tonyrenshaw268(at)gmail.c

Guest

|

Posted: Mon Oct 28, 2013 1:59 pm Post subject: AN3 Nut Torque Values…….or any Torque Values depending on ty Posted: Mon Oct 28, 2013 1:59 pm Post subject: AN3 Nut Torque Values…….or any Torque Values depending on ty |

|

|

Gidday,

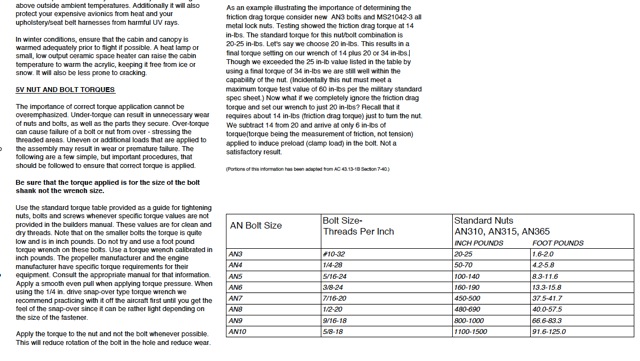

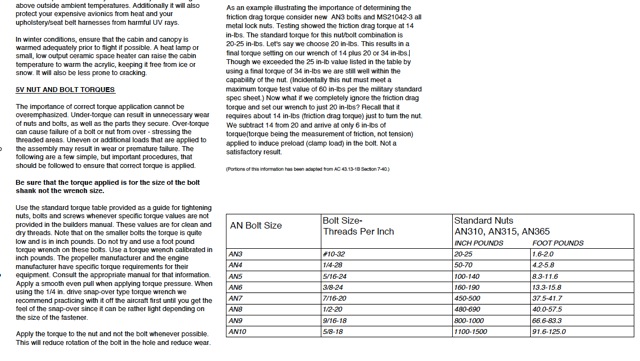

Yesterday I was tightening by hand one of the two AN3 bolts that clamp the flap cross tube to the articulating/hinge arms that are attached in the floor. So, in case there is the slightest movement and this would exacerbate in my flaps I decided to do them up "tight". Guess what, I snapped one, yep snapped. It broke at the top of the shank where the thread started, and did NOT strip the thread as many might have presumed. This got me thinking that normally most bolts are designed to effect a shear load, and not normally a clamping load. Anyway, I know there is counter arguments to all of this, but what matters is the applicable torque loads we use if we torque them using a wrench, and I just stumbled upon a reference I think is important. I found this on an VansForce website, and why it matters is the torque values are NOT for locknuts, which have an inherent friction drag torque value of 14 in-lbs. So, referring to the attached table an AN3 needs 20-25 in-lbw, but in actuality would be more like 34-39 in-lbs.

I think this could be easily overlooked, and if the friction drag torque of locknuts is not taken into account, people are under torquing their bolts.

Regards

Tony Renshaw

Sydney Aussie.

[img]cid:02FDA00C-82F0-44B0-8D91-DBF3B727A6A8(at)optusnet.com.au[/img]

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

94.29 KB |

| Viewed: |

667 Time(s) |

|

|

|