% and cycle the prop it goes between 70% and 50% (pretty

much like it always has).

| Quote: |

The vibration is pretty significant. It's hard to quantify but it

bounces me around pretty good. I took the piston out yet again today (5th

|

time?) and didn't find any oil in the hub.

| Quote: |

I spoke with a mechanic at the airport who is leaning towards a stuck

valve. He's going to do a compression test on wednesday. A stuck valve

|

sounds better than a bent rod...

| Quote: |

dsavarese(at)elmore.rr.co wrote:

> Scooter,

> Since you say the vibration started after you removed and replaced the

seals

|

| Quote: | > in the dome and piston and you said you did nothing else, the only

other

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

JOE HOWSE

Joined: 10 Jan 2006

Posts: 140

Location: DUNCAN BC CANADA

|

Posted: Mon Sep 04, 2006 4:16 pm Post subject: Prop seal replacement and subsequent vibration Posted: Mon Sep 04, 2006 4:16 pm Post subject: Prop seal replacement and subsequent vibration |

|

|

Dennis

Not so, the condenser part of the coil can exhibit a similar problem , I

have experienced it twice, also found this problem on Hal's airplane years

ago.

Cured by changing coils

You are correct with american mag coils that have a seperate condenser.

Joe

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

_________________

J.C. HOWSE |

|

| Back to top |

|

|

viperdoc(at)mindspring.co

Guest

|

Posted: Mon Sep 04, 2006 4:16 pm Post subject: Prop seal replacement and subsequent vibration Posted: Mon Sep 04, 2006 4:16 pm Post subject: Prop seal replacement and subsequent vibration |

|

|

YOU BET! Been there more than once and have a T shirt to prove it. It is a

heart stopping shutdown followed by it running like nothing happened for

about another 15 minutes then it starts again! Guarenteed you will suck the

seat pack halfway up your backside!

Doc

| Quote: | [Original Message]

From: A. Dennis Savarese <dsavarese(at)elmore.rr.com>

To: <yak-list(at)matronics.com>

Date: 9/4/2006 6:46:01 PM

Subject: Re: Re: Prop seal replacement and subsequent vibration

<dsavarese(at)elmore.rr.com>

|

| Quote: |

If it's a mag coil problem, it can be eliminated from the ground tests by

turning off one or the other mag. If it doesn't go away, it isn't mag

related. Mag coils either work or they don't work. They typically don't

exhibit a failure at 50% rpm and then work well at 60% and above. When a

coil fails the symptom is a complete engine shutdown for a split second.

Everyone that has experience a coil failure knows precisely what I'm

talking

|

[quote] about. Right Doc?

Dennis

---

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

mark.bitterlich(at)navy.m

Guest

|

Posted: Tue Sep 05, 2006 12:16 pm Post subject: Prop seal replacement and subsequent vibration Posted: Tue Sep 05, 2006 12:16 pm Post subject: Prop seal replacement and subsequent vibration |

|

|

Not to disagree with anyone's suggestions (all good), but the first

thing I would do would be to either purchase or borrow an Infra Red

Temperature gun.... Run the engine for awhile and then go shoot each

cylinder and check for close to the same readings on each one. It might

be something so simple as a dead cylinder. Compression checks to

follow.

Or ... Do the following first:

Take a REALLY close look at your intake drain system. A lot of these

systems were installed with #4 AN fittings and soft aluminum lines.

Over time theses things are prone to crack and break, leaving you with a

rather large leak in the intake system, which makes the engine run rough

just as you have described. The best solution here of course is to use

flexible steel braided lines. I've seen this one nail four people so

far... Me being one of them of course.

Best of luck,

Mark Bitterlich

N50YK

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

mark.bitterlich(at)navy.m

Guest

|

Posted: Tue Sep 05, 2006 12:37 pm Post subject: Prop seal replacement and subsequent vibration Posted: Tue Sep 05, 2006 12:37 pm Post subject: Prop seal replacement and subsequent vibration |

|

|

But with all that said, my money is "the bent oil tube" suggestion.

Mark

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

viperdoc(at)mindspring.co

Guest

|

Posted: Tue Sep 05, 2006 4:46 pm Post subject: Prop seal replacement and subsequent vibration Posted: Tue Sep 05, 2006 4:46 pm Post subject: Prop seal replacement and subsequent vibration |

|

|

Mark,

I have left my intake drain open a couple of times. I did notice it

misssing but not a violent vibration. If that is what Scooter was trying to

relate.

Doc

| Quote: | [Original Message]

From: Bitterlich, Mark G CIV Det Cherry Point, MALS-14 64E

<mark.bitterlich(at)navy.mil>

|

| Quote: | To: <yak-list(at)matronics.com>

Date: 9/5/2006 3:31:20 PM

Subject: RE: Re: Prop seal replacement and subsequent vibration

MALS-14 64E" <mark.bitterlich(at)navy.mil>

|

| Quote: |

Not to disagree with anyone's suggestions (all good), but the first

thing I would do would be to either purchase or borrow an Infra Red

Temperature gun.... Run the engine for awhile and then go shoot each

cylinder and check for close to the same readings on each one. It might

be something so simple as a dead cylinder. Compression checks to

follow.

Or ... Do the following first:

Take a REALLY close look at your intake drain system. A lot of these

systems were installed with #4 AN fittings and soft aluminum lines.

Over time theses things are prone to crack and break, leaving you with a

rather large leak in the intake system, which makes the engine run rough

just as you have described. The best solution here of course is to use

flexible steel braided lines. I've seen this one nail four people so

far... Me being one of them of course.

Best of luck,

Mark Bitterlich

N50YK

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

Scooter

Joined: 10 Jan 2006

Posts: 155

|

Posted: Tue Sep 05, 2006 5:07 pm Post subject: Re: Prop seal replacement and subsequent vibration Posted: Tue Sep 05, 2006 5:07 pm Post subject: Re: Prop seal replacement and subsequent vibration |

|

|

Thanks for all the suggestions. I think I've checked just about everything mentioned. I ran it again today and I can quantify the vibration a bit better. It seems to have several resonant frequencies. At 44% the instrument panel shakes to a blur. At 50% the pilot shakes (and everything blurs). It is substantial.

I am again thinking it must be the prop. I pulled all the plugs, cleaned them and did a "finger" check on compression. Seemed fine (nothing stuck open).

At this point I'm thinking the next step is to make a jumbo prop wrench, take the blades off, clean out the oil, grease, etc. and replace the seals while i'm at it.

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

cjpilot710(at)aol.com

Guest

|

Posted: Tue Sep 05, 2006 6:45 pm Post subject: Prop seal replacement and subsequent vibration Posted: Tue Sep 05, 2006 6:45 pm Post subject: Prop seal replacement and subsequent vibration |

|

|

Have you check to make sure your primer is closed and locked? Also at least a Chinese primer, once had a broken spring in the bottom which allowed it to stay open.

The primer line goes into the case right near #9 cylinders. It will flood out that cylinder. Vibration can be quite as you describe.

Jim "Pappy" Goolsby

[quote][b]

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

dsavarese(at)elmore.rr.co

Guest

|

Posted: Wed Sep 06, 2006 3:42 am Post subject: Prop seal replacement and subsequent vibration Posted: Wed Sep 06, 2006 3:42 am Post subject: Prop seal replacement and subsequent vibration |

|

|

Scooter,

Why don't you try the simple test I mentioned yesterday? Put a wrap of duct

tape on one of the blades about 2" in from the tip and run the engine. If

it improves, you've got the right blade. If it gets worse, remove the tape

on that blade and put a wrap on the other blade and run it. Regardless of

which blade it is, add a wrap at a time until the vibration becomes

acceptable. You can add spray paint to the back side of the blade once you

find out which blade needs additional weight. Somewhat crude, but it works

and it's a very simple test.

Dennis

---

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|