|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Feb 21, 2011 11:18 pm Post subject: DIY CBOVM: variations on a theme Posted: Mon Feb 21, 2011 11:18 pm Post subject: DIY CBOVM: variations on a theme |

|

|

| Quote: | I am still wondering if a zener diode could be used instead of the SBS. If not, it would be interesting to know what the disadvantages of the zener diode are, or if it would even work at all.

Thanks for any advice.

Joe |

Joe,

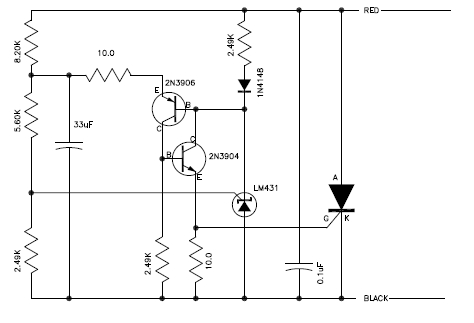

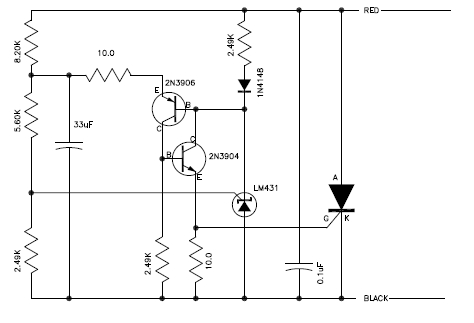

Feeling adventuresome? I pondered the idea

of exploiting the LM431's precise voltage set

point with a design goal of eliminating the

potentiometer and the post assembly calibration.

Here's what I came up with.

[img]cid:7.1.0.9.0.20110222010338.01f7bff8(at)aeroelectric.com.0[/img]

The parts count is unchanged but it should be

calibrated as soon as the last solder joint is

cool. Temperature stability should be as good

or better than any previous versions.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

37.72 KB |

| Viewed: |

9918 Time(s) |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1929

Location: Riley TWP Michigan

|

Posted: Tue Feb 22, 2011 9:58 am Post subject: Re: DIY CBOVM: variations on a theme Posted: Tue Feb 22, 2011 9:58 am Post subject: Re: DIY CBOVM: variations on a theme |

|

|

Thanks for that O.V. circuit using the LM431, Bob. I will add that IC to my next electronics parts order.

Joe

Do not archive

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1929

Location: Riley TWP Michigan

|

Posted: Mon Mar 24, 2014 10:41 am Post subject: Re: DIY CBOVM: variations on a theme Posted: Mon Mar 24, 2014 10:41 am Post subject: Re: DIY CBOVM: variations on a theme |

|

|

I built Bob's circuit. To test it, I wired it in series with an automotive lamp to a DC-DC converter like this one: http://tinyurl.com/kmpqcb8

I slowly turned the pot to increase the voltage. The lamp illuminated at almost 17 volts. Since my Rotax rectifier/regulator puts out about 13.8 volts, I decided to lower the set point of the over-voltage protector by substituting a 5.1K resistor for the 5.6K. Now the test lamp comes on at 16.2 volts. When the voltage increases above 15.8, the circuit becomes sensitive. Just touching the circuit with a digital voltmeter probe is enough to fire the SCR. Using a different voltmeter had the same affect. No doubt that in an electrically noisy environment like an airplane, the circuit will trip at 15.8 volts. That is not a problem though. 15.8 volts is 2 volts above my aircraft system voltage. If spring weather ever comes to Michigan, I will install it in the airplane.

Thanks for designing the circuit, Bob. You are my mentor.

Joe

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Mar 24, 2014 7:04 pm Post subject: DIY CBOVM: variations on a theme Posted: Mon Mar 24, 2014 7:04 pm Post subject: DIY CBOVM: variations on a theme |

|

|

At 01:41 PM 3/24/2014, you wrote:

I built Bob's circuit. To test it, I wired it in series with an

automotive lamp to a DC-DC converter like this one: http://tinyurl.com/kmpqcb8

I slowly turned the pot to increase the voltage. The lamp

illuminated at almost 17 volts. Since my Rotax rectifier/regulator

puts out about 13.8 volts, I decided to lower the set point of the

over-voltage protector by substituting a 5.1K resistor for the

5.6K. Now the test lamp comes on at 16.2 volts. When the voltage

increases above 15.8, the circuit becomes sensitive. Just touching

the circuit with a digital voltmeter probe is enough to fire the

SCR. Using a different voltmeter had the same affect. No doubt that

in an electrically noisy environment like an airplane, the circuit

will trip at 15.8 volts. That is not a problem though. 15.8 volts

is 2 volts above my aircraft system voltage. If spring weather ever

comes to Michigan, I will install it in the airplane.

That should not be so sensitive to probing.

How is this circuit packaged? Can you send me a pucture?

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1929

Location: Riley TWP Michigan

|

Posted: Wed Mar 26, 2014 6:40 am Post subject: Re: DIY CBOVM: variations on a theme Posted: Wed Mar 26, 2014 6:40 am Post subject: Re: DIY CBOVM: variations on a theme |

|

|

I repeated testing of the over-voltage circuit today, doing a better job of connecting wires. If the voltage is steadily increased, the SCR fires at 16.2 volts. But if the voltage is set at 16.0 volts and held there, the SCR would fire after waiting a couple of minutes. Probing the input with a voltmeter intermittently caused the SCR to fire only when the voltage was above 15.9. Circuit instability, if any, is within 0.1 volt of the set-point. The adjustable voltage power supply only cost $6. Who knows how stable that is. The components are all through-hole, not surface mounted, and are mounted to a 1 x 2 inch area of PCB. I am happy with the circuit.

I intend to connect the over-voltage circuit in series with a relay coil that is powered by a 3 amp fuse.. The normally closed contacts of the relay will be in series with the AC output of the permanent magnet dynamo. In case of high voltage, the SCR will fire, connecting one leg of the coil to ground to energize the relay, opening the AC circuit to the rectifier/voltage regulator. The SCR will continue to hold the relay energized until battery power is disconnected from the relay coil.

This will not be a crowbar type of over-voltage protection. So no circuit breaker is required. High voltage will not blow the fuse.

Joe

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

jluckey(at)pacbell.net

Guest

|

Posted: Wed Mar 26, 2014 7:25 am Post subject: DIY CBOVM: variations on a theme Posted: Wed Mar 26, 2014 7:25 am Post subject: DIY CBOVM: variations on a theme |

|

|

Joe,

1. How much power can the dynamo produce?

2. Are there only 2 wires for the AC output? (I've never worked w/ a PM type alternator but most non-PM machines have 3 wires for AC output)

3. As you probably already know, on some relays, the current-handling capability of the NC contacts is less than the NO contacts

-Jeff

From: user9253 <fransew(at)gmail.com>

To: aeroelectric-list(at)matronics.com

Sent: Wednesday, March 26, 2014 7:40 AM

Subject: Re: DIY CBOVM: variations on a theme

--> AeroElectric-List message posted by: "user9253" <fransew(at)gmail.com (fransew(at)gmail.com)>

I repeated testing of the over-voltage circuit today, doing a better job of connecting wires. If the voltage is steadily increased, the SCR fires at 16.2 volts. But if the voltage is set at 16.0 volts and held there, the SCR would fire after waiting a couple of minutes. Probing the input with a voltmeter intermittently caused the SCR to fire only when the voltage was above 15.9. Circuit instability, if any, is within 0.1 volt of the set-point. The adjustable voltage power supply only cost $6. Who knows how stable that is. The components are all through-hole, not surface mounted, and are mounted to a 1 x 2 inch area of PCB. I am happy with the circuit.

I intend to connect the over-voltage circuit in series with a relay coil that is powered by a 3 amp fuse.. The normally closed contacts of the relay will be in series with the AC output of the permanent magnet dynamo. In case of high voltage, the SCR will fire, connecting one leg of the coil to ground to energize the relay, opening the AC circuit to the rectifier/voltage regulator. The SCR will continue to hold the relay energized until battery power is disconnected from the relay coil.

This will not be a crowbar type of over-voltage protection. So no circuit breaker is required. High voltage will not blow the fuse.

Joe

--------

Joe Gores

Read this topic online here:

http://forums.matronics.com/viewtopic//www.matronics.com/Navigator?AeroElectric-List" target="_blank">http://w--> http://fo= - List Contribution Web Site &nbs="http://www.matronics.com/contribution" target="_blank">http://www.mat=====================

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

kleh(at)dialupatcost.ca

Guest

|

Posted: Wed Mar 26, 2014 8:45 am Post subject: DIY CBOVM: variations on a theme Posted: Wed Mar 26, 2014 8:45 am Post subject: DIY CBOVM: variations on a theme |

|

|

In regards to stability you might check that there is a capacitor across

the voltage reference diode and another from the SCR gate to ground. If

you happen to have an old circuit diagram dated before about 2005 it may

not show that update.

One nice thing about the crowbar and circuit breaker in the Z diagrams

is that the voltage is brought under control immediately when the SCR

fires. If I understand your post it sounds like your implementation

waits for the relay to open and for any subsequent arcing to extinguish.

Perhaps that is good enough but it seems preferable to use the circuit

breaker as per the Z diagrams so that the SCR clamps the voltage faster.

Might be other small advantages as well such as a subsequent dead

battery could not cause the alternator to come back on line.

Ken

On 26/03/2014 10:40 AM, user9253 wrote:

| Quote: |

<fransew(at)gmail.com>

I repeated testing of the over-voltage circuit today, doing a better

job of connecting wires. If the voltage is steadily increased, the

SCR fires at 16.2 volts. But if the voltage is set at 16.0 volts and

held there, the SCR would fire after waiting a couple of minutes.

Probing the input with a voltmeter intermittently caused the SCR to

fire only when the voltage was above 15.9. Circuit instability, if

any, is within 0.1 volt of the set-point. The adjustable voltage

power supply only cost $6. Who knows how stable that is. The

components are all through-hole, not surface mounted, and are mounted

to a 1 x 2 inch area of PCB. I am happy with the circuit. I intend

to connect the over-voltage circuit in series with a relay coil that

is powered by a 3 amp fuse.. The normally closed contacts of the

relay will be in series with the AC output of the permanent magnet

dynamo. In case of high voltage, the SCR will fire, connecting one

leg of the coil to ground to energize the relay, opening the AC

circuit to the rectifier/voltage regulator. The SCR will continue to

hold the relay energized until battery power is disconnected from the

relay coil. This will not be a crowbar type of over-voltage

protection. So no circuit breaker is required. High voltage will

not blow the fuse. Joe

-------- Joe Gores

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=421067#421067

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1929

Location: Riley TWP Michigan

|

Posted: Wed Mar 26, 2014 8:54 am Post subject: Re: DIY CBOVM: variations on a theme Posted: Wed Mar 26, 2014 8:54 am Post subject: Re: DIY CBOVM: variations on a theme |

|

|

Jeff,

1. The Rotax 912 dynamo can generate up to about 20 amps. Although many recommend not loading it to more than 16 amps. My plane uses about 10 amps.

2. Yes, the AC output has two wires and is single phase.

3. If I am interpreting this data sheet correctly http://pewa.panasonic.com/assets/pcsd/catalog/cb-catalog.pdf

the normally closed contacts can handle 30 amps. I suspect that, over the long term, corrosion due to lack of exercise will be more of a problem than the contact rating.

Joe

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Mar 26, 2014 9:05 am Post subject: DIY CBOVM: variations on a theme Posted: Wed Mar 26, 2014 9:05 am Post subject: DIY CBOVM: variations on a theme |

|

|

At 10:23 AM 3/26/2014, you wrote:

| Quote: | Joe,

1. How much power can the dynamo produce?

|

Most are limited to about 30A. The single phase

(2-wire) offerings by B&C, Rotax and others

are in the 8-20A class. The 3-phase, 3-wire

devices for the larger 'tractors' can

get you 30A or so.

The problem with PM alternators is not the

power generating ability of the mechanism but

the power handling ability of the rectifier/

regulator. Unlike the 3-phase automotive

alternator that runs output power through

simple junction diodes. The regulator carries

only a couple amps of field current.

In the PM regulator, total output current of

up to 30A flows through regulator semiconductors.

Hence the heat sinks and limited size with

respect to power.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1929

Location: Riley TWP Michigan

|

Posted: Wed Mar 26, 2014 9:23 am Post subject: Re: DIY CBOVM: variations on a theme Posted: Wed Mar 26, 2014 9:23 am Post subject: Re: DIY CBOVM: variations on a theme |

|

|

Ken,

Thanks for suggesting the capacitors. The circuit is stable unless the voltage gets very close to the trip point. That is OK with me as long as there is no nuisance tripping. Time will tell.

Good point about the crowbar circuit acting immediately by clamping the supply to ground. The data sheet for my relay says it will operate in 15 milliseconds. I am hoping the battery will limit the voltage until the relay contacts open. I will try to land before the battery runs down enough (almost completely dead) to drop out the relay.

Joe

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

kleh(at)dialupatcost.ca

Guest

|

Posted: Wed Mar 26, 2014 9:59 am Post subject: DIY CBOVM: variations on a theme Posted: Wed Mar 26, 2014 9:59 am Post subject: DIY CBOVM: variations on a theme |

|

|

Joe

600 hours on two of the OVMs and never a nuisance trip.

Have had a real trip on the Dynamo one when I started up with one of my

two small Z-14 AGM batteries dead. The totally dead battery wouldn't

accept current and the John Deere regulator immediately failed full on.

The battery did eventually charge but initially it would not accept current.

Note to self - if I leave a switch on by mistake for a week and can't

charge the battery first - at least run with that alternator off and the

batteries paralleled to the other alternator for awhile with engine

speed low enough to keep the charge current reasonable.

Ken

do not archive

On 26/03/2014 1:23 PM, user9253 wrote:

| Quote: |

<fransew(at)gmail.com>

Ken, Thanks for suggesting the capacitors. The circuit is stable

unless the voltage gets very close to the trip point. That is OK

with me as long as there is no nuisance tripping. Time will tell.

Good point about the crowbar circuit acting immediately by clamping

the supply to ground. The data sheet for my relay says it will

operate in 15 milliseconds. I am hoping the battery will limit the

voltage until the relay contacts open. I will try to land before the

battery runs down enough (almost completely dead) to drop out the

relay. Joe

-------- Joe Gores

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Mar 26, 2014 11:47 am Post subject: DIY CBOVM: variations on a theme Posted: Wed Mar 26, 2014 11:47 am Post subject: DIY CBOVM: variations on a theme |

|

|

At 11:45 AM 3/26/2014, you wrote:

| Quote: |

In regards to stability you might check that there is a capacitor

across the voltage reference diode and another from the SCR gate to

ground. If you happen to have an old circuit diagram dated before

about 2005 it may not show that update.

One nice thing about the crowbar and circuit breaker in the Z

diagrams is that the voltage is brought under control immediately

when the SCR fires. If I understand your post it sounds like your

implementation waits for the relay to open and for any subsequent

arcing to extinguish. Perhaps that is good enough but it seems

preferable to use the circuit breaker as per the Z diagrams so that

the SCR clamps the voltage faster. Might be other small advantages

as well such as a subsequent dead battery could not cause the

alternator to come back on line.

|

For the run-of-the-mill ov conditions with a good

battery, an ov even is not one of extreme urgency.

The ships air-worthy battery will stand off a runaway

alternator for significant intervals. If one waited

100 mS to evaluate an ov condition for a true runaway

alternator, it wouldn't be a bad thing.

In fact, the next generation ov module will do just

that. Sensing an ov condition start a 100mS timer

that continue to run as long as the voltage does not

drop back below 16V before the timer runs out.

On the other hand, a second threshold at 20V assumes

no air worthy battery is present and an immediate trip

is initiated.

We're still going to pull down on the field supply

breaker . . .

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jan_de_jong(at)casema.nl

Guest

|

Posted: Mon Mar 31, 2014 9:16 am Post subject: DIY CBOVM: variations on a theme Posted: Mon Mar 31, 2014 9:16 am Post subject: DIY CBOVM: variations on a theme |

|

|

That's another issue with a lithium battery - it does not keep OV down

well - even if not fitted with a BMS. And it seriously dislikes

overvoltage. It thus requires a fast OV switch at the alternator.

And if it has a BMS it will also have a battery OV cutoff switch built

in. Making the battery unavailable just when it is needed.

My conclusion has been that if I want Lithium I will have to make the

under/over cell voltage and cell temperature monitoring and top

balancing myself.

With backed up OV protection at the alternator.

And have the individual cells accessible to thermistors.

Jan de Jong

On 3/26/2014 8:45 PM, Robert L. Nuckolls, III wrote:

| Quote: |

<nuckolls.bob(at)aeroelectric.com>

At 11:45 AM 3/26/2014, you wrote:

>

>

> In regards to stability you might check that there is a capacitor

> across the voltage reference diode and another from the SCR gate to

> ground. If you happen to have an old circuit diagram dated before

> about 2005 it may not show that update.

>

> One nice thing about the crowbar and circuit breaker in the Z

> diagrams is that the voltage is brought under control immediately

> when the SCR fires. If I understand your post it sounds like your

> implementation waits for the relay to open and for any subsequent

> arcing to extinguish. Perhaps that is good enough but it seems

> preferable to use the circuit breaker as per the Z diagrams so that

> the SCR clamps the voltage faster. Might be other small advantages as

> well such as a subsequent dead battery could not cause the alternator

> to come back on line.

For the run-of-the-mill ov conditions with a good

battery, an ov even is not one of extreme urgency.

The ships air-worthy battery will stand off a runaway

alternator for significant intervals. If one waited

100 mS to evaluate an ov condition for a true runaway

alternator, it wouldn't be a bad thing.

In fact, the next generation ov module will do just

that. Sensing an ov condition start a 100mS timer

that continue to run as long as the voltage does not

drop back below 16V before the timer runs out.

On the other hand, a second threshold at 20V assumes

no air worthy battery is present and an immediate trip

is initiated.

We're still going to pull down on the field supply

breaker . . .

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Mar 31, 2014 10:13 am Post subject: DIY CBOVM: variations on a theme Posted: Mon Mar 31, 2014 10:13 am Post subject: DIY CBOVM: variations on a theme |

|

|

At 12:15 PM 3/31/2014, you wrote:

| Quote: |

That's another issue with a lithium battery - it does not keep OV

down well - even if not fitted with a BMS. And it seriously dislikes

overvoltage. It thus requires a fast OV switch at the alternator.

And if it has a BMS it will also have a battery OV cutoff switch

built in. Making the battery unavailable just when it is needed.

My conclusion has been that if I want Lithium I will have to make

the under/over cell voltage and cell temperature monitoring and top

balancing myself.

With backed up OV protection at the alternator.

And have the individual cells accessible to thermistors.

|

Your perceptions of being inadequately informed

with respect to operating details of the various

lithium products are accurate.

There is no industry standard for the term "BMS".

I'm working the 4th installment on the series

of battery articles for Kitplanes. The past 7

weeks have been enlightening.

I'm not sure that alternator OV protection needs

to be anything beyond the ordinary . . . I'm still

stirring the stew of simple-ideas . . .

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jan_de_jong(at)casema.nl

Guest

|

Posted: Mon Mar 31, 2014 12:02 pm Post subject: DIY CBOVM: variations on a theme Posted: Mon Mar 31, 2014 12:02 pm Post subject: DIY CBOVM: variations on a theme |

|

|

The implicit "trust us" attitude is in any case unwarranted. Full

specifications of the built-in electronics are absolutely necessary.

What I have seen is not very compatible with aircraft use. We do not

want OV cut-out built-in (should be done somewhere up in the charging

path). We probably do not want LV cut-out built-in either (saving the

battery may not always be the highest goal). But we want monitoring and

warning. And as a pilot I want to know about temperatures. When used

well (correct voltages and currents within limits, no recharging ever

after full discharge) the remaining danger is a manufacturing fault,

with temperature discrepancy the only available signal.

And a measure of top balancing is needed unless we are willing to adopt

a discipline of doing that externally. A certain minimum balancing

current per Ah, say 50mA or so is required. I've seen balancing currents

quoted for Chinese BMS products that are likely useless for any

realistic battery size (they may be intended for UPS batteries - very

long charging times and smallish charging currents).

And the balancing algorithm is often primitive - most balancers only

balance at the very end of the charging process by comparing a cell

voltage with a high limit-voltage, not during the charging process by

comparing a cell voltage with the voltages of other cells. The latter

allows good balancing with a lower alternator set voltage. In exchange

for a few percent of charge you get much longer life - apparently.

I wish you wisdom with the 4th article on batteries (great articles so

far, I approve of the current editor in chief of KP!)

Jan de Jong

On 3/31/2014 8:12 PM, Robert L. Nuckolls, III wrote:

| Quote: |

<nuckolls.bob(at)aeroelectric.com>

At 12:15 PM 3/31/2014, you wrote:

>

> <jan_de_jong(at)casema.nl>

>

> That's another issue with a lithium battery - it does not keep OV

> down well - even if not fitted with a BMS. And it seriously dislikes

> overvoltage. It thus requires a fast OV switch at the alternator.

> And if it has a BMS it will also have a battery OV cutoff switch

> built in. Making the battery unavailable just when it is needed.

>

> My conclusion has been that if I want Lithium I will have to make the

> under/over cell voltage and cell temperature monitoring and top

> balancing myself.

> With backed up OV protection at the alternator.

> And have the individual cells accessible to thermistors.

Your perceptions of being inadequately informed

with respect to operating details of the various

lithium products are accurate.

There is no industry standard for the term "BMS".

I'm working the 4th installment on the series

of battery articles for Kitplanes. The past 7

weeks have been enlightening.

I'm not sure that alternator OV protection needs

to be anything beyond the ordinary . . . I'm still

stirring the stew of simple-ideas . . .

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Mar 31, 2014 3:24 pm Post subject: DIY CBOVM: variations on a theme Posted: Mon Mar 31, 2014 3:24 pm Post subject: DIY CBOVM: variations on a theme |

|

|

At 03:00 PM 3/31/2014, you wrote:

The implicit "trust us" attitude is in any case unwarranted. Full

specifications of the built-in electronics are absolutely necessary.

that will be a primary premise of the 'last' article.

What I have seen is not very compatible with aircraft use. We do not

want OV cut-out built-in (should be done somewhere up in the charging path).

This is certainly the legacy philosophy for lead-acid

and/or Ni-Cad batteries wherein the battery was a

'current sink' of demonstrable value for managing

a runaway generator/alternator.

But let's assume for the moment that one of our

future design goals is to craft and prove airworthiness

of an alternator-only operation protocol. Now we need

to show that the runaway alternator can be controlled

within the DO160/MilSTD704 envelope.

If that proves to be practical, then the electronics

in the battery need not assume any duties beyond those

for protecting the battery . . . the battery MIGHT be

relieved of duty for standing guard at the gates

standing off runaway alternators.

We probably do not want LV cut-out built-in either (saving the

battery may not always be the highest goal). But we want monitoring

and warning.

Yeah . . . but it depends on WHERE the l.v. cutout

occurs.

Toyota writes software intended to maintain their

lithium cells at some place between 30 and 85% capacity.

This is the ENERGY operating range that offers the

advertised cell life. But they don't force disconnect

the battery . . . as far as I've been able to learn

so far.

Depending on the BMS designer's charter from on-high . . .

he may well have other bounds. Without advocating for

any particular energy range . . . I'll suggest that any

offering that includes a BMS would do well to tell

all . . . inquiring pilots NEED to know.

And as a pilot I want to know about temperatures. When used well

(correct voltages and currents within limits, no recharging ever

after full discharge) the remaining danger is a manufacturing fault,

with temperature discrepancy the only available signal.

And a measure of top balancing is needed unless we are willing to

adopt a discipline of doing that externally. A certain minimum

balancing current per Ah, say 50mA or so is required. I've seen

balancing currents quoted for Chinese BMS products that are likely

useless for any realistic battery size (they may be intended for UPS

batteries - very long charging times and smallish charging currents).

Exactly. An these issues drive cost of ownership. Yes,

the lithium products have stellar performance in some

venues but with LIMITS that much be UNDERSTOOD and

incorporated into the user's operating philosophy.

$time$ fiddling with batteries is $time$ not available

to go flying.

And the balancing algorithm is often primitive - most balancers only

balance at the very end of the charging process by comparing a cell

voltage with a high limit-voltage, not during the charging process by

comparing a cell voltage with the voltages of other cells. The latter

allows good balancing with a lower alternator set voltage. In

exchange for a few percent of charge you get much longer life - apparently.

"Apparently" is the operative term. The family

of lithium cells available for incorporation into

finished goods is not large . . . There's probably

no more than a half dozen shakers-n-movers in

the cylindrical cell market. They're all pretty

big names . . . I doubt that core capabilities

of the range of offerings varies much. But we

see a large variation in proposed operating

philosophies across the spectrum of "assemblers"

who package these cells up for market.

I wish you wisdom with the 4th article on batteries (great articles

so far, I approve of the current editor in chief of KP!)

Thank you my friend. I'm learning. But I wish that the

questions were being answered faster than they surface!

This first past at lithium-for-airplanes will probably

be disappointing for many who hope that a an ideal

drop-in-replacement for SVRLA is going to emerge.

But as you've noted, no matter what the advertising

hype says, "Their ain't no such thing as a lithium

drop-in for lead-acid."

For anything beyond the day-vfr machine with

gravity flow fuel and magnetos, the prudent

owner/pilot would do well to understand the

limitations. Further, assuming a willingness to

$invest$ in weight savings know that changes to

ownership and operating philosophy are inevitable.

Thank you for contributing to the dialog . . .

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jan_de_jong(at)casema.nl

Guest

|

Posted: Tue Apr 01, 2014 2:44 am Post subject: DIY CBOVM: variations on a theme Posted: Tue Apr 01, 2014 2:44 am Post subject: DIY CBOVM: variations on a theme |

|

|

| Quote: | What I have seen is not very compatible with aircraft use. We do not

want OV cut-out built-in (should be done somewhere up in the charging

path).

This is certainly the legacy philosophy for lead-acid

and/or Ni-Cad batteries wherein the battery was a

'current sink' of demonstrable value for managing

a runaway generator/alternator.

But let's assume for the moment that one of our

future design goals is to craft and prove airworthiness

of an alternator-only operation protocol. Now we need

to show that the runaway alternator can be controlled

within the DO160/MilSTD704 envelope.

If that proves to be practical, then the electronics

in the battery need not assume any duties beyond those

for protecting the battery . . . the battery MIGHT be

relieved of duty for standing guard at the gates

standing off runaway alternators.

|

The current lead-acid battery has 2 tasks when an OV event occurs:

1. slowing the event down to facilitate OVP without false triggering

2. keeping the battery-connected busses powered when the charging

system responsible for the OV event is disconnected from the bus

Both tasks must be covered or made unnecessary with any new alternative

use of a battery.

Jan de Jong

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|