|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Feb 05, 2014 6:43 pm Post subject: Rotax crank failures Posted: Wed Feb 05, 2014 6:43 pm Post subject: Rotax crank failures |

|

|

| Quote: | | 6) The ability to use roller bearings. (I have no idea if they actually should or do). |

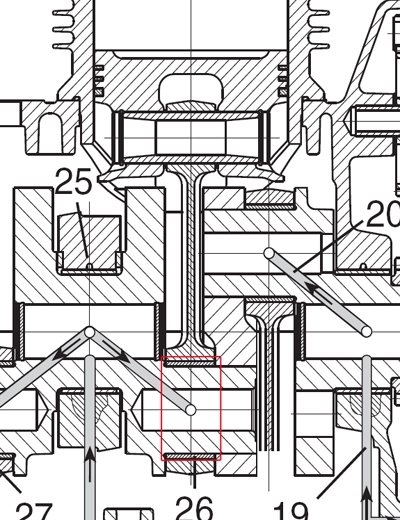

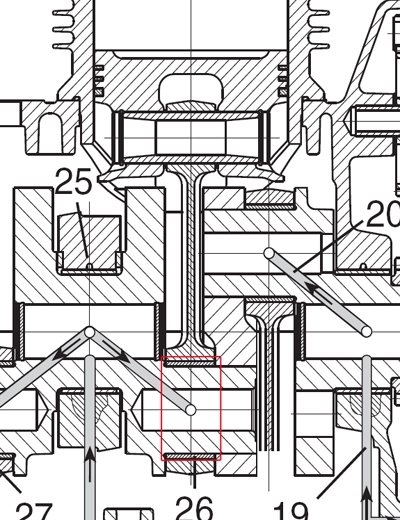

Interesting point to ponder . . . if they do use

roller bearings, then in no way will a loss of

lubrication put a destructive torque moment on

the crank end of the rod in a mere ten seconds

of running . . .

but no . . .

This excerpt from the 912/914 maintenance

manual . . .

http://tinyurl.com/mresg6r

suggests that the classic pressure

lubricated sleeve bearings are used on the

connecting rods.

[img]cid:.0[/img]

| Quote: | | As long as the rod and main bearings are good, the idea that the crank can come apart is simply a distraction. Porsche 4-cam racing engines used a similar design, although they keyed theirs. But Still... Your Mileage May Vary. |

. . . I've not heard of crank disassembly

in the field . . . those engines have been

around for a very long time. It's hard

to argue with success!

A short web-cruise did turn up this crank

failure accident

http://tinyurl.com/lzhk22s

which failed to identify any errors of manufacture.

The press-fit technology is not a high-risk

process. Interruption fits of highly stressed

parts has along history of success.

Also found an AD against a production batch

of Rotax 912 cranks for suspected vulnerability

to cracking.

All incidents of slipped assembly joints

I found were byproducts of prop strikes.

I think there's a slip clutch mod that

reduces probability of a prop-strike from

over-torque slipping of the joints.

All in all, a pretty clean track record.

do not archive.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

182.49 KB |

| Viewed: |

1278 Time(s) |

|

|

|

| Back to top |

|

|

tim2542(at)sbcglobal.net

Guest

|

Posted: Wed Feb 05, 2014 7:26 pm Post subject: Rotax crank failures Posted: Wed Feb 05, 2014 7:26 pm Post subject: Rotax crank failures |

|

|

From the pics on the Europa site posted earlier, it clear they uses one piece rods. Only way to do that is with roller bearings and a press assembled crank. The main bearings seen are typical automotive style Babbitt bearings.

Also the blueing on the rod beam shows the amount of heat generated when the failure occurred.

Tim

[quote] On Feb 5, 2014, at 6:41 PM, "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com> wrote:

> 6) The ability to use roller bearings. (I have no idea if they actually should or do).

Interesting point to ponder . . . if they do use

roller bearings, then in no way will a loss of

lubrication put a destructive torque moment on

the crank end of the rod in a mere ten seconds

of running . . .

but no . . .

This excerpt from the 912/914 maintenance

manual . . .

http://tinyurl.com/mresg6r

suggests that the classic pressure

lubricated sleeve bearings are used on the

connecting rods.

<34add2aa.jpg>

> As long as the rod and main bearings are good, the idea that the crank can come apart is simply a distraction. Porsche 4-cam racing engines used a similar design, although they keyed theirs. But Still... Your Mileage May Vary

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|